tempered glass for tft display manufacturer

Our products are broadly identified and trustworthy by people and may meet continually modifying financial and social requires of Front Cover Glass for TFT Display, Borosilicate Glass Tubes, Transparent Stage, Tempered Glass Light Switch Plates Front End Cover,Hotel Light Touch Switch. We have four leading products. Our products are best sold not only in the Chinese market, but also welcomed in the international market. The product will supply to all over the world, such as Europe, America, Australia,Roman, Ghana,Casablanca, Russia.Furthermore, all of our items are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our goods, please don"t hesitate to contact us. We will do our best to meet your needs.

Welcome at Riverdi University. In this lecture we’ll talk about different kinds of glass in TFT LCD displays and surfaces that we use to protect displays, or we can use to protect with the glass the entire devices

We will talk about different types of glass in TFT LCD displays, then the surface treatments, what we do to achieve different parameters of glass surfaces, about the hardness – important when we want to protect something, then about painting the glass, how we do it and what we can achieve, IK rate, how much mechanical impact we can place on the glass, and will it withstand this still and at the end about laminated glass, why we laminate glass and what we can achieve by doing that.

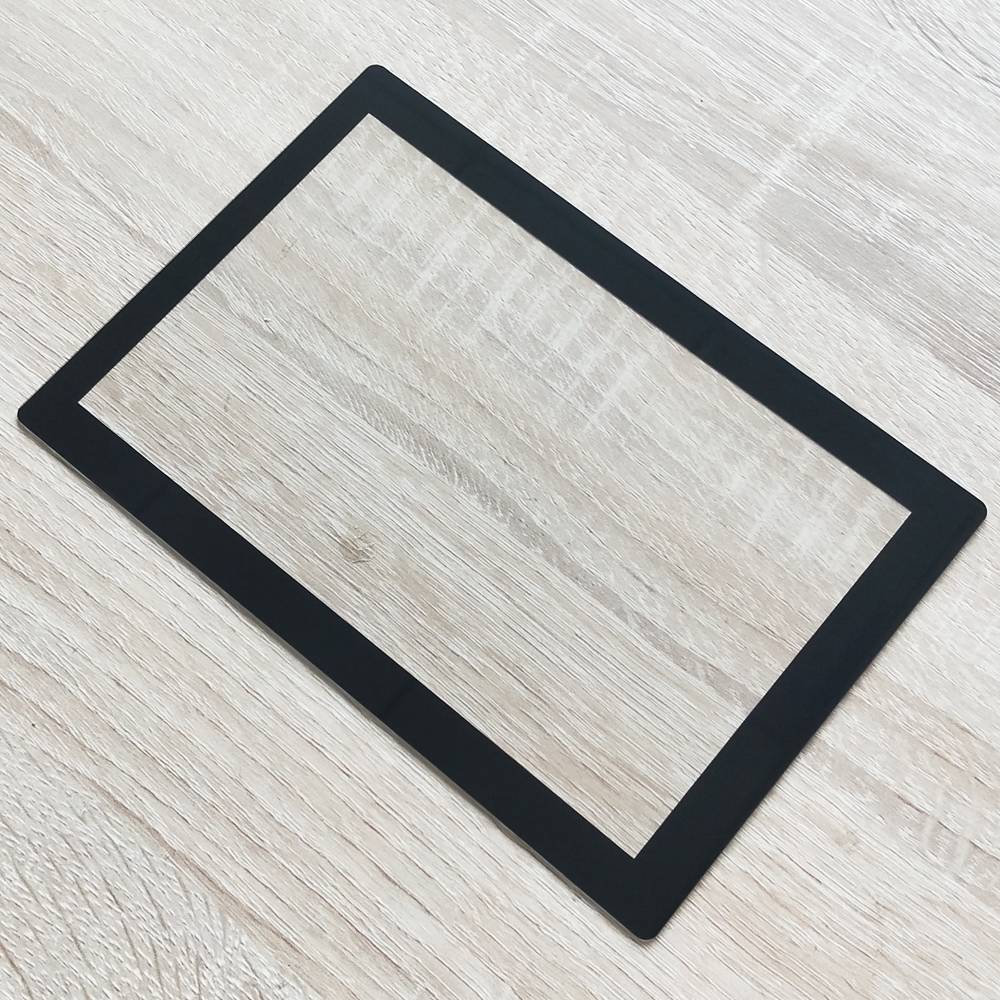

The most important thing with the glass in TFT LCD displays is to protect the display, but not only. As you can see on the pictures above, glass is an element of the design of the devices. It makes devices look better and can be designed in a way that protects not only the display, but the entire surface of a device, like for example for the coffee machine on the picture above, where we have a display with some additional graphic that covers the whole front of the device. Glass is one of the best materials that we use in electronics to protect screens, because it is very hard and it is hard to scratch. It is mechanically strong, cheap, and exceptionally good in optics. For glass, the transparency rate is typically more than 90% or even 95% percent. It is widely available, we know a lot of techniques how to manufacture it and how to prepare it for some special advanced designs as we can change the shape of glass quite easily nowadays.

Now we will talk about types of glass that we use to protect screens and devices. Mainly we use two types of glass in TFT LCD displays, one is chemically strengthened glass, that we call CS type glass, the other is thermally tempered glass, hardened glass where we use hot temperature to make it stronger. For our standard products we typically use on the touch screens chemically strengthened glass. Our standard thickness is 1.1-millimeter thickness. This kind of glass is pretty strong, comparing to the regular glass. Chemical strengthening means that we treat the surface with ions, usually silver ions. We increase the strength of the surface of the glass because glass usually breaks when the surface breaks. We do not change the glass internally with chemical strengthening, we just change the surface hardness, and it is enough to make the glass much stronger.

As you can see in the table above, with chemical strengthening we can make glass even 6 or 8 times mechanically stronger than the regular one. This is a very long process; it can take several hours, and we need hot temperature, 400 or more degrees. Thermally tempered glass is a separate way of strengthening glass. We use hot temperature and very fast cooling to make the glass stronger. We need a higher temperature, 700 degrees in this process, but it is much faster, it takes just several minutes, and we achieve strong glass, 4 to 5 times stronger than regular float glass. Thermally tempered glass is not as strong as chemically strengthened glass. It is cheaper, but we cannot use it for thin glass. The thinnest glass that we can thermally temper is 3-4 millimeter. If the glass is thinner, with hot temperature it starts floating and the surface will not be flat again. So, if we have a thick glass, it would be cheaper to use the thermally tempered solution. That is why it is more popular. For thinner glass we use chemical strengthening, because we cannot use the thermally tempered solution.

Now we will talk about the other difference between these two methods of strengthening glass. On the left side of the picture above, you can see chemically strengthened glass broken, and on the right side there is thermally tempered glass broken. Chemically strengthened glass breaks like regular glass because we do not change the internal part of the glass. We only make the surface stronger, but inside the glass is the same as regular float glass, and it breaks just like it. Thermally tempered glass changes the internal structure of the glass and it breaks into very small pieces. In many cases it is better because it is safer for humans, that is why we normally use thermally tempered glass in cars or in places where broken glass may injure people.

Another property or type of glass that we will talk about is Optiwhite and Float. Float is the most common glass that we use in architecture designs, but also in many touchscreens. The float glass is the most common, most popular and the cheapest, but sometimes we have specific requirements. We sometimes need to have very good color reproduction, especially light colors, white color. Then we use glass called Optiwhite. To achieve that we need to remove the iron from the glass. Float glass has a little bit of iron which makes it green or greenish. If we look straight through the glass, we may not see that but if we look like from an angle, we can see the green color. If we put a white background, we will also see this greenish color a little bit. So, if there are specific requirements, we use Optiwhite, it is especially worth considering if you have a white background. Usually, the Optiwhite is a little bit more expensive, so it is worth checking with the manufacturer of the display what we can use in our case.

Now we know how glass is made, how it is being strengthened, how it breaks and what types of glass, Float and Optiwhite, we have. To continue, we will talk about surface treatments other than strengthening. The other treatments that we use are anti-glare, anti-fingerprint, anti-reflective and anti-bacterial. About anti-reflective treatment we have talked in another video about

On the picture above there are examples of glass. One of them is a little bit blurry, it is anti-glare and the other one is clear – it is anti-reflective. In the past, anti-glare glass was more popular and used in some commercial devices, but later manufacturers have found that devices with anti-glare are being sold less frequently than the glare ones. It is because as humans we think that there is something wrong with a little bit blurry image even if the reflections are lower. When we are in a shop and looking at phones, we do not see the image clearly and we think that there is something wrong and we do not want this device. That is why we do not see any more anti-glare glass in consumer products. Everything is glare in consumer products, it could be anti-reflective or could be only regular without any surface treatment. But in the professional market that we are working on, like medical devices, military devices, we have many projects where we use anti-glare and anti-reflective treatments, both solutions to reduce reflections and increase contrast.

Next, we have anti-fingerprint treatment. All of you have this on your phones and you know how it works. It works better or worse, usually worse, so we can see a lot of fingers especially when anti-fingerprint is connected with anti-reflective treatment. On the anti-glare we do not see the fingerprints because it is blurry. So, both solutions have different advantages and disadvantages. As the last treatment we have antibacterial surfaces. There are even surfaces that are anti-Covid tested. We can use them in some special cases, for medical devices or public purpose devices. This is an important and growing market, because we have more and more screens in public places, for example in McDonald’s or other places with automated cash register machines where we touch the screens and exchange bacteria with other people. In such cases it is really important to have antibacterial surface treatments, that is why we offer it, usually for bigger screens for public solutions.

Now let us talk about hardness of glass in TFT LCD displays. Of course, to talk about hardness we need to measure it. For that we have the Mohs scale where we have 11 different levels of hardness. Like you see on the picture above, the 10th is diamond and the 1st is talk. What we normally use is glass with hardness between 5 and 7. In some cases we also use Gorilla glass with hardness 9. It is used on our phones or tablets. As you can see, we can achieve hardness 7 with chemically strengthened glass and usually 6 with thermally strengthened glass. Gorilla glass is also chemically strengthened glass, patented by the Corning company and it is the strongest that we can achieve in the cover glass to protect the screen.

This scale is about surface hardness – how hard is it to scratch the surface. As you know, even glass with hardness 9 can be scratched, everybody has some scratches on their phone because this hard layer is very thin – 10 micrometers only. If we put enough force and break this barrier, then we have soft glass with hardness 6 or even lower, that is why we have the scratches.

A couple more words about Gorilla glass. Now there is the sixth generation of Gorilla Glass on the market. The goal for Corning company and Gorilla Glass is to make the glass as strong and as light as possible, because most of the cases are handheld devices, where we want the glass to be light, that is why we want to make it very thin. We have also other companies that are making equivalents of Gorilla Glass, like Dragontrail from AGC or Xensation from Shott. They are not so popular but in many mobile phones or tablets on the market you can find these types of glass.

Now let us talk about the painting. We know the types of glass that we use in TFT LCD displays, we know how to make the glass stronger, we know the surface treatments, how to make the glass less reflective or anti-fingerprint or antibacterial, but it is not enough because glass will only be transparent. If we want to cover it, we need to paint it. Typically, we paint glass with the technique called Screen Printing. It is the most popular, cheapest and fastest technique.

When we do the Screen Printing, we need a screen for each color, so to minimize cost, we try to reduce the number of colors to 2–4, like the background and the colored logo. Each color is a different process, we need to wait until the previous painting dries and then we need to put another screen and print another color. More colors mean a longer process and of course a higher cost. Of course, we can change the shape of the glass, we can make rounded corners or custom design of the glass, but it is expensive because first it is just the rectangular piece, then you need to go to the CNC machine to make the proper shape of the glass.

The other printing technique we use nowadays is Jet Printing. It is like a regular printer that you use in your office. You can print every color, even paintings. This process is long, and it is expensive, so it is reserved for special applications, but we can do it if it is necessary.

Now we will talk about mechanical impact protection. It is different than the surface hardness we talked about before. On the picture above, we have the test and scale to measure the mechanical strength of glass, that means how much energy we can put on the glass before it breaks. It is measured in IK rate. IK rate is a scale where we have different levels and different energy that will boost. For example, if we want to test IK 9, we need to take 5-kilogram mass from 200-millimeter height. The mass is kept above the tested glass using an electromagnet, then we just drop it, and we see if it breaks or not. If not, of course the test is passed.

You have app. 15% of the article left. That content is exclusive for our Riverdi University members only. Please fill out the Riverdi University Membership form below and join our community!

If the glass has not passed the test, we can try to change the glass type from thermally tempered to chemically strengthened or go to a thicker glass.

The last point in this article is laminated glass. We laminate glass because of a few reasons. First, what is laminated glass. Laminated glass is like putting the film inside two glass sheets. This process is expensive, we need pressure, we need temperature, we need time, and we need an exceptionally clean environment, because when we laminate together two sheets of glass, we need to be sure that no particles get inside. This kind of process needs to be done in a Clean Room, so it is expensive, but as you see on the picture above, even if the glass is broken, it still holds up because of the laminated film inside.

We laminate glass mainly because of two reasons. One is mechanical strength and impact. We use it even in our homes. Many windows used nowadays are anti-vandal and that means they are laminated glass, and they are extraordinarily strong. The other reason to laminate glass is to put a film inside with some properties, usually to block the UV or IR light. IR means infrared so heat and UV means ultraviolet, short wavelength, extremely dangerous for electronics. When we have an outdoor application, some customers want to protect the displays, touchscreens or the e-paper displays also against UV. Then we use laminated glass and as you can see on the chart above the IR cut film and UV cut film are both transparent for visible light. We can see everything through them, but what is higher and what is lower is cut by UV and IR films. Most often we use only UV cut film because UV is more dangerous, for example it makes the film sensors for capacitive touchscreens turn yellow or it can decrease the contrast of the TFT (Thin Film Transistor) display by damaging the polarizer or color filters. The IR film is used in some applications to protect the display from heat. If we add it, we can decrease the temperature of the display surface. In another video we were talking about High-TN, so liquid crystals that can work in very high temperatures. For this kind of liquid crystals, we usually do not need to decrease the temperature of the surface because they can go up to 100 or 110 degrees, but regular displays can work up to 50- or 70-degrees maximum temperature. Using the IR cut film can solve the problem with blackening and increasing the display temperature too much.

Consumers and businesses that rely on electronic devices can put them through a lot of abuse. To prevent scratches and damage of the device screen, consumers buy screen protectors to protect their investment. If you’re in the business of selling screen protector products, it’s important to partner with a tempered glass screen protector manufacturer that has experience delivering the best product.

New Vision Display is a leading custom glass screen protector manufacturer for major global retailers, OEMs, private label brands, and distributors. We can create custom solutions for nearly any electronic device: smartphone, tablets, laptops, GPS devices, POS terminals, medical devices, industrial controls, smartwatches, and more. Contact us to learn more!

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A wide variety of tft lcd glass options are available to you, such as original manufacturer, odm and agency.You can also choose from tft, ips and standard tft lcd glass,

Q3: What package do you use for the products9 A3: Usually we have professional retail package for the products. Q4: Will your product work in my country9 A4: All our products are compatible to the international standards. Q6: What"s your charger standard9 Are they available in my country9 A6: Usuallywe used USB cable line to charger.

Orient Display sunlight readable TFT displays can be categorized into high brightness TFT displays, high contrast IPS displays, transflective TFT displays, Blanview TFT displays etc.

The brightness of our standard high brightness TFT displays can be from 700 to 1000 nits. With proper adding brightness enhancement film (BEF) and double brightness enhancement film (DBEF) and adjustment of the LED chips, Orient Display high brightness TFT products can achieve 1,500 to 2,000 nits or even higher luminance. Orient Display have special thermal management design to reduce the heat release and largely extend LED life time and reduce energy consumption.

Our high contrast and wide viewing angle IPS displays can achieve contrast ratio higher than 1000:1 which can make readability under strong sunlight with lower backlight luminance. High brightness IPS displays have been widely accepted by our customers with its superb display quality and it has become one of the best sellers in all our display category.Transflective display is an old monochrome display technology but it has been utilized in our color TFT line for sunlight readable application. Orient Display has 2.4” and 3.5” to choose from.

Blanview TFT displays are the new technology developed by Ortustech in Japan. It can provide around 40% of energy consumption for TFT panels which can use smaller rechargeable or disposable batteries and generate less heat. The price is also lower than traditional transflective TFT displays. Orient Display is partnering with the technology inventor to provide 4.3” and 5.0”.

Orient Display can also provide full customized or part customized solutions for our customers to enhance the viewing experience. Orient Display can provide all the different kinds of surface treatments, such as AR (Anti-reflection); AG (Anti-glare), AF (Anti-finger print or Anti-smudge); AS (Anti-smashing); AM (Anti-microbial) etc. Orient Display can also provide both dry bonding (OCA, Optical Clear Adhesive), or wet bonding (OCR, Optical Clear Resin and OCG, Optical Clear Glue) to get rid of light reflective in air bonding products to make the products much more readable under sunlight and be more robust.

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch.

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

Engineers are always looking for lower cost, faster, more convenient interfaces to transmit signals and to accept data and commands. The numbers of available interfaces available in the market can be dazzling. Orient Display follows market trends to produce various kind of interfaces for our customers to choose.

Genetic Interfaces: Those are the interfaces which display or touch controller manufacturers provide, including parallel, MCU, SPI(,Serial Peripheral Interface), I2C, RGB (Red Green Blue), MIPI (Mobile Industry Processor Interface), LVDS (Low-Voltage Differential Signaling), eDP ( Embedded DisplayPort) etc. Orient Display has technologies to make the above interface exchangeable.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

TFT (Thin Film Transistor) LCD (Liquid Crystal Display) dominates the world flat panel display market now. Thanks for its low cost, sharp colors, acceptable view angles, low power consumption, manufacturing friendly design, slim physical structure etc., it has driven CRT(Cathode-Ray Tube) VFD ( Vacuum Fluorescent Display) out of market, squeezed LED (Light Emitting Diode) displays only to large size display area. TFT LCD displays find wide applications in TV, computer monitors, medical, appliance, automotive, kiosk, POS terminals, low end mobile phones, marine, aerospace, industrial meters, smart homes, handheld devices, video game systems, projectors, consumer electronic products, advertisement etc. For more information about TFT displays, please visit our knowledge base.

There a lot of considerations for how to choose a most suitable TFT LCD display module for your application. Please find the check list below to see if you can find a right fit.

It is the start point for every project. There aretwo dimensions to consider: outside dimension (width, height, thickness) and AA (active area or pixel area). Orient Display’s standard product line ranges from 1.0” to 32”. Our OLED size can go down to 0.66” which fit for wearable devices.

Resolution will decide the clearance. Nobody likes to see a display showing pixel clearly. That is the reason for better resolution, going from QVGA, VGA to HD, FHD, 4K, 8K. But higher resolution means higher cost, power consumption, memory size, data transfer speed etc. Orient Display offers low resolution of 128×128 to HD, FHD, we are working on providing 4K for our customers. For full list of resolution available, please see Introduction: LCD Resolution

TFT screen brightness selection is very important. You don’t want to be frustrated by LCD image washout under bright light or you drain the battery too fast by selecting a super brightness LCD but will be used indoor only. There are general guidance listed in the table below.

Orient Display offers standard brightness, medium brightness , high brightness, and high end sunlight readable IPS TFT LCD display products for our customers to choose from.

If the budget is tight, TN type TFT LCD can be chosen but there is viewing angle selection of either 6 o’clock or 12 o’clock. Gray scale inversion needs to be taken of carefully. If a high-end product is designed, you can pay premium to select IPS TFT LCD which doesn’t have the viewing angle issue.

It is similar to viewing angle selection, TN type TFT LCD has lower contrast but lower cost, while IPS TFT LCD has much high contrast but normally with higher cost. Orient Display provides both selections.

Normal TFT LCD displays provide wide enoughtemperature range for most of the applications. -20 to 70oC. But there are some (always) outdoor applications like -30 to 80oC or even wider, special liquid crystal fluid has to be used. Heater is needed for operating temperature requirement of -40oC. Normally, storage temperature is not an issue, many of Orient Display standard TFT display can handle -40 to 85oC, if you have any questions, feel free to contact our engineers for details.

Power consideration can be critical in some hand-held devices. For a TFT LCD display module, backlight normally consumes more power than other part of the display. Dimming or totally shutdown backlight technology has to be used when not in use. For some extreme power sensitive application, sleep mode or even using memory on controller consideration has to be in design. Feel free to contact our engineers for details.

Genetic Interfaces: Those are the interfaces which display or touch controller manufacturers provide, including parallel, MCU, SPI(,Serial Peripheral Interface), I2C, RGB (Red Green Blue), MIPI (Mobile Industry Processor Interface), LVDS (Low-Voltage Differential Signaling), eDP ( Embedded DisplayPort) etc. Orient Display has technologies to make the above interface exchangeable.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

If you can’t find a very suitable TFT LCD Display in our product line, don’t be discouraged. The products listed on our website is only small part of standard products. We have thousands of standard products in our database, feel free to contact our engineers for details.

If you like to have a special display, Orient Display is always flexible to do partial custom solution. For example, to modify the FPC to different length or shape, or use as fewer pinouts as possible, or design an ultra-bright LCD display, or a cover lens with your company logo on it, or design an extreme low power or low cost TFT display etc. our engineers will help you to achieve the goals. The NER cost can start from hundreds of dollars to Thousands. In rare case, it can be tens of thousands of dollars.

A fully custom TFT LCD panel can have very high NRE cost. Depending on the size of the display, quantity and which generation production line to be used. The tooling cost can start from $100,000 to over $1M.

【LCD Screen replacement for Samsung Galaxy S3 i9300】This lcd screen replacement for samsung galaxy s3 is brand new and A+quality, repairing your broken or malfunctioning screen,Compatible with samsung galaxy s3 i9300, perfect fit for your phone, note pls: This is lcd display ,not original AMOLED SCREEN, but can compatible with samsung S3/I9300

【Strict Quality Control】 LCD screen belongs to glass products, which are very fragile and easy to break.Our QC will strict check all the products before shipment,make sure there is no scratch in surface of screen、no dead area in touch screen、no dot pixel or line in lcd display.We refuse any flaw,provide A+ quality products only.

【Installation note】Please test the screen before installation to ensure the normal use of the screen. Non-professional installation is not recommended. If you need help and an installation instruction video, please contact us and we will get back to you within 24 hours, or find the installation video on YouTube.

The principle of the liquid crystal display determines that its best resolution is its fixed resolution. The dot pitch of the liquid crystal display of the same level is also fixed, and the dot pitch of the liquid crystal display is exactly the same at any point of the full screen.

Generally, the brightness is indicated in the specifications of liquid crystal displays, and the indication of brightness is the maximum brightness that the backlight light source can produce, which is different from the brightness unit “Candle Lux” of ordinary light bulbs. The unit used by LCD monitors is cd/m2, and general LCD monitors have the ability to display 200cd/m2 brightness. Now the mainstream even reaches 300cd/m2 or above, and its function lies in the coordination of suitable working environment light. If the light in the operating environment is brighter, the LCD display will be more unclear if the brightness of the LCD display is not adjusted a little higher, so the larger the maximum brightness, the larger the environmental range can be adapted.

When choosing a monitor, users should also pay attention to the contrast and brightness of the LCD monitor. That is: the higher of the contrast, the more distinct between the white and black output. The higher the brightness, the clearer the image can be displayed in a lighter environment. Moreover, in different operating environment light, proper adjustment of the contrast value will help the picture display clear, high-contrast and high-brightness displays are too light, easy to make eyes tired. Therefore, users must adjust the brightness and contrast to appropriate levels when using LCD monitors.

The viewing angle of a liquid crystal display includes two indicators, a horizontal viewing angle and a vertical viewing angle. The horizontal viewing angle is expressed by the vertical normal of the display (that is, the vertical imaginary line in the middle of the display). The displayed image can still be seen normally at a certain angle to the left or right perpendicular to the normal. This angle range is the horizontal viewing angle of the liquid crystal display. Also if the horizontal normal is the standard, the vertical viewing angle is called It is the vertical viewing angle.

The 5 inch capacitive touch screen lcd module,Strong anti-interference performance, support touch with water on the surface, support touch with gloves of different materials and thickness. mainly used in industrial, medical electronics, smart home appliances and other fields, supporting deep customization of structures. most common operation systems are supported. touch screen IIC/USB interface optional, brightness can be customized, display can match the different interface conversion board according to the requirement.

A: The impact of the Sensor on TP performance is huge. In the capacitive touch screen module, the sensor is the sensing element, and the controller IC is the analog-to-digital converter. The sensor quality directly affects the quality of the signal received by the IC. From the structure point of view, sensor is divided into two categories, namely DITO and SITO. From the material point of view, sensor is mainly divided into two categories, namely Glass and Film. DITO uses the lower layer TX for shielding, so no shielding layer is needed. SITO"s TX and RX are all on one layer, so you need a shield on the back. Technical improvements can remove the back shield. The Cypress solution uses a DITO structure with a mesh pattern to solve linearity and dangling problems. The SITO structure usually adopts a diamond pattern. This pattern has many problems, and the power supply noise is large, linearity, floating, and poor waterproof performance. The Cypress scheme uses the SITO structure plus a bee pattern to achieve the performance of the DITO structure with a mesh pattern. Because the FLASH process does not support high voltage, it can be seen that other chips in the market need high voltage when it needs to externally boost the chip. In addition to the boost, the Cypress chip adds a lot of algorithms and adopts its own patented SENSOR pattern, so in the letter The noise ratio can be done very well.

The display solution includes: the current mainstream display glass panel, and we can customize the brightness of the display screen, FPC shape, interface definition, driver IC solution according to the actual needs of customers, etc.

Choosing from material options such as soda lime, chemical and heat strengthened, tempered and toughened glass and PMMA, Polycarbonate and Optolite™ high scratch resistant plastics, our team can pinpoint the ideal solution. Our bespoke service also includes enhancement such as Anti-Glare (AG), Anti-Reflection (AR) and Anti-Smudge (AS) optical treatments. Finally, colour and graphic logo printing, circular, rectangular and free-form cut-out detailing can fully customise your monitors.

As the ultimate in sensory and intuitive user experience, delivering product differentiation from competitors, we offer integrated Haptic feedback technology to our TFT touch sensors. Users experience added satisfaction of a tactile sensation of simulating clicks and vibrations through the touch screen, giving the enhanced perception of using physical buttons and switches.

When clarity and functionality is essential to create the best end-user experience, Optical Bonding offers the perfect solution for increasing visibility and durability in light-challenging and harsh environments.

Specially designed embedded SBC solutions for our AMOLED displays, contain all the essential hardware, software, electronics and interface drivers to reduce your development cycle and speed up time to market.

When maintaining maximum performance, reliability and output efficiency is essential, our in house engineer designed and developed protective EMI shields and ground pads to limit Electromagnetic Interference (EMI) and provide noise immunity.

VMD 1001 is a 7-inch TFT LCD monitor with 4 wire resistant touch screen sensor. With the high brightness display and automatically brightness control, it is designed for in-vehicle application. In support ...

Engage customers with a complete digital advertising solution. The wall-mounted outdoor display combines a high-bright screen with a weatherproof body. ...

Model Name:AMG-19OPDX01T7Screen Size:19"Active Display Area (mm):376.32(H)x301.06(V)Pixel Pitch (mm):0.294(H)x0.294(V)Display Mode:Normally whiteDisplay Resolution (pixel):1280x1024Contrast Ratio:1000:1Touch screen(optional):PCAP ...

... comfortable viewing experience, and compatibility with a standard 100 x 100mm VESA mount allows flexible wall mounting or installation on a display arm.

... daisy chainable HS272PDB monitor has both a DisplayPort input and a DisplayPort output. The DisplayPort output connects to the next downstream display. This cabling arrangement, with one DisplayPort cable between each ...

... open frame LCD monitor with 1280 x 1024 resolution and a 250-nit LED backlight display. The monitor features multiple video inputs including VGA, HDMI, DVI, or DP input. Designed with a heavy-duty steel ...

... and the touch screen form a unit with air distance (necessary). Standing air in the interspace is prevented by additional fans. An inserted black plastic cover insulates the mounting bracket ...

Hsintek is a Certificated ISO 13485 Medical Certification Manufacturer, we have 30 years experience in Monitor display field, and we are looking for the long term partnership in Medical industry.

... They have a slim, flat and aesthetic panel design. Frames can be chosen from white or black. Memory card is protected by a theft-proof lock. For LCD screen protection, they include AG or AR glass.

HUAWEI IdeaHub Board, a 4K soft light screen and smart board designed for collaboration and creation: a space where fresh thinking and new ideas can be brought to life.

Is your phone broken? You have several options when choosing a new TFT LCD display. In this article, we will advise which is the best and most advantageous.

Both the iPhone SE (2020) and the iPhone 11 are among the more affordable models in the Apple brand portfolio with more or less integrated equipment. This is reflected, for example, in displays that use In-Cell TFT LCD technology, which can also be found in older models, including:

Despite the fact that TFT LCD displays lag significantly behind more modern OLED displays, they are still top displays. This is also evidenced by the fact that devices with this technology (whether it is the iPhone SE (2020), iPhone 11, or one of the older models) are still very popular with users. Thanks to this popularity, there are several options on the market when it comes to replacing a cracked display on such a device.

In the case of broken glass on the iPhone TFT LCD display, there are basically three different options. The first is the exchange for the original. Although this option guarantees the same quality as the original display, we prefer not to recommend it due to its higher price. In this case, the customer pays only "per brand". The price difference between the original and the quality display from the OEM manufacturer does not balance essentially zero difference in the quality of both components.

Displays from OEM manufacturers also differ in quality and also here it is possible to reach for verified brands and quality. In our portfolio, you will find, for example, top FixPremium displays from the SHARP Electronics brand. Like the originals, these panels use In-Cell TFT LCD technology, which provides superior color rendering and excellent viewing angles. In addition, thanks to constantly innovated production, FixPremium displays are less energy-intensive, and with the new display, it is even possible to achieve better battery life.

There are other cheaper alternatives on the market. However, they often cannot be compared at all with the quality of original or FixPremium displays, and by purchasing them, the customer is exposed to unnecessary risk.

We, therefore, recommend looking for a replacement display, for example, in our e-shop, or having the entire replacement carried out by us. We guarantee professional service, verified quality of spare parts, and fast return of the device to its owner.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey