difference between tft lcd and resistive touchscreen free sample

There are types of touch screen,such as resistive touch panel(RTP), capacitive touch panel (CTP), surface acoustic wave touch display, infrared touch screen. RTP and CTP are used more than others. Can you tell the difference between RTP and CTP? If not, you may want to read along.

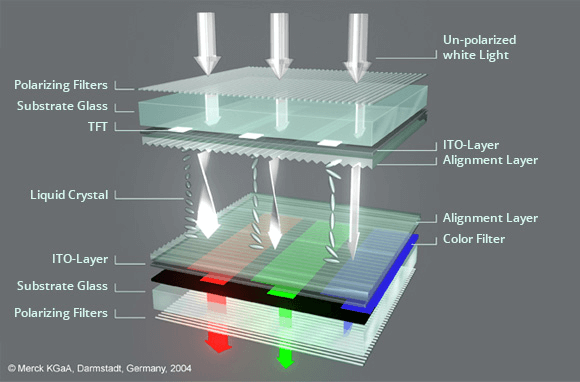

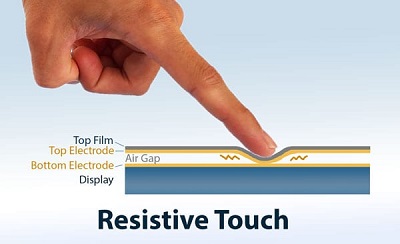

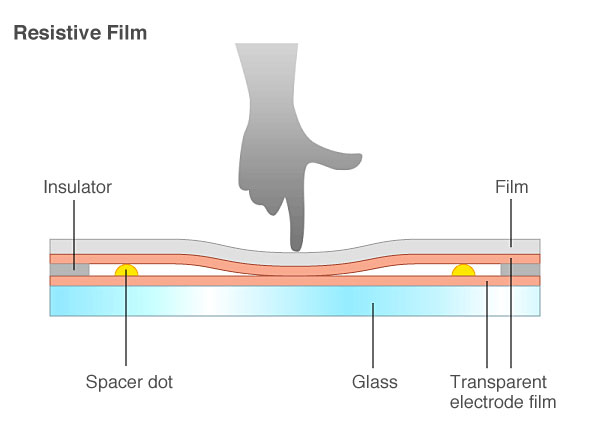

In resistive touch screens, two very thin layers of material are separated by a thin gap of air. PET film and glass are typically used. Both upper and bottom layers are lined with conductors such as indium tin oxide (ITO). The conducting sides are placed facing one another. So, when you press the screen with finger or stylus, it connects top and bottom layers, creates a change in resistance (an increase in voltage). RTP controller detects this change, and calculates its coordinates, then determines the position of touch.

Capacitive touchscreens, on the other hand, respond directly to the touch of your finger or an input device such as a stylus. On top of LCD panel, lies a thin layer of transparent electrodes. When a human finger touches the screen, some of the electrical charge travels from screen to user. The change of capacitance is then detected by sensors located at screen"s four corners, allowing controller determine the touched location.

Resistive touch screens are effective in a variety of environments. Any object capable of applying force to the screen can trigger a touch event. For example, users wearing gloves can operate RTP with no difficulty.Resistive touch screens work well even when liquids or debris are present on the surface. This makes them especially useful in situations where substances could disrupt the function of other types of touch screens, for example, agricultural equipment, boats and underwater machinery. Due to its mature technology and simple structure, cost of resistive screens is lower.

Supporting of Multiple touches is a clear winner for capacitive touch screens (CTP). Thanks to smartphone and tablet, users are comfortable with using gesture on screen. And capacitive touch screen is what user is familiar with. In more specialized settings, such as multi-player gaming application, capacitiv e touch screens can support more than 10 inputs at a single time. Additionally, CTP needs no calibration and is highly accurate.

Resistive touch display cannot determine the location of a touch if more than one input is present. In terms of visibility, the film substrate commonly used as the top surface in resistive touch screens is less transmissive than glass. This leads to reduced brightness and a certain level of haze compared to touch screens with a top layer of glass. The film layer can also expand or contract based on temperature, which alters the distance between the two layers and affects touch accuracy. Additionally, the film substrates are susceptible to scratches and can start to wear away with repeated use, necessitating occasional recalibration or replacement over time.

Capacitive touch screens depend on variations in an electrical field to operate. While a passive stylus can activate this screen, a non-conductive tool like a pencil can"t. If cost is a top concern for a project, CTP may not align with budget limits. It is a more expensive technology than resistive screens, although it continues to grow more accessible in terms of price as the technology advances and improves.

There are many types of touch panel technologies available in the market, the popular types are we are going to discuss the two most widely used types, and compare resistive vs capacitive touch screen

Projected Capacitive Touch Panel (PCAP) was actually invented 10 years earlier than the first resistive touchscreen. But it was no popular until Apple first used it in iPhone in 2007. After that, PCAP dominates the touch market, such as mobile phones, IT, automotive, home appliances, industrial, IoT, military, aviation, ATMs, kiosks, Android cell phones etc.

Projected capacitive touchscreen contains X and Y electrodes with insulation layer between them. The transparent electrodes are normally made into diamond pattern with ITO and with metal bridge.

Human body is conductive because it contains water. Projected capacitive technology makes use of conductivity of human body. When a bare finger touches the sensor with the pattern of X and Y electrodes, a capacitance coupling happens between the human finger and the electrodes which makes change of the electrostatic capacitance between the X and Y electrodes. The touchscreen controller detects the electrostatic field change and the location.

Projected capacitive supports multiple touches (Multi-touch), so it supports a lot of gestures: Zoom in and out (pinch/spread), scroll, swipe, drag, slide, hold/press, rotate, tap etc.

With the new development, projected capacitive touch panels can support gloved hand touch with different glove materials and touch with water or even with salt water.

Before 2007, resistive technology was the most popular touch panel market. From its name, we know that the technology relies on resistance. A resistive touch screen is made of a glass substrate as the bottom layer and a film substrate (normally, clear poly-carbonate or PET) as the top layer, each coated with a transparent conductive layer (ITO: Indium Tin Oxide), separated by spacer dots to make a small air gap. The two conducting layers of material (ITO) face each other. When a user touches the part of the screen with finger or a stylus, the conductive ITO thin layers contacted. It changes the resistance. The RTP controller detects the change and calculate the touch position. The point of contact is detected by this change in voltage.

With the fast development of projected capacitive, resistive touchscreen devices market is shrinking rapidly but it is still widely used in some industrial applications because of the following advantages.

The following table shows the comparison of resistive and capacitive touch screens. It is up to your application to select the types of technology to use.

Touchscreens have changed the way people expect to interact with their devices. When it comes to smartphones and tablets, touch is the way to go. Even handheld game consoles, laptops, and car navigation systems are moving towards touch. Manufacturers of these devices need to give their respective consumers the responsiveness these consumers are looking for. Selecting the right TFT-LCD display to use for different devices is important.

For touch-sensitive displays, two types of technologies are used: resistive and capacitive. The main difference is in how they respond to touch. Mobile phone comparison site Omio indicates that resistive technology is more accurate but capacitive technology is more responsive.

To elaborate on that, resistive touchscreens allow input from fingers and non-finger objects, like a stylus. A stylus has a smaller point than a finger and makes interaction on a resistive screen more accurate. This makes the technology suitable for devices whose applications require high accuracy, like sketching and pinpoint games. Mobile devices that use a stylus typically have resistive touchscreens.

Capacitive touchscreens, on the other hand, offer more responsiveness with better optical clarity and multi-touch performance. They detect more complex finger gestures. These qualities are shown to be more important for general interaction so it’s more dominant in smartphones and tablets, as well as in other devices with small to medium screen sizes.

As you can see, capacitive screens get general usage while resistive screens cater to more specific applications. With this, TFT-LCD module manufacturers, like Microtips Technology, focus on continuously improving capacitive screen technology.

Electronic Design states that many technological advances can be used to integrate touch sensors directly into the display. In some, manufacturers stack-up the touch sensors and integrate the controller with the display driver ICs. These advances allowed thinner and smarter capacitive touchscreens – a trend that you see in many devices today. For example, Windows phones originally worked exclusively with resistive touchscreen technology but later on moved over to capacitive. If the continuous development of capacitive touchscreen technology becomes successful, these screens may soon have abilities they don’t possess at the moment, such as hover support, non-finger support, and many more.

A surface capacitive touchscreen uses a transparent layer of conductive film overlaid onto a glass sublayer. A protective layer is then applied to the conductive film. Voltage is applied to the electrodes on the four corners of the glass sublayer to generate a uniform electric field. When a conductor touches the screen, current flows from the electrodes to the conductor. The location of the conductor is then calculated based on the activity of the currents. Surface capacitive touchscreens are often used for large screen panels.

Projected capacitive touchscreens are extremely precise and quick to respond and are typically found on smaller devices such as iPhones, iPod touches, or iPads. Unlike the surface capacitive touchscreens, which use four electrodes and a transparent conductive film, the projected capacitive touchscreens use a vast amount of transparent electrodes arranged in a specific pattern and on two separate layers. When a conductor moves near the screen, the electrical field between the electrodes changes, and sensors can instantly identify the location on the screen. Projected capacitive touchscreens can accurately register multi-touch events.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The Resistive touch panel senses a touch by measuring where contact is made on the glass. It is independent of temperature and humidity and simple to integrate independent of a separate controller chip.

The Transmissive polarizer is best used for displays that run with the backlight on all the time. This polarizer provides the brightest backlight possible. If you have a need for a bright backlight with lower power drain, transmissive is a good choice for this TFT LCD display.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

The Resistive touch panel senses a touch by measuring where contact is made on the glass. It is independent of temperature and humidity and simple to integrate independent of a separate controller chip.

The Transmissive polarizer is best used for displays that run with the backlight on all the time. This polarizer provides the brightest backlight possible. If you have a need for a bright backlight with lower power drain, transmissive is a good choice for this TFT LCD display.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

Are you looking for a small LCD touchscreen display for your device or product? We carry a number of touch screen TFTs, OLEDs, and STN displays. If you need a capacitive or a resistive touch screen we have both available.

Capacitive touch technology is increasingly used in user interfaces for a variety of devices. A capacitive touch display is created by attaching a capacitive layer on top of a glass panel substrate. These components are then covered with a protective outer layer, and the surface of the device will maintain a static charge. As a person’s finger or a stylus touches the surface, the charge will transfer from the panel surface to the device or finger. This allows the capacitive device to register the touch location.

Thin-film transistor (TFT) LCD capacitive touch screens have become a popular choice when compared to the other leading touch screen technology – resistive touch. While resistive touch screens have been around for a longer time and can be built at a lower cost, capacitive touch displays offer several significant advantages over other display technologies. In this post, we’ll explore what makes capacitive touch technology unique and how it performs across several parameters.

Capacitive touch technology offers excellent screen sensitivity when used with a finger or stylus. The surface of these devices will respond to varying degrees of pressure, as opposed to a resistive touch screen where firm and direct pressure must be used. A TFT LCD capacitive touch screen is also sensitive enough to be used only with fingers without the need for a stylus.

Capacitive stylus devices can be used for added precision and niche applications such as digital drawing. Another related benefit is support for multi-touch operation using multiple fingers simultaneously. This includes advanced gestures such as pinch-zoom that is a popular feature in many device applications today.

TFT LCD capacitive displays are known for their excellent optical quality. The glass substrate that sits below the electrode film transmits most of the available light to the surface resulting in crisp sharpness and display contrast. These screens are also known for outstanding color fidelity that supports the viewing of high-quality images, video, and software content. This also has a positive impact on the user experience when integrated into larger kiosks and interactive displays.

Capacitive touch devices are very stable, with little to no shift in the image being transferred to the screen. This is an important advantage over other display types, as image shift can get worse over time and require manual correction with other types of displays. A capacitive touch device, therefore, does not require the periodic calibrations that are commonly necessary with many older display technologies. Maintaining a stable image is an essential requirement in high-performance display applications, such as those found in the broadcasting and entertainment industries.

The glass substrate of a capacitive touch display is very strong, and the protective layer helps prevent scratches and other marks. Like most displays, a capacitive touch screen can crack if dropped or exposed to significant pressure. It should be noted that a cracked resistive touch screen most often ceases to operate, while a cracked capacitive device will usually maintain some functionality. This has made capacitive screens popular for commercial applications that are exposed to significant wear and tear.

The screen of a capacitive touch device can be completely sealed, preventing contaminants from entering the seams on the outer edges of the display. Preventing dust and condensation from getting inside the display is important for long-term use. This also makes a capacitive touch display easy to clean. Due to the ease of cleaning and other advantages, capacitive touch technology is often used for public digital displays in high-traffic areas.

The sensitivity of a capacitive touch display also contributes to excellent response times. As a user touches the screen at different locations, the surface can register these movements with a high degree of accuracy. A capacitive touch screen also performs very well when the user’s finger or stylus is dragged across the surface. This makes capacitive touch a preferred choice for graphic design and audio-visual applications.

One final advantage of capacitive touch technology is false touch rejection. A resistive display can be easily confused if multiple fingers touch the screen at the same time, making it unable to register accurate movement. The improved sensitivity of a capacitive display increases the ability of the surface to differentiate between multiple points of contact. In addition to enabling the custom gestures, sliding motions, and light touches mentioned above, this also eliminates the potential for a missed touchpoint.

Capacitive touch is a relatively new touchscreen technology that is having a significant impact on the display industry. With several advantages over competing design options, the use of TFT LCD capacitive touch technology is expected to grow significantly in the coming years. This will be an important trend for device manufactures, designers, and end-users to follow as an opportunity to improve product quality and performance.

Capacitive touch panels are the more modern and advanced touchscreen option because of their advanced capabilities. They are commonly found in consumer products like smartphones, tablets, appliances, and monitors.

A capacitive touchscreen detects and responds to changes in capacitance caused by the screen"s electrostatic field when the screen"s surface is touched.

Capacitive touchscreen displays allow for touch gestures and respond to multi-touch inputs. You’ll typically be able to enter one to five touch inputs simultaneously, but some capacitive touchscreens can process even more.

Capacitive touchscreens deliver brighter, higher contrast images due to the makeup of their panels. Displays with capacitive touch screens are more durable than resistive touch screens because they are designed with cover glass on their top layer. In fact, all of our capacitive TFT displays have standard 0.7mm thick built-in cover glass and can be further

While the cost is currently higher than resistive touchscreens, capacitive touchscreens are quickly becoming the industry standard in touchscreen technology.

The enhanced responsiveness can be a downside depending on how and where the display is used. For example, a capacitive touchscreen would not easily respond to the user while wearing certain types of gloves. Although capacitive touchscreens don’t respond to inorganic inputs, they can still be accidentally activated by other conductive elements. One of the the most common elements that causes interruptions is water.

Rain, humidity, and condensation on the surface of capacitive touchscreens will often cause accidental inputs and reduced accuracy until the water is removed. This is one of the main reasons why a resistive touchscreen would be chosen over a capacitive touchscreen in certain situations.

Any device that utilizes touch gestures like swiping, pinching, or multi-touch will require a capacitive touchscreen. These features often help make capacitive touchscreen displays more intuitive and user-friendly than resistive touchscreens. Capacitive touchscreens are best suited for applications requiring improved touch responsiveness with better image brightness and contrast.

sense pressure on the display"s top layer and send a signal to the circuit layer to activate the touchscreen functionality. Because they use pressure to activate the touch inputs, resistive touchscreen displays can be used with a stylus, gloves, and other items. Resistive touchscreens are built without cover glass and made of plastic, making them more susceptible to dents and scratches.

"touch event" occurs when these two layers make contact with each other (closing the circuit) by the user"s action of pressing into the soft, semi-flexible top layer. Each layer consists of horizontal and vertical lines (x,y matrix) that detects the exact location of the touch.

The gap or space layer typically consists of air or inert gas and some spacers whose only purpose is to separate the soft top layer from the bottom layer.

Resistive touchscreens are often seen as the less advanced variety of touch panel compared to capacitive touch panels. However, being able to interact with non-organic inputs keeps these touchscreens relevant in specific industries.

Resistive touchscreen displays are less sensitive than capacitive touchscreen displays. This is considered an advantage in some cases and is why they’re chosen for specific applications. Resistive touchscreens will not respond to accidental inputs from the environment, so they won’t be interrupted by things like water spills or lightweight debris landing on the screen.

This type of touchscreen requires more intentional inputs from the user, making them more reliable in rugged and unstable environments. For example, a resistive touchscreen is the perfect solution on a construction site where water or debris might land on the screen. They’re also the best touchscreen display option for situations where the user is wearing gloves.

Resistive touchscreen panels are unfortunately more susceptible to dents and scratches. Their poor visibility in direct sunlight does not make them ideal for outdoor applications. Their inability to respond to multi-touch inputs can be a disadvantage in fast-paced applications requiring such. Because resistive touchscreens rely on the pressure applied to the top layer, they tend to be abused and mishandled, which makes them less durable over time than capacitive touchscreens.

Resistive touchscreen technology is ideal for low-cost applications involving rugged environments, indirect sunlight, and simple touch features. Fewer accidental touch inputs, better resistance to heat and moisture, and the ability to be operated with pretty much anything (stylus, pen, gloves, fingers, etc.) make this touchscreen technology a more reliable solution when user input is crucial.

While it’s clear that capacitive touchscreens are dominating the consumer electronics market, resistive touchscreens still have an advantage in some ways.

If you’re looking for a cost-effective touchscreen that can operate with simple tap inputs in rugged environments, resistive is the way to go. For more advanced and intuitive touchscreen technology with higher quality applications, choose capacitive touchscreens.

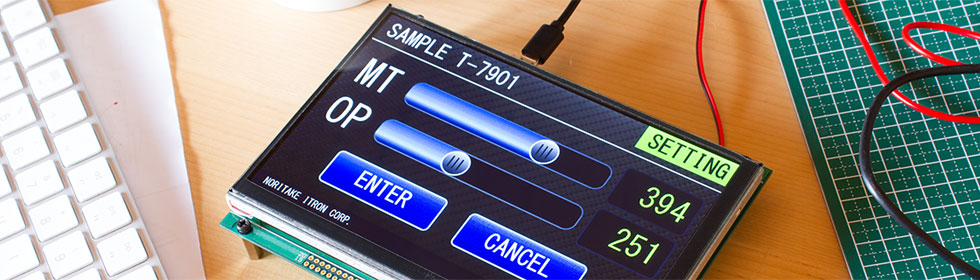

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

As the code is a bit longer and for better understanding I will post the source code of the program in sections with description for each section. And at the end of this article I will post the complete source code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Next is the distance sensor button. First we need to set the color and then using the fillRoundRect() function we will draw the rounded rectangle. Then we will set the color back to white and using the drawRoundRect() function we will draw another rounded rectangle on top of the previous one, but this one will be without a fill so the overall appearance of the button looks like it has a frame. On top of the button we will print the text using the big font and the same background color as the fill of the button. The same procedure goes for the two other buttons.

Now we need to make the buttons functional so that when we press them they would send us to the appropriate example. In the setup section we set the character ‘0’ to the currentPage variable, which will indicate that we are at the home screen. So if that’s true, and if we press on the screen this if statement would become true and using these lines here we will get the X and Y coordinates where the screen has been pressed. If that’s the area that covers the first button we will call the drawDistanceSensor() custom function which will activate the distance sensor example. Also we will set the character ‘1’ to the variable currentPage which will indicate that we are at the first example. The drawFrame() custom function is used for highlighting the button when it’s pressed. The same procedure goes for the two other buttons.

getDistance(); // Gets distance from the sensor and this function is repeatedly called while we are at the first example in order to print the lasest results from the distance sensor

Here’s that function which uses the ultrasonic sensor to calculate the distance and print the values with SevenSegNum font in green color, either in centimeters or inches. If you need more details how the ultrasonic sensor works you can check my particular tutorialfor that. Back in the loop section we can see what happens when we press the select unit buttons as well as the back button.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

getDistance(); // Gets distance from the sensor and this function is repeatedly called while we are at the first example in order to print the lasest results from the distance sensor

2) FPC interfaces include soldering, plug-in, and B2B connection, the reinforcement materials we commonly use include PI, PET, FR4, steel sheet, aluminum sheet, and so on, which can be selected according to different applications environments.

Dr Pan: Hello, Greg. TFT LCD module is one of the best LCD technology. We can simply consider it as TFT+LCD+LED backlight, and monochrome LCD module consists of LCD+LED backlight. An image on an LCD we can see is composed of pixels. TFT is the abbreviation for thin film transistor and it controls the R, G, B colors of each pixel respectively on the surface of LCD.

TFT LCD is a high standard product and it is not well customized as monochrome LCD. But still, it has a variety of options to meet the customers’ requirements.The sizes range from 1.44 inch to 130.0 inch;

It has been widely used in our everyday life. It includes industrial control, coffee machine, POS system, automation, GPS navigator, white goods, energy control, telecoms, medical equipment and etc.

At present the research and development of PANASYS type resistance touch screen mainly ITO F+G structure, size covers 0.9-22 inch (support custom size). The general purpose four wire, five wire and eight wire resistive screens are mainly used for industrial control devices, commercial POS machines, self-service machines, military equipment, security and vehicle GPS applications.

Shenzhen SLS Industrial Co.,ltd established in 2003, is a professional LCD module manufacturer and solution provider. We have 1 full-auto COG assembly line, 2 semi-auto assembly line, backlight assembly line, no dust TP bonding line and manufacturing tech support, we can provide unique, innovative and cost effective LCD module development and manufacturing. Our product range includes: middle-small size TFT LCD, industrial capacitive touch panel... Our LCD products have been widely used in communications, GPS, Equipment, electronic audio-visual, instrumentation, household appliances, PDA and other industries.

To provide superior, commercially-ready LCM and TP solutions that fulfill our vision of exceeding customers’ expectations through design, manufacturing and worldclass customer support of our core technology.

I purchased this LCD Touch along with the TFT LCD Mega Shield 2.2 shield for the Arduino Mega also from Amazon. It was easy to figure out getting the UFTF library from Rinky Dink Electronics to work. I used "UTFT myGLCD(CTE32_R2,38,39,40,41);" or "UTFT myGLCD(ILI9341_16,38,39,40,41);" and they both worked. I had a very hard time getting the actual touch function to work. The default of "URTouch myTouch(6, 5, 4, 3, 2);" for the touch library is correct on the Mega. It turned out to be a connection issue. I just reseated the board a couple of times and it worked. I recommend testing this LCD with the examples from the URTouch library. The online examples are too complicated and have too many dependencies to break. Get the basic screen and touch working first. Don"t forget to debounce the touch with a short delay. This screen is touchy which makes it fast to enter numbers for me. It worked just powered from my PC with a USB cable to the Arduino Mega. Very Easy.

Whenever you buy a touchscreen, it isn"t always advertised whether it"s a capacitive or a resistive touchscreen. Yet, touchscreens of both types are used throughout the electronics industry.

If you pay attention, you"ll notice the difference between the two screens. In the case of capacitive touchscreens, such as on very expensive smartphones and tablets, are very responsive to the slightest touch. Meanwhile, resistive touchscreens may require more pressure, or the use of a stylus.

The resistive touchscreen has always been the most common type used in industrial electronics. This is mostly because they"re cheaper to make and are easier to use in difficult environments.

This type of touchscreen is created out of two very thin layers of material, separated by a thin gap. The top layer is typically some type of clear poly-carbonate material, while the bottom layer is made up of a rigid material. Manufacturers typically use PET film and glass for these layers.

When you press your finger or a stylus against the screen, it creates a change in resistance (an increase in voltage). The sensor layer then detects this change, and the tablet or mobile phone processor calculates the coordinates of that change.

Resistive touchscreen technology relies on electrodes that layer a uniform voltage across the entire conductive area. This provides a specific voltage reading when an area of the two years make contact.

This means that a more expensive resistive touchscreen with an 8-wire analog circuit will last longer. It also avoids the "drift" problems older phones used to have when trying to sense the location of your finger or stylus.

Resistive touchscreens are meant to sense the location of one touch, and early generation touchscreens couldn"t respond to two-finger pinch or zoom actions.

However, later generations saw some mobile device manufacturers introducing new algorithms and other tricks that allowed for two-finger touch features.

Capacitive touchscreens were actually invented almost 10 years before the first resistive touchscreen. Nevertheless, today"s capacitive touchscreens are highly accurate and respond instantly when lightly touched by a human finger. So how does it work?

As opposed to the resistive touchscreen, which relies on the mechanical pressure made by the finger or stylus, the capacitive touchscreen makes use of the fact that the human body is naturally conductive.

In a surface capacitive setup, there are four electrodes placed at each corner of the touchscreen, which maintain a level voltage over the entire conductive layer.

When your conductive finger comes in contact with any part of the screen, it initiates current flow between those electrodes and your finger. Sensors positioned under the screen sense the change in voltage, and the location of that change.

One line of electrodes (vertical) maintain a constant level of current when the screen isn"t in use. Another line (horizontal) are triggered when your finger touches the screen and initiates current flow in that area of the screen.

The matrix formation creates an electrostatic field where the two lines intersect. This is one of the most sensitive types of touchscreens, and is how some phones can sense a finger touch even before you make contact with the screen itself.

Most devices with resistive screens are used in manufacturing, ATMs and kiosks, and medical devices. This is because in most industries the users need to wear gloves when using the touchscreens.

If it weren"t for cutting edge touchscreen technologies, we could never enjoy cool new applications like Opera"s one-handed browsing for Android. The applications are only going to expand as the technology continues to be refined.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey