vex lcd module supplier

VEX Robotics is educational robotics for everyone. VEX solutions span all levels of both formal and informal education with accessible, scalable, and affordable solutions. Beyond science and engineering principles, VEX encourages creativity, teamwork, leadership, and problem solving among groups. It allows educators of all types to engage and inspire the STEM problem solvers of tomorrow!

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

We love the LCD screen. Really. It is one of our favorite tools. Here’s a more technical run-down of the uses that the girls mention in their STEM Educational Video that they entered this week in the REC Foundation’s 2017 Online Challenge.

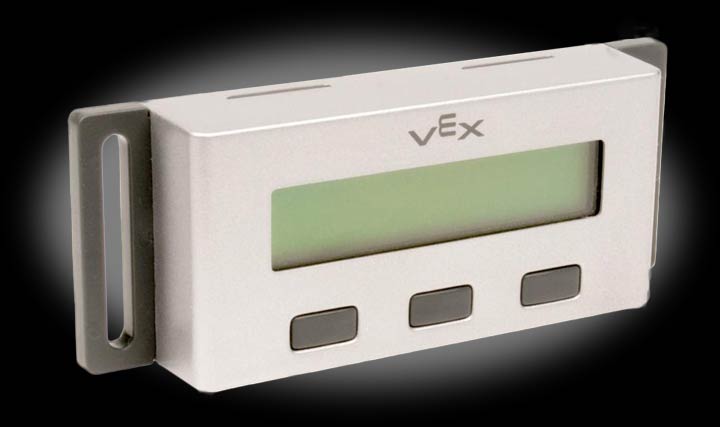

First, you need to buy yourself an LCD screen, and a Serial Y Cable. NOTE: the cable does not come with the screen, even though it seems like it should. You must buy it separately. You can use up to 2 LCD screens on your robot at one time, though honestly I’ve never seen anyone use 2.

Plug the 4-prong end of the Y-cable into either UART1 or UART2 on the Cortex (remember which one you use; convenient to always use UART1, unless you have a specific reason not to). This plug is over on one corner of the Cortex, near where motor encoders get plugged in. You’ll plug the other wires into the LCD screen. We have a little mnemonic to remember which wires go into which plug: whiTe goes into TX (over-emphasize the “T” when you say “white”), and yell-ER goes into RX (pronouncing “yellow” with a southern drawl). If they are plugged in backward, it will not work.

Make sure your kids install the LCD on the robot (a) where it’s easily accessible to read the screen and press the buttons, and (b) also protected from being struck by game elements or other robots.

(Much of this programming information is in easyC, because that’s what we used at the time of this writing. The exact function names used in RobotC can be found on the RobotC help page, under Command Library – VEX Cortex / ROBOTC / LCD Display.

As a first test to make sure your screen is working, include in your program (autonomous, joystick, or competition) a line of code that just displays a message, and does nothing else. You’ll need to initialize the LCD screen at the start of the program, and somewhere before you have the message display, it’s helpful to make the back-light turn on.

In EasyC, you need to use one LCD display block for each line of the LCD screen that you want to use. Drag over a block and enter the text for your Line 1 message, and leave all of the other stuff blank (the stuff related to variables, etc.); do the same for Line 2 if you’re using it. NOTE: If you put a message on Line 2, and later in your program display a different message, but only use Line 1 at that time, the Line 2 text will remain on the screen unless you specifically drag over a block and tell Line 2 to display a blank line.

Enter the LCD screen! You can put somewhere in your Main() loop a get command to get the latest sensor value and then an LCD command to display it on the screen. If it’s a variable you’re after, just make sure that the LCD display command is somewhere after the variable is being calculated.

Beware! Each line of the LCD screen can only hold 16 characters. If you give it text that’s 14 characters, plus a 3-digit sensor value, the LCD will show you the first 2 digits of your sensor value, and will just cut off/not display the 3rd digit. So you may think that you’re getting sensor data just fine, but at some point it will look like the numbers wrap around and restart their numbering at 0 again. It will look like it has wrapped around to, say, “11”, when the sensor value is really 110.

Beware some more (RobotC users)! When displaying sensor values on the screen—especially in a while loop—be sure to clear the existing text before displaying the sensor’s value. We were trying to calibrate our gyro sensor recently, and when we turned the robot around 360º, the value in RobotC is supposed to reset to 0, but on our robot, once we passed 3599 (the gyro reports values in tenths-of-a-degree, so 360º = 3600), it would jump to 1599, and then if we kept turning it, the values got ridiculously huge—3299, 9099, etc. Whaaaaa??? After half of a meeting devoted to this problem, we realized that once we passed 0, it was in fact displaying the new degree values, starting in the left-most position on top of what was already there, so what we were reading as 1599 was really a sensor value of 15, written on top of the previous value of 3599. So we added a line of code inside the while loop to clear the first line of the LCD display and then write the sensor value. (This appears to be only a RobotC problem; easyC is fine with the blocks of code shown above, without an extra block for clearing the line.)

One other use where we find the LCD to be valuable is debugging our programs. There are many times when a program is not working, and you just can’t figure out what is actually executing in the code. You’ve got some code that seems like it should be doing the right thing, but nothing is happening.

You could put different messages in different sections of your code, but be aware that a joystick program is looping through rapidly, and if you have Message1 display when x happens, and then Message2 display when y happens, Message1 may display for a tiny fraction of a second, and then be over-written by Message2. It’s good to stick with at most 2 non-exclusive messages, each of which occupies one line of the LCD screen (so that they can both display at the same time if necessary).

Our FAVORITE use of the LCD is as a little menu-selector to choose an autonomous program during a competition. If you’ve got an autonomous program that involves moving left or right, you’ve undoubtedly got 2 of them, depending on what square your robot starts in. In one scenario it’ll need to move left, but if it starts in the other colored starting square for that alliance team, it’ll need to move right.

Without the LCD screen, your team needs to find their alliance partner, decide who’s going to start where (and communicate clearly what they mean by “start on the left square,” for example), and then go back to the pits and load the correct program onto the robot. Let me tell you how many times I have seen this result in the wrong program on the robot—20% of the time, maybe? Your team could lose a match without those autonomous points, and it’s incredibly frustrating for the kids to have their perfect code work backward when the clock starts. So why not remove 99% of human error and have a little menu selector on the robot itself! That way your team never has to load a program on the robot all day long at a competition. We even include our programming skills challenge code as one of the menu items, so we rarely have to open up the computer at a tournament.

You can download EasyC code (or pseudo-code) on our downloads page that will get you started creating your own menu (full credit goes Ephemeral_Being from the VEX forum for writing this code). Important notes, as the girls mention in their video:

Edit 7/2/18: Here’s a very clear and helpful YouTube tutorial on programming your own auton menu selector in easyC. There are many RobotC examples of this type of code on the VEX Forum; a simple search will find some for you. You can also read my detailed post that walks you through how Ephemeral Being’s code works.

Distributor of component LCDs for equipment which provide high-contrast ratio, color saturation, luminance and performance enhancements such as advanced wide viewing (AWV) for true color fidelity, super-high brightness (SHB) and wide temperature range. Focus on industrial, instrumentation, hand-helds, medical and other low-to-medium volume markets. High-bright LED backlights for outdoor use. LVDS interfaces decrease EMI. Factory installed touch screen solutions. 3.5" to 12.1" QVGA, HVGA, VGA, WVGA, SVGA, XGA, WXGA. Also distributes other related products including LED drivers, lamps, indicators, LED assemblies, segment displays, LED mounts, LEDs, and light pipes. Distributor of electronic components, hardware and fasteners and provides design/value engineering support, fulfillment strategies, procurement services and transactional models to meet specific needs and priorities.

The VEX IQ Robot Brain has 12 identical Smart Ports. Plug any VEX IQ device into any port and the device is automatically detected - there are no dedicated input or output banks. Smart Port devices include: Smart Motor, Distance Sensor, Color Sensor, Gyro Sensor, Touch LED, and Bumper Switch.

The VEX IQ Brain comes loaded with default programs that get you up and running quickly. No computer or programming required. The Driver Control program gives you instant control of up to four drive motors and four additional mechanism motors, plus features for limit switches. Multiple pre-loaded autonomous programs will allow robots to move by themselves using sensors.

The backlit LCD makes VEX IQ simple to use. Using the 4-button interface, you can start your favorite program or configure the Driver Control program. Your Modkit or ROBOTC programs can write messages on-screen to customize your robot and simplify program debugging. Smartphone-like icons keep you in touch with your battery level and wireless connection.

VEX has partnered with Modkit to bring a new level of graphical programming to robots. Now students can graphically configure and program their robot. Alternatively, ROBOTC allows students to use C programming to control their robot, an industry standard programming language. Both languages allow you to create programs that work with driver control or are completely autonomous.

All devices connected to the Brain support Event Programming. This simplifies the software by allowing events to trigger software. Traditional programming methods involve continuous running loops that check values over and over again, looking for a change. This method creates code that is difficult to visualize and learn. Event programming looks like: "when the button is pressed do ...", "when the angle is 90 degrees do ...", "when the motor stops do ...". Instead of constantly polling each device to see if the event has occurred, the VEX IQ system allows each smart module to report back if the event occurs. When the event occurs, the smart module tells the brain what occurred. Not only is software simplified, but the Brain does not have to constantly poll each sensor about what is happening, which increases overall system performance.

The Robot Brain uses the latest Texas Instruments Tiva microcontroller running at 80 MHz to perform 100 million operations per second. The brain has to simultaneously communicate with the controller wirelessly, talk to 12 devices on the Smart Ports, update the LCD and have time left over to run the students programs. It does all this with a custom built operating system developed just for VEX IQ that gives the students" programs 98% of the processer"s power, able to perform calculations in 0.00000001 seconds. All of this technology works together to make a Robot Brain that is simple, flexible and powerful.

The VEX IQ system makes Firmware Updates quick and easy. All electronic components can be upgraded including the Robot Brain, VEX Controller, Smart Motors, and sensors. See the Firmware Update page for more details and to download the VEX IQ Firmware Update Utility.

**You will need to provide your own PWM cables. Here are the instructions taken directly from the included documentation (also available here: https://vexforum.com/wiki/images/b/b3/VEX-LCD-Display.pdf):

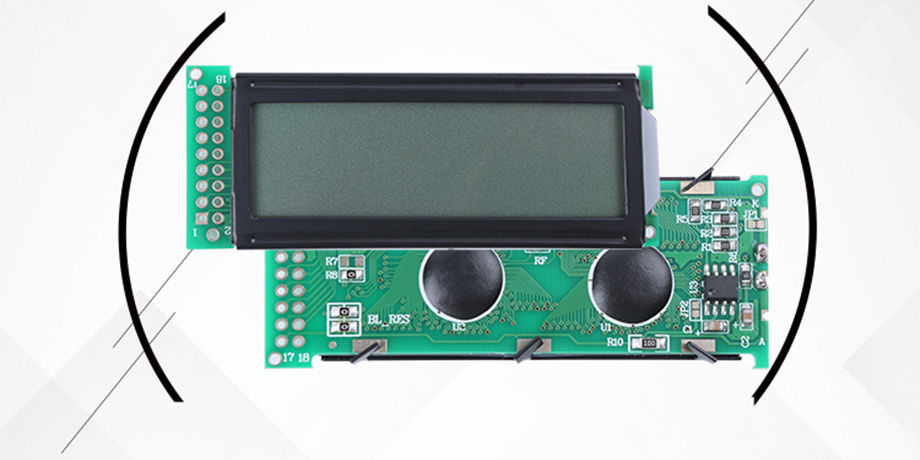

There are two interconnect ports on the side of the LCD module. The two interconnect ports are labeled RX and TX. The RX and TX ports are labeled with respect to the device that connects to the LCD Display Module.

(output) port on the LCD Display Module should connect to the RX (input) port on the VEX PIC Microcontroller. Likewise, the TX (input) port on the LCD Display Module should connect to the TX port (output) on the VEX PIC Microcontroller.

Use standard VEX Keyed PWM Cables for connecting the LCD Display Module to the VEX PIC Microcontroller. Use the VEX Serial Y-Cable for connecting the LCD Display Module to the VEX Cortex Microcontroller. The Y section of the Serial Y-Cable with the Yellow wire connects to the RX port and the Y section with the White wire connects to the TX port on the LCD Module.**

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

Improve performance of the Integrated Motor Encoders on the VEX Cortex, support multiple motors being synchronized (so robots will move in a straight line).

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey