fill gouge in lcd panel factory

This article was written by Linh Le and by wikiHow staff writer, Jack Lloyd. Linh Le is a Certified Mobile Repair Specialist and the Owner of SC Mobile Repairs in San Clemente, California. With more than 12 years of experience, he specializes in smartphone, tablet, and smartwatch hardware repair. Linh has an iTech Mobile Device Repair Certification and an iOS Certification. He holds a Bachelor’s degree from The Franciscan University of Steubenville.

Magic erasers are usually used for cleaning up messes, but could they clean up scratches? Yup. It wiped out small scratches on the phone"s screen in just a few seconds. Taylor Martin has a tutorial on how to make your own magic erasers for just around $0.10 (£0.07 or AU$0.14) each.

Wiping a screen with toothpaste (not the gel kind) supposedly works for fixing scratched screens. All it did in my tests was make the screen shinier and seemed to add small abrasion marks. I also tried toothpaste on a plastic screen protector, such as the kind that comes with OtterBox phone cases. It worked great on that! So it"s a no for screens, but a yes for plastic screen protectors.

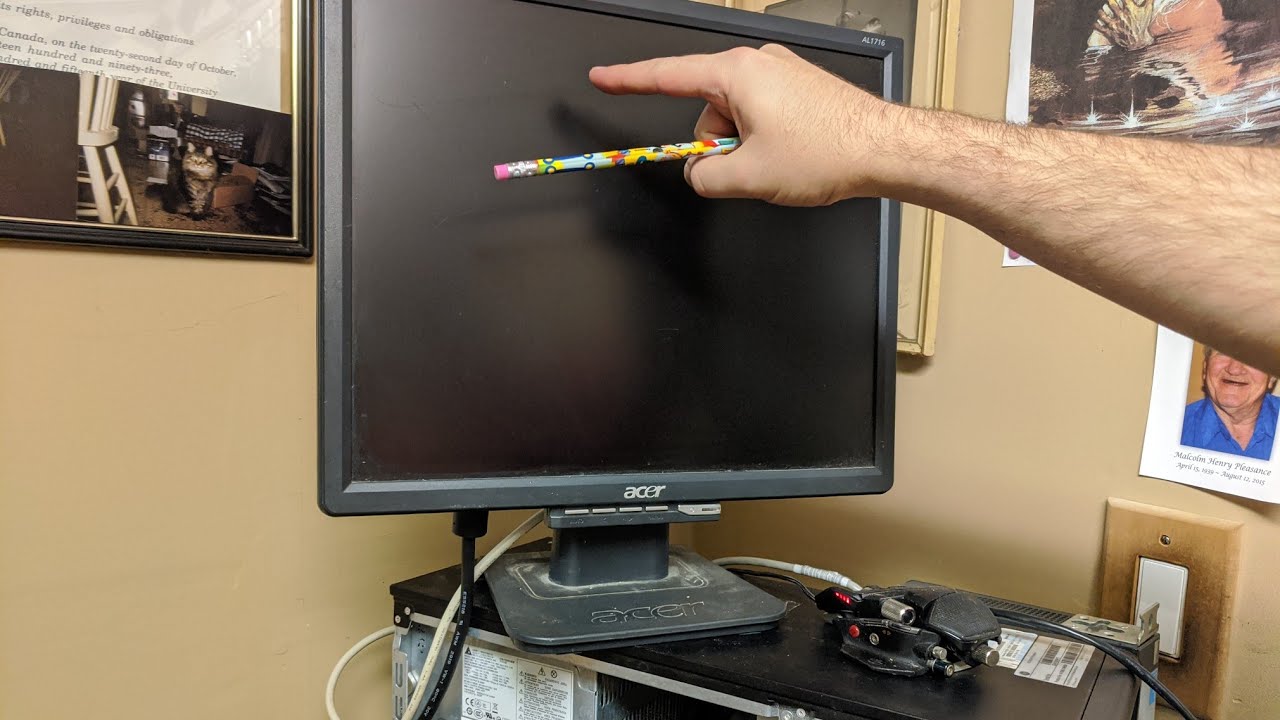

Erasers work great for making scratches disappear. I used a white rubber eraser, but you can also use the type that"s found on the end of a pencil. Simply rub the scratch left and right with the eraser for about 60 seconds, and then rub it up and down for 60 seconds. The friction softens the eraser and it fills in the scratch. Don"t press down too hard, though!

Car waxes and headlight lens creams are supposed to be effective at removing scratches on screens, so I gave Mothers PowerPlastic 4Lights headlight cream a try. It made the scratches fade significantly, and l liked the shine it gave my screen.

A paste of two parts baking soda to one part water has been bandied about as a great screen fixer. Nope. It just made the screen really shiny. Plus, the moisture in the paste could damage your device.

According to the internet, coconut oil can solve just about any problem. Shockingly, it didn"t work well on phone scratches. Like with the petroleum jelly, it just made the phone super slippery.

I wasn"t sure about this tip. Sites say to mix the corn starch with a little water to make a paste, rub it on the screen with a soft cloth, and then wipe it off. It didn"t do anything to the scratches, but it made the screen shiny.

OK, this one freaked me out. A lot. Putting gooey, oily stuff on electronics is never a good idea, but I gave it a shot in the name of science. I dabbed a bit on as recommended, and rubbed it into the screen with a tissue. As I feared, all it did was make the test screen oily and sticky.

Why do people think it"s a good idea to rub food on their phones? Nope, rubbing a banana peel on your screen won"t help it. I tried it a couple different ways and it just left a crusty mess that is hard to remove.

Powdered cleanser like Bar Keepers Friend, Comet, Ajax and the like seem a good idea for buffing out scratches. They are slightly abrasive, so you"d think they"d polish your screen to a gleaming scratch-free shine. Well, they don"t. They can even leave new little scratches on your screen. Yah, this test didn"t go well.

I do take extreme care when replacing screens but the screen shattered on this one & the tool i was using to get the shattered bits of glass off slipped

Mitsubishi Electric company from Japan is well-known the world over for large-screen display panels and industrial-strength LCD monitors. Some of the popular models in use today include the Mitsubishi LDT461V industrial monitor along with the MDT461S and MDT402S LCD monitors.

You may notice that all of these monitors are pretty big in size, ranging from 40-46 ″. To make a comparison, they are similar to the sizes common among plasma televisions, but the technology that powers them is pure LCD.

And like any other LCD monitor manufactured in past two decades, there are two problems that affect even the Mitsubishi monitor– (1) Scratched screen, and (2) Dead backlight.

Since Mitsubishi LCDs are used as industrial-grade displays, the front panel is pretty strong and resistant to scratching. There’s a manufacturing difference between screens used in an industrial setup and one installed in homes.

In the latter case, chances of minor yet visible scratches across the screen are pretty high. The quick fix is to either use a little toothpaste to “fill in” the scratch gaps, or to use a white eraser and vigorously (but gently) rub over the visible scratches.

Make sure it is a brand new one that has never been used before if you’re using an eraser. I’ve tried this scratch repair trick on certain projection TVs and it works fine there.

The second problem is that of backlight repair. The backlight is a thin CCFL tube that lights up the monitor screen. It is powered by an inverter board that converts low-voltage DC input to high-voltage AC output.

Backlight failure is a problem that affects all LCD monitors– including Mitsubishi– though the lifespan will vary based on how you operate it and the quality of in-built electronic components.

The easiest way to repair a LCD backlight is to get a compatible replacement from eBay or the manufacturer’s website. For the most part, you don’t need to buy a new inverter as the existing one can be reused.

The second problem is that of backlight repair. The backlight is a thin CCFL tube that lights up the monitor screen. It is powered by an inverter board that converts low-voltage DC input to high-voltage AC output.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

I just got my NIB WOZ ECLE this evening and have been really enjoying it. After getting my initial games in I decided to update the software and while taking the time to closely examine things I noticed what I thought was a hair on the back glass. When I looked closer I saw that it was actually a scratch on the monitor underneath the glass. When I removed the back glass I could also tell that I was not the first to notice since with the glass off I could see there were smudgy finger prints across the scratch where I guess someone tried to rub it out with their finger. So while it"s a little disappointing that the scratch was noticed at the factory and not handled there I totally understand that things happen it was probably small enough to not trigger any action. After all it"s barely noticeable and had I not been staring at the screen watching the update I probably would never had noticed just playing the game.

So my question is, is there a safe way to remove a scratch from the WOZ LCD screen? I guess it really applies to any LCD screen. The scratch is small (about 1/2" long but deep enough that running a soft cloth over the area i can feel a slight ridge.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

I have replaced the plastic screen coating on my C3 after the anti-reflective coating became degraded. It worked, but it wasnt as good as "new" - you can see the discussion & result here: http://www.dpreview.com/forums/thread/3336594

1) If your camera has a touch screen you need to make sure that the replacement layer doesnt block the touch-screen function. Search & find someone who did the same & see what brand they bought.

2) Your replacement glass/plastic will probably not have an anti-glare coating. So either look for an option that has this or get a separate anti-glare coating after.

- as someone else mentioned, if you get it fixed by Sony, get a protective layer afterwards so your anti-glare coating doesnt get damaged again - but BEWARE that this protective layer is not the kind that would stick permanently & then peel off the anti-glare if you remove it. - again, search & find someone else who did this before.

I did the same thing to a 3007WFP monitor some years ago and tried to fix it myself by polishing with toothpaste as recommended by some internet know-it-all. It did not remove the scratch but it did leave a small glossy spot where I polished off the factory non-glare finish. My recommendation is to leave it alone unless you can"t stand it, in which caseyou can buy a new outer screen panel if you can find one. I wish I had left mine alone, but I"ve learned to live with it.

There’s nothing quite as frustrating as pulling out your phone to use Face ID only to find a fresh scratch getting in the way of your phone screen and reflection. (Well, other than whenFace ID stops workingentirely, or theentire screen is cracked).

Not only are these scrapes bothersome, but they make it challenging to see the display and can even interfere with touchscreen capabilities (if they’re deep enough). So, how can you fix these phone screen scratches?

There are several options available. Before you doanything, however, be sure to power off your phone and avoid getting any liquids or debris in the device. It can cause harm if you don’t follow theseprecisely, leaving you with more damage to fix. Let’s look at the best – and worst – bets when it comes to fixing phone screen scratches.

A simple Google search for how to fix a scratched cell phone screen will yield several results, but the most interesting and common tip we’ve come across? Toothpaste.

Cheap and easy to find, toothpaste seems like a magic fix that’s too good to be true. Well, that’s because it is. Most tests reveal that using toothpaste results in a squeaky clean but still scratched screen. That is unless you’re trying to buff scratches out of a plastic screen protector or case, as many people do experience some success there.

With glass, however, that isnotthe case. In fact, you may even make your screen even more smudged, forcing you to use some elbow grease to get it out. (Particularly if you use something stronger like, say, AquaFresh.)

While it never hurts to try, just set your expectations low. If you’re feeling adventurous, use toothpaste like Colgate or Crest and not anything gel-related. Just apply the paste to the scratch with something soft like a cotton swab or cloth and rub it in.

Forget the delete key, rememberMagic Erasers? Back in the day, they were known to get rid of stains all around the house. But, surprise, they can actually eliminate phone screen scratches.

However, just remember that they remove them as long as the scratches are small and shallow. While deep abrasions are untouchable by the eraser, surface-level cosmetic scratches buff away pretty quickly. It never hurts to have one around, just in case.

Baking soda mixed with water is touted as a quick fix for phone screen scratches, but does it work? Thanks to its similarly abrasive nature, it turns out that this method is about the same as toothpaste as far as results go.

It’ll take care of marks decently enough on plastic covers and screen protectors, but definitely not glass. The Internet will tell you to make the baking soda mixture and then gently apply it to the screen, rubbing it in a circular motion. Afterward, you might notice that your screen is shinier, but chances are that the scratches will most likely remain. So unless you have a plastic screen, look elsewhere.

Depending on how deep the scratches are, this method is actually pretty effective. Products likeTurtle Wax,Meguiar’s Mirror Glaze Swirl Remover,3M Scratch Remover, and more can all help get rid of fine cuts on your phone screen. Just follow the instructions on your chosen product and imagine you’re buffing out the scratch your high school-ex left when they keyed your first car. (That’s not just us, right? Um, right?)

Another common fix touted all over the Internet is to use silver polish for your phone. I know what you’re thinking: If it can work wonders on my Nana’s heirloom silver, it’s obviously good enough for cell phone screen scratches. Right?

Wrong. Dead wrong.While products likeSilvo,Brasso, orWeimansilver polish can get tarnished metal shining like new again, it can do a number on your device. Not only is the method not proven to work, but it can also damage the coating on your screen, making the matter much worse. In this particular case, all that glitters is not silver.

Let’s be honest – sometimes home remedies can only do so much to fix your phone screen scratches. Want to bring out the big guns and spend a bit more money? Have your carrier or the phone’s manufacturer replace the screen altogether.

Apple offers repairs for $29 for cracked screens withAppleCare+(or up to $149 if you’re out of warranty). A third-party repair can be cheaper, or you could buy a kit online for around $60 to tackle shallow scratches. You get what you pay for here, and without having to pour some weird substance over the surface of your phone.

(One quick side note. Due to COVID restrictions, it may take you a little longer to take your phone into a Genius Bar for repair. If you have the option, send it in instead. Who knows, Apple may even send you a replacement in its place, depending on your coverage plans!)

If you don’t want to risk further phone screen scratches by using the above methods and you’d rather not spend the cash on having it professionally repaired, you can always cover scratches using a screen protector. While this won’t remove or reduce the visibility of deep scratches, it will help you avoid doing further damage to your phone. So it won’t fix the problem, but it’ll keep it from getting worse.

If you’re tired of looking at all the knicks and dings on your device’s phone screen and it’s time for an upgrade anyway, consider selling your phone to us here atGadgetGone.

GadgetGone will buy phones (plus other devices) in any condition for a good price. It’s easy to use, and we make sure you get what your phone is worth every time. Selling through GadgetGone is fast and straightforward, and you can get a quote in seconds. You ship your device for free, and once you receive and accept your updated offer, your cash is on its way to you fast.

We hope these methods (well, most of them, anyway) guide you in getting rid of those bothersome scratches. Now, as far as those dents in the Ford Mustang in the parking lot…you’re on your own.

Follow us onInstagram,Facebook,TikTokandTwitterfor more helpful tech tips, future special offers and behind-the-scenes GadgetGone goodness! (Plus, we have a dog!)

Many don’t realize that the electronics, devices, and items they own are built upon several internal components which work collaboratively to provide the necessary functionality and features they use. A mobile phone, for example, is more than just the casing, buttons, and display you see on the outside. Inside the device are several pieces that house and connect the necessary components. One of those core pieces is called a printed circuit board or PCB for short.

Printed circuit boards are the foundation of most electronics. By the end of 2018 alone, the global PCB product sales value is expected to reach 82 billion U.S. dollars. That should give you some idea of just how often PCBs are used in manufacturing.

Without them, many devices would simply cease to function entirely. In the event of a major failure or malfunction, it can cause some pretty serious issues. Circuit boards aren’t invulnerable either. Over time, they experience a great deal of wear and tear that can deteriorate their performance and functionality. Things such as the weather, humidity, age, and even elevation can affect the condition of a board.

Luckily, it’s possible to repair or remanufacture boards to make them like new again. This does one of two things. Either the board in question can be returned to its original device, making it function again. Or, it can be used in a completely different device, as a form of recycling if you will.

Of course, before any board can be repaired or reconditioned, engineers need to discern and understand why it failed in the first place. You can’t very well fix a problem if you don’t know what went wrong, can you?

It’s highly beneficial to know and identify some of the most common problems associated with PCBs, so that if and when a device does fail, you at least know what went wrong. We’re going to take a look at some of the most common printed circuit board problems, and explore ways in which they can be solved.

A printed circuit board or PCB is a core component of nearly all electronic devices. Everything except the simplest of electronics uses a board of some kind to connect and mechanically sync all elements of the product. A coffee maker, for instance, might have a small PCB inside to connect the electronic control system, heater element and display.

In the early days—way before design software was a thing—printed circuit boards were planned using Mylar sheets through manual hands-on development, and were often four times bigger than the circuit board itself. The designers would lay pin pads, traces and components out in a proposed design, which was used sort-of like a storyboard to test and explain circuits. Today, it’s all done via design and manufacturing software.

PCBs are mechanically necessary to support and connect all components within the device, which are synced using conductive tracks—this allows electricity to flow freely through the board and from component to component.

PCB components are soldered to the board, which electrically and mechanically fastens them to the overall circuit. Those “components” include things like the battery, resistors, LEDs, transistors, capacitors and more.

Boards are often produced in layers, which include various levels of conductive and non-conductive sheets. They can be one-sided with a single copper layer, two-sided with a double copper layer on both sides of a substrate layer, or multi-layer with differing layers of copper and substrate. It is worth mentioning that multi-layer boards provide a variety of benefits like an increased component density, however they are much harder to analyze, repair and modify.

It’s important to understand that circuit board repair parts and practices often consist of the same materials and components used to build the hardware in the first place. There are very few substitutes or alternatives, especially when talking about reliable and conductive materials. This highlights the need to find a proper, professional repair team with the right assets and connections.

PCBs are used in nearly every electronic device you may find, from smartphones and computers to televisions and vacuums. If a device requires an electrical connection to be passed through it to operate, it’s a safe bet that there’s some kind of circuit board inside, sometimes incredibly small and thin.

As technology has advanced over the years, so has the design and development of circuit boards allowing for smaller, more complex components, and thinner, less bulky boards. This makes the circuit board repair process particularly tricky because there are so many different types of varying sizes and design. You can’t go to just anyone to have a printed circuit board repair, modified or re-manufactured. It is crucial that you go to an authorized party who has both the experience and necessary gear to make it happen.

As with anything that deteriorates over time and extended use, printed circuit boards can run into a variety of problems. From trace damage which affects the conductivity of the board and circuit to component failure which sees capacitors or diodes dying, there are many points of contention on a circuit board.

It helps to identify and understand some of the most common PCB problems, that way you can deal with the problem in a relevant manner. This may also help people—who don’t have direct experience with circuit boards—keep them in better shape.

This is the more obvious choice when it pertains to the damage of a circuit board. In fact, the most common causes of PCB failures all stem from physical damage to a device or its internals. This can be just about anything pertaining to physical pressure or shock. The device in question might have been dropped from a great distance. Perhaps it was smacked or hit forcibly by another object? There’s also the possibility that the device was disassembled for whatever reason, and damage happened directly to the board.

So long as complete failure is not the scenario—the board fell upon the ground and shattered or broke completely—physical damage can be remedied through the remanufacturing process. Generally, this involves melting down the damage sections of the board or repairing through disassembly and reassembly. Due to the nature of most physical damage, it’s highly unlikely that this can be done as a DIY project by those without experience with printed circuit board repair. The repair of physical damage should only be done by a trained and experienced professional. In most cases, it calls for remodeling of the board, resoldering of components, and the reballing of conductive traces.

Aside from physical damage, faulty components are the other most common cause of printed circuit board problems. In fact, if and when there is no physical damage but a device has failed to operate or power on, you can almost guarantee it has to do with one of the components connected to the board.

The component itself could be anything from a capacitor to a diode or microprocessor. If the component is the issue and has died or failed to work, it may need to be replaced entirely. However, it’s not always the actual component that’s the problem. Sometimes due to aging, overheating and voltage sags the trace circuit may have deteriorated to a point where it’s no longer conductive. It’s also possible that a component—or several—have dislodged entirely from the board and need to be reseated.

You may be asking, how to fix a printed circuit board when a component fails? Again, the repair and remanufacturing process for faulty components is best left to professionals. There are voltage tools and various devices that can be used to test the conductivity of a board’s circuit. They can also be used to discern if there’s electricity flowing to a component, or if an element of the board has failed entirely. A lot of times, by just opening up the device you can see components that have failed. Their outer shell may seem burnt, cracked or broken, or the component is completely detached from the board and loose.

Traces on a circuit board are the conductive pathways comprised of silver or copper. Generally, you can see an issue with traces using the naked eye, but not always. If a trace suffers damage, whether through regular use or physical damage then it can cause significant issues with the printed circuit boards conductivity, components and the device in question.

Some of the more common reasons for trace damage include lightning strikes, severe power surges or shorts, metallic dust contamination, overheating and normal wear.

Provided the trace is not incredibly thin and difficult to see, you can usually discern damage simply by scanning the pathway. Copper and silver by nature are bright and shiny, which makes it easier to identify when there’s a break or damage. Keep in mind this is not always the case, but it’s a sure bet.

As much as we’d love to praise every single engineer or product developer in existence, that’s just not viable. Sometimes, for whatever reason, a team may cut corners when designing a board or manufacturing the necessary components. This can result in the poor design and construction of a board, which causes issues later down the line.

You’ll know as soon as you have a faulty or poor circuit board because your device will continue to fail time and time again, even after a repair or service session. The best solution for a shoddy circuit board is to replace it completely, by visiting an official or licensed repair center.

The easiest way to identify a poorly designed board is the number of failures or problems after extended use. Barring significant physical or electrical damage to the device, if you take the board to be repaired or analyzed somewhere and there are a handful of issues, there’s likely something wrong with the way the board was constructed. In some cases, this simply means the original manufacturer used cheap or unreliable components, but the board itself is fine.

In most cases, a power failure is remarkably similar to a component failure, it may even be one in the same. The ultimate issue stems from the fact that there was a major power failure to all or part of the board. One of the PCB components could have been exposed to higher voltages than normal, causing it to receive heat damage and explode. Or maybe there was a trace failure causing a short somewhere? Whatever the case, a power meter can be used to test each individual component and the general conductivity of the board.

All professional repair teams have a power or voltage meter that can be used to identify electrical issues with a board and its components. Voltage tools are really the only way to diagnose a problem outside of visible damage to a component. As for repair, the process is best left to professionals but generally involves reseating or replacing components.

There are several ways in which a printed circuit board can be repaired or serviced, with varying degrees of skill required. For the most part, however, anything to do with the internals of an electronic or device calls for knowledge of engineering and mechanics, and basic electrical circuits. For some of the larger devices on the market, you could seriously injure or even fatally wound yourself if you don’t know what you’re doing.

With traces and conductive pathways, you may need to coat, remove or replace the necessary material: be it copper or silver. Often, this relies on tools such as a soldering iron or heat gun.

For physical or visible damage to a board, base board repair is necessary. This may include melting down similar materials to reshape or modify the board, or can sometimes even call for complete disassembly.

For conductor and component repair, knowledge and skill of soldering, desoldering, BGA rework and pinpoint accuracy may all be necessary. If you’ve ever worked with or held a soldering iron before, it’s not so easy to retain a steady hand and spread the material evenly. You will want extensive experience with a soldering and desoldering iron, just to be sure the components and parts are seated properly to the board.

Of course, there are a variety of IPC and ICO standards necessary to follow for professionals, to ensure electronics and components are constructed and repaired using proper protocols. If you are not aware or don’t know enough about these standards, you may find yourself in hot water later.

An EMS, if you don’t know, is often a circuit board repair company that designs, manufactures, tests, distributes, and repairs electronic components and internal assemblies. They commonly service components and devices for OEMs or original equipment manufacturers. An OEM is the company that originally designed and owns the product in question.

As is to be expected, most repairs require the same materials—or improved materials—used in the official design of a board. It may call for copper or silver to be reseated to repair trace pathways. PCB substrates are often comprised of fiberglass or an epoxy resin with copper foil bonded to the conductive layer. They may also be comprised of reinforced phenolic resin, a more paper-like material that’s thinner than fiberglass.

The best service and repair teams can reassemble or fix a damaged board near enough to its original condition that there’s almost no difference in a previous version and the upgraded one. Certainly, this requires a great deal of finesse and experience that you won’t find outside of an experienced and professional setting.

An important part of researching and hiring a professional repair service is making sure they have the proper PCB repair materials and tools available to get the job done. Some service repair teams don’t have everything on property or on-site, which can balloon the time it takes to repair or reassemble parts. They have to wait to receive the requisite materials or tools.

It’s no secret that a lot of the materials used are not environmentally-friendly or conducive to safety. We’re a long ways off, but there are scientists and bleeding edge teams working on bio-degradeable PCBs that will break down naturally after being discarded.

For PCB repair and remanufacturing and industrial PCB repair service options you can’t do any better than EMSG Inc. (Electronic Manufacturing Services Group). We are well suited to handle board level and complete box build assemblies, including any custom packaging you may have created or utilized.

We have a highly advanced facilitywith the latest manufacturing and repair technologies, which allow us to be incredibly precise, yet efficient in our duties. This, coupled with our incredibly experienced personnel, modern equipment and great management team means we can be swift and reliable and get any repairs or development done within the schedule of your choosing.

At EMSG, our primary goal is to help you enter the market successfully, but also in a competitive, reliable setting. We understand every business is unique, and the design and specifications of their components entails personalized attention. We can and will afford you the absolute focus and dedication you need, to ensure any and all work exceeds your expectations.

We are highly confident that EMSG will play an integral role in the design and development of your product. The information presented here is merely scratching the surface of what’s necessary to conduct and perform a professional-grade repair and remanufacturing service. You can rest assured, we have the skills, experience and tools to get you to market as soon as possible.

If you’re interested in our manufacturing or repair services, please fill out this contact form and allow us to reach out to you. You can also give us a call, anytime, to speak to a company representative.

Unless the car you"re repairing is over 20 years old or was custom-painted, the paint is almost certainly a clear-coated catalyzed enamel. Artificially hardened by toxic chemicals, it"s stable within hours of factory application.

On the other hand, the paint you"re applying, whether it"s primer, color or clear, is a lacquer. Lacquers dry because the solvent evaporates, leaving the solids behind. While they may feel hard and be sandable within a few minutes, they will continue to shrink for a while. Allow lacquers to dry at least overnight so they can shrink before you add another coat. If you need multiple coats to build up the paint film to full thickness for a repair, one coat a day is best. Of course, be safe. The amounts of solvents used are small, but work in a well-ventilated area. Make sure to degrease the area with solvent before starting.

I often thought about that same question and if like other substances ( wood or metal ) if you start out with a heavier grit and work to super super fine polishing paste if that would work, of course I"ve never tried it on my camera ,, and dont know that I would LOL

I often thought about that same question and if like other substances ( wood or metal ) if you start out with a heavier grit and work to super super fine polishing paste if that would work, of course I"ve never tried it on my camera ,, and dont know that I would LOLYes they are made out of glass most of the time. The problem is the glass is micro in that it is very thin. But you are right that you have to use various grits of abrasives to polish it out, the problem is that the glass is too thin for that type of repair. That and it takes about six grades of abrasive to do it. Now what you might try if it bothers you that much is some clear nail polish. You take a toothpick and get a small drop on it and put it in the scratch. All this will do is get rid of the whiteness of the scratch. Also do not go over board, use only enough to fill the scratch. I have the GGS screen protector over mine, so if you do choose the clear NP method you might think about one of those to protect it. I am on my third one of those, well I actually nned to replace this one as well. It had an unfortunate collision with a rock while I was climbing.

There"s also a product available for restoring headlights, although I forget it"s name right now. It"s a liquid that you might be able to use on the display without damage.

There"s also a product available for restoring headlights, although I forget it"s name right now. It"s a liquid that you might be able to use on the display without damage.

There"s also a product available for restoring headlights, although I forget it"s name right now. It"s a liquid that you might be able to use on the display without damage.

You talking about the one that mounts on cordless drill?I have two different kits. One uses a small buffing pad that goes on a drill, the other is a series of pads (of varying grit) that you use manually. A friend from a body shop says they use a manual method.

By continuing to use AliExpress you accept our use of cookies (view more on our Privacy Policy). You can adjust your Cookie Preferences at the bottom of this page.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey