lcd panel custom housing quotation

For over 20 years we"ve been helping clients worldwide by designing, developing, & manufacturing custom LCD displays, screens, and panels across all industries.

Newhaven Display has extensive experience manufacturing a wide array of digital display products, including TFT, IPS, character displays, graphic displays, LCD modules, COG displays, and LCD panels. Along with these products, we specialize in creating high-quality and affordable custom LCD solutions. While our focus is on high-quality LCD products, we also have a variety of graphic and character OLED displays we manufacture.

As a longtime leader in LCD manufacturing, producing top-quality LCD modules and panels is our highest priority. At Newhaven Display, we’re also incredibly proud to uphold our reputation as a trusted and friendly custom LCD manufacturing company.

As a custom LCD manufacturing company, we ensure complete control of our custom displays" reliability by providing the industry"s highest quality standards. Our design, development, production, and quality engineers work closely to help our clients bring their products to life with a fully custom display solution.

Our excellent in-house support sets Newhaven Display apart from other display manufacturers. Modifications in the customization process are completed at our Illinois facility, allowing us to provide an exceptionally fast turnaround time.

Customer support requests sent by phone, email, or on our support forum will typically receive a response within 24 hours. For custom LCD project inquiries, our response time can take a few days or weeks, depending on the complexity of your display customization requirements. With different production facilities and a robust supply chain, we are able to deliver thefastest turnaround times for display customizations.

Our excellent in-house support and custom display modifications set Newhaven Display apart from other LCD display manufacturers. From TFTs, IPS, sunlight readable displays, HDMI modules, EVE2 modules, to COG, character, and graphic LCDs, our modifications in the customization process are completed at our Illinois facility, allowing us to provide quality and fast turnaround times.

As a display manufacturer, distributor, and wholesaler, we are able to deliver the best quality displays at the best prices. Design, manufacturing, and product assembly are completed at our headquarters in Elgin, Illinois. Newhaven Display International ensures the best quality LCD products in the industry in this newly expanded facility with a renovated production and manufacturing space.

With assembly facilities in the US, manufacturing facilities in China, and distribution channels worldwide, we pride ourselves on delivering high-quality custom display solutions quickly to locations worldwide.

Since 1990, AccuView is dedicated to delivering fully customized LCD display solutions for our customers. Our strength lies in understanding and meeting our customers" EXACT requirements coupled with AccuView"s comprehensive manufacturing capabilities and expertise to deliver the right LCD display solution. Let AccuView be your total video solution provider.

As an expert in engineering display solutions, Canvysoffers a variety of custom built enclosures for industrial and medical environments.We utilize only the highest quality materials

We offer various housing designs: open frame, panel / chassis / rack mount, customized bezel, back cover design, cable management, rugged housings, slim and light weight designs

Customer-specific requirements such as a boot logo, back-printed customer logo on the protective glass or touch screen or specific requirements for the respective housing material can also be implemented

The application possibilities are nearly endless with how Envision Plastics" No Molds Required fabrication technology can be used to manufacture custom plastic bezels, displays, and monitor housings. Examples of such fabricated plastic parts using the NMR Technology include:

With the NMR plastic fabrication technology we can add additional aesthetics by incorporating one direction cold formed radii on our custom fabricated parts. In addition to that cosmetic design feature, digital printing can also be added to showcase branding or text to enhance product usability.

Most custom enclosure designs can also accommodate cutouts for LCD windows. We can leave the cutout open or solvent weld in acrylic or polycarbonate pieces to protect the LCD face. This customizable option gives NMR Technology an advantage over off the shelf solutions since these custom windows can accommodate any size LCD (assuming it fits within the enclosure design paramenters).

Many Size Options – Flexible design requirements allow for a wide range of size options for custom glass LCD. Designs can be as small as 1.5″ and as large as 10″.

Very Fast Tooling Process – Concept to Production as fast as 12 weeks – Tooled samples delivered in as little as 4 weeks. Once customer provides drawing to sales@azdisplays.com , we can have a proposed design within in 1-2 days.Proposal Design

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

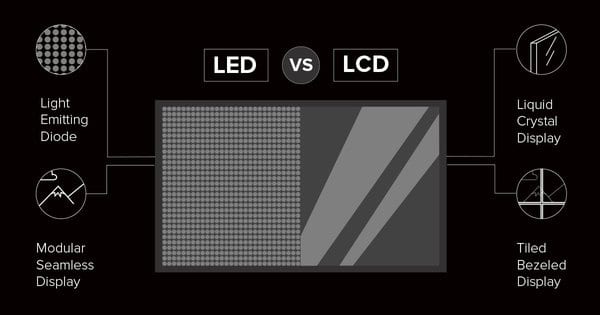

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

If your products need to be used with a switchable backlight, then trans-reflective reflectors are best to be used for front reflectors. If the device has to be used without backlight, then we can select a reflective polarizer for the back-panel as it gives the best contrast ratio.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

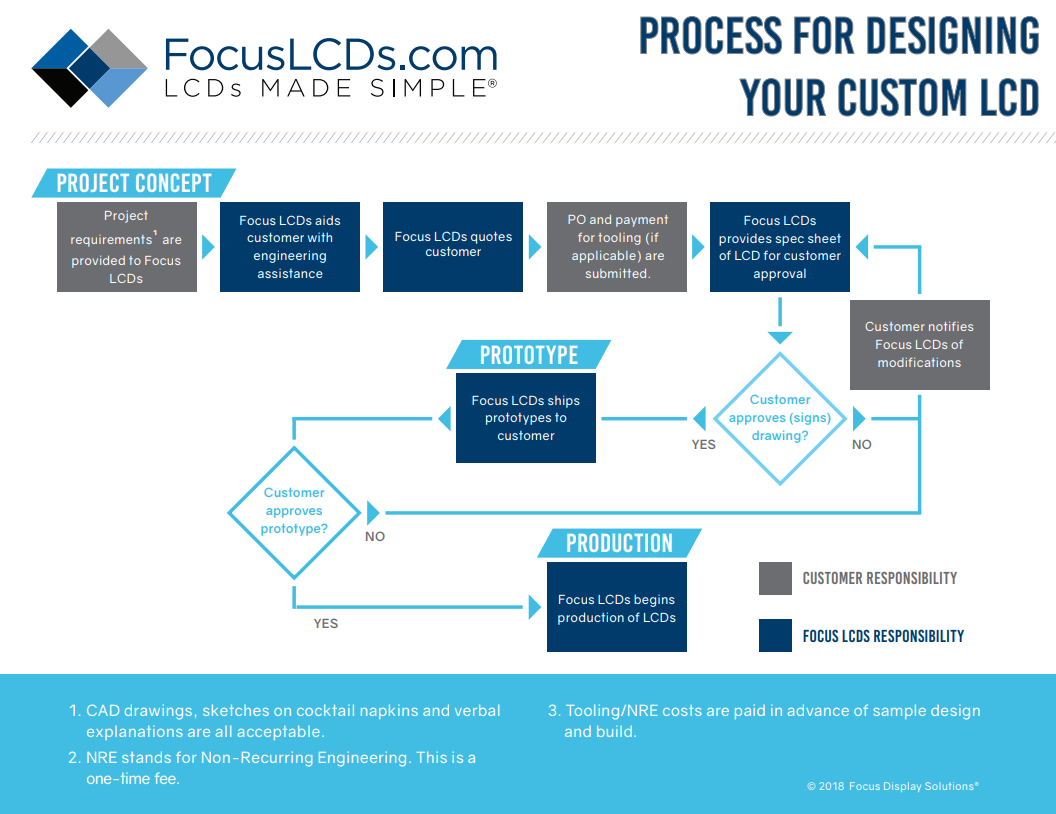

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

In the above image of a custom display design, we sent to the manufacturer, the red lines over multiple characters indicate that all these are considered as a single segment. For the sake of simplicity, we added test like T, S, U, B to denote Text, Symbols, Units, and Battery respectively. These characters were followed by numbers to simplify communication between us and the manufacturer. For example, if we needed any particular text or symbol to remain on, we can easily specify that to the manufacturer by using the corresponding text for that segment.

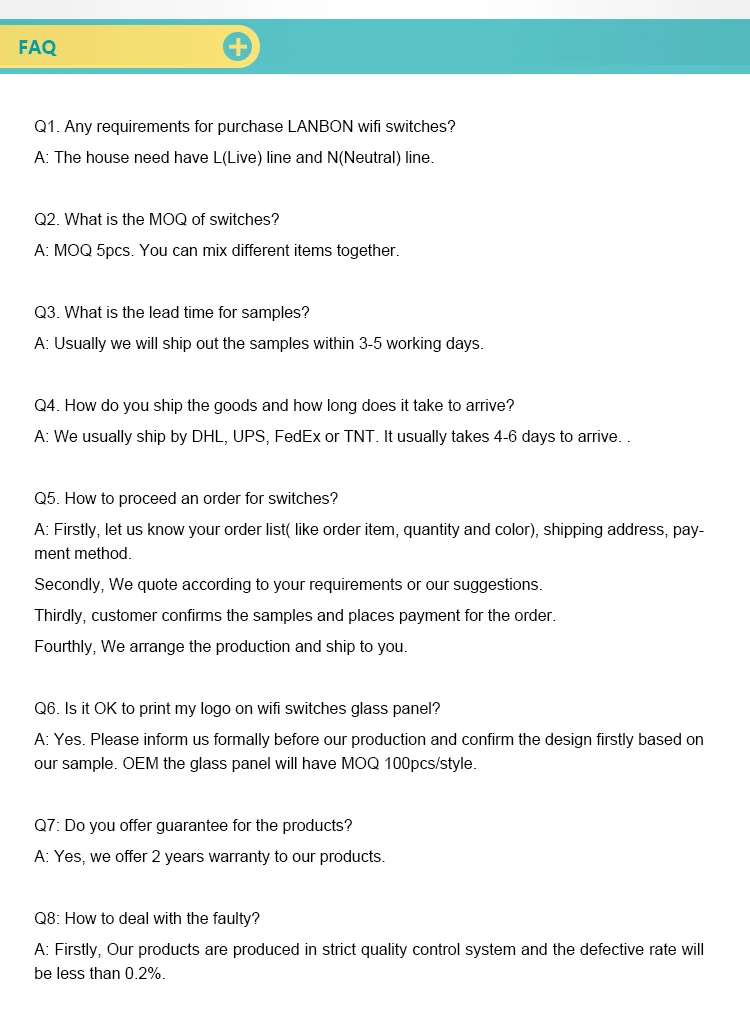

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

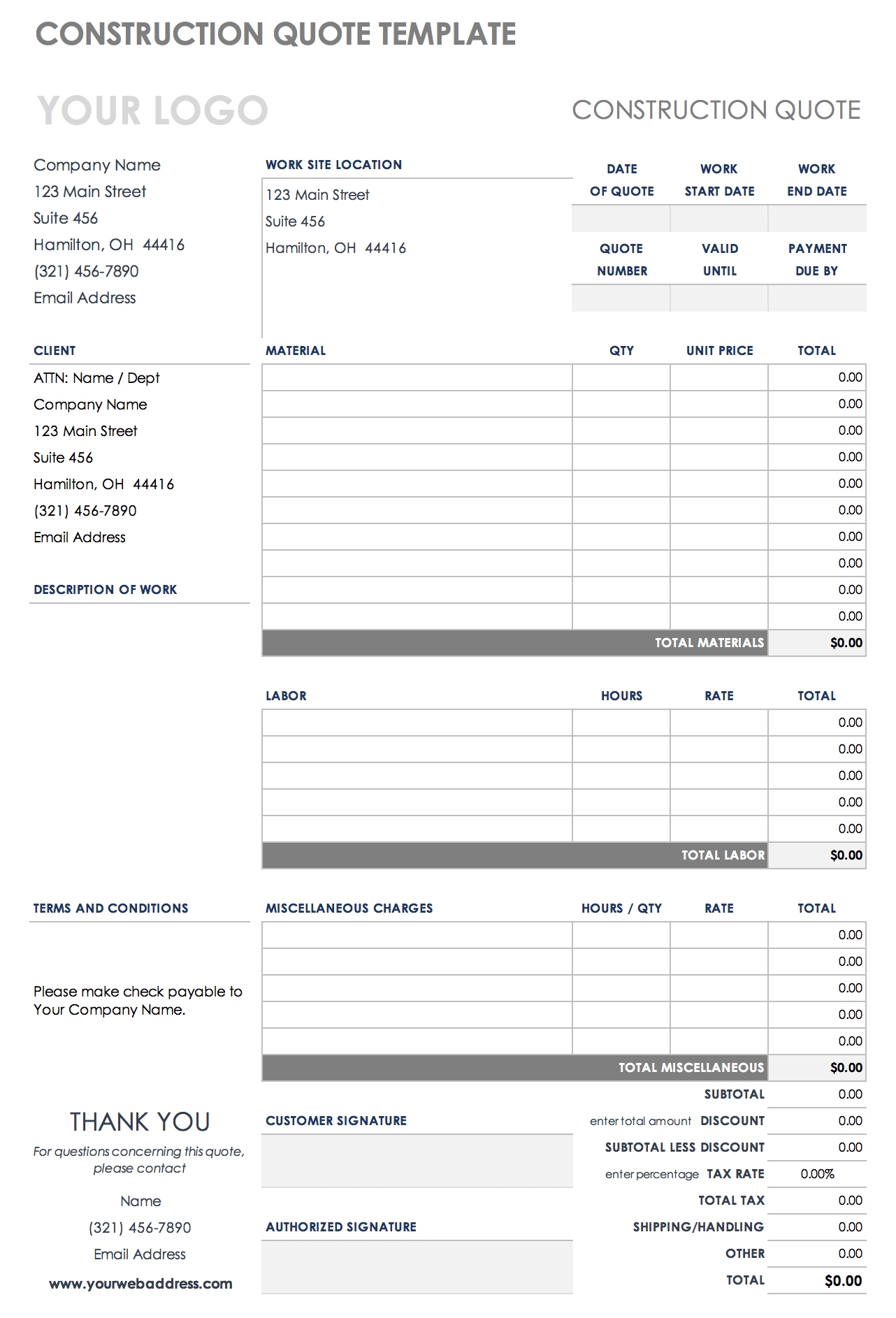

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

For most Passive Matrix LCD modules, we can deliver a custom LCD with active area size and resolution or a custom backlight, mechanical housing, and electrical interface for a total NRE cost of less than USD 10k. Likewise, Createxplay can customize an Active Matrix LCD module’s backlight, housing, and mechanical interface for an NRE cost of less than USD 10k.

However, customizing the Active Matrix LCD itself (size/resolution) can cost restrictive for most applications since the minimum NRE required for panel mask sets is around USD 100k. Unless the scope of the business dictates a customer-owned TFT panel or the project volumes depending on the size, are over 500k pieces per year. In many applications, combining a standard active matrix TFT cell with a custom-designed module and electrical interface offers the most favorable overall cost solution.

The lead time is another consideration for a custom design that can be shorter than you would think. Short lead time is made off-the-shelf LCD modules attractive for designers.

LCD manufacturers like Createxplay can typically design custom housing for passive or active matrix LCDs – with integrated capacitive touch sensor and interface – within one to two weeks of the initial RFQ and then provide sample custom LCD modules 4-5wks after that.

Createxplay also offers customers the option to use off-the-shelf modules as prototypes within their design before the custom display is ready to evaluate other design aspects and perform qualification work (e.g., testing software).

For many implementers, the design freedom and iterative optimization that customization offers are well worth the additional time required to sample custom LCD modules.

With unlimited customization options, it is essential to partner with an experienced POP display fabrication team to create a point of purchase display design that optimizes product engagement. At Northern Metal Products, our design and prototype team will work with you to quickly create the most effective, engaging display for your product.

Ideation:Based on your needs and budget, we utilize the ideation stage to determine the most effective type of display, the required materials, and an innovative visual design that will draw the most attention and motivate customers to purchase. In this collaborative process, we provide you with detailed 3D renderings to help visualize the final product.

The majority of purchase decisions are not made until the customer is inside the store. POP displays can drive impulse purchases by drawing the customer’s attention. Apart from increasing attention, POP displays offer several other advantages, including:

Increased Sales:A professionally designed POP display helps products stand out amongst a sea of merchandise, increasing the probability that customers will purchase your product.

At Northern Metal Products, we take a collaborative approach to create eye-catching, custom displays focused on design and advanced structural engineering to fit the unique needs of our customers. We complete every step of the process in-house, giving us total control of design and production. This allows us to focus on customer satisfaction through superior design and prototyping.

From permanent and temporary displays to floor and counter displays, we can customize every type of display with features like custom display shelving, sign holders, hooks, bold graphics, and more to optimize your product display and ensure enhanced product visibility.

For more than 50 years we have been a trusted partner in metal fabrication and high-quality in-house manufacturing. We pride ourselves in continually improving our practices and products to provide our customers with solutions that exceed their expectations.

In order to process your design to print, we will require a “workable” file in return. Any non-photographic content (including graphics and text) are best sent to us as vector-based PDFs or Adobe Illustrator (.AI) files. We will never modify your artwork although we may need to resize your work for a centered panel fit.

The size of your church’s screen depends on various factors, including the size of your church, architectural details, and the impression you want your screen to have on your congregation. Whatever your needs may be, we can create custom screens in all shapes and sizes to achieve the look you are seeking.

We offer unlimited color capacity, low energy consumption, and routine maintenance.LED message centers utilize easy-to-use software that allows you to create a custom message to display for customers or your community.

Are you ready to move forward with a no-commitment quote? Let’s talk about a custom display or printed promotional products that will make you proud to use at future events.

Transparent LCD’s provide an innovative display solution opening up new ways for brands to promote their products and services. Examples include retail stores looking to advertise a new fashion clothing or accessory, museums securely housing a precious artifact with information displayed on screen or brands looking to launch a new product at a live event or show. The opportunities are endless!

Our Transparent LCD Displays include a Grade A LCD panel with metal bezel protecting the edges / electronics and a media board supporting HDMI or VGA inputs from your PC, Laptop or Media Player.

The combination of HD LCD technology (4K on our 65″, 86″, 98″ version) with a transparent screen substrate opens up creative avenues that were previously closed with traditional LCD displays. Solid black pixels on a transparent background can be used in intriguing ways to hide (and gradually reveal) whatever is behind the screen.

Our Transparent LCD monitors are designed for integration into the customers own furniture housing or display case while our Transparent LCD showcases offer a complete solution including the display, housing and backlight with white or black options available on request. We can also offer custom freestanding options for POP / POS displays. Transparent LCD’s are predominantly fully housed however we’ve recently developed an innovative housing method using a high brightness LED panel which allows the display case sides to remain transparent for improved visibly into the display case.

Using their original design as a starting point, we worked closely with the team at Nike to adapt to the mechanical aspects of the design, the result was a sleek and minimalist set of nine Transparent LCD Display Screens, custom built to suit the applications requirements, bringing Nike’s original concept ideas to life.

Transparent LCD’s comprise of an LCD panel without the backlight with white pixels appearing as transparent. In order to display an image, the Transparent LCD needs to be integrated into a housing with a high bright LED backlight.

We can also offer more complete solutions like our Transparent LCD Showcase that comes fully contained and ready to use with a powerful backlighting system to guarantee the best picture quality.

Yes in order to display an image Transparent LCD’s need to have a strong backlight. Notoriously Transparent LCD’s have also needed some form of housing to achieve optimum image quality, however, Nike’s House of Innovation paired our Transparent LCD’s with powerful, oversized backlights that allowed the screens to be mounted with no surround but still producing a high-quality image.

Transparent LCD’s are arguably the most popular transparent screens but are hindered by their need for a backlight to operate. For applications looking for a similar effect without the backlighting, Transparent OLEDs require no housing or surround but are only currently available in a 55″ screen size with HD quality. For larger transparent screen applications, Transparent LED’s are recommended with external and internal solutions usually installed to glass facades for the impact of an led screen without compromising the view from inside the building.

Transparent LCD’s are a great way to combine physical and digital displays in one central place making them a popular choice for museums and exhibitions. Our transparent screens can also be integrated into display furniture and appliances & vending machines like freezer doors for supermarkets. Other uses include POS displays, store window displays, trade shows and product launches.

We manufacture in Britain and ship worldwide – if you need further information, a pricing quote, or want to discuss ideas for using our Transparent LCD Display click the link below to contact us, email us via info@prodisplay.com or call us on +44 (0)1226 361 306.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey