stm32 tft display project quotation

Worldwide,Asia,Europe,Africa,North America,South America,Oceania,Afghanistan,Bahrain,Bangladesh,Bhutan,Brunei,Burma (Myanmar),Cambodia,China,East Timor,India,Indonesia,Iraq,Japan,Jordan,Kazakhstan,Kuwait,Kyrgyzstan,Laos,Malaysia,Maldives,Mongolia,Nepal,Oman,Pakistan,Philippines,Qatar,Russian Federation,Saudi Arabia,Singapore,South Korea,Sri Lanka,Taiwan,Tajikistan,Thailand,Turkmenistan,United Arab Emirates,Uzbekistan,Vietnam,Yemen,Albania,Andorra,Armenia,Austria,Azerbaijan,Belarus,Belgium,Bosnia and Herzegovina,Bulgaria,Croatia,Cyprus,Czech Republic,Denmark,Estonia,Finland,France,Georgia,Germany,Greece,Hungary,Iceland,Ireland,Israel,Italy,Latvia,Liechtenstein,Lithuania,Luxembourg,Macedonia,Malta,Moldova,Monaco,Montenegro,Netherlands,Norway,Poland,Portugal,Romania,San Marino,Serbia,Slovakia,Slovenia,Spain,Sweden,Switzerland,Turkey,Ukraine,United Kingdom,Vatican City,Algeria,Angola,Benin,Botswana,Burkina,Burundi,Cameroon,Cape Verde,Central African Republic,Chad,Comoros,Democratic Republic of Congo,Djibouti,Egypt,Equatorial Guinea,Eritrea,Ethiopia,Gabon,Gambia,Ghana,Guinea,Guinea-Bissau,Ivory Coast,Kenya,Lesotho,Liberia,Libya,Madagascar,Malawi,Mali,Mauritania,Mauritius,Morocco,Mozambique,Namibia,Niger,Nigeria,Rwanda,Sao Tome and Principe,Senegal,Seychelles,Sierra Leone,Somalia,South Africa,Swaziland,Tanzania,Togo,Tunisia,Uganda,Zambia,Zimbabwe,Antigua and Barbuda,Bahamas,Barbados,Belize,Canada,Costa Rica,Dominica,Dominican Republic,El Salvador,Grenada,Guatemala,Haiti,Honduras,Jamaica,Mexico,Nicaragua,Panama,Saint Kitts and Nevis,Saint Lucia,Saint Vincent and the Grenadines,Trinidad and Tobago,United States,Argentina,Bolivia,Brazil,Chile,Colombia,Ecuador,Guyana,Paraguay,Peru,Suriname,Uruguay,Venezuela,Australia,Fiji,Kiribati,Marshall Islands,Micronesia,Nauru,New Zealand,Palau,Papua New Guinea,Samoa,Solomon Islands,Tonga,Tuvalu,Vanuatu Active TouchGFX advanced and free of charge graphical framework optimized for STM32 microcontrollers STM32Cube Expansion Packages ST X-CUBE-TOUCHGFX

The main component of Me TFT LCD Screen module is a LCD display communicating with Makeblock Orion through serial port to show characters and graphics of different size and colors. The module is integrated with MCU and memory chip, and the Chinese characters, letters, and figures stored in the memory chip can be invoked easily through the serial port. Its blue/gray ID means that it has a double-digital signal port and needs to be connected to the port with blue or gray ID on Makeblock Orion.

Since the port of Me TFT LCD Screen has blue/gray ID, you need to connect the port with blue or gray ID on Makeblock Orion when using RJ25 port. Taking Makeblock Orion as example, you can connect to ports No. 5 as follows:

If you use Arduino to write a program, the library Makeblock-Library-master should be invoked to control the Me TFT LCD Screen. This program serves to display different graphics and characters through Arduino programming.

This module (Me TFT LCD Screen – 2.2 Inch) contains a voltage converter, an STM32 chip, and a serial flash memory of 2M. In contrast with other displays, it needs only serial port for communication, so it is easy to operate and connect.

A special serial port assistant is provided to help you set the baud rate of transmission, and store the processed pictures you want to display into the flash memory so as to implement the display or switch of boot pictures in your own project. To download pictures, you need other serial port for conversion. In addition, it also supports superposition of background pictures and the letters, and GUI display. Its applications include the calendar, voltage meter, ampere meter, etc.

![]()

This is a third release of combined soldering iron controller for Hakko T12 tips and 858D rework station based on STM32 micro controller. This time the oled display was replaced by ili9341 TFT one with SPI interface. There are several display variants (2.2", 2.4", 2.8" or 3.2") in the market, so you can chose the one that satisfies your requirements, I used 2.2" display. The touch screen feature is not used in this project, but you can use display with touch screen panel.

The soldering controller supports using soldering iron and Hot Air Gun at the same time. In the main mode, you can activate any device or activate both devices simultaneously or turn them off. As soosn as the display resolution is higher than oled display, the information of both devices can be displayed on the main screen.

Before updating the firmware, save the PID parameters if you have modified them. The landscape orientation is still the default. Some issues can be faced in the portrait display mode. Report them to be fixed.

This project has several features:The controller allows managing Hot Air Gun and soldering iron independently. Two independednt rotary encoders simplifies this type of managing devices. The reed switch of the Hakko 858D Hot Air Gun handle used to activate rework capability.

To decrease the controller price and increase its reusability, the complete schematics was split in 3 separate PCBs. The main PCB conntains the main low-voltage components: stm32 blackpill board, op-amps, voltage dc-dc converter and regulator, mosfets that manage the soldering iron and Hot Air Gun fan. The AC power PCB contains the high-voltage part of the project: the triac, optional high-voltage relay and opto-couplers that creates galvanic isolation from the main board. These boards connected via 5-wire interface cable. The display PCB contains the TFT display and two rotary encoders.

JP11 is a optional DIP-type connector for SD-card reader on the TFT display. This connector is used to load external files to the SPI flash memory IC. Just solder the pin-header here.

Thehigh-voltage pcb is also available in EasyEdasite. The schematics contains the TRIAC and opto-coipler modules allowing to isolate the board from low-voltage part of the project.

The schematics of the board is very simple. It contains two rotary encoders and TFT display. Also, you can see the mosfet that manages the TFT display brightness.

The controller requires big size PCB to fit all the components so it is convenient to create the display separate board. Also, It is convenient to solder rotary encoders to the display board and use encoder neck to fix this board on the acrylic front panel.

This controller is working with ili9341 based TFT displays only. You can select the display size (2.2", 2.4", 2.8" or 3.2"). The display has sufficient resolution 320x240 to show required information. I used the 2.2" one to fit the case.

This feature increases the safety of soldering iron. There are two automatic power-off features are implemented inside the controller, software driven and hardware driven. The hardware driven one requires optional TILT or REED switch installed in the iron handle. In the software mode, the controller turns on the Idle mode if the supplied power to the iron is stable for a while. In this case, the controller will power off the iron in specified timeout. When the time to automatic shutdown near, it will be displayed as a seconds remaining. When you use the iron, the supplied power changes and the controller resets the automatic power off timeout.

To use the hardware TILT switch, you must setup automatic power off timeout and standby temperature. If the standby temperature is "OFF" the hardware tilt switch will not be used and software solution described previously will be activated. Also, you can setup standby time (timeout to switch to low power mode). When the tilt switch enabled, the main working mode changes the following way. The iron is starting heating. When it reaches the preset temperature the "Ready" message will be displayed and the controller will keep the preset temperature. If the soldering IRON is not used (laying on the table) the controller will switch low power mode. If the iron keep laying for automatic off timeout, the controller will switch off the power completely. As soon as you start using the iron, the controller restores the preset temperature.

The main component is the BlackPill board. You can use the pure STM32F401CCU6 micro controller if you wish to create compact variant of the soldering station.

Connect this DC-DC converter consequently with b0505 isolated cobverter: 24v -> MP1584 DC-DC converter -> b0505 -> ams1117 gnd you get isolated power supply for your stm32 micro controller. This king of power supply is isolated and low-noise power that ensure accurate ADC temperature readings.

This project is based on the BlackPill board with STM32F401CCU6 micro controller. To flash prebuilt firmware to the controller the st link v2 programmer and ST link utility are required.

Download the STM32 ST-LINK utility fromstsite. Install the utility in your system. Launch the ST-LINK utility, connect the programmer to the 4pins SWD interface of BlackPill board, press "connect" button. The main window should display the memory content of the BlackPill board. Press flash button to write the firmaware to the BlackPill board.

As you can see, the main AC power after fuse that can be installed on the pannel of the case, goes into JP3 socket on the high voltage board. You can connect main power switch to the JP6 socket or short it oins and completely remove main switch if do not like to use it. JP4 and JP2 sockets are used to connect to the GX16-8 connector of the Hot Air Gun. The power to the heater goes from JP4 socket and all other wires connected to the JP2. Earth ground should be connected to the Earth ground of AC power (not shown here). JP8 and JP9 connectors should be connected together. Soldering Iron GX12-5 connector should be connected to JP1 and JP5 sockets. JP10 used to connect optional automatic mode switch. Using this switch you can disconnect the Hot Air Gun completely from the controller when it is not needed. JP3 should be connected to the J1 connector on the TFT board. This is 14-wires connector to attach the display and rotary encoders.

Using JP11 you can connect the SD-CARD installed on TFT display to the controller when going to upload some files from SD-CARD to SPI FLASH. For instance, it can be used whel upload localization data files.

To simplify controller tuning procedure, the tune modes are implemented in the controller. This modes can be activated from the system menu item "tune iron" or "gun menu->tune gun". When the tune mode is activated, the controller powers on the iron or Hot Air Gun and displays on the screen applied power (in percents) and the gauge of the current temperature readings. The gauge has a label "450" or "500" depending on what hardware you are tuning. When the gauge reaches this label, the temperature should be 450 or 500 degrees of Celsius.

As soon as you have stabilized the iron temperature near 450 degrees, rotate the 500k potentiometer trim to shift gauge bar on the display left or right. Adjust the potentiometer so the bar would be as near to the reference temperature as possible. Then long press the encoder handle (for about 2 seconds) to turn the iron off and finish the procedure. It is recommended to use the thick tip that produce the highest voltage when performing the tune procedure. For example, T12-K, T12-D52 or similar.

As you can see from the picture above, the debug screen shows the following information:iron status (off or on). You can manage the power supplied to the soldering iron by rotating the upper encoder. As the encoder rotated, you adjust the power supplied to the iron (in internal units). The more power supplied to the iron the faster it heats. Supplied power value displayied in the right column ("irnP") in the internal units.

If the SPI FLASH is formatted and working correctly, you should see the screen above. As you can see, it is the root directory list of SPI FLASH. In case of FLASH error, the error message would be displayed indicating the FLASH is not readable. If your SPI FLASH is unformatted, the corresponding message would be displayed and the controller asks you to confirm the FLASH should be formatted. When the FLASH will be formatted, you should see the empty file list.

The current tip can be calibrated using "calibrate tip" menu item. If the tip is not calibrated yet, the "[!]" sign would be displayed near the tip name on the main screen. There are two calibration modes in the current version of the controller firmware: automatic and manual.

The progress bar in the lower part of the display shows the difference between preset and current temperature (in internal units) of the tip. The controller keeps the tip temperature near the preset value (vertical line on the progress bar) all the time. To increment the preset temperature, turn the encoder right, to decrease - turn it left.

When the low power (standby) mode activated, the controller shows the "standby" icon in the upper-right corner of the display lie shown on the picture below.

The "tune iron PID" and "gun setup->tune gun PID" menu items in the main menu allowing tuning PID parameters of soldering iron and Hot Air Gun. When tune PID mode activated, you can see three values of PID parameters on the display, Kp - proportional, Ki - integral, Kd - differential. First, choose the parameter you are going to change and press the encoder button. You turn into tuning test mode. There are two graphs: the temperature difference and power math dispersion. Both graphs are auto magnifying ones and its maximum value is shown on the Y-axis by the corresponding color.

Prebuilt version of the controller software can be downloaded from the github repository. To upload this hex file into controller, you can use stm32 st-linkutility.

My firiend Armindo translated all messages to Portugeese, so the project hast two additional languages: Russian and Portugeese. The binary font ubuntu_we.font contains ASCII and Western Europe characters including Greek symbols. You can use this font for your language if you are speaking on one of the european language. To do this, you have to add new line tocfg.jsonfile and create new message file.

In order to use your native language, the NLS data should be uploaded into SPI FLASH. To do so, you have to:Connect your SD-CARD reader (the TFT display board has one) to the JP11 connector via 4 wires: SD_CS (Chip Select), MOSI, MISO, SCK. If you have not implemet the JP11 socket, remember following: SD_CS (Chip Select) - PB12, MOSI - PB15, MISO - PB14, SCK - PB10.

1. After the program is downloaded, run it directly and observe the running status. If it can be displayed normally, the program runs successfully, as shown in the following figure (take the colligate_test test program as an example):For more technical resources please contact us please !

I am working on STM32F103ZT6 and with SSD1963. I have connected 480X272 and 320X240 LCD’s. I am initializing SSD1963 with the Init Commands on same pins as you use, but in GPIO mode & not in FSMC mode. The Clock Freq from Crystal is 8MHz and in STM32 acitvating PLL is made to 72MHz. So, Clk Freq for SSD1963 is 8MHz. Hope we should configure the PLL in SSD1963. So below is my Initialisation Sequence details.

1. After the program is downloaded, run it directly and observe the running status. If it can be displayed normally, the program runs successfully, as shown in the following figure (take the colligate_test test program as an example):For more technical resources please contact us please !

QuoteRecommended price is about $20 and its a perfect toy to learn some adult COrtex M4F microcontroller. With that 20 dollars or so you get the processor, SDRAM, TFT display and mainly a free programmer/debugger which is not locked to the kit or any specific MCU. You can use it with whatever MCU from ST you like without limitations. That"s imho quite friendly, unlike other vendors. You will have a lot of fun with that kit.

VERY cheap price for the features! does this kit drive the TFT directly (using the MCU itself interfaced with SRAM...) or does it use a drive chip? I will definitely get this board! the renesas one is great and has 2 great books to support it, but it is 99$. does this kit or mcu family has any book to learn from? As I wrote before, I must learn ARM based MCUs first.

Pay once and never worry about it again. Once you buy Visual TFT you are entitled to a lifetime of free upgrades. Upgrading the software takes only a few minutes and a few clicks. We are constantly adding new features, and you can keep track of what is happening on the Software Roadmap page.

The Visual TFT currently supports 17 graphics controllers from leading manufacturers. You can be a part of the process by letting us know what graphics controllers you wish to see supported next, by using our helpdesk and submitting a ticket.

Visual TFT supports a total of 17 TFT controllers and many different display sizes, from 131x131 to 800x600 pixels. The most popular ones are the 320x240 TFT displays running on ILI9341controller. This display is found in many embedded devices worldwide. All MikroElektronika multimedia boards have this display integrated, so you’ll have all the hardware you need to get started. You can also order TFT displays separately from MikroElektronika’s online store.

Visual TFT also supports FTDI chip™ - the latest EVE GUI Platform and FT8x and FT81x families of graphics controllers. These powerful devices allow for sophisticated forms of human-machine interaction and more satisfying user experiences, including video playback. EVE integrates display, audio and touch onto a low cost, easy-to-use, single-chip solution. The EVE family has an object-based structure (where objects can be images, fonts, etc). This offers you an easy way to design more effective GUIs for TFTs, with all the display, audio and touch functionality included. Visual TFT is the first software in the world to provide full support for many of EVE’s powerful features like sound, transparency and anti-aliasing fonts. There are many new components available for GUI design, which are natively supported in the controller itself.

Visual TFT supports all our development and multimedia boards, so you will find all the hardware you could possibly need in one place. Each board has a hardware pattern, a configuration template with hardware connections for TFT and touch screen, and you can do all necessary settings with a single click.

Three major compiler groups are currently supported: mikroC, mikroBasic and mikroPascal for PIC, dsPIC, PIC32, AVR, ARM and FT90x. This means that no matter what compiler you will write your project in, source code generated by Visual TFT Tool will be integrated smoothly.

The Visual TFT Interface is really easy to use, and implements standard intuitive behavior, so you will feel like using any other vector graphic editors. But we have mixed functionalities from both worlds: world of design and world of programming. There are several palettes of most useful components that you can use in your application. Just drag a component onto a pixel grid display screen and it will be drawn instantly. Use Object Inspector to edit component properties and to assign desired events.

Do you need more space for your images and fonts? Do you want to create image slideshows, or to even play a video from MMC/SD Card? With new Resource file feature, Visual TFT software brings you all this and much more. If this option is selected, after code generation, Visual TFT will store all of your images and fonts in the resource file and will optimize them as much as possible for faster utilization. You just have to copy that file onto your MMC/SD card and you are ready to go.

The help file is the best place to start if you want to get to know the Visual TFT software. The easy-to-read format and detailed explanations of every functionality and feature will make you an expert in no time.

Nobody likes complicated settings and options at the beginning of each project. With new hardware templates, single click on a dropdown list item does all the work for you. Everything will be automatically set.

Since it’s inception the Arduino IDE has demonstrated the desire to support all kind of platforms, from Arduino clones and variations of different manufacturers to third party boards like the ESP32 and ESp8266. As more people get familiar with the IDE, they are beginning to support more boards that are not based on ATMEL chips and for today’s tutorial we will look on one of such boards. We will examine how to program the STM32 based, STM32F103C8T6 development board with the Arduino IDE.

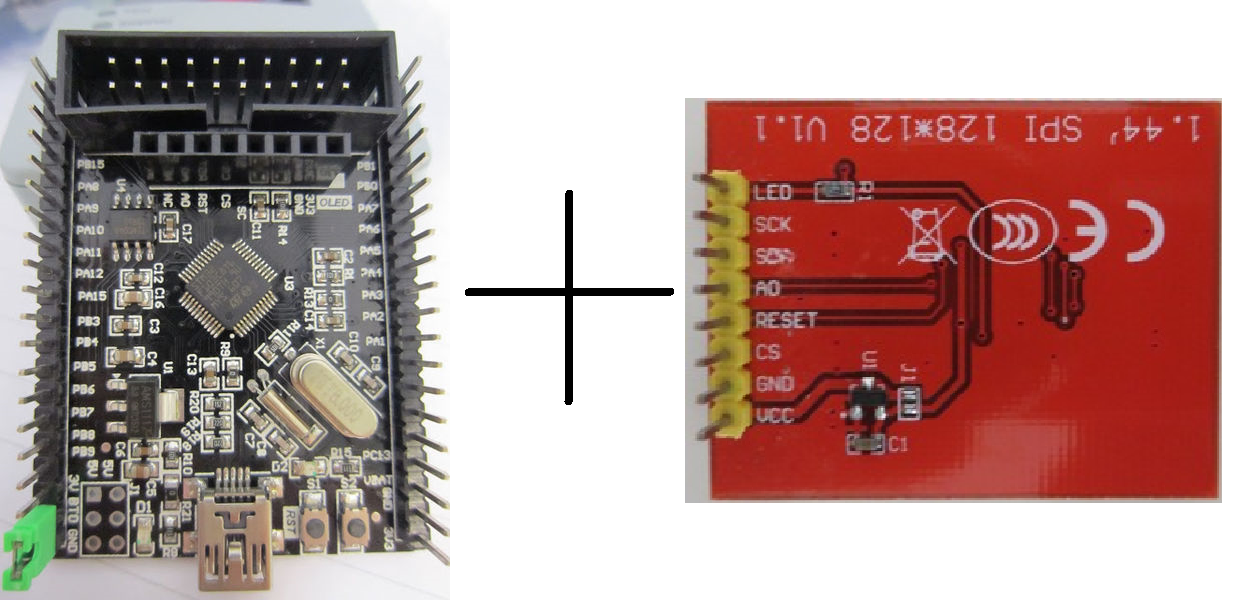

The STM32 board to be used for this tutorial is none other than the STM32F103C8T6 chip based STM32F1 development board commonly referred to as “Blue Pill” in line with the blue color of its PCB. Blue Pill is powered by the powerful 32-bit STM32F103C8T6 ARM processor, clocked at 72MHz. The board operates on 3.3v logic levels but its GPIO pins have been tested to be 5v tolerant. While it does not come with WiFi or Bluetooth like the ESP32 and Arduino variants, it offers 20KB of RAM and 64KB of flash memory which makes it adequate for large projects. It also possesses 37 GPIO pins, 10 of which can be used for Analog sensors since they have ADC enabled, along with others which are enabled for SPI, I2C, CAN, UART, and DMA. For a board which costs around $3, you will agree with me that these are impressive specs. A summarized version of these specifications compared with that of an Arduino Uno is shown in the image below.

Based on the specs above, the frequency at which Blue pill operates is about 4.5 times higher than an Arduino UNO, for today’s tutorial, as an example on how to use the STM32F1 board, we will connect it to a 1.44″ TFT display and program it to calculate the “Pi” constant. We will note how long it took the board to obtain the value an compare it with the time it takes an Arduino Uno to perform the same task.

As usual, all the components used for this tutorial can be bought from the attached links. The power bank is however only needed if you want to deploy the project in a stand-alone mode.

As mentioned earlier, we will connect the STM32F1 board to the1.8″ ST7735 based colored TFT Display along with a push button. The push button will be used to instruct the board to start the calculation.

Go over the connections once again to be sure everything is as it should be as it tends to get a little bit tricky. With this done, we proceed to set up the STM32 board to be programmed with the Arduino IDE.

As with most boards not made by Arduino, a bit of setup needs to be done before the board can be used with the Arduino IDE. This involves installing the board file either via the Arduino Board manager or downloading from the internet and copy the files into the hardware folder. The Board Manager route is the less tedious one and since the STM32F1 is among the listed boards, we will go that route.

Start by adding the link for the STM32 board to the Arduino preference lists. Go to File -> Preferences, then enter this URL ( http://dan.drown.org/stm32duino/package_STM32duino_index.json ) in the box as indicated below and click ok.

The code will be written the same way we’d write any other sketch for an Arduino project, with the only difference being the way the pins are referenced.

To be able to easily develop the code for this project, we will use two libraries which are both modifications of standard Arduino Libraries to make them compatible for the STM32. We will use the modified version of the Adafruit GFX and the Adafruit ST7735 libraries. Both libraries can be downloaded via the links attached to them.

With this done, we create an object of the ST7735 library which will be used to reference the display all through the entire project. We also indicate the pin of the STM32 to which the pushbutton is connected and create a variable to hold its state.

Next, we initialize serial communication and the screen, setting the background of the display to black and calling the printUI() function to display the interface.

We start by reading the state of the push button. If the button has been pressed, we remove the current message on the screen using the removePressKeyText() and draw the changing progress bar using the drawBar() function. We then call the start calculation function to obtain and display the value of Pi along with the time it took to calculate it.

The remaining part of the code are the functions called to achieve the tasks from drawing the bar to calculating the Pi. Most of these functions have been covered in several other tutorials that involve the use of the ST7735 display.

Uploading sketches to the STM32f1 is a little bit complex compared to standard Arduino compatible boards. To upload code to the board, we need an FTDI based, USB to Serial converter.

With the code complete, follow the upload process described above to upload the code to your setup. You should see the display come up as shown in the Image below.

Press the pushbutton to start the calculation. You should see the progress bar slide gradually until the end. At the end of the process, the value of Pi is displayed along with the time which the calculation took.

Comparing these two values, we see that “Blue Pill” is over 7 times faster than the Arduino Uno. This makes it ideal for projects which involves heavy processing and time constraints. The small size of the Blue pill also serves as an advantage here as it is only a bit bigger than the Arduino nano and it can be used in place where the Nano won’t be fast enough.

This is a third release of combined soldering iron controller for Hakko T12 tips and 858D rework station based on STM32 micro controller. This time the oled display was replaced by ili9341 TFT one with SPI interface. There are several display variants (2.2", 2.4", 2.8" or 3.2") in the market, so you can chose the one that satisfies your requirements, I used 2.2" display. The touch screen feature is not used in this project, but you can use display with touch screen panel.

The soldering controller supports using soldering iron and Hot Air Gun at the same time. In the main mode, you can activate any device or activate both devices simultaneously or turn them off. As soosn as the display resolution is higher than oled display, the information of both devices can be displayed on the main screen.

Before updating the firmware, save the PID parameters if you have modified them. The landscape orientation is still the default. Some issues can be faced in the portrait display mode. Report them to be fixed.

This project has several features:The controller allows managing Hot Air Gun and soldering iron independently. Two independednt rotary encoders simplifies this type of managing devices. The reed switch of the Hakko 858D Hot Air Gun handle used to activate rework capability.

To decrease the controller price and increase its reusability, the complete schematics was split in 3 separate PCBs. The main PCB conntains the main low-voltage components: stm32 blackpill board, op-amps, voltage dc-dc converter and regulator, mosfets that manage the soldering iron and Hot Air Gun fan. The AC power PCB contains the high-voltage part of the project: the triac, optional high-voltage relay and opto-couplers that creates galvanic isolation from the main board. These boards connected via 5-wire interface cable. The display PCB contains the TFT display and two rotary encoders.

JP11 is a optional DIP-type connector for SD-card reader on the TFT display. This connector is used to load external files to the SPI flash memory IC. Just solder the pin-header here.

Thehigh-voltage pcb is also available in EasyEdasite. The schematics contains the TRIAC and opto-coipler modules allowing to isolate the board from low-voltage part of the project.

The schematics of the board is very simple. It contains two rotary encoders and TFT display. Also, you can see the mosfet that manages the TFT display brightness.

The controller requires big size PCB to fit all the components so it is convenient to create the display separate board. Also, It is convenient to solder rotary encoders to the display board and use encoder neck to fix this board on the acrylic front panel.

This controller is working with ili9341 based TFT displays only. You can select the display size (2.2", 2.4", 2.8" or 3.2"). The display has sufficient resolution 320x240 to show required information. I used the 2.2" one to fit the case.

This feature increases the safety of soldering iron. There are two automatic power-off features are implemented inside the controller, software driven and hardware driven. The hardware driven one requires optional TILT or REED switch installed in the iron handle. In the software mode, the controller turns on the Idle mode if the supplied power to the iron is stable for a while. In this case, the controller will power off the iron in specified timeout. When the time to automatic shutdown near, it will be displayed as a seconds remaining. When you use the iron, the supplied power changes and the controller resets the automatic power off timeout.

To use the hardware TILT switch, you must setup automatic power off timeout and standby temperature. If the standby temperature is "OFF" the hardware tilt switch will not be used and software solution described previously will be activated. Also, you can setup standby time (timeout to switch to low power mode). When the tilt switch enabled, the main working mode changes the following way. The iron is starting heating. When it reaches the preset temperature the "Ready" message will be displayed and the controller will keep the preset temperature. If the soldering IRON is not used (laying on the table) the controller will switch low power mode. If the iron keep laying for automatic off timeout, the controller will switch off the power completely. As soon as you start using the iron, the controller restores the preset temperature.

The main component is the BlackPill board. You can use the pure STM32F401CCU6 micro controller if you wish to create compact variant of the soldering station.

Connect this DC-DC converter consequently with b0505 isolated cobverter: 24v -> MP1584 DC-DC converter -> b0505 -> ams1117 gnd you get isolated power supply for your stm32 micro controller. This king of power supply is isolated and low-noise power that ensure accurate ADC temperature readings.

This project is based on the BlackPill board with STM32F401CCU6 micro controller. To flash prebuilt firmware to the controller the st link v2 programmer and ST link utility are required.

Download the STM32 ST-LINK utility fromstsite. Install the utility in your system. Launch the ST-LINK utility, connect the programmer to the 4pins SWD interface of BlackPill board, press "connect" button. The main window should display the memory content of the BlackPill board. Press flash button to write the firmaware to the BlackPill board.

As you can see, the main AC power after fuse that can be installed on the pannel of the case, goes into JP3 socket on the high voltage board. You can connect main power switch to the JP6 socket or short it oins and completely remove main switch if do not like to use it. JP4 and JP2 sockets are used to connect to the GX16-8 connector of the Hot Air Gun. The power to the heater goes from JP4 socket and all other wires connected to the JP2. Earth ground should be connected to the Earth ground of AC power (not shown here). JP8 and JP9 connectors should be connected together. Soldering Iron GX12-5 connector should be connected to JP1 and JP5 sockets. JP10 used to connect optional automatic mode switch. Using this switch you can disconnect the Hot Air Gun completely from the controller when it is not needed. JP3 should be connected to the J1 connector on the TFT board. This is 14-wires connector to attach the display and rotary encoders.

Using JP11 you can connect the SD-CARD installed on TFT display to the controller when going to upload some files from SD-CARD to SPI FLASH. For instance, it can be used whel upload localization data files.

To simplify controller tuning procedure, the tune modes are implemented in the controller. This modes can be activated from the system menu item "tune iron" or "gun menu->tune gun". When the tune mode is activated, the controller powers on the iron or Hot Air Gun and displays on the screen applied power (in percents) and the gauge of the current temperature readings. The gauge has a label "450" or "500" depending on what hardware you are tuning. When the gauge reaches this label, the temperature should be 450 or 500 degrees of Celsius.

As soon as you have stabilized the iron temperature near 450 degrees, rotate the 500k potentiometer trim to shift gauge bar on the display left or right. Adjust the potentiometer so the bar would be as near to the reference temperature as possible. Then long press the encoder handle (for about 2 seconds) to turn the iron off and finish the procedure. It is recommended to use the thick tip that produce the highest voltage when performing the tune procedure. For example, T12-K, T12-D52 or similar.

As you can see from the picture above, the debug screen shows the following information:iron status (off or on). You can manage the power supplied to the soldering iron by rotating the upper encoder. As the encoder rotated, you adjust the power supplied to the iron (in internal units). The more power supplied to the iron the faster it heats. Supplied power value displayied in the right column ("irnP") in the internal units.

If the SPI FLASH is formatted and working correctly, you should see the screen above. As you can see, it is the root directory list of SPI FLASH. In case of FLASH error, the error message would be displayed indicating the FLASH is not readable. If your SPI FLASH is unformatted, the corresponding message would be displayed and the controller asks you to confirm the FLASH should be formatted. When the FLASH will be formatted, you should see the empty file list.

The current tip can be calibrated using "calibrate tip" menu item. If the tip is not calibrated yet, the "[!]" sign would be displayed near the tip name on the main screen. There are two calibration modes in the current version of the controller firmware: automatic and manual.

The progress bar in the lower part of the display shows the difference between preset and current temperature (in internal units) of the tip. The controller keeps the tip temperature near the preset value (vertical line on the progress bar) all the time. To increment the preset temperature, turn the encoder right, to decrease - turn it left.

When the low power (standby) mode activated, the controller shows the "standby" icon in the upper-right corner of the display lie shown on the picture below.

The "tune iron PID" and "gun setup->tune gun PID" menu items in the main menu allowing tuning PID parameters of soldering iron and Hot Air Gun. When tune PID mode activated, you can see three values of PID parameters on the display, Kp - proportional, Ki - integral, Kd - differential. First, choose the parameter you are going to change and press the encoder button. You turn into tuning test mode. There are two graphs: the temperature difference and power math dispersion. Both graphs are auto magnifying ones and its maximum value is shown on the Y-axis by the corresponding color.

Prebuilt version of the controller software can be downloaded from the github repository. To upload this hex file into controller, you can use stm32 st-linkutility.

My firiend Armindo translated all messages to Portugeese, so the project hast two additional languages: Russian and Portugeese. The binary font ubuntu_we.font contains ASCII and Western Europe characters including Greek symbols. You can use this font for your language if you are speaking on one of the european language. To do this, you have to add new line tocfg.jsonfile and create new message file.

In order to use your native language, the NLS data should be uploaded into SPI FLASH. To do so, you have to:Connect your SD-CARD reader (the TFT display board has one) to the JP11 connector via 4 wires: SD_CS (Chip Select), MOSI, MISO, SCK. If you have not implemet the JP11 socket, remember following: SD_CS (Chip Select) - PB12, MOSI - PB15, MISO - PB14, SCK - PB10.

I picked up the project again today and de-soldered my SAMD51 T4 clone pcb as I need speed! The T4 would have been perfect, so tried a few code changes, got the screen running in the setup function (static text etc), but as soon as it enters the loop(), you guessed it....white screen. Its as if the t4 is too fast on spi or something, but I have changed the clock speeds down to 5mhz and yield the same results...

To confirm, I had the T4 intermittently working on both the adafruit ili9341 library and the optimised ili9341_t3. I"ve been through 3 T4s and I have 5 different ILI934 displays. (all give the same results, pull ups, no pullups, removed sd circuitry, ran the T4 at 5v I"ve tried it all!)

I have been working on a custom board based around the STM32F746IGT6 MCU, external SDRAM (AS4C4M16SA-6TIN) and external flash (MT25QL128ABA1ESE-0SIT) to run a 7in, 800x480 display (4DLCD-70800480-CTP). However, I have been facing flickering issues with the display, so a board redesign may be necessary.

1. Make a custom board with a STM32F7 or STM32H7, with external SDRAM and external FLASH to run the TFT display through the LTDC interface, in 24-bit mode. The display would be ran in double buffer mode, so the SDRAM need to be big enough to accommodate that. Ideally, the external flash should be as big as possible. The end goal is to be able to run smooth animations on the display.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey