lcd panel market share 2016 made in china

Chinese display manufacturers are chasing their South Korean rivals closely by planning to release a larger volume of liquid-crystal panels over 32 inches this year, said a market researcher Sunday.

According to a report on the 2017 shipment strategies of Chinese TV panel makers by IHS Markit, Chinese LCD panel suppliers are forecast to ship out a total of 320,000 large-size panels larger than 32 inches by the end of this year, a 33 percent surge from last year.

In the report, Wu mentioned the plans of major Chinese panel firms such as BOE, CSOT, CEC-Panda and HKC to focus on expanding production of 43, 55 and 58-inch panels, adding that demand for 32-inch panels will gradually decrease.

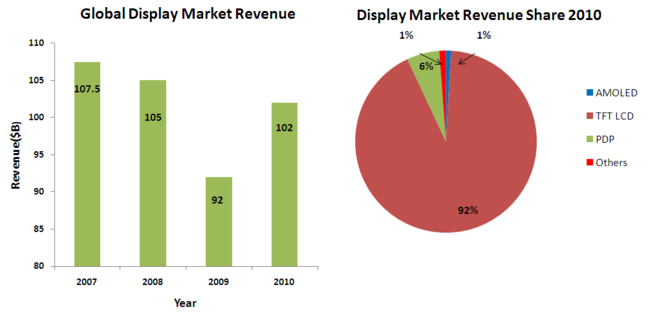

“By the end of 2018, China will be the largest region for TFT LCD capacity, and larger-sized products may make their factories more efficient and profitable than they have been when producing 32-inch panels,” he said.

The strategy shift of the Chinese players suggests that they might outstrip Korean display makers in the global large-size display market, the analyst said.

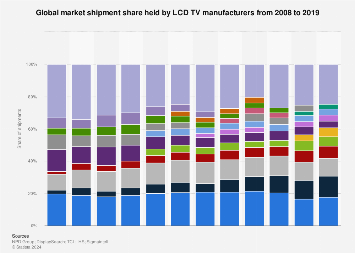

“The strategies of Chinese panel makers will significantly influence global supply and demand,” Wu said. “In 2015 and 2016, the Chinese companies shipped 33.2 percent of worldwide LCD TV panel, trailing only Korean panel makers at 36.4 percent.”

The competition structure has been advantageous for the Korean players, since their Chinese rivals had been focusing on small LCD panels until last year. But now the Korean firms are facing fiercer competition in prices.

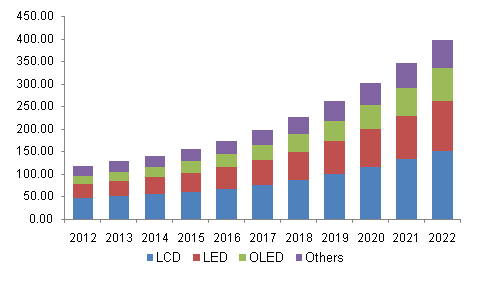

Although demand for organic-light emitting diode panels in the TV market is gradually rising, dominance of LCD panels is projected to continue for the foreseeable future.

“While OLEDs are expected to post sharp growth, they will not be able to usurp LCD as the panels of choice for upper-end TVs,” another report by IHS Markit said.

China is the leader in producing LCD display panels, with a forecast capacity share of 56 percent in 2020. China"s share is expected to increase in the coming years, stabilizing at 69 percent from 2023 onwards.Read moreLCD panel production capacity share from 2016 to 2025, by countryCharacteristicChinaJapanSouth KoreaTaiwan-----

DSCC. (June 8, 2020). LCD panel production capacity share from 2016 to 2025, by country [Graph]. In Statista. Retrieved January 29, 2023, from https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "LCD panel production capacity share from 2016 to 2025, by country." Chart. June 8, 2020. Statista. Accessed January 29, 2023. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. (2020). LCD panel production capacity share from 2016 to 2025, by country. Statista. Statista Inc.. Accessed: January 29, 2023. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "Lcd Panel Production Capacity Share from 2016 to 2025, by Country." Statista, Statista Inc., 8 Jun 2020, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC, LCD panel production capacity share from 2016 to 2025, by country Statista, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/ (last visited January 29, 2023)

LCD panel production capacity share from 2016 to 2025, by country [Graph], DSCC, June 8, 2020. [Online]. Available: https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

BOE Technology Group, the Chinese electronic components producer, is expected to be the leader in producing LCD display panels in the coming years, with a forecast capacity share of 24 percent by 2022. China is the country that has the largest LCD capacity, with a 56 percent share in 2020.Read moreLCD panel production capacity share from 2016 to 2022, by manufacturerCharacteristicBOEChina StarInnoluxAUOLGDHKCCEC PandaSharpSDCOther-----------

DSCC. (June 8, 2020). LCD panel production capacity share from 2016 to 2022, by manufacturer [Graph]. In Statista. Retrieved January 29, 2023, from https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/

DSCC. "LCD panel production capacity share from 2016 to 2022, by manufacturer." Chart. June 8, 2020. Statista. Accessed January 29, 2023. https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/

DSCC. (2020). LCD panel production capacity share from 2016 to 2022, by manufacturer. Statista. Statista Inc.. Accessed: January 29, 2023. https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/

DSCC. "Lcd Panel Production Capacity Share from 2016 to 2022, by Manufacturer." Statista, Statista Inc., 8 Jun 2020, https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/

DSCC, LCD panel production capacity share from 2016 to 2022, by manufacturer Statista, https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/ (last visited January 29, 2023)

LCD panel production capacity share from 2016 to 2022, by manufacturer [Graph], DSCC, June 8, 2020. [Online]. Available: https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/

The upstream materials or components of the LCD panel industry mainly include liquid crystal materials, glass substrates, polarizing lenses, and backlight LEDs (or CCFL, which accounts for less than 5% of the market).

The middle reaches is the main panel factory processing and manufacturing, through the glass substrate TFT arrays and CF substrate, CF as upper and TFT self-built perfusion liquid crystal and the lower joint, and then put a polaroid, connection driver IC and control circuit board, and a backlight module assembling, eventually forming the whole piece of LCD module. The downstream is a variety of fields of application terminal-based brand, assembly manufacturers. At present, the United States, Japan, and Germany mainly focus on upstream raw materials, while South Korea, Taiwan, and the mainland mainly seek development in mid-stream panel manufacturing.

With the successive production of the high generation line in mainland China, the panel production capacity and technology level have been steadily improved, and the industrial competitiveness has been gradually enhanced. Nowadays, the panel industry is divided into three parts: South Korea, mainland China, and Taiwan, and mainland China is expected to become the no.1 in the world in 2019.

In the past decade, China’s panel display industryhas achieved leapfrog development, and the overall size of the industry has ranked among the top three in the world. Chinese mainland panel production capacity is expanding rapidly, although Japanese panel manufacturers master a large number of key technologies, gradually lose the price competitive advantage, compression panel production capacity. Panel production is concentrated in South Korea, Taiwan, and China, which is poised to become the world’s largest producer of LCD panels.

Up to 2016, BOE‘s global market share continued to increase: smartphone LCD, tablet PC display, and laptop display accounted for the world’s first market share, and display screen increased to the world’s second, while TV LCD remained the world’s third. In LCD TV panels, Chinese panel makers have accounted for 30 percent of global shipments to 77 million units, surpassing Taiwan’s 25.5 percent market share for the first time and ranking second only to South Korea.

In terms of the area of shipment, the area of board shipment of JD accounted for only 8.3% in 2015, which has been greatly increased to 13.6% in the first half of 2016, while the area of shipment of hu xing optoelectronics in the first half of 2015 was only 5.1%, which has reached 7.8% in the first half of 2016. The panel factories in mainland China are expanding their capacity at an average rate of double-digit growth and transforming it into actual shipments and areas of shipment. On the other hand, although the market share of South Korea, Japan, and Taiwan is gradually decreasing, some South Korean and Japanese manufacturers have been inclined to the large-size HD panel and AMOLED market, and the production capacity of the high-end LCD panel is further concentrated in mainland China.

Domestic LCD panel production line capacity gradually released, overlay the decline in global economic growth, lead to panel makers from 15 in the second half began, in a low profit or loss, especially small and medium-sized production line, the South Korean manufacturers take the lead in transformation strategy, closed in medium and small size panel production line, South Korea’s 19-panel production line has shut down nine, and part of the production line is to research and development purposes. Some production lines are converted to LTPS production lines through process conversion. Korean manufacturers are turning to OLED panels in a comprehensive way, while Japanese manufacturers are basically giving up the LCD panel manufacturing business and turning to the core equipment and materials side. In addition to the technical direction of the research and judgment, more is the LCD panel business orders and profits have been severely compressed, Korean and Japanese manufacturers have no desire to fight. Since many OLED technologies are still in their infancy in mainland China, it is a priority to move to high-end panels such as OLED as soon as possible. Taiwanese manufacturers have not shut down factories on a large scale, but their advantages in LCD technology and OLED technology have been slowly eroded by the mainland.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

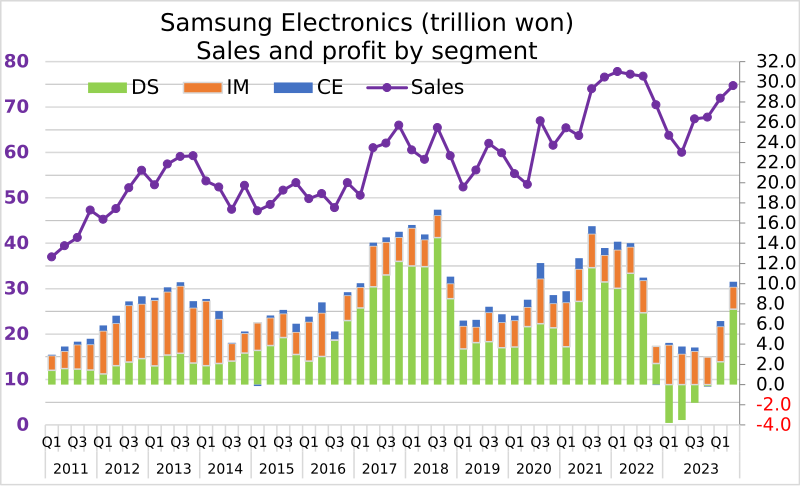

LG Display and Samsung Display are struggling to find their ways out of the deterioration of their performance even after withdrawing from production of liquid crystal display (LCD) panels. The high-priced organic light emitting diode (OLED) panel sector regarded as a future growth engine is not growing fast due to the economic downturn. Even in the OLED panel sector, Chinese display makers are within striking distance of Korean display makers, experts say.

On Aug. 30, Display Supply Chain Consultants (DSCC), a market research company, predicted that LCD TV panel prices hit an all-time low in August and that an L-shaped recession will continue in the fourth quarter. According to DSCC, the average price of a 65-inch ultra-high-definition (UHD) panel in August was only US$109, a 62 percent drop from the highest price of US$288 recorded in July in 2021. The average price of a 75-inch UHD panel was only US$218, which was only about half of the highest price of US$410 in July last year. DSCC predicted that the average panel price in the third quarter will fall by 15.7 percent. As Chinese companies’ price war and the effect of stagnation in consumption overlapped, the more LCD panels display makers produce, the more loss they suffer.

As panel prices fell, manufacturers responded by lowering facility utilization rates. DSCC said that the LCD factory utilization rate descended from 87 percent in April to 83 percent in May, 73 percent in June, and 70 percent in July.

Now that the LCD panel business has become no longer lucrative, Korean display makers have shut down their LCD business or shrunk their sizes. In the LCD sector, China has outpaced Korea since 2018. China’s LCD market share reached 50.9 percent in 2021, while that of Korea dropped to 14.4 percent, lower than Taiwan’s 31.6 percent.

Samsung Display already announced its withdrawal from the LCD business in June. Only 10 years have passed since the company was spun off from Samsung Electronics in 2012. LG Display has decided to halt domestic LCD TV panel production until 2023 and reorganize its business structure centering on OLED panels. Its Chinese LCD production line will be gradually converted to produce LCD panels for IT or commercial products. TrendForce predicted that LG Display will stop operating its P7 Plant in the first quarter of next year.

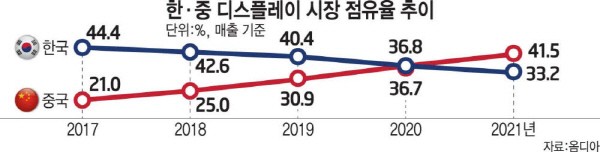

Korean display makers’ waning LCD business led to a situation in which Korea even lost first place in the display industry. Korea with a display market share of 33.2 percent was already overtaken by China with 41.5 percent) in 2021 according to market researcher Omdia and the Korea Display Industry Association. Korea’s market share has never rebounded in for five years since 2017 amid the Korean government’s neglect. Seventeen years have passed since 2004 when Korea overtook Japan to rise to the top of the world in the LCD industry. Korea’s LCD exports amounted to more than US$30 billion in 2014, but fell to US$21.4 billion last year.

A bigger problem is that Korean display makers may lose its leadership in the OLED panel sector although it is still standing at the top spot. While Korea’s OLED market share fell from 98.1 percent in 2016 to 82.8 percent last year, that of China rose from 1.1 percent to 16.6 percent. Considering that the high-end TV market is highly likely to shrink for the time being due to a full-fledged global consumption contraction, some analysts say that the technology gap between Korea and China can be sharply narrowed through this looming TV market slump. According to industry sources, the Chinese government is now focusing on giving subsidies to the development of OLED panel technology rather LCD technology. On the other hand, in Korea, displays were also wiped out from national strategic technology industry items under the Restriction of Special Taxation Act which can receive tax benefits for R&D activities on displays.

China’s display market share is expected to rise to 43 percent this year from 41.5 percent in 2021. Korean companies logged a market share of 33.2 percent in 2021, losing the No. 1 position they have maintained for 17 years since 2004 to Chinese manufacturers.

In the LCD market, China"s market share reached 50.9 percent in 2021 while Korea posted a mere 14.4 percent. Korea’s market share was lower than that of Taiwan (31.6 percent). As profitability deteriorated due to a price war waged by Chinese companies, Samsung Display decided to suspend LCD production in the second quarter of this year. LG Display, which is dependent on LCDs for 65 percent of its sales, implemented an LCD exit strategy ahead of schedule after recording a loss for two consecutive quarters.

China is also in hot pursuit of Korea in the OLED sector as well. While Korea’s OLED market share fell from 98.1 percent in 2016 to 82.8 percent in 2021, that of China rose from 1.1 percent to 16.6 percent during the same period.

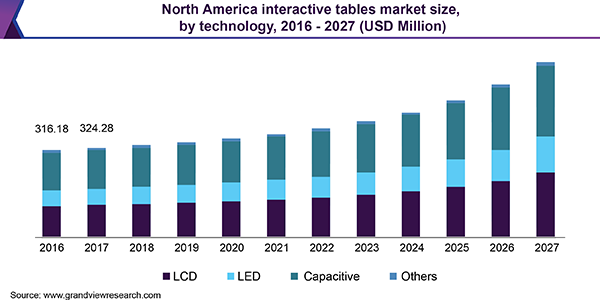

This market research report includes a detailed segmentation of the global large area LCD display market by application (TVs, notebooks, monitors, tablets, and others). It outlines the market shares for key regions such as the Americas, APAC, and EMEA. The key vendors analyzed in this report are AU Optronics, BOE Technology, Innolux, LG Display, and Samsung Display.

Technavio’s research analyst predicts the global large area LCD display market to grow at a CAGR of 3% during the forecast period. The formation of UHD alliances is the primary growth driver for this market. During 2015, supply chain members of the global UHD TV market announced the formation of the UHD Alliance to support innovative technologies including 4K and higher resolution, high dynamic range, immersive 3D audio, and wider color gamut.

The decline in ASP of the LCD panel is expected to boost the market growth during the forecast period. During 2014, per meter square, ASP of LCD panel was $472, which declined to $416 during 2015. Vendors reduced the ASP to reduce excess inventory. The declining per square meter ASP of LCD panel drove the shipment of LCD display in terms of area.

During 2015, the TV segment dominated the large area LCD display market with a market share of 38%. The primary reason for the growth of this product segment was the strong demand for 4K TVs of 40 inches and larger screen size. During 2015, several manufacturers introduced 4K TVs ranging from 50 inches and above.

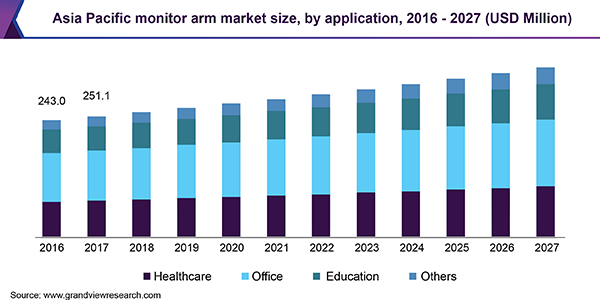

During 2015, APAC accounted for 81% of the market share and is expected to grow at a CAGR of 1% during the forecast period. The high concentration of display device manufacturers and LCD panel manufacturers in this region are the primary growth drivers. Technavio expects that the well-established supply chain for display devices in APAC would continue to support the dominance of this region in the market during the forecast period. China is emerging fast as a leading hub for large area TFT LCD display manufacturers because of the rise in the number of display device manufacturers in the country.

Manufacturing LCD display panels require economies of scale because the equipment used to manufacture displays are expensive. This presents high entry barriers for LCD display panel manufacturers. Currently, the global large area LCD display market is dominated by China, Japan, South Korea, and Taiwan in terms of production and revenue contribution. Chinese manufacturers have the advantage of manufacturing LCD panels at a lower cost. This has resulted in price wars among LCD manufacturers and has accelerated the declining ASP of LCD panels. Vendors such as LG and Samsung are under a lot of pressure as profit margins have come down because of increased competition.

Other prominent vendors in the market include Chi Mei Optoelectronics, Chunghwa Picture Tube (CPT), HannsTouch Solution, HannStar Display, InfoVision Optoelectronics, Japan Display, Kaohsiung Opto-Electronics, NEC Display Solutions, Panasonic, and Sharp.

China’s display market share is expected to rise to 43% this year from 41.5% in 2021. Korean companies logged a market share of 33.2% in 2021, losing the No. 1 position they have maintained for 17 years since 2004 to Chinese manufacturers, reported Business Korea on November 3.

In the LCD market, China"s market share reached 50.9% in 2021, while South Korea posted a mere 14.4%. As profitability deteriorated due to a price war waged by Chinese companies, Samsung Display decided to suspend LCD production in the second quarter of this year. LG Display implemented an LCD exit strategy ahead of schedule after recording a loss for two consecutive quarters.

China is also in hot pursuit of South Korea in the OLED sector. While South Korea’s OLED market share fell from 98.1% in 2016 to 82.8% in 2021, China rose from 1.1% to 16.6% during the same period, said the Business Korea report.

TOKYO -- In the past two years, eight plants have been set up in China to produce smartphone panels. Five more are scheduled to start operating in the next two years.

Backed by massive state funding, Chinese panel makers are taking a bigger bite of the market for smartphone display panels, which has so far been dominated by Japanese and South Koreans makers.

Chinese display manufacturers are chasing their South Korean rivals closely by planning to release a larger volume of liquid-crystal panels over 32 inches this year, said a market researcher Sunday.

According to a report on the 2017 shipment strategies of Chinese TV panel makers by IHS Markit, Chinese LCD panel suppliers are forecast to ship out a total of 320,000 large-size panels larger than 32 inches by the end of this year, a 33 percent surge from last year.

In the report, Wu mentioned the plans of major Chinese panel firms such as BOE, CSOT, CEC-Panda and HKC to focus on expanding production of 43, 55 and 58-inch panels, adding that demand for 32-inch panels will gradually decrease.

“By the end of 2018, China will be the largest region for TFT LCD capacity, and larger-sized products may make their factories more efficient and profitable than they have been when producing 32-inch panels,” he said.

The strategy shift of the Chinese players suggests that they might outstrip Korean display makers in the global large-size display market, the analyst said.

“The strategies of Chinese panel makers will significantly influence global supply and demand,” Wu said. “In 2015 and 2016, the Chinese companies shipped 33.2 percent of worldwide LCD TV panel, trailing only Korean panel makers at 36.4 percent.”

The competition structure has been advantageous for the Korean players, since their Chinese rivals had been focusing on small LCD panels until last year. But now the Korean firms are facing fiercer competition in prices.

Although demand for organic-light emitting diode panels in the TV market is gradually rising, dominance of LCD panels is projected to continue for the foreseeable future.

“While OLEDs are expected to post sharp growth, they will not be able to usurp LCD as the panels of choice for upper-end TVs,” another report by IHS Markit said.

Data from China Optics and Optoelectronics Manufactures Association Liquid Crystal Branch (CODA) shows that in 2021, the output value of China"s display industry was about 586.8 billion yuan (about $84.05 billion), nearly eight times higher than 10 years ago while delivered display panels totaled about 160 million square meters, more than seven times that of a decade ago.

According to CODA, China"s proportion of industry scale and display panel delivered area in the global market has increased to 36.9 percent and 63.3 percent respectively, ranking first in the world.

As for the organic light-emitting diode (OLED), domestic enterprises have mastered the core technologies and are making technological innovations in high refresh rate and pixel geometry and other fields. Meanwhile, production scale has expanded rapidly, and the market share of small- and medium-sized OLED increased.

Statistics show that in the third quarter of 2022, the market share of OLED panels for domestic smart phones accounted for 30 percent of the global market, an increase of 10 percent over the same period last year.

LCD panel makers are at risk of incurring deep losses this year as the rise of Chinese manufacturers aggravates already severe oversupply, IHS Technology said yesterday.

The global supply of LCD panels is expected to increase 6 percent annually this year, outpacing the 3 percent growth in demand, mostly on the back of Chinese panel manufacturers BOE Technology Group (京東方) and China Star Optoelectronics Technology Co (華星光電), the market researcher projected.

China’s global market share is expected to expand to 23.7 percent this year by capacity from last year’s 19.5 percent, stealing share from Taiwan, IHS Technology said.

“We only see a brief rebound in panel prices in the second quarter and third quarter, primarily due to stock-building demand from major TV brands including Samsung Electronics Co and Chinese TV vendors,” IHS Technology senior director David Hsieh (謝勤益) said at an annual display forum.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

TCL Technology (originally an abbreviation for Telephone Communication Limited) is a Chinese electronics company headquartered in Huizhou, Guangdong Province. It designs, develops, manufactures, and sells consumer products including television sets, mobile phones, air conditioners, washing machines, refrigerators, and small electrical appliances. In 2010, it was the world"s 25th-largest consumer electronics producer. It became the second-largest television manufacturer by market share by 2019.

TCL comprises five listed companies: TCL Technology, listed on the Shenzhen Stock Exchange (SZSE: 000100), TCL Electronics Holdings, Ltd. (SEHK: 1070), TCL Communication Technology Holdings, Ltd. (former code SEHK: 2618; delisted in 2016), China Display Optoelectronics Technology Holdings Ltd. (SEHK: 334), and Tonly Electronics Holdings Ltd. (SEHK: 1249), listed on the Hong Kong Stock Exchange.

In July 2003, TCL chairman Li Dongsheng formally announced a "Dragon and Tiger Plan" to establish two competitive TCL businesses in global markets ("Dragons") and three leading businesses inside China ("Tigers").

In May 2005, TCL announced that its Hong Kong-listed unit would acquire Alcatel"s 45 per cent stake in their mobile-phone joint venture for consideration of HK$63.34 million ($8.1 million) worth of TCL Communication shares.

In July 2008, TCL announced that it planned to raise 1.7 billion yuan ($249 million) via a share placement on the Shenzhen Stock Exchange to fund the construction of two production lines for LCD televisions; one for screens of up to 42 inches, and the other for screens of up to 56 inches.

In March 2010, TCL Multimedia raised HK$525 million through the sale of shares on the Hong Kong Stock Exchange, in order to fund the development of its LCD and LED businesses and to generate working capital.

In February 2014, TCL spent 280 million RMB to purchase 11 percent shareholdings of Tianjin 712 Communication & Broadcasting Co., Ltd, a Chinese military-owned company which produces communication devices and navigation systems for the Chinese army.

In 2016, TCL reached an agreement with BlackBerry Limited to produce smartphones under the BlackBerry brand,BlackBerry Mobile. This deal ceased on 31 August 2020.

In 2016, it contract manufactured the DTEK50 and DTEK60, for BlackBerry Limited, under their flagship BlackBerry brand. In December 2016, it became a licensee of the BlackBerry brand, to manufacture, distribute, and design devices for the global market. As of 2017, it distributes BlackBerry devices under the name of BlackBerry Mobile.

"TCL International announces acquisition of assets from Schneider" (PDF). TCL Press Release. 19 September 2002. Archived (PDF) from the original on 28 May 2016. Retrieved 11 January 2019.

"TCL signs an exclusive deal to build BlackBerry-branded phones". TechCrunch. 15 December 2016. Archived from the original on 15 December 2016. Retrieved 15 December 2016.

China may become the world’s largest LCD panel manufacturing base. Data shows that in the third quarter of this year, our country’s well-known display panel manufacturer BOE surpassed LG Display to become the world’s largest large-size panel manufacturer. At the same time, technological integration and breakthroughs in my country’s display industry are accelerating, and China’s display manufacturing is attracting more and more attention on the global stage.

Recently, market research agency IHS Markit released data showing that the third quarter. South Korea’s well-known panel manufacturer LG Display’s share of the global large-size panel market fell to 19.3%, and BOE’s market share reached 21.7%, which means that BOE surpassed LG to become the world’s largest large-size panel manufacturer.

This is another breakthrough made by BOE this year, and before that, BOE has successfully attracted global attention in the manufacture of small-size panels.A few days ago, BOE announced the mass production of the 6th generation flexible small-size OLED screen production line in Chengdu. It is China’s first 6th generation flexible small-size OLED screen production line, and the world’s second mass-production 6th generation flexible small-size OLED screen production line. The production line uses the world’s most advanced evaporation process, and uses flexible packaging technology to achieve display screen bending and folding. This year is considered to be the first year of my country’s mobile high-end flexible screen to break the South Korean Samsung’s exclusive monopoly and begin to become self-sufficient.

In addition to BOE, CSOT, another panel manufacturing company in my country, has also made many breakthroughs this year. Recently, TCL Group revealed that its subsidiary CSOT has increased its production capacity and continues to maintain full production and full sales. The order in the fourth quarter is in good condition. The production research and development of Wuhan Huaxing’s full-screen products is in progress, and mass production is expected in the fourth quarter.

It is reported that at present, CSOT already has one 11 generation line in Shenzhen, mainly producing TV panels; two 6th generation lines in Wuhan, mainly producing small-size panels such as mobile phones.

The transcripts handed over by BOE and CSOT are just a microcosm of the sudden rise of Chinese panel manufacturing in recent years. Previously, South Korean companies Samsung Display and LG Display occupies an absolute leading position in the global size of panel manufacturing, but now, the situation is changing. Chinese panel manufacturing companies represented by BOE, CSOT, and Tianma Technology are gradually strengthening their own strengths, and they are competing with Korean companies to compete for the “one brother” throne in the world panel manufacturing field.It shows that the industry is under construction and planned investment reaches 800 billion yuan.

At the same time that BOE became the world’s largest large-size panel manufacturer, Juhua Printing Display Public Platform was inaugurated on the 28th in Guangzhou. This is the first public open R&D platform for my country’s display industry.

According to the latest data from the China Electronics Video Association and the China Optical Optoelectronics Industry Association Liquid Crystal Branch, the investment in flat panel display production lines under construction and announced in my country has reached 800 billion yuan. Among them, the LCD panel investment exceeded 500 billion yuan. It is estimated that around 2019, my country will become the world’s largest flat panel display production base.

The information society shows everywhere. TVs, computers, smart phones, wearable devices, etc., are inseparable from the support of the display screen. According to statistics, in 2016 my country’s display industry operating income exceeded 200 billion yuan. In the first half of this year, my country’s display panel shipment area was about 57 million square meters, accounting for about 1/3 of global shipments, second only to South Korea in the world.

In fact, in addition to the breakthrough in the production line, this year, driven by the good news, my country’s panel companies have also handed out good transcripts in the A-share market. In the first three quarters of this year, BOE’s total revenue was 69.408 billion yuan, a year-on-year increase of 51.41%; the net profit was 6.48 billion yuan, a year-on-year increase of 450.45%; basic earnings per share was 0.185 yuan, an increase 4525%; and CSOT revenue and profits have also maintained strong growth, strongly driving TCL Group to “reverse the market” in the color TV field.

Regarding the development trend of China’s display industry, well-known home appliance industry analyst Liu Buchen told reporters that in recent years, Chinese panel manufacturing companies have developed rapidly. At present, in display technology, ordinary liquid crystal displays have no technical problems. Next, OLED, QLED and other futures The development of display technology will become the focus.

“The production capacity of ordinary liquid crystal displays has been relatively sufficient. Next, domestic companies will make structural adjustments in the production of display products, and Chinese manufacturing will overcome more display technical difficulties, and the future display market such as OLED will be a big one. Trend.” Liu Buchen said.

As Liu Buchen said, BOE’s products have become more and more mature in small-size OLED displays. Next, it is planned to develop flexible and foldable OLED small-size panels, while in large-size OLED displays, including BOE and Huaxing Optoelectronics and other enterprises intend to break through key technologies through the form of cooperative research and development between Chinese and foreign companies to compete in the future display market.

More bad news for South Korea is that Taiwan is also set to grow beyond its capacity, pushing the country down to third place. Analysts estimate that Taiwan’s capacity share will rise to 29.8%, a growth of 0.9% year-on-year, while South Korea drops to 28.8%, a decline of 5.3%.

“Both domestic and foreign panel makers continue to build and expand their fabs in China because of the country’s enormous market and the financial support from the Chinese government. At the same time, the capacity share of South Korea has shrunk. Samsung Display (SDC) closed its Gen-7 fab L7-1 at the end of 2016, and both SDC and LG Display (LGD) have lowered their Gen-5 capacity”.

It’s strange to see the US featuring on this kind of forecast! I remember hearing the Korean ministry of Industry saying at an IMID conference that Korea would dominate the LCD industry with more than 50% share. I was amazed that at one point, this was achieved. It showed the value of coordination around a common objective, although it didn’t always mean profitability. Checking back in my database, it was interesting to see that at IMID in 2005, Nikkei was forecasting that UltraHD would be important by 2010. As it turned out, it took twice as long. I guess that might suggest that 8K might be a very long way away, in volume, anyway. (BR)

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey