stm32 tft display project pricelist

Worldwide,Asia,Europe,Africa,North America,South America,Oceania,Afghanistan,Bahrain,Bangladesh,Bhutan,Brunei,Burma (Myanmar),Cambodia,China,East Timor,India,Indonesia,Iraq,Japan,Jordan,Kazakhstan,Kuwait,Kyrgyzstan,Laos,Malaysia,Maldives,Mongolia,Nepal,Oman,Pakistan,Philippines,Qatar,Russian Federation,Saudi Arabia,Singapore,South Korea,Sri Lanka,Taiwan,Tajikistan,Thailand,Turkmenistan,United Arab Emirates,Uzbekistan,Vietnam,Yemen,Albania,Andorra,Armenia,Austria,Azerbaijan,Belarus,Belgium,Bosnia and Herzegovina,Bulgaria,Croatia,Cyprus,Czech Republic,Denmark,Estonia,Finland,France,Georgia,Germany,Greece,Hungary,Iceland,Ireland,Israel,Italy,Latvia,Liechtenstein,Lithuania,Luxembourg,Macedonia,Malta,Moldova,Monaco,Montenegro,Netherlands,Norway,Poland,Portugal,Romania,San Marino,Serbia,Slovakia,Slovenia,Spain,Sweden,Switzerland,Turkey,Ukraine,United Kingdom,Vatican City,Algeria,Angola,Benin,Botswana,Burkina,Burundi,Cameroon,Cape Verde,Central African Republic,Chad,Comoros,Democratic Republic of Congo,Djibouti,Egypt,Equatorial Guinea,Eritrea,Ethiopia,Gabon,Gambia,Ghana,Guinea,Guinea-Bissau,Ivory Coast,Kenya,Lesotho,Liberia,Libya,Madagascar,Malawi,Mali,Mauritania,Mauritius,Morocco,Mozambique,Namibia,Niger,Nigeria,Rwanda,Sao Tome and Principe,Senegal,Seychelles,Sierra Leone,Somalia,South Africa,Swaziland,Tanzania,Togo,Tunisia,Uganda,Zambia,Zimbabwe,Antigua and Barbuda,Bahamas,Barbados,Belize,Canada,Costa Rica,Dominica,Dominican Republic,El Salvador,Grenada,Guatemala,Haiti,Honduras,Jamaica,Mexico,Nicaragua,Panama,Saint Kitts and Nevis,Saint Lucia,Saint Vincent and the Grenadines,Trinidad and Tobago,United States,Argentina,Bolivia,Brazil,Chile,Colombia,Ecuador,Guyana,Paraguay,Peru,Suriname,Uruguay,Venezuela,Australia,Fiji,Kiribati,Marshall Islands,Micronesia,Nauru,New Zealand,Palau,Papua New Guinea,Samoa,Solomon Islands,Tonga,Tuvalu,Vanuatu Active TouchGFX advanced and free of charge graphical framework optimized for STM32 microcontrollers STM32Cube Expansion Packages ST X-CUBE-TOUCHGFX

ST cooperates with Riverdi because we believe that such partnership brings value to our joint customers. On top of this, we also discovered that we shared some business visions about how to make it easier and faster to go from the initial stages of designing a product embedding a graphical user interface to a production ready product. The conclusion was that combining the STM32 High performance microcontrollers, with the free STM32 graphics toolchain and Riverdi displays + PCB and then merge all of this into a board support package ready to run TouchGFX, would be a compelling offering.

Designing and developing a product with an embedded user interface (GUI), can be complex, as it involves many building block and disciplines, which all requires expert knowledge. Riverdi offer is covering a lot of them, allowing the customer to focus on the most important part of the development, the GUI Application itself. And remember that this is the face of your product. Choosing such solution, the customer does not need to worry about sourcing components like the display, microcontrollers, memory, etc. or even writing low-level drivers, development the board support package or porting TouchGFX. Its all ready done. What makes cooperation with Riverdi unique is that Riverdi has been able to drive a 1280*800 display resolution in high colors, with a STM32H7 microcontroller and a TouchGFX application showing a smart home UI. This shows that Riverdi is well aware of how to exploit all the capabilities of the STM32 Graphics offering combining hardware and software in a unique solution. From the first business meetings, it was clear that we shared visions of the market for embedded GUIs. And Riverdi proved that they can go from an idea and concept to actual working hardware, very fast.

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big (5" diagonal) bright (18 white-LED backlight) and colorful 800x480 pixels with individual pixel control. As a bonus, this display has a capacitive touch panel attached on screen by default.

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Spice up your Arduino project with a beautiful large touchscreen display shield with built in MicroSD card connection. This TFT display is big (5" diagonal) bright (12 white-LED backlight) and colorfu 800x480 pixels with individual pixel control. As a bonus, this display has a optional resistive or capacitive touch panel with controller, attached by default

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

Microtips also provides value-added services to all its clients. The company’s Electronic Manufacturing Services team gives product suggestions and shares insights on how clients can successfully manage their projects.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

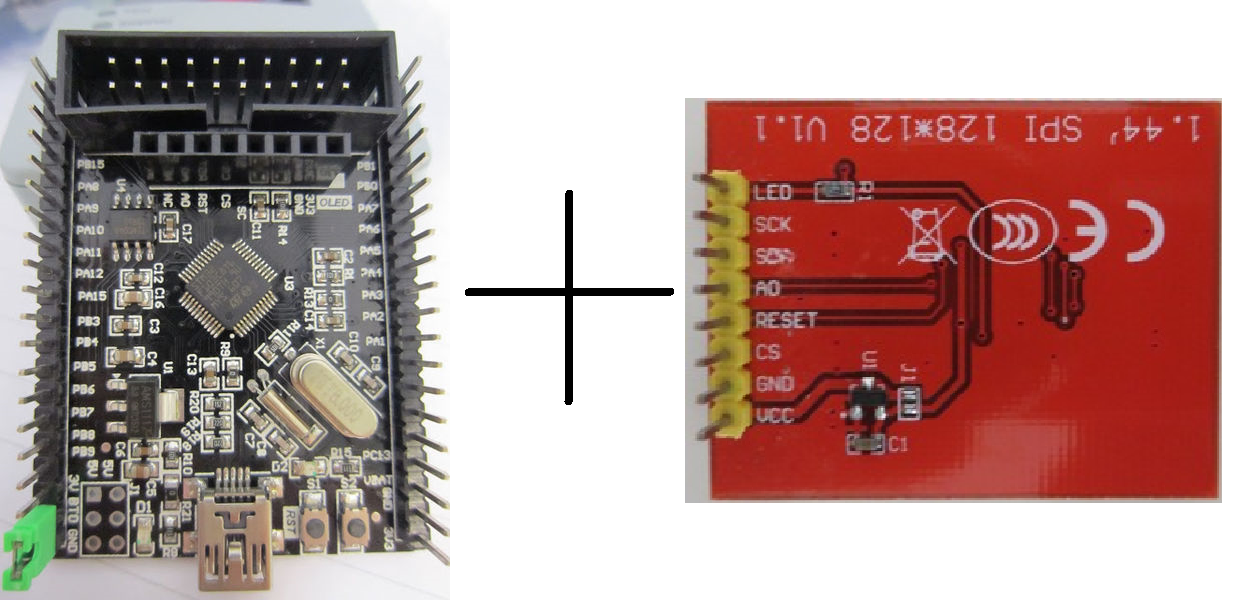

In this guide we’re going to show you how you can use the 1.8 TFT display with the Arduino. You’ll learn how to wire the display, write text, draw shapes and display images on the screen.

The 1.8 TFT is a colorful display with 128 x 160 color pixels. The display can load images from an SD card – it has an SD card slot at the back. The following figure shows the screen front and back view.

This module uses SPI communication – see the wiring below . To control the display we’ll use the TFT library, which is already included with Arduino IDE 1.0.5 and later.

The TFT display communicates with the Arduino via SPI communication, so you need to include the SPI library on your code. We also use the TFT library to write and draw on the display.

In which “Hello, World!” is the text you want to display and the (x, y) coordinate is the location where you want to start display text on the screen.

The 1.8 TFT display can load images from the SD card. To read from the SD card you use the SD library, already included in the Arduino IDE software. Follow the next steps to display an image on the display:

Note: some people find issues with this display when trying to read from the SD card. We don’t know why that happens. In fact, we tested a couple of times and it worked well, and then, when we were about to record to show you the final result, the display didn’t recognized the SD card anymore – we’re not sure if it’s a problem with the SD card holder that doesn’t establish a proper connection with the SD card. However, we are sure these instructions work, because we’ve tested them.

In this guide we’ve shown you how to use the 1.8 TFT display with the Arduino: display text, draw shapes and display images. You can easily add a nice visual interface to your projects using this display.

I don"t actually have a display at present. I purchased a 7in one some months ago. It had an LT7381 controller and was supplied with a Hunda LT7381 library for Arduino and some basic display design software. However, I couldn"t get the hardware to work despite it being described as Arduino compatible. As it turned out, it also didn"t display anything when used with the supplied USB adaptor and design software for the PC, so it may have been faulty anyway. I posted something at the time but the controller is quite new and there was not much feedback. I ended up sending it back and getting a refund although it still cost me to send it back to china.

The reason I posted was because the project is now at the stage where the LCD display really needs to be added and I intended to get advice before making another purchase. In the meantime I have been working on the project using a 20x4 display.

Thank you for that information. Since I am using an ESP8266, it sounds like I need to look for a board that uses SPI for the display. From what I can tell, it seems that some of the cheap ones from china only use SPI only for the SD card which further confuses things.

I don"t posses an Arduino shield which is why I was trying to ascertain whether I need something like that. What is their purpose? A lot of photos show the display plugged into one and then into typically a Mega 2560. I don"t understand what the purpose of the shield is? Is it just a convenient way to provide a means of fitting the board to an Arduino with level shifting? SPI needs only 4 wires. Can"t these be connected directly to the ESP SPI pins?

Displays have over time, emerged as one of the best ways to drive user interactions on any device. They make it easy to collect inputs and present information (outputs) to users in a graphical, easy to understand format. This usefulness has led to improvements in their quality, with improved resolution and low power features, but almost little has changed when it comes to the complexity of creating beautiful user interfaces for them. This is why the team at STONE Tech created the STVC035WT-01 intelligent Smart display which we will explore for today’s tutorial.

The STONE STVC035WT-01 display is a 16-bit, 3.5″ display with a 320×480 (RGB) resolution, has a 49.0 x 73.4mm viewing area, and pixel spacing of 0.1905mm×0.0635mm (H×V). The display is a Class A industry Panel with an Industry level 4 wire resistance based touch screen, all layered on an integrated CPU, driver, and flash memory with several communication interfaces to enable it to connect to data sources like microcontrollers. For communication with a microcontroller, the display supports serial communication protocols likeUART/TTL, RS232, and RS485, ensuring it can communicate with any kind of microcontroller or industrial computers. The UART/TTL pin on the Display supports both 3.3v/5v logic level which adds another layer of ease to the use of the display as users need not worry about the need for logic level shifters when building using a microcontroller that operates on either of the voltage level mentioned.

One of the major benefits of using this display is its compatibility with the STONE TOOL GUI Designer which allows the development of User Interfaces in a fast and easy manner.

To demonstrate the capabilities of the display, we will build a heart rate monitor using an Arduino Uno with the MAX30100 pulse oximetry and heart rate sensor. The Arduino will serve as the brain of the project and perform the simple task of obtaining the heart rate and blood oxygen data from the MAX30100, displaying it on the screen.

At the end of this tutorial, you would know how to interface Arduino boards with the STONETech displays, and also how to interface sensors like the MAX30100 with the Arduino.

Our development process for today’s project will follow this outline. We will first create the GUI for the project after which we will proceed to write the firmware to interface the microcontroller with the display.

As mentioned during the introduction, today’s tutorial will focus on creating a heart rate and Oxygen-level monitoring system using the display and to get things started, we create the GUI image (shown below) using Photoshop.

The design is quite simple, we illustrate label elements to hold the date, the project title, and the values from the microcontroller. The values from the microcontroller include; the status of the connection between the microcontroller and the display, the heart rate, and the oxygen levels.

1. With the software downloaded on your computer, launch it and go to File>New Project. This will launch the “New Project dialog box ” where you will be expected to fill in the details of your display, set the storage path, and the name of your project. Since we will use the STVC035WT-01 display which has a resolution of 320*480 and a default flash space size of 128Mbyte (expandable to 1024MByte), I have entered its details as shown in the image below. If you are using any of the other StoneTech displays, you will need to enter the details of that display instead.

2. Next, on the left side of your screen, you will see the project tree (under the project window) with its assets. Expand the Picture file, and delete the 0.jpg image inside it by right-clicking on it, and selecting “Remove”. For every new project, the 0.jpg file is always created as the default background for your UI, since we will use our background (the one we designed with photoshop), we can delete it.

4. Next, we add fonts to the project’s assets to determine how texts appear on the display. Right-click the “Font” file, and select the appropriate font to add to the project. For this tutorial, we will use the ASCII 24 by 48 font. With that done we are now ready to begin adding the GUI elements.

5. We will only use the “Text Display” GUI element since the display is only meant to display data from the MAX30100. The text display elements are capable of holding texts that can be changed programmatically by updating the data stored in their memory addresses. Add text displays on the lines as highlighted in the image below. Also, create a text display for the day-time section at the top of the display image to help users note the date/time each reading was observed.

6. Next, we set the properties of the text displays especially their memory addresses. The properties of each GUI element will be available on the right-hand side of your PC screen after clicking on the element. Note the memory address down as it will play an important role later.

7. With all of these done, we compile the GUI and upload it to the screen. To do this, click on button 1 in the image below to Compile the GUI design and click on button 2 to upload the GUI to your display.

Uploading the GUI display requires you either connect the display directly to your computer or you put the GUI on a flash drive and plug the flash drive into the USB port of the display. Because of the little complexity associated with the second option, we will be going with it.

Plug the USB flash drive into the computer then click the “Download to u-disk” button on the STONE GUI TOOL.With the “download to u-disk” process complete, pull out the USB flash disk, insert it into the USB interface of the display module and wait for the completion of the upgrade. When the upgrade is completed, there will be a prompt sound.

The model of the STONE display being used for this tutorial communicates via RS232, as such, to be able to interface the display with the Arduino, we have to connect it through a MAX3232 chip. This extra requirement can be avoided by using one of the STONE displays with a TTL interface.

Due to the simplicity embedded in the design of STONETECH displays, the microcontroller’s interaction with any of the GUI components is usually via the “memory address” of each component. for instance, to send a message to the display from the microcontroller (the Arduino in this case), the message has to be published to the memory address of the GUI Component (in this case, the text-display component). The same holds for GUI Components that are meant to send data to the microcontroller, as the microcontroller has to poll their memory address to obtain information from them. As a result of these, we need to obtain the memory address of all the GUI components before proceeding. For each GUI component, the memory address is usually listed among the properties of the component, under the property toolbar, at the right-hand side of the STONE TOOL interface.

With this obtained, we can now proceed to write the code for the project. One of the good things about using the STONETech displays is the fact that you don’t need a library to write code for them because of their simplicity, but since we will use serial communication, we will use the software serial library to avoid having to use the hardware serial port on the Arduino Uno. To interface with the MAX30100, we will also need to install the MAX30100 library. The Max30100 library can be installed using the Arduino Library Manager or by downloading it from the attached link and installing manually by extracting the file, copying its content and pasting it in the Arduino libraries folder. The software serial library comes pre-installed with the Arduino IDE.

Next, we initialize the MAX30100 and send the status of the initialization to the display. If the initialization fails, 0x00 meaning 0 is sent to the display, but if successful, 0x01 meaning 1 is sent to it.

We start the void loop() function by calling for updated readings, after which we check if the reporting period has elapsed. If the reporting period has elapsed, it means we need to take new measurements, so we call the pox.getHeartRate and pox.getSp02 commands to get new heart rate and oxygen levels. These new readings are displayed on the serial monitor and also sent to the display.

With the code complete, connect your Arduino board to your computer and upload the code to your setup. Place a finger on the Max30100 and after a while, you should see the live pulse rate and oxygen levels appear on the display as shown in the image below.

While this project only demonstrates less than 35% of the capabilities of the STONE TECH display, it provides a good foundation for you to build amazing projects. As an engineer, the key benefit of the display to me is the ease of use both in the creation of the GUI and also the development of the code to tie it together with a microcontroller. The fact that the display doesn’t require any library makes it perfect for use with any language and any microcontroller with serial port access.

The quality, size ανδ variety of the STONE TECH displays makes them perfect for HMI Applications and one of my next projects will be a Home Automation Panel using one of the STONETECH displays.

The LCD I am using is a 2.8″ TFT LCD with SPI communication. I also have another 16-bit Parallel TFT LCD but it will be another story for another time. For this post, let’s focus on how to display what you want on the 2.8″ LCD. You can find all details about this LCD from this page:http://www.lcdwiki.com/2.8inch_SPI_Module_ILI9341_SKU:MSP2807

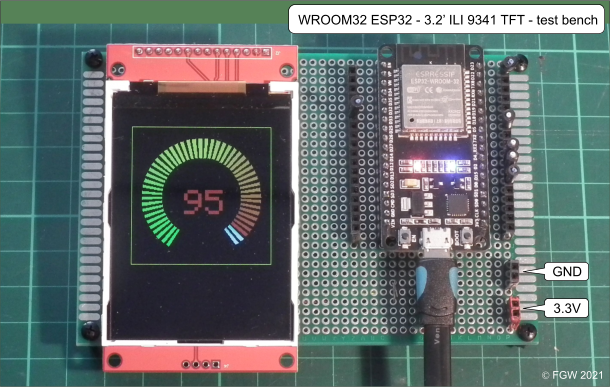

First thing first, this LCD use SPI as the main communication protocol with your MCU. For STM32 users, HAL Library has already implemented this protocol which makes this project easier for us. But, a little knowledge about this protocol does not hurt anyone. SPI is short for Serial Peripheral Interface which, aside from two data lines, also has a clock line and select lines to choose between devices you want to communicate with.

This LCD uses ILI9341 as a single-chip SOC driver for a display with a resolution of 240×320. More details can be found in the official document of ILI9341. But the most important thing is that we have to establish astart sequencein order for this LCD to work. The “start sequence” includes many other sequences which are also defined in the datasheet. Each sequence starts when you send a command to ILI9341 and then some parameters to follow up. This sequence is applied for all communication between MCU and ILI9341.

For this project, I recommend using theSystem Workbench for STM32for coding and building the code. After installing and open the program, go to the source code you have just downloaded and double click the.cprojectfile. It will automatically be open in your IDE. Then build the program by right click on the folder you just open (TFTLCD) and chooseBuild Project. Wait for it to finish and upload it to the board by right clicking the folder, choose Run As and then clickAc6 STM32C/C++ Application. And that’s it for running the example.

The most important library for this project is obviously the ILI9341_Driver. This driver is built from the provided source code in the lcdwiki.com page. I only choose the part that we need to use the most in many applications like writing string, displaying image and drawing symbols. Another library from the wiki page is the TOUCH library. Most of the libraries I got from the Internet were not working properly due to some adjustments to the original one.

To draw symbols or even display images, we need a “byte array” of that image or symbol. As an illustration, to display an image from a game called Transistor, I have a “byte array” of that image stored in a file named transistor.h. You can find this file in the link below. Then, I draw each pixel from the image to the LCD by adding the code in the Display_Picture() function in the Display folder.void Display_Picture()

The above example is just only for displaying black and white image. In order to show a color image, we need to a little bit different. First, go tothis websiteto generate the array of the colour image. Remember to change your size to 320×240 and choose the 65K color option. Because it now takes up two bytes for one pixel, we need to send two bytes at once. You can check the Display_Color_Picture() function in the Display folder.void Display_Color_Picture()

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey