pre lcd screen manufacturer

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

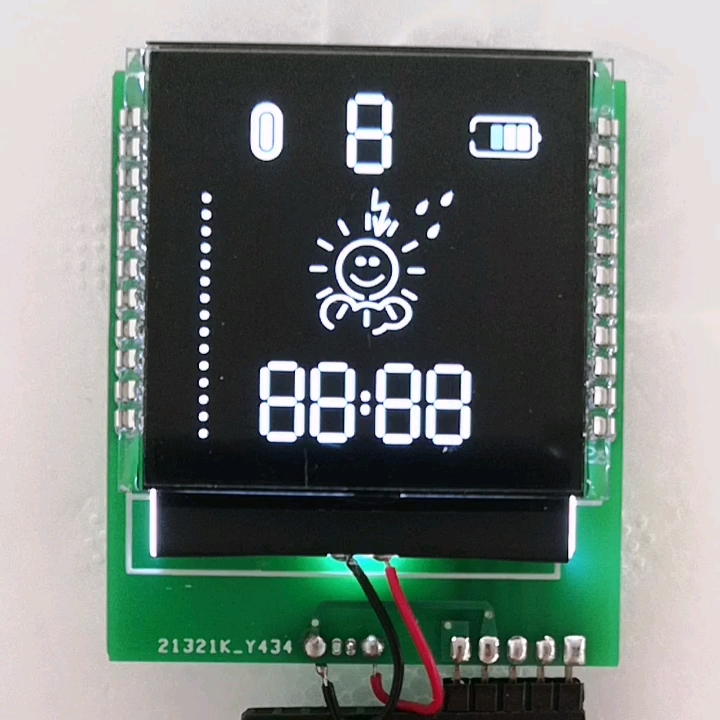

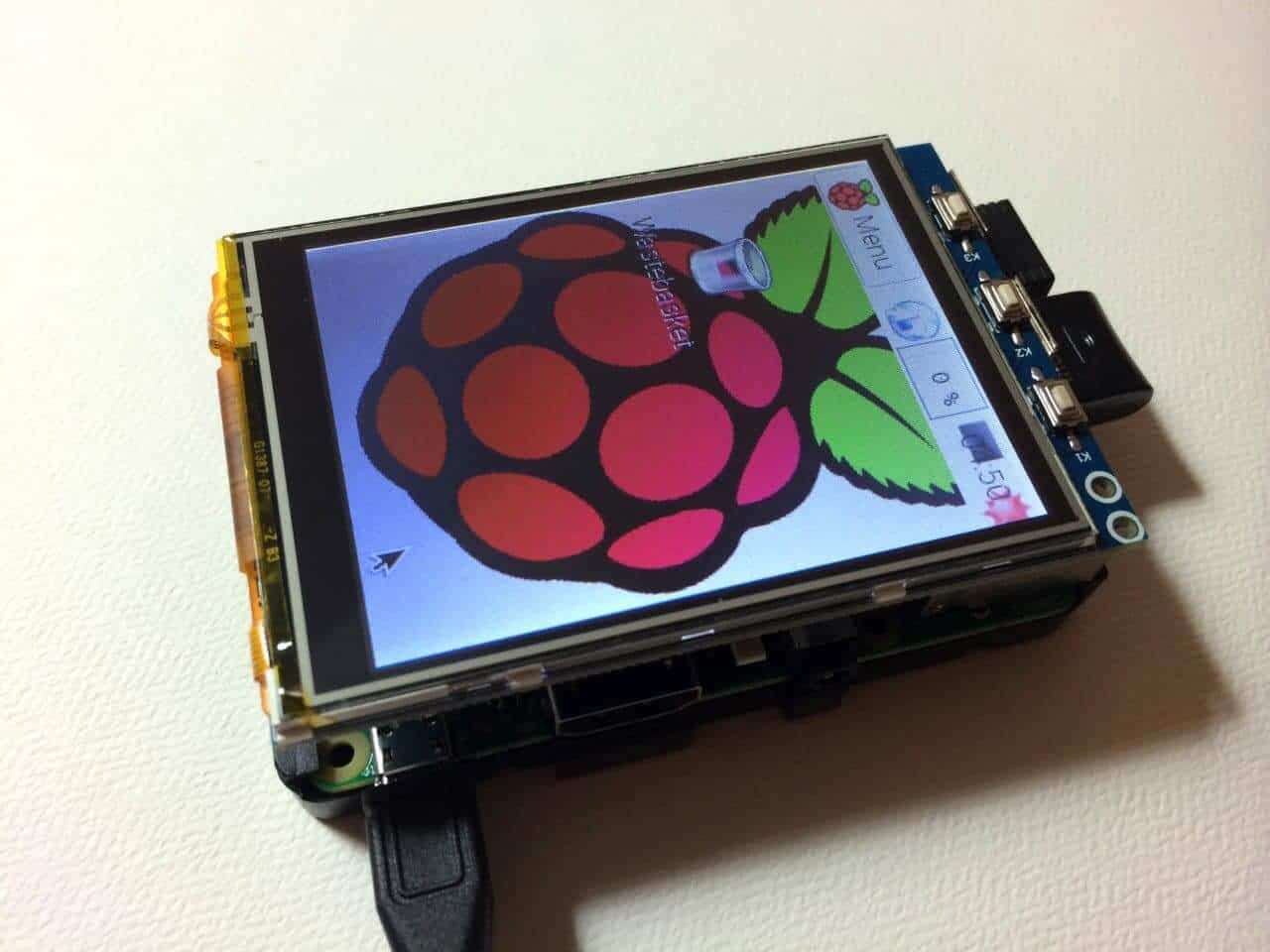

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Manufacturer of standard & custom operator interface terminals, industrial computers, panel personal computers, software, LCD displays, VFD displays & accessories. Types of operator interface terminals include touch screen operator interface terminals, graphic operator interface terminals, PLC & motion controller interfaces, ASCII & motion controller interfaces, high speed operator interface terminals & widescreen operator interface terminals. Accessories such as controller cables, power cables, power supplies, memory cards, adapters & power isolators are also available. Types of software include industrial process control software, process monitoring software, utility software & operator interface software. Products are used in retail, kiosk, packaging, transportation, plastic manufacturing, medical, pharmaceutical, printing, security, water treatment, petrochemical, bottling & power generation applications. Products are UL® listed, CE certified & RoHS compliant.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Without a shadow of a doubt, Orient Display stands out from other custom display manufacturers. Why? Because we employ 3600 specialists, includingmore than 720 engineers that constantly research available solutions in order to refine strategies that allow us to keep up with the latest technologiesand manufacture the finest displays showing our innovative and creative approach. We continuously strive to improve our skills and stay up to date with the changing world of displays so that we can provide our customers with supreme, cutting-edge solutions that make their lives easier and more enjoyable.

Customer service is another element we are particularly proud of. To facilitate the pre-production and product development process, thousands of standard solutions are stored in our warehouses. This ensures efficient order realization which is a recipe to win the hearts of customers who chose Orient Display. We always go to great lengths to respond to any inquiries and questions in less than 24 hours which proves that we treat buyers with due respect.

Choosing services offered by Orient Display equals a fair, side-by-side cooperation between the customer and our specialists. In each and every project, we strive to develop the most appropriate concepts and prototypes that allow us to seamlessly deliver satisfactory end-products. Forget about irritating employee turnover - with us, you will always work with a prepared expert informed about your needs.

In a nutshell, Orient Display means 18% of global market share for automotive touch screen displays, emphasis on innovation, flexibility and customer satisfaction.Don"t wait and see for yourself that the game is worth the candle!

The industry is flooded with manufacturers of varying capabilities, resources, commitment to quality and pre/post sales support. Some of these manufacturers will produce average quality displays without the needed enhancements that your customers expect today.

... glands. All versions have a smooth, seamless display surface for perfect cleanability. Its IP69K protection makes the new monitor also suited for washdown applications like high-pressure cleaning.

... and dusty conditions. Plus, the protective glass serves to protect the display against sharp foreign objects, meaning the screen is still operable even with scratches on the surface.

... be used on the screen to maximize safety and hygiene. Plus, white-colored housing makes it easy for users to detect and remove dust or any other foreign substances.

VisuNet FLX is, as its name suggests, a comprehensive range of highly flexible operator workstations and monitoring systems from Pepperl+Fuchs for ATEX/IECEx Zone 2/22 and Division 2, and non-hazardous areas. The new ...

... with a complete digital advertising solution. The wall-mounted outdoor display combines a high-bright screen with a weatherproof body. The 1,500 NITS screen captures attention, and auto-dimming keeps ...

... engaging digital signage in any weather. The high-brightness LCD screen keeps your content clear in direct sunlight, for maximum customer engagement. An IP54/NEMA 4 enclosure protects the screen ...

... turn-key system solutions in a stainless steel enclosure as wall, floor or ceiling mounting versions. The screen of the POLARIS Remote 15"" is a TFT display with an XGA resolution (1024 x 768 pixels) ...

... the main display for applications requiring a small screen. End-cap shelf displays in retail settings or as personal gaming screens as part of a larger interactive gaming table benefit from the features and design of ...

An LCD monitor is a flat screen using liquid crystal technology to create the display. It is used in place of CRT (cathode ray tube) monitors to display all types of verbal or graphic information.

These monitors are used wherever displays are necessary, including numerical control screens for machine tools, human-machine interfaces (HMI) or simply as industrial computer screens.

LCD monitors are among those that control the transmission or reflection of a separate light source rather than generating their own. The various technologies include twisted nematic (TN), super twisted nematic (STN), film compensated super twisted nematic (FSTN) and thin film transistor (TFT).

Founded in 2009, Sansi North America (SNA Displays) has become a leading LED display manufacturer in the United States with offices across the country and LED displays in major cities from coast to coast. We are the only LED signage manufacturer headquartered in Times Square and boast a major percentage of the digital LED displays in the world’s most coveted advertising space right outside our doors. In recent years, we’ve provided more LED display technology to Times Square than any of our competitors. Likewise, SNA Displays leads the industry in providing LED screens to the Los Angeles area and other major markets in North America.

Whether from the BRILLIANT™, BOLD™, or EMPIRE™ product series, our LED screens come in a vast array of sizes and pixel pitches for numerous indoor and outdoor applications. Whether you need an LED display screen for a conference room or one big enough to cover a skyscraper, SNA Displays has the custom-engineering knowledge and experience to make your vision come to life. We also have all-in-one, out-of-the-box LED screens perfect for on-the-go messaging.

Cookies policies do not apply to third party websites Please note that this Cookie Policy does not apply to the privacy practices of third party websites and we are not responsible for them that may be linked to this website. Viewing a different resolution requires either a video scaler that causes blur and jagged edges, or running the display at native resolution with 1:1 pixel mapping, which either does not fill the screen (letterbox display) or runs from the bottom or right edges of the screen. Although the microfiber should pose little to no risk to the screen, avoiding cleaning in small circular motions avoids the risk of creating stains or swirl marks on the surface of the screen by avoiding cleaning in small circular motions. Custom pixel response time is also important because all displays have inherent latency when displaying an image that can be large enough to create visual artifacts when the displayed image changes rapidly. The LEDs can be placed: Along the bottom The top and bottom of the left and drive side of all four sides of the are not local dimming functions in edge-lit displays, so they cannot create images as high quality as those created by full array LEDs. This means training your children not to smash their snacks covered hands against the TV to reach Bob the Builder, and train your spouse, not tapping the pad of their finger on the laptop screen to emphasize what they are trying to show you. You will have seen a pop-up to this effect on your first visit to this website; although it will not normally appear on subsequent visits, you can revoke your consent at any time by following the instructions below. If the applied voltage is large enough, the liquid crystal molecules in the middle of the layer are almost completely turned off, and the polarization of the incident light is not rotated when passing through the liquid crystal layer. Cookies collect information in an anonymous form, including the number of visitors to the website from which visitors and visitors came to the website, and the pages they visited. Each pixel has three separate backlights that can shine through the red, blue, or green color filter — so a pixel can emit a specific color. They are also less susceptible to “bleeding” or “clouds” at the edges of the screen, which use such screens good candidates for movie lovers and beautiful for general work. A color range that exceeds the content displayed on the screen has no benefits, so displays can only run within or below the range of a specific specification. Most of the time you will look at brighter and more colorful shades, where these displays stand out, but it"s always worth looking beyond figures on paper. The physics of the blue phase mode LCDs suggest that very short switching times (about 1 ms) can be achieved, so that sequential color control can be realized and expensive color filters would be outdated. The less you need to clean your screen, the better, and things like skin oil and other attachments are so much harder to get than simple things like dust particles. The choice of resolutions, less price and color performance expands their attractiveness beyond the “color-critical” work, making them attractive candidates for other applications, including gaming and general desktop work. By controlling the voltage applied over the liquid crystal layer in each pixel, light can pass in different quantities and thus form different shades of gray. When liquid touches the edge of these finely layered screens, this liquid can easily enter the layers by capillary action, just as water quickly moves over a piece of fabric that touches it. If the organization setting the cookie provides an automated deactivation tool for its cookies, we list the name of that organization, the category of cookies it sets, along with a link to its automated deactivation tool. Disabling cookies If you do not agree to the use of these cookies, please disable them by following the instructions for your browser available at http://allaboutcookies. While the names can be confusing for those who wade through specifications to find the best monitor, once you break it, it"s easier to.

Whether for entering data on a touch screen, understanding it on an outdoor display or something in between, Comark offers a variety of pre-configured industrial-grade display units that can be easily integrated into larger systems or mounted as needed. Select for sunlight readability, dust and water resistance, or other criteria in the size that best meets your need.

Best of all, you can combine the benefits of pre-configured systems designed to support common use cases with Comark’s expert engineering capabilities to create a customized solutions, tailored to your needs or industry certification requirements.

Here at Phoenix Display, we talk about LCD displays every day. With LCDs being such a big part of our daily lives, we thought it would be useful to explore the history of this important technology and where we see it going in the future.

In 1973, Sharp Corporation made use of LCD displays in calculators. Shortly after, the company followed BBC’s lead and mass produced TN LCD displays for watches in 1975.

1980s. After wristwatches came televisions (TVs), with the first color LCD TVs being developed as handheld TVs in Japan. In 1982, Seiko Epson released the first LCD TV, the Epson TV Watch, a wristwatch equipped with a small active-matrix LCD TV.

1990s. The 90s gave way to technology acceleration in the LCD space. Through multiple breakthroughs, researchers and inventors were able to improve contrast and viewing angles, as well as bring costs down.

2000s. After 30+ years of competition, LCD technology surpassed longstanding CRTs. Namely, in 2007, LCD TVs could claim better image quality than CRT-based TVs. Subsequently, in the fourth quarter of 2007,

Next, let’s take a brief look at how the technology works. Essentially, the LCD glass is just a light valve whose sole purpose is to either block light or allow light to go through it. We go into greater details in our post,

Finally, let’s look at the LCD display landscape in the near future. There’s three big areas that are being explored with LCD displays: Flexible displays, 3D displays, and reel-to-reel manufacturing.

In contrast, reel-to-reel manufacturing enables the continuous building of glass panels. This will represent a dramatic reduction in costs, which can be passed along to the customer and allow for more competitive pricing.

In 1991, a business unit called Samsung Display was formed to produce the panels used in products made by its parent company, Samsung Electronics. Afterward, it was a leading supplier of LCD panels not just for Samsung Electronics but for other companies in the industry as well.

The business received a stay of execution when the pandemic led to a global surge in demand for consumer electronics, but that demand is now declining, and projections aren"t good for LCD panel revenue.

Add to that the fact that emerging technologies like QD-OLED are the future for TV and monitors, and the case for keeping Samsung Display"s LCD business going becomes a hard one to make.

It was previously reported that Samsung planned to sunset the business at the end of 2020, but The Korea Times claims that the faster-than-expected falloff in consumer demand accelerated the timeline.

Samsung Display will now focus heavily on OLED and quantum dot. Most of the employees working in the LCD business will move to quantum dot, the publication claims.

Even if there isn"t a statement about a change in direction, the writing has been on the wall for Samsung"s LCD business. Unless something radical changes, it"s more a question of when than if at this point.

Every unit is pre-calibrated at the factory and comes with its own color calibration report. Giving you the highest quality color calibration possible, right out of the box. Time spent fine-tuning ColorPro® monitors bring you the highest quality color calibration possible.

With a full range of swivel, pivot, tilt, and height adjustments, The ColorPro® VP2756-2K allows you to find the most comfortable monitor positioning for your workflow. Auto Pivot can even let photos to be automatically adjusted to the screen’s orientation when pivoted.

Multitasking has never been easier. Run multiple windows side-by-side and switch between layouts to suit the task at hand. Split Screen helps you clean up your desktop and speed up your workflow.

LCDs, or liquid crystal displays, are the oldest of all display types on this list. They are made up of two primary components: a backlight and a liquid crystal layer.

Put simply, liquid crystals are tiny rod-shaped molecules that change their orientation in the presence of an electric current. In a display, we manipulate this property to allow or block light from passing through. This process is also aided by color filters to produce different subpixels. These are essentially shades of red, green, and blue primary colors that combine to form the desired color, as shown in the above image. At a reasonable viewing distance, individual pixels are (usually) invisible to our eyes.

Since liquid crystals don’t produce any light by themselves, LCDs rely on a white (or sometimes blue) backlight. The liquid crystal layer then simply has to let this light pass through, depending on the image that needs to be displayed.

You may have noticed that the term LCD has started to disappear of late, especially in the television industry. Instead, many manufacturers now prefer branding their televisions as LED models instead of LCD. Don’t be fooled, though — this is just a marketing ploy.

These so-called LED displays still use a liquid crystal layer. The only difference is that the backlights used to illuminate the display now use LEDs instead of cathode fluorescent lamps, or CFLs. LEDs are a better light source than CFLs in almost every way. They are smaller, consume lesser power, and last longer. However, the displays are still fundamentally LCDs.

Twisted nematic, or TN, was the very first LCD technology. Developed in the late 20th century, it paved the way for the display industry to transition away from CRT.

This default vertical arrangement blocks a lot more of the backlight from coming through to the front of the display. Consequently, VA panels are known for producing deeper blacks and offering better contrast compared to other LCD display types. As for bit-depth and color gamut coverage, VA is capable of doing just as well as IPS.

From this description alone, it’s easy to see how OLED differs from LCD and prior display types. Since the compounds used in OLEDs emit their own light, they are an emissive technology. In other words, you don’t need a backlight for OLEDs. This is why OLEDs are universally thinner and lighter than LCD panels.

Since each organic molecule in an OLED panel is emissive, you can control whether a particular pixel is lit up or not. Take away the current and the pixel turns off. This simple principle allows OLEDs to achieve remarkable black levels, outperforming LCDs that are forced to use an always-on backlight. Besides delivering a high contrast ratio, turning off pixels also reduces power consumption.

OLED’s Achilles heel is that it is prone to permanent image retention or burn-in. This is the phenomenon where a static image on the screen can become embossed, burned-in, or simply age differently over time. Having said that, manufacturers now employ several mitigation strategies to prevent burn-in.

The AM bit in AMOLED refers to the use of an active matrix circuit for supplying current, as opposed to the more primitive passive matrix (PM) approach. The P in POLED, meanwhile, indicates the use of a plastic substrate at the base. Plastic is thinner, lighter, and more flexible than glass. There’s also Super AMOLED, which is just fancy branding for a display that has an integrated touch screen digitizer.

Even though Samsung uses the Super AMOLED branding, many of its displays use a plastic substrate too. Smartphones with curved screens would not be possible without the flexibility of plastic. Similarly, almost every POLED display uses an active matrix.

In summary, OLED subtypes aren’t nearly as varied as LCDs. Furthermore, only a handful of companies manufacture OLEDs so there’s even less quality variance than you’d expect. Samsung manufactures the majority of OLEDs in the smartphone industry. Meanwhile, LG Display has a near-monopoly on the large-sized OLED market. It supplies panels to Sony, Vizio, and other giants in the television industry.

In the section on LCDs, we saw how the technology can vary based on differences in the liquid crystal layer. Mini-LED, however, attempts to improve contrast and image quality at the backlight level instead.

The backlights in conventional LCDs have only two modes of operation — on and off. This means that the display has to rely on the liquid crystal layer to adequately block light in darker scenes. Failing to do that results in the display producing grays instead of true black.

This technique, known as local dimming, has become ubiquitous in higher-end LCD televisions. Until recently, though, it wasn’t viable for smaller displays like those found in laptops or smartphones. And even in larger devices like monitors and TVs, you run the risk of not having enough dimming zones.

Still, it’s not hard to see how mini-LEDs can eventually deliver better contrast than conventional local dimming implementations. Furthermore, since mini-LED displays still rely on traditional LCD technologies, they aren’t prone to burn-in like OLEDs.

Quantum dot technology has become increasingly common — usually positioned as a key selling point for many mid-range televisions. You may also know it by Samsung’s marketing shorthand: QLED. Similar to mini-LED, however, it isn’t some radically new panel technology. Instead, quantum dot displays are basically conventional LCDs with an additional layer sandwiched in between.

Many older display types are capable of fully covering the decades-old standard RGB (sRGB) color gamut. However, the same cannot be said for wider gamuts like DCI-P3. Coverage of the latter is important because that’s the color gamut predominantly used in HDR content.

A quantum dot display contains billions of these nanocrystals spread across a thin film. Then, when the backlight is turned on, these crystals are capable of producing extremely specific shades of green and red. The exact shade depends on the size of the crystal itself.

When combined with traditional LCD color filters, quantum dot displays can cover a greater percentage of the visible light spectrum. Put simply, you get richer and ore accurate colors — enough to deliver a satisfactory HDR experience. And since the crystals emit their own light, you also get a tangible bump in brightness compared to traditional LCDs.

However, quantum dot technology does not improve other pain points of LCDs such as contrast and viewing angles. For that, you’d have to combine quantum dots with local dimming or mini-LED technologies. And until those mature, you’re unlikely to find a quantum dot display that can rival OLED in all aspects.

Quantum-dot OLED, or QD-OLED, is an amalgamation of two existing technologies — quantum dots and OLED. More specifically, it aims to eliminate the drawbacks of both traditional OLEDs and LCD-based quantum dot displays.

Modern OLED implementations combat this by leaving the fourth sub-pixel white (without any color filters) to improve the perception of brightness. However, they still usually fall short in terms of brightness, especially against high-end LCDs with larger backlights.

QD-OLED, on the other hand, uses a completely different subpixel arrangement — these displays start with blue emitters instead of white. And instead of color filters, they use quantum dots. In the previous section on QLED, we discussed how quantum dots are capable of producing extremely specific shades of green and red. The same property comes into play here as well. Put simply, quantum dots convert the original blue light into various colors instead of destructively filtering it, preserving the display’s overall brightness.

Their small size means that you can build an entire display out of microLEDs alone. The result is an emissive display — much like OLED, but without the drawbacks of that technology’s organic component. There’s no backlight either, so each pixel can be turned off completely to represent black. All in all, the technology delivers an exceptionally high contrast ratio and wide viewing angles.

Manufacturer of standard & custom operator interface terminals, industrial computers, panel personal computers, software, LCD displays, VFD displays & accessories. Types of operator interface terminals include touch screen operator interface terminals, graphic operator interface terminals, PLC & motion controller interfaces, ASCII & motion controller interfaces, high speed operator interface terminals & widescreen operator interface terminals. Accessories such as controller cables, power cables, power supplies, memory cards, adapters & power isolators are also available. Types of software include industrial process control software, process monitoring software, utility software & operator interface software. Products are used in retail, kiosk, packaging, transportation, plastic manufacturing, medical, pharmaceutical, printing, security, water treatment, petrochemical, bottling & power generation applications. Products are UL® listed, CE certified & RoHS compliant.

In 1991, a business unit called Samsung Display was formed to produce the panels used in products made by its parent company, Samsung Electronics. Afterward, it was a leading supplier of LCD panels not just for Samsung Electronics but for other companies in the industry as well.

The business received a stay of execution when the pandemic led to a global surge in demand for consumer electronics, but that demand is now declining, and projections aren"t good for LCD panel revenue.

Add to that the fact that emerging technologies like QD-OLED are the future for TV and monitors, and the case for keeping Samsung Display"s LCD business going becomes a hard one to make.

It was previously reported that Samsung planned to sunset the business at the end of 2020, but The Korea Times claims that the faster-than-expected falloff in consumer demand accelerated the timeline.

Samsung Display will now focus heavily on OLED and quantum dot. Most of the employees working in the LCD business will move to quantum dot, the publication claims.

Even if there isn"t a statement about a change in direction, the writing has been on the wall for Samsung"s LCD business. Unless something radical changes, it"s more a question of when than if at this point.

Here at Phoenix Display, we talk about LCD displays every day. With LCDs being such a big part of our daily lives, we thought it would be useful to explore the history of this important technology and where we see it going in the future.

In 1973, Sharp Corporation made use of LCD displays in calculators. Shortly after, the company followed BBC’s lead and mass produced TN LCD displays for watches in 1975.

1980s. After wristwatches came televisions (TVs), with the first color LCD TVs being developed as handheld TVs in Japan. In 1982, Seiko Epson released the first LCD TV, the Epson TV Watch, a wristwatch equipped with a small active-matrix LCD TV.

1990s. The 90s gave way to technology acceleration in the LCD space. Through multiple breakthroughs, researchers and inventors were able to improve contrast and viewing angles, as well as bring costs down.

2000s. After 30+ years of competition, LCD technology surpassed longstanding CRTs. Namely, in 2007, LCD TVs could claim better image quality than CRT-based TVs. Subsequently, in the fourth quarter of 2007,

Next, let’s take a brief look at how the technology works. Essentially, the LCD glass is just a light valve whose sole purpose is to either block light or allow light to go through it. We go into greater details in our post,

Finally, let’s look at the LCD display landscape in the near future. There’s three big areas that are being explored with LCD displays: Flexible displays, 3D displays, and reel-to-reel manufacturing.

In contrast, reel-to-reel manufacturing enables the continuous building of glass panels. This will represent a dramatic reduction in costs, which can be passed along to the customer and allow for more competitive pricing.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey