do lcd displays have firnware in stock

To check the firmware version of your Studio Display, choose Apple menu > About This Mac, click System Report, then click Graphics/Displays. In the Studio Display section, the firmware version is listed next to Display Firmware Version.

From the Apple menu in the corner of your screen, do one of the following depending on the version of macOS you have:On macOS Ventura or later, choose System Settings, click General in the sidebar, then click Software Update.

LCD Firmware is the software code that allows the LCD’s controller to communicate with the customer’s processor. When a customer first designs their end product, they write the firmware for a specific controller.

The challenge comes when the controller on a LCD module is discontinued and replaced with an equivalent controller. The LCD firmware that was written for the original controller may or may not be 100% compatible with the new controller. The majority of the time a customer can swap out the old controller for the new without any issues.

If you do need to modify the LCD firmware for your Character, and Graphic displays, you might want to keep in mind that current product out in the field which contain LCD displays will still need the old controller. When you find out that a controller is being discontinued and the suggested replacement "equivalent" controller is not a drop-in equivalent, and the firmware needs to be modified; it might be wise to order extra displays with the old controller to have in stock to serve as replacements for the products you have out in the field.

Segment displays do not contain a controller and therefore do not require any firmware. This includes 7(seven) segment LCD display, 14(fourteen) segment LCD display, and 16(sixteen) segment LCD displays.

Character LCD Modules do contain controllers. This includes 8x1 LCD displays, 8x2 LCD displays, 16x1 LCD displays, 16x2 LCD displays, 16x4 LCD displays, 20x2 LCD displays, 20x4 LCD displays, 24x2 LCD displays, 40x1 LCD displays, 40x2 LCD displays, and 40x4 LCD displays.

Are you in need of help because of a discontinued LCD controller? Contact a technical support engineer for you design needs or call us at 480-503-4295. We"re ready to help.

When using a Desktop computer, you can have another monitor with video that is only connected to view the download instructions. DO NOT have any USB cables connected to this monitor.

This package contains the LCD Panel Firmware Update Utility. The LCD firmware accepts data and commands from either a serial or a parallel interface and enables the display to generate text or an image.

This file contains a compressed (or zipped) set of files. Download the file to a folder on your hard drive, and then run (double-click) it to unzip the set of files. Follow the instructions to complete the installation.

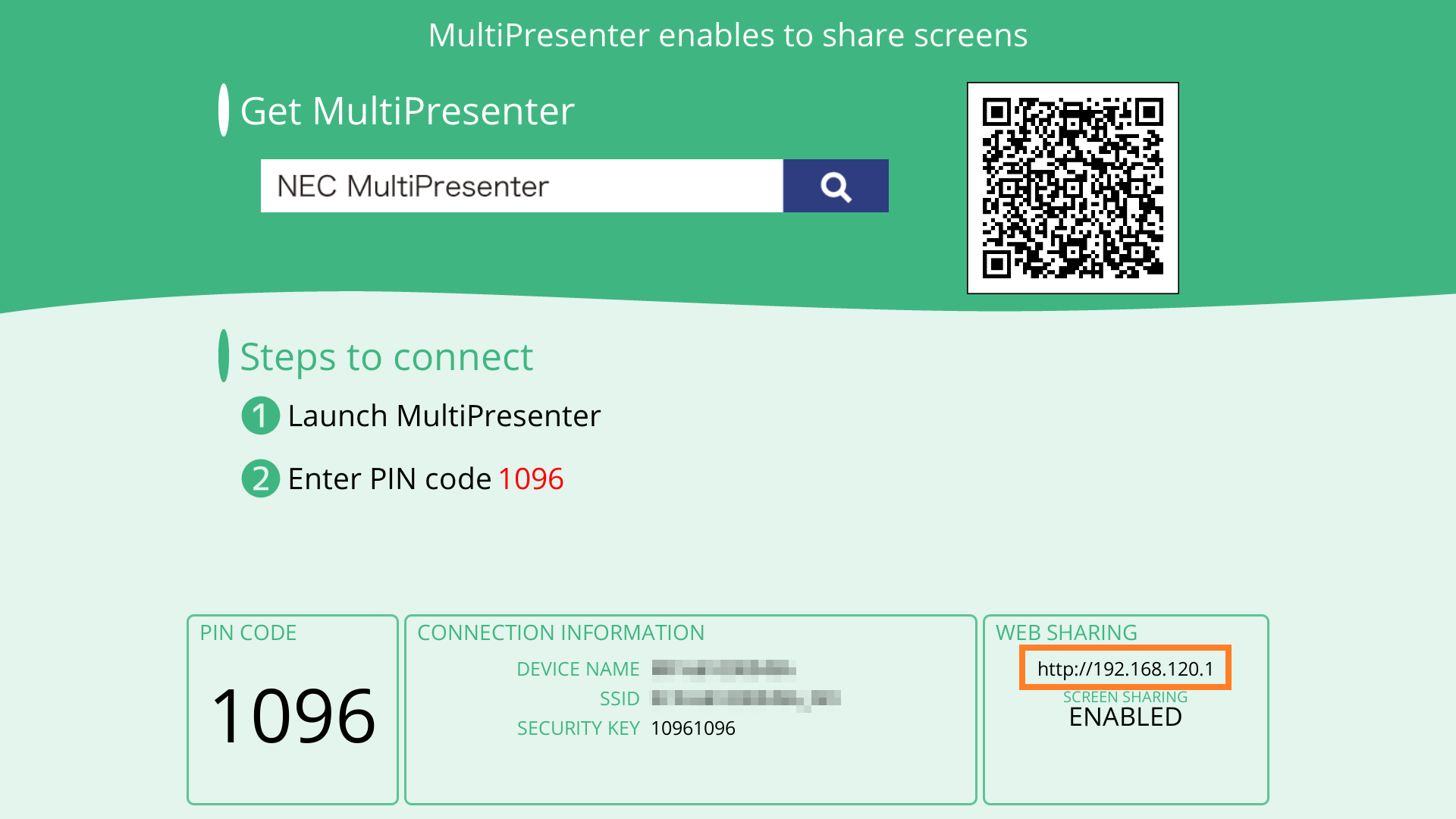

The NEC Display Firmware Update Tool is a utility to assist with updating the firmware in large-screen NEC LCD displays and some models of desktop NEC LCD displays.

Almost every device you can buy nowadays has upgradable firmware. New firmware versions can fix bugs, patch security vulnerability, improve features, or add features. As computer monitors get more complex and feature-packed, it becomes more important to use the latest firmware. Samsung doesn’t provide instructions on performing a firmware update in user guides on on download pages. This guide explains the exact steps for updating the firmware on Samsung monitor, and will hopefully save you a lot of searching.

To download the latest firmware for your monitor go to the Samsung support website, click search for your model number, and enter your model number. Click on manuals and software. Under firmware, click download.

The flash drive needs to be formatted with a FAT32 filesystem. The easiest way to do this is to use the free an open source drive flashing tool, Rufus. Rufus is a simple GUI utility for flashing drives

Plug the flash drive into the USB Type A port labeled Service. Same Samsung monitors have two USB Type A ports, but only one of those ports is a service port that can be used to upgrade firmware. Some monitors only have a service port. Others have multiple USB ports, with only one port as a service port.

Now that we know the mainboard version, let"s head over to the creality3dofficial.com website. Head over to the support section and select "Firmware Download".

Here you see, there is different firmware versions for the different mainboards. In my case, I would have to select one of the 4.2.2 firmware builds and if you have the 4.2.7, you would select one of these other builds.

The selection depends whether you have a BLTouch in combination with that mainboard or not. We"re going to talk about the BLTouch installation in another video.

Now, we download the right firmware and what we get from the Creality website is a RAR file, which is similar to a zip file but windows cannot handle it unless you install something like winrar or 7-zip, which is what I"m using.

Now one little remark that I need to make here. If you already flashed this particular firmware to the printer and for any reason you like to re-flash the same bin file again to the printer, you need to rename it before you do this.

So because, I already have flashed this firmware version but I still want to re-flash it to show you the process, I am renaming it to some other name, ending with bin and I should be fine.

If you run into the issue of a black screen after doing this or the printer starts beeping continously, you somehow missed one of the steps or mistakenly tried to flash a wrong version of the firmware to your mainboard.

I received this same error - had to update DWIN_SET first. I can confirm the 9/16 DWIN_SET works fine with the 9/17 firmware build for 4.2.2 board (except the display is dimmer than usual). I only had a 32GB sdcard lying around, and initially DWIN_SET failed to properly flash (screen flashed blue for less than a second then orange - when it’s successful it will stay blue for a few seconds). I worked around this by destroying the partition map of the sdcard and creating a new msdos partition map (not gpt - dont know if that makes a difference but I got it working with msdos), with a single 4GB partition formatted as FAT32.

The length of the 4-way cable is not critical, however the resistance per conductor should not exceed 0.1 ohm. The SD card socket on the TFT panel will not be functional. The cables supplied by Escher3D and Duet3D are about 800mm long. There have been reports of cables up to 1500mm long being successfully used. Take care to route the cable away from motor and endstop cables. Twisting the cables may help prevent cross talk interference.

A PanelDue can be connected to connector IO_0 using a 4-core cable wired like the one shown in the images below. The 4-wire cable supplied with the PanelDue has a 4-way Molex KK connecter on each end, but is supplied with a 5-way Molex KK connector for use with Duet 3. You will need to rewire one end. The 4-wire cable does not allow access to the SD card socket on the PanelDue.

In order to use the SD card slot on the PanelDue, you must use the ribbon cable option. If you do not wish to use the SD card slot, it"s recommended to use the 4-wire cable option described in Option 1.

Although the Duet 3 MB6HC does not have a connector for the PanelDue ribbon cable, if access to the SD card on PanelDue is required then this is possible using a special wiring arrangement. You must use RepRapFirmware 3.4 or later, and you must enable the external SD card using this command:

Note: if you are using an older version of either PanelDue 7i or PanelDue 5i, or a non-integrated version of PanelDue, then those do not support the CD signal. In that case you should omit the second port, for example:

If you have no temperature daughter boards installed, then one way to cable this is to use both the ribbon cable and the 4-way cable, and remove conductors 1, 9 and 10 of the ribbon cable as illustrated here. Caution! Using a ribbon cable with all conductors present will feed +5V into the microcontroller!

The card detect signal (CD) is used to tell the Duet whether a card is inserted or not. Non-integrated versions of PanelDue (V2, V3) and older versions of PanelDue 5i and 7i (v1.0 of the 5i and v2.0 of the 7i) do not provide a card detect signal.

Duet 2 boards do not support the card detect signal on the external SD card, so can never tell whether a card is inserted or not except by trying to read it, and can"t detect a card being removed. No modifications are required connected older or newer PanelDue, or other external SD card adapters, to Duet 2 boards.

Duet 3 boards do support the card detect signal. Newer versions of the PanelDue 5i and 7i (v1.01 and later of the 5i and v2.01 and later of the 7i) provide this signal.

PanelDue will display the bed heater H0 first (even if it is disabled), then iterate the defined tools. It then iterates the defined heaters below this. It expects a 1:1 relationship between tools and heaters. This means:if you have a machine that uses one heater for more than one tool (eg a 2-into-1, filament-swapping hot end), it will display more tools than heaters. Tools may not line up with their respective heaters.

if you have more heaters defined than tools (eg extra bed heater/chamber heater, or a tool that uses multiple heaters), you"ll have more heaters than tools.

The PanelDue also iterates the heaters from the first defined heater to the last, including all heaters in between, whether defined or not. This means if you have a heater defined on H0 (bed) and one on H5 (Duex output), it will show all the ones in between, eg H0, H1, H2, H3, H4 and H5. For an example, see |https://forum.duet3d.com/post/136207|this forum post|. Ideally, configure heaters on consecutive heater connections.

You can use the external SD card socket on the LCD panel if you have used a ribbon cable as described above. Please note, the SPI interface provided by this SD card socket is much slower than the on-board SD card socket built into the Duet. Therefore we recommend that you do not upload files to this card over the network. Use the external SD card socket only if you want to write files to the SD card on a PC and then move the SD card to your printer.

Caution! Do not use an SD extender cable from the SD socket on the Panel Due. Some types of SD card extender cable have been found to damage the SD card socket. Damage to the SD card socket from using an extender cable is not covered by the warranty.

These displays are typically clones of the RepRapDiscount Full Graphic Smart Controller and look like this. The better ones include a contrast adjustment potentiometer. Unfortunately some manufacturers of other displays using the same controller chip reverse the pinouts on the two ribbon cable connectors. The ST7920 controller chip is invariably powered from 5V, which means that the display need 5V input signal levels.

An example of this is the Fysetc Mini 12864 Panel. The controller chip is run from 3.3V, so these displays normally include level shifters which tolerate a wide range of input voltages.

The contrast setting for these displays is done in software. the M918 command supports a C parameter for this purpose. It is also necessary to set a resistor ratio parameter in software, which can be done using the M918 R parameter.

We do not recommend connecting a 12864 display with ST7920 controller to the Duet 3 Mini because the 3.3V signals provided by the Duet 3 Mini do not meet the specifications of the ST7920 controller chip when it is powered from 5V. If you do wish to try it, you will most likely have to reduce the clock frequency (M918 F parameter) to get it working at all, and it may not work reliably. Also, note that when configured for 12864 display with ST7920 controller, RRF provides the CS signal on the pin normally uses for A0 because that more closely matched the pinout of typical 12864/ST7920 displays.

RepRapFirmware 3.2 and later also support displays using the ST7567 controller. For these displays, use the standard cable EXCEPT the following two wires need to be connected to the EXPANSION header pins:

We do not recommend connecting a 12864 display with ST7920 controller because the 3.3V signals provided by the Duet 2 WiFi/Ethernet do not meet the specifications of the ST7920 controller chip when it is powered from 5V. If you do wish to try it, you will most likely have to reduce the clock frequency (M918 F parameter) to get it working at all, and it may not work reliably.

The most recent version of the standard bigtreetech TFT firmware has built in support for RepRapFirmware. The pre-built images have this enabled by default.

This product supports Windows 10/8.1/8/7 operation systems. For the Windows 10/8.1/8 OS, the touch screen supports multi-touch up to 10 points. For some Window 7 OS, the touch screen supports single touch only.

Turn on the "backlight" switch then connect the LCD to your PC (USB Port of LCD -> USB Port of PC; HDMI Port of LCD -> HDMI Port of PC. Please first connect the USB Ports then connect the HDMI Port). A new touch drive will be recognized by Windows and you can use the LCD as a human interface device. When multiple displays are detected by your PC, the LCD can only be used to control the cursor on main display. So it is proposed to set the LCD as the main display.

For the Windows OS on PC, the resolution of the LCD is automatically identified. Hence, you do not need to make the relative settings. When working with Raspberry Pi, you should set the resolution of the LCD by yourself, or else the LCD screen will not work. For more detail information, please read the following section.

Turn on the "backlight" switch then connect the LCD to your Pi (HDMI Port of LCD -> HDMI Port of Pi; USB Port of LCD -> USB Port of Pi; 5V~2A power supply). Download the Raspbian image from Raspberry Pi web site. Write the image to a TF card and append the following lines to the config.txt file which is located in the root of your TF card:

If this LCD module is used for display only, you can program the latest Angstrom image file to the board directly without any change. The BeagleBone will read the display parameters of the 7 inch HDMI displayer and set the resolution to 800*480 automatically.

Connect the USB Touch interface on the LCD to the USB interface on the BeagleBone board with a type-A-to-micro USB cable. (BeagleBone has two USB interfaces, one for host and the other for client. In here, you should connect the LCD module to the USB host interface).

Before powering up the Banana Pi, you should connect it to a LCD displayer properly, since the Banana Pi may read the resolution parameters of the LCD displayer on startup. And the connection should be remained till the Banana Pi enters the desktop. In this case, even if you disconnect the LCD displayer and reconnect it again to the Banana Pi, the LCD can still work properly.

I had a similar issue when I last updated my Marlin firmware after I installed my Swiss Micro direct drive (It needs some X and Y Presets changed because the dimensions are a bit different), After F*ing around for hours I finally installed the latest and greates software with all the modifications I have (Bigtreetech SKR mini, BL-Touch, Direct Drive, full metal Hot end (Higher temps possible) ) Everything worked fine and even my screen was normal until I needed to change the filament on my stock display, the whole menu item was just friggin gone, after some searching they told me the stock screen was no longer supported in the SKR marlin software, (Everything worked except filament change) I could spend some time reprogramming it in there OR spend 35€ on a BigTreeTech TFT35-E3 which was certainly supported. So I chose the latter (Nice marketing scheme BTT), but hck now I have color touch etc except.....Regular filament change gives me an error of unknown command, up until now I have been too lazy to put the right commands in and solve it by going to movement and unload and load there (Somehow the commands are correct there like WTF), I have spoken to BTT since and they did send me the latest firmware but then I would have to change Evry other MOD aswell, I fing hate doing that. But hey

Or maybe just look for the correct Marlin for your device, there is like 200 versions out there, but only one is fitted for the Ender 3 Pro, you should get them all when you download it, but when you choose to reprogram you need to pick the correct one

To check which firmware version you already have on your printer, power it up and go to LCD menu -> Support. Scroll down and you will see the firmware version. The procedure for installing an older version of the firmware (downgrading) is exactly the same.

PrusaSlicer and the printer"s driver must be installed. If you do not have this installed, it is found in the Drivers and Apps package available where you download the latest firmware.

Enter our our downloads section and download the firmware (green square). To find the correct firmware, see the name and picture of the printers/upgrades and compare it to your machine. Be aware that Original Prusa MK3 and MK3S do not use the same firmware file. However, MK3S and MK3S+ use the same firmware.

Make sure the Serial Port field (red square right picture) displays your printer"s name (Original Prusa i3 MK3) and has a COM port assigned (ex. COM4). Click Flash! and let the procedure complete. Progress is indicated on both the Firmware flasher and the printer"s display.

Since Ender 3 V2 & Ender 3 S1 are using the same knob LCD screen, they have slight different pin out compared with the LCD12864 or BTT TFT Screen. SKR Mini E3 V2/V3 are viable drop-in replacements for Creality 4.2.X boards as they are equip with TMC2209 in UART, Linear Advance and many more extra ports & features. Making it the best alternative to buying a new board from Creality.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey