tft display im pins quotation

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

So the drawDistanceSensor() custom function needs to be called only once when the button is pressed in order to draw all the graphics of this example in similar way as we described for the home screen. However, the getDistance() custom function needs to be called repeatedly in order to print the latest results of the distance measured by the sensor.

Here’s that function which uses the ultrasonic sensor to calculate the distance and print the values with SevenSegNum font in green color, either in centimeters or inches. If you need more details how the ultrasonic sensor works you can check my particular tutorialfor that. Back in the loop section we can see what happens when we press the select unit buttons as well as the back button.

Most displays are designed to be "on top" of a stack of shields, so they don"t use stacking connectors, but that doesn"t mean that they are actually using all of the pins. You have to connect your other signals to some shield "underneath" the display, and no longer have the luxury of just sticking wires into the connectors. I mean, it"s a DISPLAY and it"s supposed to look nice! For example, the Adafruit TFT display specifically says:

QuoteThe display uses digital pins 13-9. Touchscreen controller requires digital pin 8. microSD pin requires digital #4. That means you can use digital pins 2, 3, 5, 6, 7 and analog 0-5. Pin 4 is available if not using the microSD

Displays are one of the best ways to provide feedback to users of a particular device or project and often the bigger the display, the better. For today’s tutorial, we will look on how to use the relatively big, low cost, ILI9481 based, 3.5″ Color TFT display with Arduino.

This 3.5″ color TFT display as mentioned above, is based on the ILI9481 TFT display driver. The module offers a resolution of 480×320 pixels and comes with an SD card slot through which an SD card loaded with graphics and UI can be attached to the display. The module is also pre-soldered with pins for easy mount (like a shield) on either of the Arduino Mega and Uno, which is nice since there are not many big TFT displays that work with the Arduino Uno.

One of the good things about this module is the ease with which it can be connected to either of the Arduino Mega or Uno. For this tutorial, we will use the Arduino Uno, since the module comes as a shield with pins soldered to match the Uno’s pinout. All we need to do is snap it onto the top of the Arduino Uno as shown in the image below, thus no wiring required.

This ease of using the module mentioned above is, however, one of the few downsides of the display. If we do not use the attached SD card slot, we will be left with 6 digital and one analog pin as the module use the majority of the Arduino pins. When we use the SD card part of the display, we will be left with just 2 digital and one analog pin which at times limits the kind of project in which we can use this display. This is one of the reasons while the compatibility of this display with the Arduino Mega is such a good news, as the “Mega” offers more digital and analog pins to work with, so when you need extra pins, and size is not an issue, use the Mega.

To easily write code to use this display, we will use the GFX and TFT LCD libraries from “Adafruit” which can be downloaded here. With the library installed we can easily navigate through the examples that come with it and upload them to our setup to see the display in action. By studying these examples, one could easily learn how to use this display. However, I have compiled some of the most important functions for the display of text and graphics into an Arduino sketch for the sake of this tutorial. The complete sketch is attached in a zip file under the download section of this tutorial.

As usual, we will do a quick run through of the code and we start by including the libraries which we will use for the project, in this case, the Adafruit GFX and TFT LCD libraries.

With this done, the Void Setup() function is next. We start the function by issuing atft.reset() command to reset the LCD to default configurations. Next, we specify the type of the LCD we are using via the LCD.begin function and set the rotation of the TFT as desired. We proceed to fill the screen with different colors and display different kind of text using diverse color (via the tft.SetTextColor() function) and font size (via the tft.setTextSize() function).

Next is the void loop() function. Here we basically create a UI to display the youtube subscribe button, using some of the same functions we used under the void setup() function.

The Adafruit library helps reduce the amount of work one needs to do while developing the code for this display, leaving the quality of the user interface to the limitations of the creativity and imagination of the person writing the code.

Now learning arduino tft, got a cheap 1.8 tft spi display from ebay, trying the arduino TFTDsiplayText example with potentiometer, and all my "goal" is the white screen.

You can use TFT displays in HMI products such as room temperature controllers and attendance systems, weather monitoring devices, infotainment systems, and even video game consoles.

This article is part of our series on the different types of displaysthat you can use with Arduino, so if you’re weighing up the options, then do check out our guide to the best displays to use with Arduino.

Let us see a view of a TFT LCD module. In the following section, we will see the pin definition and the pin mapping table for the connection between Arduino and the TFT display.

A0 / DCData Command Select Pin / Analog PinMost of the time, you have to find the relevant termination needed from the LCD datasheet. Terminate this pin to Logic high using a 10 ㏀

You can see the tradeoff here. Going for a better color resolution provides vibrant display options, but memory usage will increase with the color resolution.

The overall memory needed increases by 33 % if you switch from RBG 4-4-4 format to RGB 5-6-5. This increase the demand for the MCU RAM, code size, and time delay to transfer higher data.

There is a tradeoff between the quality of the display, power consumption, and the simplicity of coding. The TFT displays consume more power and need more programming than a simple monochrome display.

TFT displays provide a faster refresh rate and provide smoother transitions. The quicker processing improves the look and feels of the so-called user experience for the user.

I am confident that the article was beneficial and easy to understand. I have used TFT displays in my hobby projects to learn more about the available libraries.

This project uses the SPIFFS (ESP32 flash memory) to store images used as background. You"ll need to upload these to the ESP32 before you upload the sketch to the ESP32. For this you"ll need the ESP32 Sketch Data Upload tool.

Firstly, depending on the board you are using (with resistive touch, capacitive touch, or no touch) you will have to uncomment the correct one. For example, if you are using the ESP32 TouchDown uncomment: "#define ENABLE_CAP_TOUCH". If you are using a DevKitC with separate TFT, uncomment "#define ENABLE_RES_TOUCH".

You can also set the scale of the y-axis of the graphs. This is done under "// The scale of the Y-axis per graph". If these are to big or to small, the data will not be displayed correctly on the graph. You might have to experiment with these.

Go ahead and upload the Bluetooth-System-Monitor.ino sketch to the ESP32. The settings under tools besides the Partition Scheme can be left to the default (see image). Go to "Sketch" and select "Upload". This may take a while because it is a large sketch.

The linear power supply is [+]Efficient and [+]Small but [-]Can"t output 5v [-]Low max current output [-]Have 500mV dropout voltage @500mA so the battery is unusable when it is 3.7 volts, which is real bad as lithium batteries" protector boards over discharge kicks in @2.4v. I also need 5v for the USB host port for keyboards and mouse. Because the host port is not needed at all times, so I wanted to use existing power bank circuit that auto turns on when peripherals are connected. (Existing circuits are great, maybe efficient and safer), so no boosting required if not needed.

PIN connection is the most widely used connection because it is very steady. Unfortunately, not everyone is an expert at soldering. Every now and then, we can hear customers complaining about the high failure rate after the PINs were soldered on PCB. And I was always wondering if they did the soldering properly. More often than not, it’s the soldering problem. It’s not the quality problem of LCD screen itself. We feel it is our obligation to do some tests to help those who lack experience.

In order to test the impact of the soldering temperature, we deliberately made it 350 degrees Celsius far higher than the normal. The soldering iron head was placed at the distance of 4.0 mm from bottom of LCD screen.

One interesting idea was that we located the PIN which was responsible for the missing segments of LCD screen and re-soldered it with overheated temperature. Pulled the PIN down a little, which would make it temperately connect in normal again. We could see it displaying the whole diagram for a while. When we were glad that we fixed the LCD screen, the old problem repeated again. It was easy to understand because the overheated temperature damaged the glue and turned the chemical composition into something else. Now the LCD screen was completely damaged and was unrepairable.

Let us try another experiment. We soldered the perfectly normal LCD screen with overheated temperature. It was as sure as the sun comes from the east that the old missing segment problem recurred. I am going to remind everyone here don’t ever solder the PINs with overheated temperature because it will definitely cause the missing segment problem.

Let us hit the PINs with overheated temperature while we don’t use the UV glue to fasten the positions of the PINs. Wait. Is it possible not to use UV glue? Of course, it isn’t. It is never able to fasten the PINs without UV glue. This was just an experiment to explain what would happen in a hypothetical situation. Now we continued the experiment. We put a 350 degree Celsius soldering iron head directly on PIN for 10 seconds and more until the polarizer turned yellow. To our surprise, the LCD screen was working perfectly fine. Now we could conclude that it was UV glue which was overheated that caused the missing segments and other problems. But we can’t make a LCD screen without it.

1. The distance from the soldering iron head to the bottom of LCD screen should be at least 4.0 mm and the temperature should be below 260 degrees Celsius. The time should be less than 4 seconds for the soldering iron head on PINs to avoid making the glue bubble.

2. The soldering iron head should contact two adjacent PINs at the same time and make the heat transfer more evenly. It should form 30 degree angle with PINs because this will make contacting area larger and heat transfer faster. It will be a perfect heating condition if we can make the two adjacent PINs reach the same temperature at the same time.

3. It is forbidden to let the PINs bear any pressure while we are welding the PINs. In order to prevent the displacing of the PINs because of the pressure from outside, it is best if we lay the front surface of LCD screen flat on a table.

5. The two PINs on the two ends bear a greater tension and they are more likely to be damaged because of the pressure. We strongly suggest that we add two more extra PINs that are not connected on two ends to lighten the burden if the products have a high-quality requirement.

So I have a sketch that utilizes both the RFM69 and TFT libraries and there seems to be a conflict between the two. Each half of the sketch works flawlessly without the other, i.e. I comment out the radio.initialize() or TFTdisplay.begin() line for either the TFT or RFM69. However, when together neither works. The moteino fails to receive data through the radio commands and the TFT screen remains black or displays static white noise.

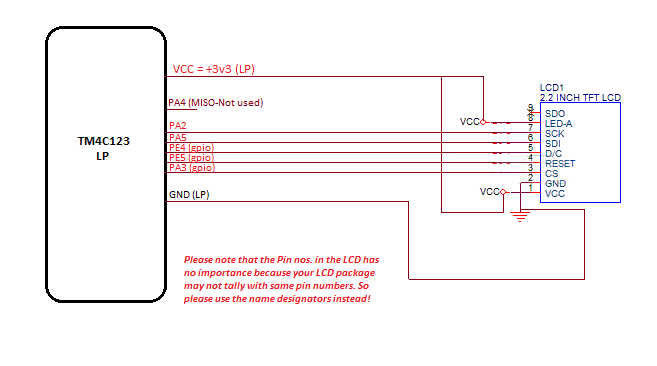

I have already check to make sure there are no pin conflicts. Also the order of initialization does not mater either, I"ve tried both ways with the same result. One puzzling development I discovered though is if I disconnect the MISO pin (pin 12) to the TFT display then then both the display and RFM69 initialize and function properly, but the screen has a noticeable flicker to it which I am wondering if it is a result from disconnecting MISO.

So, I have a purpose built pcb with the teensy 4.0 footprint (little did I know the financial implications this would have...I"ve been through >�60 worth of teensy 4.0).

To confirm, I had the T4 intermittently working on both the adafruit ili9341 library and the optimised ili9341_t3. I"ve been through 3 T4s and I have 5 different ILI934 displays. (all give the same results, pull ups, no pullups, removed sd circuitry, ran the T4 at 5v I"ve tried it all!)

As it is an RGB interface you can directly connect it to the Raspberry DPI interface (https://www.raspberrypi.org/documentati ... /README.md) without "glue logic".So, what you will need is an adapter board which converts the 40pin GPIO (2.54mm pitch) interface to 0.5mm FFC. In addition you will need to input the timing (page 10) to let the RPI now how to drive the display.

This is what the above setup looks like "in action". That 5.6in display is 640x480pixels native resolution. I"m running KMS graphics driver which allows me to scale my desktop to 1024x768pixels which still has a good readability on the display (xrandr --output DPI-1 --primary --scale 1.6x1.6)

Note: DSI to RGB chip used on the RPI display is EOL; so there is the chance that we will see a new official display in the future (but also a risk that RPi decided to make a last-time-buy with huge quantaties in orderto be able to ship longer).

if you did not/been unable to salvage that component from your display donar device you need to find a new one (extra costs, different specs, ..). And..there is still the risk the backlight fails on first start attempt!

Simplest use of a DPI display is by adding the timing to `panel-simple.c", write an overlay which uses it, compile everything and then add the overlay to config.txt. No need to write any driver.

The board use 3.3V so we can attach it direct to the mbed. The backlite LED need a resistor to limit the current. I use two 10R resistors parallel to get 5R driven by 3.3V.

SPI is serial and we have to transfer 320 * 240 * 16 = 1228800 bits to the display to fill it up. Will it be to slow ? No ! We can drive the SPI to display with 48Mhz clock speed !

To print characters to a graphic screen we need a font. To code a font by paper is ok for a small lcd, but for a 320*240 pixel display we need bigger fonts. A 12*12 pixel font is readable, but a lot of work to construct.

To construct a bitmap we can use gimp. http://www.gimp.org/ Load a image (edit and resize) and save it as BMP. You have to select the option 16 bit R5 G6 B5 !

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey