difference between tft lcd and resistive touchscreen brands

![]()

Touchscreens have changed the way people expect to interact with their devices. When it comes to smartphones and tablets, touch is the way to go. Even handheld game consoles, laptops, and car navigation systems are moving towards touch. Manufacturers of these devices need to give their respective consumers the responsiveness these consumers are looking for. Selecting the right TFT-LCD display to use for different devices is important.

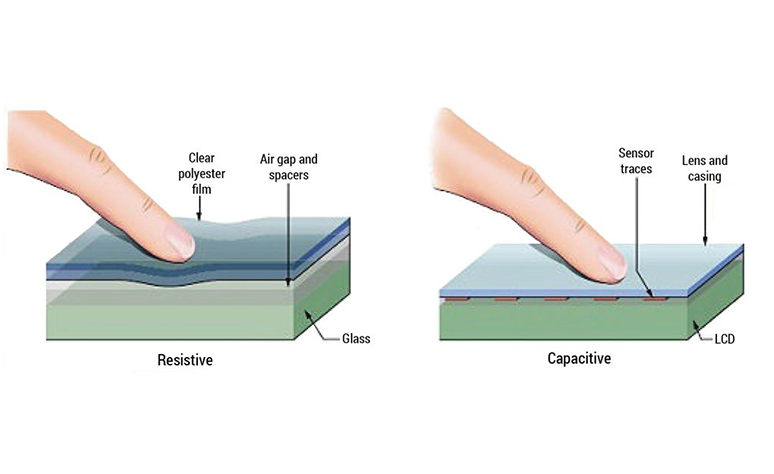

For touch-sensitive displays, two types of technologies are used: resistive and capacitive. The main difference is in how they respond to touch. Mobile phone comparison site Omio indicates that resistive technology is more accurate but capacitive technology is more responsive.

To elaborate on that, resistive touchscreens allow input from fingers and non-finger objects, like a stylus. A stylus has a smaller point than a finger and makes interaction on a resistive screen more accurate. This makes the technology suitable for devices whose applications require high accuracy, like sketching and pinpoint games. Mobile devices that use a stylus typically have resistive touchscreens.

Capacitive touchscreens, on the other hand, offer more responsiveness with better optical clarity and multi-touch performance. They detect more complex finger gestures. These qualities are shown to be more important for general interaction so it’s more dominant in smartphones and tablets, as well as in other devices with small to medium screen sizes.

As you can see, capacitive screens get general usage while resistive screens cater to more specific applications. With this, TFT-LCD module manufacturers, like Microtips Technology, focus on continuously improving capacitive screen technology.

Electronic Design states that many technological advances can be used to integrate touch sensors directly into the display. In some, manufacturers stack-up the touch sensors and integrate the controller with the display driver ICs. These advances allowed thinner and smarter capacitive touchscreens – a trend that you see in many devices today. For example, Windows phones originally worked exclusively with resistive touchscreen technology but later on moved over to capacitive. If the continuous development of capacitive touchscreen technology becomes successful, these screens may soon have abilities they don’t possess at the moment, such as hover support, non-finger support, and many more.

A surface capacitive touchscreen uses a transparent layer of conductive film overlaid onto a glass sublayer. A protective layer is then applied to the conductive film. Voltage is applied to the electrodes on the four corners of the glass sublayer to generate a uniform electric field. When a conductor touches the screen, current flows from the electrodes to the conductor. The location of the conductor is then calculated based on the activity of the currents. Surface capacitive touchscreens are often used for large screen panels.

Projected capacitive touchscreens are extremely precise and quick to respond and are typically found on smaller devices such as iPhones, iPod touches, or iPads. Unlike the surface capacitive touchscreens, which use four electrodes and a transparent conductive film, the projected capacitive touchscreens use a vast amount of transparent electrodes arranged in a specific pattern and on two separate layers. When a conductor moves near the screen, the electrical field between the electrodes changes, and sensors can instantly identify the location on the screen. Projected capacitive touchscreens can accurately register multi-touch events.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Projected capacitive touch screen contains X and Y electrodes with insulation layer between them. The transparent electrodes are normally made into diamond pattern with ITO and with metal bridge.

Human body is conductive because it contains water. Projected capacitive technology makes use of conductivity of human body. When a bare finger touches the sensor with the pattern of X and Y electrodes, a capacitance coupling happens between the human finger and the electrodes which makes change of the electrostatic capacitance between the X and Y electrodes. The touchscreen controller detects the electrostatic field change and the location.

A resistive touch screen is made of a glass substrate as the bottom layer and a film substrate (normally, clear poly-carbonate or PET) as the top layer, each coated with a transparent conductive layer (ITO: Indium Tin Oxide), separated by spacer dots to make a small air gap. The two conducting layers of material (ITO) face each other. When a user touches the part of the screen with finger or a stylus, the conductive ITO thin layers contacted. It changes the resistance. The RTP controller detects the change and calculate the touch position. The point of contact is detected by this change in voltage.

Resistive touch screens still reign in cost-sensitive applications. They also prevail in point-of-sale terminals, industrial, automotive, and medical applications.

Projected Capacitive Touch Panel (PCAP) was actually invented 10 years earlier than the first resistive touchscreen. But it was no popular until Apple first used it in iPhone in 2007. After that, PCAP dominates the touch market, such as mobile phones, IT, automotive, home appliances, industrial, IoT, military, aviation, ATMs, kiosks, Android cell phones etc.

A resistive touch screen is made of a glass substrate as the bottom layer and a film substrate (normally, clear poly-carbonate or PET) as the top layer, each coated with a transparent conductive layer (ITO: Indium Tin Oxide), separated by spacer dots to make a small air gap. The two conducting layers of material (ITO) face each other. When a user touches the part of the screen with finger or a stylus, the conductive ITO thin layers contacted. It changes the resistance. The RTP controller detects the change and calculate the touch position. The point of contact is detected by this change in voltage.

One of the main reasons why resistive touch panels still exist is its simple manufacturing process and low production cost. The MOQ (Minimum Order Quantity) and NRE (Non-Recurring Expense) are low. The driving is simple and low cost. The power consumption is low too. Resistive touch panel also immune to EMI well. Although it can’t use cover lens at the surface, the overlay can make it flexible for designs.

Resistive touchscreens offer an unparalleled level of durability. Manufacturing companies, restaurants and retailers often prefer them over other types of touchscreens for this very reason. With their durable construction, resistive touchscreens can withstand moisture and stress without succumbing to damage.

You can control a resistive touchscreen using a stylus or while wearing gloves. Most capacitive touchscreens only register commands performed with a bare finger (or a special capacitive stylus). If you use a stylus or a gloved finger to tap the interface, the capacitive touchscreen won’t respond to your command. Resistive touchscreens register and respond to all forms of input, though. You can control them with a bare finger, a gloved finger, a stylus or pretty much any other object.

The biggest advantages for resistive touch panel are its touch experience and clarity. It can only be used for single touch, no gestures or multi-touch. False touches can be generated if using two or more fingers to touch it.

Resistive touch panel’s transparency is relatively low. In order to prevent Newton rings or fingerprint mark, sometimes AG(anti-glare) film has to be used to make it look more smoky. Optical bonding can’t be used for RTP. The surface of resistive touch panel is soft and easily get scratched.

There are still a few potential cons associated with resistive touchscreens. When compared to capacitive touchscreens, resistive touchscreens aren’t as sensitive. They are still responsive, but you’ll have to tap or press the interface with greater force for a resistive touchscreen to recognize your input.

Resistive touchscreens usually offer lower display resolutions than capacitive touchscreens. Granted, not all applications require a high-resolution display. If a touchscreen is used as a point-of-sale (POS) system in a retail environment, for example, resolution shouldn’t be a concern.

Touch screens have become very commonplace in our day-to-day lives. Devices using touch panels to enable user interaction without the use of keyboard or mouse. But do you know there are couple distinctively different types of touch screens? The five most common types are: Resistive, Surface Capacitive, Projected Capacitive, Surface Acoustic Wave and Infrared.

Resistive Touch is the most widely used touch technology these days. Because it is cheaper to make and easier to use in different environments. A resistive touch screen is composed of two very thin layers of material, separated by a thin gap. The top layer is typically some type of clear polycarbonate material, while as the bottom layer is made from rigid material. LCD manufacturers normally use PET film and glass for these layers. The upper and bottom layers are lined with conducting material like indium tin oxide (ITO), facing each other, separated by a narrow gap. When a user touches the screen, two metallic layers make contact, it creates a change in resistance.

In a 4-wire analog setup, both the top and bottom layers contain two electrodes called “bushbar”. These electrodes are oriented perpendicular to one another.

Electrodes on the top are positive and negative Y axis, while the ones on the bottom are positive and negative X axis. Using this setup, screen can sense the coordinates where the two layers have come in contact.

When user’s finger or stylus makes an area of the two layers touch, the sensing wire sends the voltage for the coordinates to device processor. With fewer components and a simpler design, the 5-wire analog circuit is a bit more durable than other designs.

The most sensitive resistive touch screen design is that of the 8-wire sensing circuit. Its layout is similar to the 4-wire one, but each of the “bushbar” connects with two wires.

Capacitive touch panel technology relies on the capacitance of the human body, and not on mechanical pressure like resistive technology. There are two types of capacitive touch panels – surface capacitive and projected one.

Surface Capacitive Touch are the second most popular type of touch screens on the market. In a surface capacitive touch panel a thin glass surface covers capacitive touch screen. Under this glass surface, lies a thin layer of transparent electrodes on top of LCD glass panel.

Projected Capacitive is like Surface Capacitive, with two main advantages: besides bare finger, it can also be activated with fingers inside thin surgical or cotton gloves; and it enables multi-touch activation.

Beneath the glass with protective cover, there is a pattern of electrode layers – or the matrix. This pattern forms the plane of X and Y coordinates which the controller uses to calculate the event of touch.

SAW (Surface Acoustic Wave) touch screen utilizes a series of piezoelectric transducers and receivers along the sides of the glass plate to create an invisible grid of ultrasonic waves on the surface. When the panel is touched, a portion of the wave is absorbed. This allows the receiving transducer to locate the touch point and send this data to the computer. SAW monitors can be activated by a finger, gloved hand, or soft-tip stylus. SAW monitors offer easy use and high visibility.

Infrared touch screen monitors do not overlay the display with an additional screen or screen sandwich. Instead, infrared monitors use IR emitters and receivers to create an invisible grid of light beams across the screen. This ensures the best possible image quality. When an object interrupts the invisible infrared light beam, the sensors are able to locate the touch point.

There are types of touch screen,such as resistive touch panel(RTP), capacitive touch panel (CTP), surface acoustic wave touch display, infrared touch screen. RTP and CTP are used more than others. Can you tell the difference between RTP and CTP? If not, you may want to read along.

In resistive touch screens, two very thin layers of material are separated by a thin gap of air. PET film and glass are typically used. Both upper and bottom layers are lined with conductors such as indium tin oxide (ITO). The conducting sides are placed facing one another. So, when you press the screen with finger or stylus, it connects top and bottom layers, creates a change in resistance (an increase in voltage). RTP controller detects this change, and calculates its coordinates, then determines the position of touch.

Capacitive touchscreens, on the other hand, respond directly to the touch of your finger or an input device such as a stylus. On top of LCD panel, lies a thin layer of transparent electrodes. When a human finger touches the screen, some of the electrical charge travels from screen to user. The change of capacitance is then detected by sensors located at screen"s four corners, allowing controller determine the touched location.

Resistive touch screens are effective in a variety of environments. Any object capable of applying force to the screen can trigger a touch event. For example, users wearing gloves can operate RTP with no difficulty.Resistive touch screens work well even when liquids or debris are present on the surface. This makes them especially useful in situations where substances could disrupt the function of other types of touch screens, for example, agricultural equipment, boats and underwater machinery. Due to its mature technology and simple structure, cost of resistive screens is lower.

Supporting of Multiple touches is a clear winner for capacitive touch screens (CTP). Thanks to smartphone and tablet, users are comfortable with using gesture on screen. And capacitive touch screen is what user is familiar with. In more specialized settings, such as multi-player gaming application, capacitiv e touch screens can support more than 10 inputs at a single time. Additionally, CTP needs no calibration and is highly accurate.

Resistive touch display cannot determine the location of a touch if more than one input is present. In terms of visibility, the film substrate commonly used as the top surface in resistive touch screens is less transmissive than glass. This leads to reduced brightness and a certain level of haze compared to touch screens with a top layer of glass. The film layer can also expand or contract based on temperature, which alters the distance between the two layers and affects touch accuracy. Additionally, the film substrates are susceptible to scratches and can start to wear away with repeated use, necessitating occasional recalibration or replacement over time.

Capacitive touch screens depend on variations in an electrical field to operate. While a passive stylus can activate this screen, a non-conductive tool like a pencil can"t. If cost is a top concern for a project, CTP may not align with budget limits. It is a more expensive technology than resistive screens, although it continues to grow more accessible in terms of price as the technology advances and improves.

Selecting the most suitable type of touch screen for your project can improve device functionality and durability, which can mean a significant increase in customer adoption.

This article highlights the unique advantages and drawbacks of common touch screen technology, to help product design engineers make an informed decision.

Resistive touch is a legacy form of touch screen technology that was broadly popular for many years, but has been replaced by capacitive touch for many applications. Currently, resistive touch has a smaller range of common uses, but can still capably address certain needs.

The core elements of a resistive touch screen are two substrate layers, separated by a gap filled with either air or an inert gas. A flexible film-based substrate is always used for the top layer, while the bottom layers substrate can be either film or glass. A conductive material is applied to the inner-facing sides of the substrate layers, across from the air gap.

When a user applies pressure to the top surface, the film indents and causes the conductive material on the top layer to make an electrical contact with the conductive surface of the bottom layer. This activity creates a difference in voltage that the system registers as a touch. The location of this contact is pinpointed on the X and Y axes, and the touch controller then interprets the action. Because physical force is needed for a resistive touch screen to function, it is similar to a mechanical switch.

Resistive touch screens must be calibrated before they are used to ensure accurate and reliable operation. A user must apply pressure to the four corners of the screen, and sometimes on its center, to calibrate the screen with the rest of the system via a lookup database.

Because resistive touch screens interpret physical pressure as a touch, they are effective in a variety of environments using single touch. Any object capable of applying force to the screen can be used with the same result. For example, in applications where end users wear gloves, resistive touch screens offer reliable single-touch functionality.

Since resistive touch screens area actuated via mechanical force, they continue to function as intended even when liquids or debris are present on the surface. This makes them especially useful in situations where substances could disrupt the function of other types of touch screens. For example, on single-touch applications within agricultural equipment, boats and underwater machinery.

Besides the functional advantages of resistive touch screens, price is a common reason why OEMs select this option. In projects where cost is a top concern, companies can use this option to realize savings that may not be possible with alternatives.

The configuration of a resistive touch screen removes the possibility of gestures, such as pinching and zooming, or any actions requiring multi-touch functionality. These screens cannot determine the location of a touch if more than one input is present.

In terms of visibility, the film substrate commonly used as the top surface in resistive touch screens is less transmissive than glass. This leads to reduced brightness and a certain level of haze compared to touch screens with a top layer of glass. The film layer can also expand or contract based on temperature, which alters the distance between the two layers and affects touch accuracy. Additionally, the film substrates are susceptible to scratches and can start to wear away with repeated use, necessitating occasional recalibration or replacement over time.

Capacitive touch screens were invented before resistive touch screens. However, early iterations of this technology were prone to sensing false touches and creating noise that interfered with other nearby electronics. Due to these limitations, resistive touch screens and other options, like infrared touch screens, dominated the industry.

With more development and refinement of controller ICs, projected capacitive (PCAP) touch screens became the preferred touch technology for a majority of applications. For example, this technology is now commonly used on tablets, laptops and smartphones. Though PCAP stands for “projected capacitive (PCAP) touch”, it’s more commonly referred to as “capacitive touch”.

The foundation of PCAP touch screens is an array of conductors that create an electromagnetic field. As a user touches a PCAP screen, the conductive finger or object pulls or adds charge to that field, changing its strength. A touch controller measures the location of this change and then instructs the system to take a certain action, depending on the type of input received.

For a device with PCAP touch technology to acknowledge an input, users simply need to touch the screen. No physical pressure is required, unlike resistive touch screens.

Another key difference from resistive touch technology is that PCAP screens can accommodate a variety of inputs, with different gestures and more contact points instructing the system to take a variety of actions. PCAP touch can support multi-touch functionality, swipes, pinches, and zoom gestures which aren’t possible with resistive touch screens.

The value that comes with recognizing multiple inputs is a clear and positive differentiator for PCAP touch screens. Users can initiate a variety of commands, providing more functionality in devices where this technology is used. Consider how consumers now expect smartphones, tablets, and interactive laptop screens to support actions requiring two fingers, like pinching and zooming. In more specialized settings, such as multi-player gaming applications, PCAP touch screens can support more than 10 inputs at a single time.

PCAP touch screens do not require initial calibration, offering a simpler experience than resistive touch screens. Additionally, PCAP touch screens are highly accurate even as they support a variety of gestures and subsequent actions by the system.

Since their top layer is usually made of glass, PCAP touch screens offer a high degree of optical transmission and avoid the appearance of haze to users. Additionally, the glass top layerprovides improved durability compared to the film top layer of resistive touch screens – even for the largest sizes of up to 80 inches (and growing).

Operation in environments where a PCAP screen may be exposed to liquids or moisture — including conductive liquids like salt water — is possible through specialized controller algorithms and tuning. PCAP technology has evolved to support medical glove and thick industrial glove operation, as well as passive stylus operation.

PCAP touch screens can be customized with different cover lens materials (soda lime, super glasses, PMMA) based on application specific needs. Cover lenses can be ruggedized with chemical strengthening and substrates that improve impact resistance. This can be especially valuable for public-facing applications, like ATMs, gas pump displays, and industrial applications. Specialized films or coatings – such as AG (anti-glare), AR (anti-reflective), AF (anti-fingerprint) – can be added to the cover lens substrate to improve optical performance.

Unlike resistive touch screens, PCAP touch screens depend on variations in an electrical field to operate. While a passive stylus can activate this screen, a non-conductive tool like a pencil can’t.

If cost is a top concern for a project, PCAP may not align with budget limits. It is a more expensive technology than resistive screens, although it continues to grow more accessible in terms of price as the technology advances and improves.

The below table compares the advantages and disadvantages of projected capacitive touch vs resistive touch screens.CharacteristicsPCAP TouchResistive TouchRequires calibrationNoYes

As a leading manufacturer of touch and display products, New Vision Display can help you determine the specific needs of your project and tune your PCAP touchscreen controllers to meet them. Our PRECI-Touch® products are based primarily on PCAP touch technology and can be customized for a variety of applications using a wide range of materials, stacks, and controllers.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

The Resistive touch panel senses a touch by measuring where contact is made on the glass. It is independent of temperature and humidity and simple to integrate independent of a separate controller chip.

The Transmissive polarizer is best used for displays that run with the backlight on all the time. This polarizer provides the brightest backlight possible. If you have a need for a bright backlight with lower power drain, transmissive is a good choice for this TFT LCD display.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

The Resistive touch panel senses a touch by measuring where contact is made on the glass. It is independent of temperature and humidity and simple to integrate independent of a separate controller chip.

The Transmissive polarizer is best used for displays that run with the backlight on all the time. This polarizer provides the brightest backlight possible. If you have a need for a bright backlight with lower power drain, transmissive is a good choice for this TFT LCD display.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

Capacitive touch screen technologyUSES the human body’s current induction to work. The capacitive touch screen is a four-layer composite glass screen. The inner surface of the glass screen and the interlayer are coated with one layer of ITO respectively. The outermost layer is a thin layer of silica soil glass protective layer. When the finger touches the metal layer, the user and the touch screen surface form a coupling capacitor due to the electric field in the human body.

The capacitor is a direct conductor to the high-frequency current, so the finger sucks a small current away from the contact point. The current flows from the electrodes at the four corners of the touch screen respectively, and the current flowing through the four electrodes is proportional to the distance from the fingers to the four corners. The controller calculates the precise proportion of the four currents to get the position of the touchpoint.

In order to realize multi-touch on a capacitive screen, it is necessary to add electrodes of mutual capacitance. In a simple words, it is to divide the screen into blocks and set a group of mutual capacitance modules in each area to work independently. Therefore, the capacitive screen can independently detect the touch situation of each area and simply realize multi-touch after processing.

Capacity Touch Panel USES the current induction of the human body to work. The capacitive screen is a four-layer composite glass screen. The inner surface of the glass screen and the interlayer are coated with ITO (indium sikgold oxide nano). The outermost layer is a protective layer of silica glass with a thickness of 0.0015mm.

Whena user capacitive touch screen, the electric field due to the human body, your fingers and face form a coupling capacitance, because the working plane to have a high-frequency signal, so the fingers on a very small current, respectively from the current screen in the four corners of the electrode, and theoretically through the four electrodes with the finger to the four corners of the current is proportional to the distance, the controller through the precise calculation of the four current ratio, it is concluded that location. It can achieve 99% accuracy, with a response speed of less than 3ms.

Projective capacitive touch screens etch different ITO conductive circuit modules on two layers of ITO conductive glass coatings. The etched patterns on the two modules are perpendicular to each other and can be thought of as sliders with continuous changes in X and Y directions. As the X and Y architectures are on different surfaces, their intersection forms a capacitor node. One slider can be used as the drive wire and the other as the detection wire. When a current passes through one of the wires in the drive wire, if there is a signal of a change in the capacitance outside, it will cause a change in the capacitance node on the other layer of wire. The change in capacitance can be detected by measuring the electrical circuit connected to it, and then converted to A digital signal by A/D controller, which can be processed by A computer to obtain the (X, Y) axis position, so as to achieve the positioning target.

During operation, the controller successively supplies power to the driving wire, thus forming a specific electric field between each node and the wire. Then scan the sensor line one by one to measure the capacitance change between the electrodes so as to achieve multi-point positioning. When the finger or touch medium is close, the controller can quickly detect the change of capacitance between the touch node and the wire, and then confirm the position of the touch.

One axis is driven by a set of AC signals, and the response across the touch screen is measured by electrodes on the other axis. Users call this’ transversal ‘sensing or projective sensing. The sensor is plated with the ITO pattern of the X and Y-axis. When the finger touches the touch screen surface, the capacitance under the touchpoint increases according to the distance of the touchpoint. The continuous scanning on the sensor detects the change of capacitance value, and the control chip calculates the touchpoint and returns it to the processor.

Projective capacitive touch screens are multi-finger touch. These two capacitive touch screens have the advantages of high light transmittance, fast response speed, and long life, etc. The disadvantages are: with the change of temperature and humidity, the capacitance value will change, resulting in poor work stability, often drift phenomenon, need to frequently proofread the screen, and can not wear ordinary gloves for touch positioning.

The projected capacitive touch screen can be divided into the capacitance and mutual capacitance screen two types, one of the more common mutual capacitance screen as an example, the internal electrode and receiving electrode by the driver, drive electrode signal low voltage high frequency projected onto the receiving electrode form stable current, when human exposure to the capacitance screen, earth due to the human body, fingers and capacitance screen to form an equivalent capacitance, and the high-frequency signal by the equivalent capacitance into the ground, in this way, the receiver receives charge is reduced, when fingers near the transmitter, electric charge, the more significant, according to the receiving end receives the current strength of to determine the touchpoint.

Arrays of transverse and longitudinal electrodes are made from ITO on the surface of the glass. These transverse and longitudinal electrodes form capacitors with the ground respectively. This capacitor is commonly referred to as self-capacitance, that is, the capacitance of the electrode to the ground. When the finger touches the capacitive screen, the capacitance of the finger will be superimposed on the capacitance of the screen, thus increasing the capacitance of the screen.

During touch detection, the horizontal and longitudinal electrode arrays are respectively detected from the capacitive screen. According to the changes of capacitance before and aftertouch, the horizontal coordinates and longitudinal coordinates are determined respectively, and then the touch coordinates of the plane are combined. The scanning method of self-capacitance is equivalent to projecting the touchpoints on the touch screen to the X-axis and Y-axis directions respectively, and then calculating the coordinates in the X-axis and Y-axis directions respectively, and finally combining them into the coordinates of the touchpoints.

If it is a single touch, the projection in the X and Y direction is unique, and the combined coordinates are unique. If there are two touches on the touch screen and the two touches are not in the same X direction or the same Y direction, then there are two projections in the X and Y direction respectively, and the combined coordinates are 4.Apparently, only two of the coordinates are real, and the other two are known as ghost points. Therefore, self – the capacitive screen can not achieve true multi-touch.

The mutual capacitor screen also USES ITO to make the transverse electrode and the longitudinal electrode on the glass surface. The difference between it and the self-capacitor screen is that the place where the two groups of electrodes cross will form a capacitor, that is, the two groups of electrodes form the electrodes of the capacitor respectively. When a finger touches a capacitive screen, the coupling between two electrodes near the touchpoint is affected, thus changing the capacitance between the two electrodes.

When the mutual capacitance is detected, the transverse electrode will send out excitation signals successively, and all the longitudinal electrodes will receive signals at the same time. In this way, the capacitance value of all the intersection points of the transverse and longitudinal electrodes can be obtained, that is, the capacitance value of the entire two-dimensional surface of the touch screen. The coordinates of each touchpoint can be calculated according to the two-dimensional capacitance variation data of the touch screen. Therefore, even if there are multiple touchpoints on the screen, the actual coordinates of each touchpoint can be calculated.

The advantage of the mutual capacitive screen is less wiring, and can simultaneously identify and distinguish the difference between multiple contacts since the capacitive screen can also sense multiple contacts, but because the signal itself is fuzzy, so can’t distinguish. In addition, the induction scheme of the mutual capacitive screen has the advantages of fast speed and low power consumption, because it can measure all the nodes in a driveline at the same time, thus reducing the number of acquisition cycles by 50%. The dual-electrode structure has the function of self-shielding external noise and can improve signal stability at a certain power level.

In any case, the touch position is determined by measuring the distribution of signal changes between the X and Y electrodes, and a mathematical algorithm is then used to process the changed signal levels to determine the XY coordinates of the touchpoint.

• Capacitive schemes last longer because the components in the capacitive touch screen do not need to move at all. In a resistive touch screen, the top layer of the ITO film needs to be thin enough to be elastic so that it bends down and touches the bottom layer of the ITO film.

• The choice of capacitor or resistor depends largely on the object touching the screen. If it is a finger touch, the capacitive touch screen is a better choice. If a stylus is needed, whether plastic or metal, a resistive touch screen will do. A capacitive touch screen can also use a stylus but requires a special stylus to work with it.

• Surface capacitances can be used for large touch screens and are relatively low, but they currently do not support gesture recognition: inductive capacitances are mainly used for small and medium-sized touch screens and can support gesture recognition.

• Capacitive technology is wear-resistant, has a long service life, and has low maintenance costs when users use it, so the overall operating costs of manufacturers can be further reduced.

• Capacitive touch screens are designed to support multi-touch technology and are less responsive and less prone to wear and tear than resistive touch screens.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

Analogue Resistive Touch Screens from CDS are of the highest quality and reliability which can be used in many industrial and commercial applications including with thick gloves. Resistive touch for most applications.

Analogue Resistive Touch Screens are a very simple touch sensor that uses dual layers of a flexible, conductive material that deforms under a touch and the 2 layers make contact, the position of this contact is determined by the change in resistance of the circuits. For use with LCD panels. The touchscreen uses a series of electrodes along each edge, and the touch controller alternates between sensing x and y axis readings using electrodes on opposite sides to carry a voltage difference and one of the adjacent electrodes to sense the touch. This construction method uses a deformable material to function, so eventually the touch sensor will wear out over use and require recalibration over time to stay accurate but it is also cheap, reliable and accurate when calibrated correctly. It can also be used with a touch stylus or a gloved hand.

Although resistive is often looked at as the low end touch technology as it was one of the first it offers some benefits the others cannot such as 8 wire resistive touchscreen and 8 wire touch screens the resistive touchscreen technology when complimented by excellent touch panel suppliers and touch screen companies, mean these touch screen manufacturers can add real value to your products and operations. Whether is be 4 wire , 5 wire or 8 wire touch screens we have a solution for you for your LCD panels.

Touch screens are found everywhere from our smartphones to self-serve kiosks at the airport. Given their many uses, it should come as no surprise that there are several touch monitor types. Each has its advantages and disadvantages and is suited to specific tasks.

It’s quite possible that you’re not clear on exactly what a touch panel is, what the touch panel types are, or how they’re applied in your daily life, beyond that of your smartphone. For that and more, we’re here to help.

Quite simply, touch panels, which are also known as touchscreens or touch monitors, are tools that allow people to operate computers through direct touch. More specifically, via the use of internal sensors, a user’s touch is detected, then translated, into an instructional command that parlays into visible function.

Delving deeper into the technical side of things, touch panels are not as cut-and-dry as they may seem. In fact, the way they sense and react to touch can widely differ based on their inherent designs. As such, there are 4 touch panel types in regular use – Resistive, Optical Imaging, Projected Capacitive, and Infrared. Below, we’ll dig into their specifics, which include their advantages, disadvantages, and real-life product applications.

Resistive touch panels are cost-effective variants that detect commands by way of pressure placed on the screen. This pressure sensitivity is generally limited to single-point touch, with a 20-inch maximum screen, which is fine for many usage cases. These range from styluses to fingertips. As a result, if used correctly, resistive touch panels will remain functional even if a water drop has landed on the screen.

As a result of this versatility, however, many will find that resistive touch panels are less durable than their competitors. Moreover, with its reliance on single-point touch, this touch panel type is not actually capable of multi-touch functionality. Regardless, resistive touch panels are often found in grocery stores, where stylus-based signatures are typically required after credit card purchases.

Some like it hot and some don’t. Infrared touch panels definitely fall into the latter category. By setting up a grid of infrared beams across the panel, which may be up to 150-inches, touch is detected by way of this panel’s disruption.

Although infrared touch panels are durable and support multi-touch functionality, it does possess one potential drawback. Depending on where you sit, literally.

Light, and the disruption thereof, is not just a great way to produce a shadow, but also to design a touch panel type. To take advantage of this principle, optical imaging touch panels are designed to sense touch through infrared cameras and the disruption of light strips. This can be achieved through any input you want, across its 100-inch maximum size, from gloves to bare hands, and beyond.

All in all, optical imaging touch panels are just about the most versatile option the touch-based world can offer. From durability to multi-touch, and universal input prospects, the possibilities may truly be endless. Although its only disadvantage may be its non-compact design, common applications of optical imaging touch panels include certain varieties of interactive whiteboards.

By way of their electrical-based touch detection, Projected Capacitive touch panels are known for their high precision and high-speed response times. What’s more is that they possess multi-touch functionality and can be used within small, compact, yet expensive, devices. Due to their underlying technology, it has proven challenging to scale up to larger sizes. Figured it out yet?

Assuming you haven’t, or would like to enjoy the gratified feeling associated with being right, allow us to reveal where you interact with projected capacitive touch panels on a daily basis – Smart Phones! What’s more is that they’re not alone, with tablet computers and GPS devices also utilizing projected capacitive touch screens.

It would be a mistake to assume that the applications of all these touch panel types are limited to that of consumer-level devices, or even those that have been previously mentioned. Really, these touch panel types can be found throughout everyday life and in a variety of industries.

What’s more is that in many of these industries, these touch panel types are used less to market products to consumers, and more to sell solutions to businesses. Whether it be in regards to finance, manufacturing, retail, medicine, or education, there is always a need for touch-based solutions. In conjunction with the so-called ‘Internet-of-things’, these touch-based solutions play a key role in practices related to industry 4.0.

In practice, these solutions largely offer a form of personnel management. In hospitals, stores, or banks, for instance, these touch panel types can be used to answer basic questions, provide product information, or offer directions, based on the user’s needs. When it comes to manufacturing, on the other hand, these solutions enable employee management in the possible form of workplace allocation or attendance tracking.

At the end of the day, touch panels are here to stay. In the four decades since their inception, the level of adoption this technology has experienced is remarkable. They transform how we teach in classrooms and collaborate with colleagues.

Ais not a real display screen, but a component that is mounted above the LCD screen. The capacitive touch panel is a transparent tempered glass in appearance.

A capacitive touch panel is a touch panel that is transparent like glass and does not display anything or emit light.Thecapacitive touch panelfunction is to sense the user"s touch operation.

The TFT screen is the real display screen. TFT is the most widely used liquid crystal display material.The TFT LCD screen is a thin film transistor liquid crystal screen, which is a display screen, and has no function of sensing touch, and can only be used to display an image.

In the current display screen, two types of screens, a capacitive touch panel, and a, are usually used at the same time, and the two are vertically overlapped, and the TFT LCD panel is responsible for displaying images, and the capacitive touch screen is responsible for sensing user operations. It is the origin of "internal screen" and "outer screen".

-Select-AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijan RepublicBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia and HerzegovinaBotswanaBrazilBritish Virgin IslandsBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape Verde IslandsCayman IslandsCentral African RepublicChadChileChinaColombiaComorosCook IslandsCosta RicaCyprusCzech RepublicCôte d"Ivoire (Ivory Coast)Democratic Republic of the CongoDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Islas Malvinas)FijiFinlandFranceFrench GuianaFrench PolynesiaGabon RepublicGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHondurasHong KongHungaryIcelandIndiaIndonesiaIraqIrelandIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueNamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorwayOmanPakistanPalauPanamaPapua New GuineaParaguayPeruPhilippinesPolandPortugalPuerto RicoQatarRepublic of CroatiaRepublic of the CongoReunionRomaniaRwandaSaint HelenaSaint Kitts-NevisSaint LuciaSaint Pierre and MiquelonSaint Vincent and the GrenadinesSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth KoreaSpainSri LankaSurinameSwazilandSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTogoTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican City StateVenezuelaVietnamVirgin Islands (U.S.)Wallis and FutunaWestern SaharaWestern SamoaYemenZambiaZimbabwe

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey