cracked lcd screen laptop made in china

The Global Production of Large-Size TFT LCD Panels Will Maintain a CAGR of 7% Over The Next Five Years 2018-2022 annual global large-size LCD pane...

About Shipping: 1. Shipment Time: Cargo will be shipped within 3 days upon receipt of payment. 2.If any product is defective,please take photos of its working condition and then send photos to us. After we receive the defective screens,we will send new and good replacements to you.

It is an unfortunate fact, that there are many people out there who are ready to throw accusations around based on absolutely no research whatsoever. From time to time, we have been accused of sending fake, or cheap copies (usually from China), of original screens out.

To produce a piece of hardware as complex as a flat screen, you need a very serious setup. The facilities that these devices are produced in are clean room environments. This means they are completely dust free. Workers are usually kitted out, like astronauts, in protective white suits and head gear, to ensure that no contamination can enter the complex layers of glass and reflectors that are assembled to produce the screen.

Obviously there is a huge cost to starting up a production of LCD screens, and for this reason there are less than 10 companies that produce LCD screens, and they are all big players.

So as you can see, the possibility of a company producing knock-off copies of real screens is non-existent. Unless you have 4 billion pounds sitting in your back pocket and a clean room environment occupying several hundred thousand cubic metres, you can forget LCD production.

The reality of the situation however, doesn"t dissuade some people, from throwing wild accusations around, about fake or knock off copies of screens, based on absolutely no research whatsoever.

- The reason for this is that LCD producers are constantly producing new part numbers for their products. They do this to keep their industry moving and their money rolling in. Models they produce are almost identical to each other, yet they keep producing every quarter of a year, a bunch of new model numbers.

Even if your laptop is only 6 months old, it would have been manufactured more than a year ago, and probably the screen inside it is 2 years old. For this reason we will often send you a newer part code, which could be from a different manufacturer. This is perfectly normal and the only way we can provide a service to you.

This is in fact how the original computer manufacturer works as well, as laptops or tablets purchased at different times, will have different brands of screen fitted inside them. This is a good example from a Lenovo brand machine.

We all know how difficult it is to print on non-paper objects, such as a T-Shirt for example. So imagine the difficulty in trying to run a piece of glass through a printer. It would of course require specialised equipment. So then the question becomes, why would an LCD producer invest in specialised equipment to print a code on the screen glass? And why would this have anything to do with the screen being a cheap knock off copy?

What is actually happening here is that the protective film over the glass has not been removed. Often the LCD producer will kindly shrink-wrap a protective plastic film over the glass so that the screen does not get soiled with finger-marks during fitting. Once fitted this protective film can simply be peeled off.

I did this one on a Dell 5150 with a 15" UXGA screen. It can be very very tricky to get that reflector back into place because you"ve got the lamp in there and don"t want to break it. Meanwhile, you need to slip it around the thick (quarter inch) glass behind the LCD so that the light shoots up through the glass. The lamp has high voltage so you want to make sure there are no exposed wires. Those silicone rubber end caps might be torn after you get the thing apart.

I got my LCD out and on the back it said "DO NOT TOUCH WHITE TAPE --- SENSITIVE AREA." Unfortunately, I had touched that tape when I flipped the LCD over to the back. Fortunately, it does not seem to have been damaged.

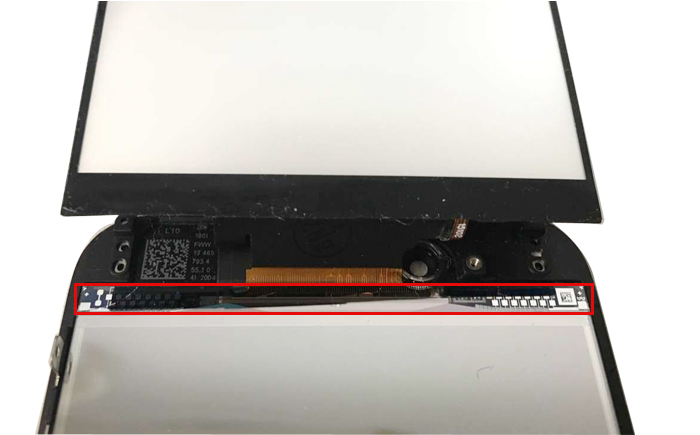

Good tip. The LCD doesn"t seem to be damaged because if you took off the white tape, there is a thin ribbon cable there. This cable contains millions of tiny wires (3 per pixel) and at one point, right before it goes into the LCD, becomes so packed the wires seem to come together into a rectangle (they"re indistinguishable). They don"t want these to break or short. However, if you"re careful, I found this cable can survive quite a bit of bang. =P (I took apart one of those LCDs completely).

Opps didnt read #8 so the glass diffuses the light evenly i thought they just like had a a bulb going across the screen and that would make it uneven (i have 6 hour jet lag at the moment so im not thinking strait JSYK)0

The inverters in these monitors are always failing because of a design flaw, or rather cheap out. There are 4 transistors that are really hard to get that fail because they are not on a heatsink and wear quickly. Anyhow I decided that it was not worth fixing the inverter and instead found a couple of old point of sale touch screen machines. (486 mi-cos yuk) they had a really nice modular inverter that sported just 5 pins kinda like a square chuck of black epoxy with pins sticking out. these things are great it is too bad they don"t use them today anymore but then again they are manufactured in Canada so go figure. if you happen across any of these old point of sale machines it is worth digging out the inverter module because you never know when you are gonna need 1500 volts...

i Got Myself an Old laptop With a Broken Screen, I Opened the Screen And Took Out the Backlight And the Inverter, Coincidentally I had another Old laptop,That Was A Similar Model,It had the Same Inverter And Cable,So I Tested the CCFL tube from the laptop with the broken screen and it worked,The Inverter+CCFL Worked Like a charm,Now I am Making Myself a lamp,I got that thing to run off of a 9V Battery,And a 13V Power source.0

To learn more about best practices on handling and using a Dell laptop, see the Dell knowledge base article Best Practices for Product Use and Handling for Dell Laptops.

If the screen abnormality is not present in the built-in self-test mode, see the Dell knowledge base article How to Troubleshoot Display or Video Issues on a Dell Monitor.

If the LCD built-in self-test (BIST) diagnostic test passed, the laptop LCD screen is working correctly. The display problem could be due to an outdated graphics driver or incorrect video settings. Follow the troubleshooting instructions in the Dell knowledge base article How to Troubleshoot Display or Video Issues on a Dell Laptop.

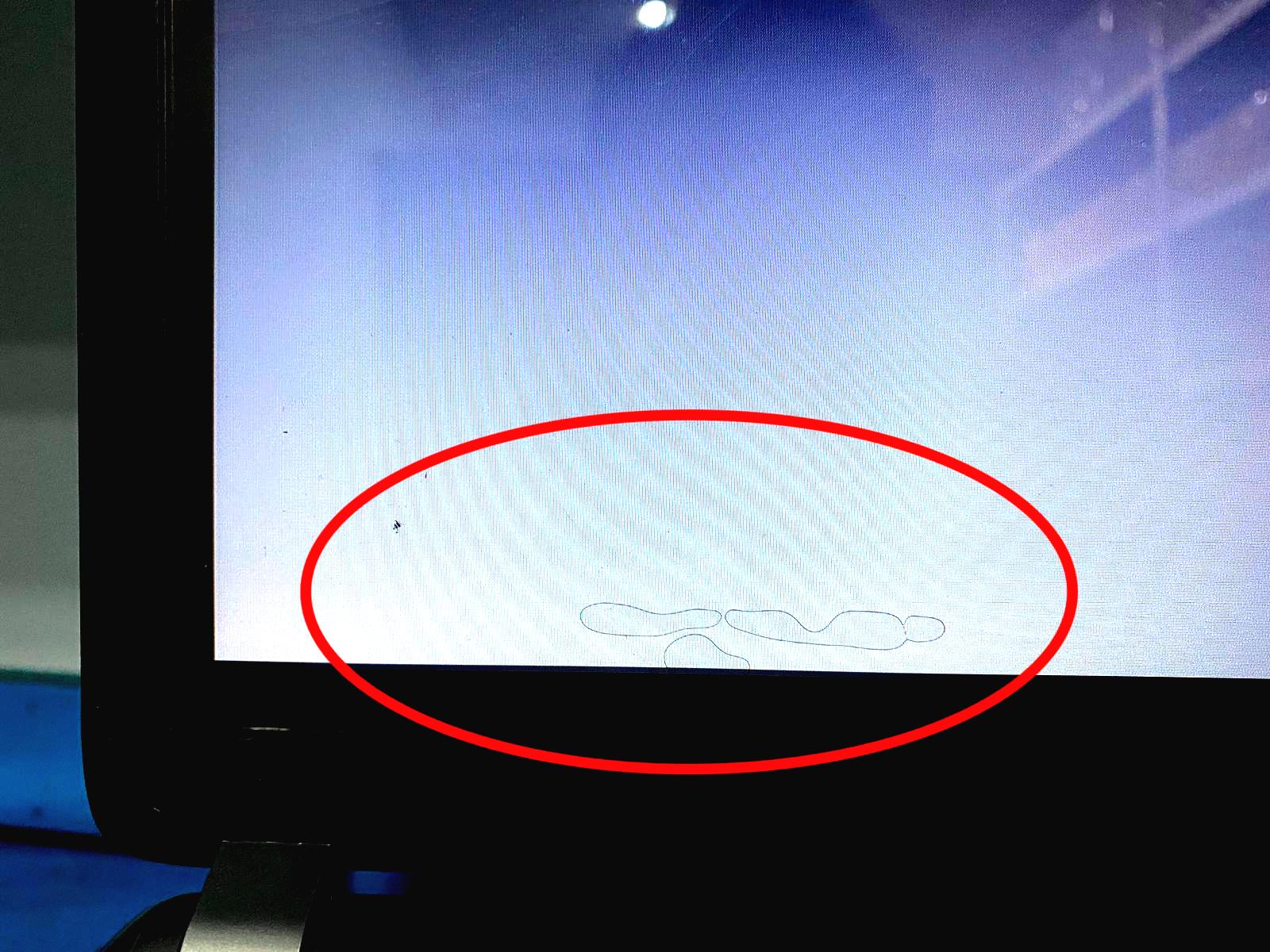

Lines on the LCD BISTin this case point to the LCD Screen itself. If the lines are not seen during the LCD BIST we would then look to the Video Card, System Board, or the LCD Cable

If the screen is working, the second test displays a series of white, red, green, andbluescreens for approximately 20 seconds. Every two seconds the system beeps and the keyboard lock LEDs flash as the screen color changes to indicate the test is in progress.

Even if you are extremely careful with your hardware, it can be unavoidable at times to run into issues such as a cracked or broken computer screen. Just because you’re experiencing problems with your display doesn’t mean that your laptop is beyond saving, however.

You should also know that repairing your laptop screen isn’t always the easiest job, and there is a possibility you can make the problem worse while voiding the manufacturer warranty. It’s important to feel confident in your skills before you begin the process of replacing your screen, and to consider if you would be more comfortable taking it in to a qualified repair shop.

Even those who have never replaced a screen can manage to do it depending on the type of computer. Just be aware that if you own a laptop with a touch screen it can make the process much more challenging.

If you’re wondering about broken laptop screen repair costs, you’ll be happy to know it’s not as expensive as you may assume. Professional repair costs are usually around $300 or so [1]. If you are comfortable working on your laptop yourself, you can usually find replacement screens online for reasonable prices - sometimes as low as $50 to $100 - and it often only takes an hour or two to complete the replacement job.

If you’re willing to take the leap and do this yourself, then you can end up rescuing a computer you may have thought you needed to replace. Here are 5 steps you can take to successfully replace or repair your cracked computer screen.

Before you begin the process of changing your screen, it’s important to know exactly what’s wrong and what needs to be repaired. The type of device you have can influence how much you’ll have to pay for another screen, as will its age, which may make finding a replacement rather difficult. You should do some research online to find out if you even have the option to fix the screen yourself.

The first step is making sure the device powers up successfully and that the screen is the only issue you need to address. As a test, hook your laptop up to a separate monitor. If your laptop seems to function well, then it’s likely that the broken laptop screen is all you have to worry about. Keep in mind that some laptops need to have some function keys pressed in order for an external display to work properly.

You will also have to do a complete inspection of your computer to determine if your screen is the only problem. A destroyed graphics card or a computer that refuses to start up indicates that a new screen isn’t enough to get you up and running again.

Also, if the frame of your laptop has suffered physical damage, then you may have some difficulty repairing your screen. Once you have looked over your device and determined whether you can fix it on your own, it’s time find the right screen for your computer.

Note: If you’re concerned about your laptop’s touch screen repair, it can be more complicated to fix this problem without professional help. These displays are designed with factors like sensitivity in mind, so it’s a good idea to have an expert take a look at it, even if it means spending a bit more than anticipated.

One of the main reasons you should know the model of your laptop is so you’re sure that you’re purchasing the correct replacement screen. While a number of companies offer laptop screen repair kits that can make the process easier, if you order the wrong screen you won’t be able to make any repairs. If you’re having difficulty figuring out your computer model, you can visit the “Settings” menu and find the serial number to assist you in your search.

Fortunately, finding the right screen for your device doesn’t have to be stressful. Often you can find what you are looking for simply by entering your laptop model number into the search bar of online retailers. You may also want to include the search term “LCD” in order to narrow down the accessories that are available for your computer. For the most part, screens should be priced fairly reasonably and you may even be able to buy some for around $50, although it depends on the type of computer you have.

Some sellers may use another form of identification for the model of your laptop, so double check that you chose the right option before you purchase. Almost all the information you need should be displayed on the seller’s listing. Again, take the time to compare your device’s specs with the screen you’re purchasing, and also make sure that the video cable on the back of your screen matches what the vendor shows online. Most of the time, it’s fairly easy to know if the right screen is available.

You will need a few tools in order to properly install your new screen. These tools can make the process much simpler and allow you to fix things efficiently.

Screen repair kits are also available for certain models, so it can be worth it to research your type of computer and see if they’re available. These kits provide you with everything you need ahead of time so you can get to work and not worry about missing an essential tool. Of course, items around your home can work just as well while saving you a bit of money.

Once you have assembled the tools you need to replace the screen, you can get to work repairing your device. Lay the closed laptop on the flat surface you have chosen and keep your tools nearby.

First, turn off your laptop and make sure that it is unplugged from a power source to avoid any risk of electric shock. After that, it also helps to remove the battery to avoid causing any other issues.

Once you have done that, you should identify the stickers that cover screws on the screen bezel. You can usually find them near the bottom of your screen where the hinges would be when you have your display opened. There should be two.

From there, you will need to use a pin to remove the stickers located on the bezel so you don’t end up damaging them. You will need to use these later, once your screen is properly installed, so make sure they aren’t lost and that you store them sticky side up so you can reuse them. Put them in a safe spot so when you go to attach your new screen, they are easy to find.

You’ll then want to use your screwdriver to remove the screws that are now visible. You may have some difficulty depending on how tightly they were screwed in during manufacturing. For the most part, if your old screen is aligned fairly well, it shouldn’t be too much of a problem to remove the screws. Place them in the dish so you don’t lose any.

It’s now time to gently remove the bezel. Make sure you are careful when removing your old screen’s bezel because you will need to reinstall it once the screen is replaced. By using a putty knife or other flat object, you should be able to pry your screen from your laptop case.

It may take a little effort to completely remove it. And don’t be alarmed if you hear some plastic snapping - that is the unfastening of the plastic tabs that hold your screen onto your case. If you have some trouble removing the old screen, the screws at the bottom might not be loosened enough, so stop and loosen them some more before trying again.

One of the trickier parts of replacing your laptop screen will be removing the LCD. First, make sure that the bezel is completely off so you can have unfettered access to the LCD screen. It will be secured onto the laptop’s metal frame, and you will have to take it off from the left and right sides.

There will be two more screws to loosen at the top corners before you can lift the screen slightly away from the metal frame. You’ll probably find a few more screws securing the LCD on the sides, and these will also need to be unscrewed. In some cases, heavy duty tape may have been used instead.

After you remove the attachments, your screen should now lie on your keyboard. It can be a bit of a challenge to make sure there is enough space between the LCD and the metal frame, but you should be gentle to avoid ruining the video cable that runs from the back of the screen to the body of the laptop. If this is damaged, you will need a professional’s help to repair it.

Now it’s time to disconnect the cable from the LCD. You can usually find the connectors in the center, though they may alternatively be located at the bottom of your screen. It’s likely that adhesive was used to connect the two, so you will need to gently pry one from the other. There may also be some tape that needs to be removed, but overall it should be pretty simple to disconnect your LCD from the video connector. Set it somewhere away from your tools.

As you remove the screen, you should be able to locate where your new one will go. Place it face down within the frame so it fits perfectly. After that, you can reattach the video connector so it is placed exactly where the previous LCD sat. Make sure that it is as aligned as possible then attach it with tape or adhesive.

Once that’s done, make sure the sides are secure. Reinsert the screws on the sides and top, or reattach any tape that was used to hold everything together. After everything is nicely tightened, you can put the bezel back on. Line it up so that it snaps properly into the screen case and won’t be easily loosened.

Reinsert the remaining screws into the bezel after you’re certain everything is snapped correctly into place. You shouldn’t be able to see any cracks at all along the edges of the screen. Once the screws are inserted, reattach the screw covers using your pin or needle.

From there, you should be ready to restart your computer. Put the battery in and connect your laptop to a power source before turning it back on. If there is no display, then you will need to double check that everything was properly put back together.

Repairing a broken laptop screen doesn’t have to be done by a professional. If you have the time and interest, then you can end up saving a lot of money by doing it yourself. By following these DIY steps, you can have your laptop display back up and running in an hour or two.

And the world of consumer electronics, specifically laptops, has not only been hit particularly hard during the pandemic, it"s a perfect metaphor for the problems with modern-day supply chains, according to experts.

Zilberman has been in business several decades, and says he"s never had a problem finding replacement parts like he is today, specifically replacement screens for things like cellphones and laptops.

"When I used to buy one or two screens, now I have to buy six or seven," Zilberman told Fox"s Investigative Unit. "High inventory means lower cash flow, the money that could go for advertising, the money that can go for the [employee] salaries, the money that can go for development... it"s not a good situation for me as a business."

Just this week, one company in the business of LCD-panel technology announced it would be opening a domestic repair facility for its U.S. customers "to avoid ongoing challenges in the volatile international supply chain."

When it comes to a device like a personal computer, the screen may be a very important part, but it is one of many. And that is perhaps what helps make the modern-day laptop the perfect metaphor for our current supply chain woes."The COVID pandemic was a wakeup call that not only tested our supply chains, but showed us that it is just not responsible to be overly dependent on China for stuff that is critical to our economic and national security." - Rep. Tom Malinowski, D-N.J.

"Something as complex as a laptop, that could be thousands of parts, hundreds of companies involved in just the making of those parts," says Michael Farlekas, whose company e2Open, helps facilitate supply chain logistics for multi-billion dollar companies.

The supply chain of a laptop computer captures the complexities that created many of our modern day supply chain issues, according to experts. (Courtesy: e2Open)

Whether it"s cracked or has one too many blown pixels, a broken laptop display can stop you dead in your tracks. But with the right tools, a little technical know-how, and a bit of patience you can replace a damaged LCD.

I also suggest you watch my earlier video on what to know before trying to fix a smartphone or tablet. It"s not specifically about laptops, but the information is still relevant, and it will help you decide if you should repair the machine yourself or take it to a shop.

To begin your fix, you"ll need a few simple tools and a replacement LCD screen. For tools, I recommend a screwdriver set with a variety of small bits, such as a Phillips #00 and a Torx T5. It"s also a good idea to have a few thin metal blades or plastic spudgers. These are really handy for removing the trim that surrounds the screen.

As for the replacement LCD, you should be able to buy one either from the laptop manufacturer"s authorized parts dealer or a third-party supplier. Depending on the screen, they usually cost between $50 and $250 dollars -- more if it"s a high-end display or if you buy an OEM replacement. Regardless, you"ll want to buy a new screen that matches your broken one exactly. The only sure way to do this is to remove the broken one.

After disconnecting the power supply and removing the battery, carefully examine the bezel around the screen. You"ll need to remove this bezel to access the screws that hold the LCD panel in place.

On this laptop, several rubber cushions hide screws, which hold the bezel in place. I"ll need to remove these cushions and the screws that are underneath.

Note: Your laptop may not have cushions or hidden screws. The bezel may simply snap onto the lid or be held in place with double-sided tape. Just adapt my instructions to fit your specific laptop.

With the LCD"s mounting brackets exposed, you can remove the screws that secure it to the lid. Then rest the display front-side-down on the case and disconnect its cable.

If your laptop was made before 2010 and has a LCD with fluorescent backlights, it will likely have two cables. But as this is an LED-backlit LCD, it only has one.

Now, locate the manufacturer"s label and note the model number. Using this information you should be able to buy an exact match for your broken screen.

If the dimensions, mounting brackets, and connector all match, you"re ready to install the screen. Connect the new panel to the cable, position the panel in the lid, and secure it using the appropriate screws.

One of today’s modern technological wonders is the flat-panel liquid crystal display (LCD) screen, which is the key component we find inside televisions, computer monitors, smartphones, and an ever-proliferating range of gadgets that display information electronically.What most people don’t realize is how complex and sophisticated the manufacturing process is. The entire world’s supply is made within two time zones in East Asia. Unless, of course, the factory proposed by Foxconn for Wisconsin actually gets built.

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass.On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through.That’s how you can get electrical signals to the middle of a screen.Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts.This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen.Each step has to be precisely aligned to the previous one within a few microns.Remember, the average human hair is 40 microns in diameter.

For the sake of efficiency, you would like to make as many panels on a sheet as possible, within the practical limitations of how big a sheet you can handle at a time.The first modern LCD Fabs built in the early 1990s made sheets the size of a single notebook computer screen, and the size grew over time. A Gen 5 sheet, from around 2003, is 1100 x 1300 mm, while a Gen 10.5 sheet is 2940 x 3370 mm (9.6 x 11 ft).The sheets of glass are only 0.5 - 0.7 mm thick or sometimes even thinner, so as you can imagine they are extremely fragile and can really only be handled by robots.The Hefei Gen 10.5 fab is designed to produce the panels for either eight 65 inch or six 75 inch TVs on a single mother glass.If you wanted to make 110 inch TVs, you could make two of them at a time.

The fab is enormous, 1.3 km from one end to the other, divided into three large buildings connected by bridges.LCD fabs are multi-story affairs.The main equipment floor is sandwiched between a ground floor that is filled with chemical pipelines, power distribution, and air handling equipment, and a third floor that also has a lot of air handling and other mechanical equipment.The main equipment floor has to provide a very stable environment with no vibrations, so an LCD fab typically uses far more structural steel in its construction than a typical skyscraper.I visited a Gen 5 fab in Taiwan in 2003, and the plant manager there told me they used three times as much structural steel as Taipei 101, which was the world’s tallest building from 2004- 2010.Since the equipment floor is usually one or two stories up, there are large loading docks on the outside of the building.When they bring the manufacturing equipment in, they load it onto a platform and hoist it with a crane on the outside of the building.That’s one way to recognize an LCD fab from the outside – loading docks on high floors that just open to the outdoors.

LCD fabs have to maintain strict standards of cleanliness inside.Any dust particles in the air could cause defects in the finished displays – tiny dark spots or uneven intensities on your screen.That means the air is passed through elaborate filtration systems and pushed downwards from the ceiling constantly.Workers have to wear special clean room protective clothing and scrub before entering to minimize dust particles or other contamination.People are the largest source of particles, from shedding dead skin cells, dust from cosmetic powders, or smoke particles exhaled from the lungs of workers who smoke.Clean rooms are rated by the number of particles per cubic meter of air.A class 100 cleanroom has less than 100 particles less than 0.3 microns in diameter per cubic meter of air, Class 10 has less than 10 particles, and so on. Fab 9 has hundeds of thousands of square meters of Class 100 cleanroom, and many critical areas like photolithography are Class 10.In comparison, the air in Harvard Square in Cambridge, MA is roughly Class 8,000,000, and probably gets substantially worse when an MBTA bus passes through.

The Hefei Gen 10.5 is one of the most sophisticated manufacturing plants in the world.On opening day for the fab, BOE shipped panels to Sony, Samsung Electronics, LG Electronics, Vizio, and Haier.So if you have a new 65 or 75-inch TV, there is some chance the LCD panel came from here.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey