tft lcd led-backlit vs tft lcd factory

In market, LCD means passive matrix LCDs which increase TN (Twisted Nematic), STN (Super Twisted Nematic), or FSTN (Film Compensated STN) LCD Displays. It is a kind of earliest and lowest cost display technology.

LCD screens are still found in the market of low cost watches, calculators, clocks, utility meters etc. because of its advantages of low cost, fast response time (speed), wide temperature range, low power consumption, sunlight readable with transflective or reflective polarizers etc. Most of them are monochrome LCD display and belong to passive-matrix LCDs.

TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy without running out of operation.

Normally, we say TFT LCD panels or TFT screens, we mean they are TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology. TFT is active-matrix LCDs, it is a kind of LCD technologies.

TFT has wider viewing angles, better contrast ratio than TN displays. TFT display technologies have been widely used for computer monitors, laptops, medical monitors, industrial monitors, ATM, point of sales etc.

Actually, IPS technology is a kind of TFT display with thin film transistors for individual pixels. But IPS displays have superior high contrast, wide viewing angle, color reproduction, image quality etc. IPS screens have been found in high-end applications, like Apple iPhones, iPads, Samsung mobile phones, more expensive LCD monitors etc.

Both TFT LCD displays and IPS LCD displays are active matrix displays, neither of them can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to make LCD showing colors. If you use a magnifier to see your monitor, you will see RGB color. With switch on/off and different level of brightness RGB, we can get many colors.

Neither of them can’t release color themselves, they have relied on extra light source in order to display. LED backlights are usually be together with them in the display modules as the light sources. Besides, both TFT screens and IPS screens are transmissive, it will need more power or more expensive than passive matrix LCD screens to be seen under sunlight. IPS screens transmittance is lower than TFT screens, more power is needed for IPS LCD display.

Confused about LED vs. LCD vs. TFT? Here"s everything you need to know. Creating or upgrading a device display or screen can involve a lot of different things, but it often comes down to one major question - what kind of display should you get?

So, there are 3 common displays LED, LCD and TFT available in the market. All terms refer to the flat-panel display, or screen, of a computer monitor or television set. In this article, we are going to differentiate between them. It will help you to choose a better one.

LCD stands for liquid crystal display. Works by adjusting the amount of light blocked. Usually has a backlight but might not (clocks, calculators, Nintendo Gameboy). The green-black ones can be very cheap and are a mature technology. Response time can be slow. An LCD display uses the light balancing qualities of crystals. Today LCDs are used in a great number of products and applications. Your TV, computer screen, calculator, cell phone and the dreaded alarm clock are all made of an LCD flat panel. Color LCDs produce the color based on two techniques: Passive matrix and active matrix. Passive matrix is the cheapest technology of the two. The other technology is called an active matrix or TFT. Active matrix displays produce really sharp and clear images.

This is a type of LCD with a thin film transistor attached to each pixel. All computer LCD screens are TFT since the early 2000s; older ones had slower response times and poorer color. Cost is now very good; power consumption is fairly good but dominated by the backlight. Has to be manufactured out of glass. The TFT layer is embedded in the screen itself, it reduces crosstalk between pixels. Crosstalk happens when a signal sends to a pixel also affects the pixel next to it. This makes the TFT technology the technology offering the best resolution and image quality. It also makes it a bit more expensive. Today TFTs have become the standard when producing LCD screens.

LED stands for a light emitting diode. As the name suggests, emits light rather than blocking it like LCD. Used for red/green/blue/white indicator lights everywhere. Some manufacturers advertise "LED" displays that are TFT screens with a white LED backlight, which is just confusing. Ones that are real LED screens are usually OLED.

An LCD panel is, in fact, 2 layers of glass with some volume of Liquid Crystal in between. These two form the panel itself. The 2 layers are usually called Color Filter Glass (above) and TFT glass (below).

LCDs can’t completely prevent light from passing through, though, even during dark scenes, so dimming the light source itself aids in creating deeper blacks and more impressive contrast in the picture.

A standard TFT has a whole "lamp" behind it, illuminating the whole screen all the time. This way, you cannot have a true black, as it is still illuminated and stay grayish.

TFTs are a type of active matrix display that controls individual pixel updates several times per second on the screen to update the image relative to the content source.

TFT displays use more electricity than regular LCD screens, so they not only cost more in the first place, but they are also more expensive to operate.

LCDs use fluorescent lights while LEDs use those light emitting diodes. The fluorescent lights in an LCD are always behind the screen. On an LED, the light emitting diodes can be placed either behind the screen or around its edges.

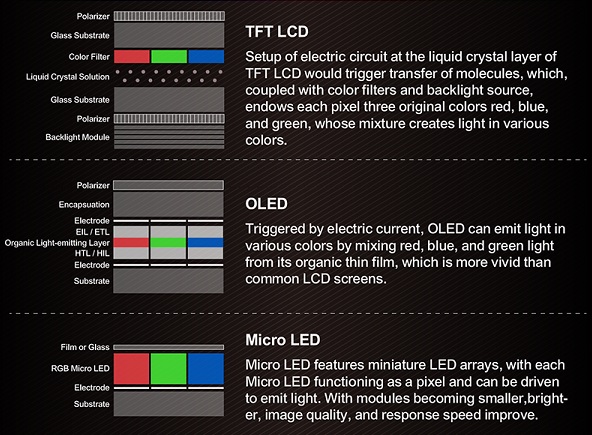

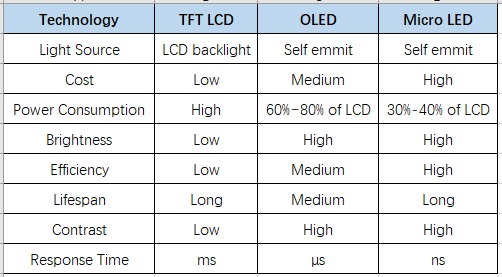

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

TFT displays are also known as an “Active Matrix TFT LCD module” and have an array of thin film transistors fabricated on the glass that makes the LCD. There is one of these transistors for each pixel on the LCD. See our blog post RGB and Color Depth for more on how TFTs show color.

LCDs use voltage applied to a field of microscopic liquid crystals to change the crystal’s orientation. The orientation of the crystals changes the polarization of the liquid crystal creating light or dark pixels on the display.

Beautiful, complex images: All of our TFT modules are full-color graphic displays. Unlike standard monochrome character displays, you can create complex images for an imaginative user experience.

Single Supply: Most of the TFTs use an integrated controller with built-in voltage generation so only a single 3.3v supply is needed for both the panel power and logic voltage.

Many of our character LCD modules use a standard HD44780 compatible controller, so they can be quickly integrated into a new product or used as a replacement in your existing products.

Many of the LCD controllers on board our graphic LCD display modules also include a CGROM (character generator ROM) which allows for easy character information as well as full bit-mapped graphic information to be shown.

Some of the graphic LCD displays have the ability to render graphics in grayscale, enabling you to show images and elements of your UI (user interface) with more depth and definition.

Let us start with the basics first; refresh the knowledge about TN and LCD displays in general, later we will talk about TFTs (Thin Film Transistors), how they differ from regular monochrome LCD displays. Then we will go on to the ghosting effect, so we will not only discuss the technology behind the construction of the TFT, but also some phenomena, like the ghosting effect, or grayscale inversion, that are important to understand when using an LCD TFT display.

Next, we will look at different technologies of the TFT LCD displays like TN, IPS, VA, and of course about transmissive and transflective LCD displays, because TFT displays also can be transmissive and transflective. In the last part we will talk about backlight.

Let us start with a short review of the most basic liquid crystal cell, which is the TN (twisted nematic) display. On the picture above, we can see that the light can be transmit through the cell or blocked by the liquid crystal cell using voltage. If you want to learn more about monochrome LCD displays and the basics of LCD displays, follow this link.

What is a TFT LCD display and how it is different from a monochrome LCD display? TFT is called an active display. Active, means we have one or more transistors in every cell, in every pixel and in every subpixel. TFT stands for Thin Film Transistor, transistors that are very small and very thin and are built into the pixel, so they are not somewhere outside in a controller, but they are in the pixel itself. For example, in a 55-inch TV set, the TFT display contains millions of transistors in the pixels. We do not see them, because they are very small and hidden, if we zoom in, however, we can see them in every corner of each pixel, like on the picture below.

On the picture above we can see subpixels, that are basic RGB (Red, Green, Blue) colors and a black part, with the transistors and electronic circuits. We just need to know that we have pixels, and subpixels, and each subpixel has transistors. This makes the display active, and thus is called the TFT display. TFT displays are usually color displays, but there are also monochrome TFT displays, that are active, and have transistors, but have no colors. The colors in the TFT LCD display are typically added by color filters on each subpixel. Usually the filters are RGB, but we also have RGBW (Red, Green, Blue, White) LCD displays with added subpixels without the filter (White) to make the display brighter.

Going a little bit deeper, into the TFT cell, there is a part inside well known to us from the monochrome LCD display Riverdi University lecture. We have a cell, liquid crystal, polarizers, an ITO (Indium Tin Oxide) layer for the electrodes, and additionally an electronic circuit. Usually, the electronic circuit consists of one transistor and some capacitors to sustain the pixel state when we switch the pixel OFF and ON. In a TFT LCD display the pixels are much more complicated because apart from building the liquid crystal part, we also need to build an electronic part.

That is why TFT LCD display technologies are very expensive to manufacture. If you are familiar with electronics, you know that the transistor is a kind of switch, and it allows us to switch the pixel ON and OFF. Because it is built into the pixel itself, it can be done very quickly and be very well controlled. We can control the exact state of every pixel not only the ON and OFF states, but also all the states in between. We can switch the light of the cells ON and OFF in several steps. Usually for TFT LCD displays it will be 8-bit steps per color, so we have 256 steps of brightness for every color, and every subpixel. Because we have three subpixels, we have a 24-bit color range, that means over 16 million combinations, we can, at least theoretically, show on our TFT LCD display over 16 million distinct colors using RGB pixels.

Now that we know how the TFT LCD display works, we can now learn some practical things one of which is LCD TFT ghosting. We know how the image is created, but what happens when we have the image on the screen for a prolonged time, and how to prevent it. In LCD displays we have something called LCD ghosting. We do not see it very often, but in some displays this phenomenon still exists.

Another issue present in TFT displays, especially TN LCD displays, is grayscale inversion. This is a phenomenon that changes the colors of the screen according to the viewing angle, and it is only one-sided. When buying a TFT LCD display, first we need to check what kind of technology it is. If it is an IPS display, like the Riverdi IPS display line, then we do not need to worry about the grayscale inversion because all the viewing angles will be the same and all of them will be very high, like 80, 85, or 89 degrees. But if you buy a more common or older display technology type, like the TN (twisted nematic) display, you need to think where it will be used, because one viewing angle will be out. It may be sometimes confusing, and you need to be careful as most factories define viewing direction of the screen and mistake this with the greyscale inversion side.

We know already that TN (twisted nematic) displays, suffer from grayscale inversion, which means the display has one viewing side, where the image color suddenly changes. It is tricky, and you need to be careful. On the picture above there is a part of the LCD TFT specification of a TN (twisted nematic) display, that has grayscale inversion, and if we go to this table, we can see the viewing angles. They are defined at 70, 70, 60 and 70 degrees, that is the maximum viewing angle, at which the user can see the image. Normally we may think that 70 degrees is better, so we will choose left and right side to be 70 degrees, and then up and down, and if we do not know the grayscale inversion phenomena, we may put our user on the bottom side which is also 70 degrees. The viewing direction will be then like a 6 o’clock direction, so we call it a 6 o’clock display. But you need to be careful! Looking at the specification, we can see that this display was defined as a 12 o’clock display, so it is best for it to be seen from a 12 o’clock direction. But we can find that the 12 o’clock has a lower viewing angle – 60 degrees. What does it mean? It means that on this side there will be no grayscale inversion. If we go to 40, 50, 60 degrees and even a little bit more, probably we will still see the image properly. Maybe with lower contrast, but the colors will not change. If we go from the bottom, from a 6 o’clock direction where we have the grayscale inversion, after 70 degrees or lower we will see a sudden color change, and of course this is something we want to avoid.

We will talk now about the other TFT technologies, that allow us to have wider viewing angles and more vivid colors. The most basic technology for monochrome and TFT LCD displays is twisted nematic (TN). As we already know, this kind of displays have a problem with grayscale inversion. On one side we have a higher retardation and will not get a clear image. That is why we have other technologies like VA (Vertical Alignment), where the liquid crystal is differently organized, and another variation of the TFT technology – IPS which is In-Plane Switching. The VA and IPS LCD displays do not have a problem with the viewing angles, you can see a clear image from all sides.

Apart from the different organization of the liquid crystals, we also organize subpixels a little bit differently in a VA and IPS LCD displays. When we look closer at the TN display, we will just see the subpixels with color filters. If we look at the VA or IPS display they will have subpixels of subpixels. The subpixels are divided into smaller parts. In this way we can achieve even wider viewing angles and better colors for the user, but of course, it is more complicated and more expensive to do.

The picture above presents the TN display and grayscale inversion. For IPS or VA technology there is no such effect. The picture will be the same from all the sides we look so these technologies are popular where we need wide viewing angles, and TN is popular where we don’t need that, like in monitors. Other advantages of IPS LCD displays are they give accurate colors, and wide viewing angles. What is also important in practice, in our projects, is that the IPS LCD displays are less susceptible to mechanical force. When we apply mechanical force to the screen, and have an optically bonded touch screen, we push the display as well as squeeze the cells. When we have a TN display, every push on the cell changes the image suddenly, with the IPS LCD displays with in-plane switching, different liquid crystals organization, this effect is lesser. It is not completely removed but it is much less distinct. That is another reason IPS displays are very popular for smartphones, tablets, when we have the touchscreens usually optically bonded.

Now, let us look at the backlight types. As we see here, on the picture above, we have four distinct types of backlight possible. The most common, 95 or 99 per cent of the TFT LCD displays on the market are the transmissive LCD display type, where we need the backlight from the back. If you remember from our Monochrome LCD Displays lecture, for transmissive LCD displays you need the backlight to be always on. If you switch the backlight off, you will not see anything. The same as for monochrome LCD displays, but less popular for TFT displays, we have the transflective LCD display type. They are not popular because usually for transflective TFT displays, the colors lack in brightness, and the displays are not very practical to use. You can see the screen, but the application is limited. Some transflective LCD displays are used by military, in applications where power consumption is paramount; where you can switch the backlight off and you agree to have lower image quality but still see the image. Power consumption and saving energy is most important in some kind of applications and you can use transflective LCD displays there. The reflective type of LCD displays are almost never used in TFT. There is one technology called Low Power Reflective Displays (LPRD) that is used in TFT but it is not popular. Lastly, we have a variation of reflective displays with frontlight, where we add frontlight to the reflective display and have the image even without external light.

Just a few words about Low Power Reflective Displays (LPRD). This kind of display uses environmental light, ambient light to reflect, and produce some colors. The colors are not perfect, not perfectly clear, but this technology is becoming increasingly popular because it allows to have color displays in battery powered applications. For example, a smartwatch would be a case for that technology, or an electrical bike or scooter, where we can not only have a standard monochrome LCD display but also a TFT LCD color display without the backlight; we can see the image even in

strong sunlight and not need backlight at all. So, this kind of TFL LCD display technology is getting more and more popular when we have outdoor LCD displays and need a low power consumption.

On the picture above, we have some examples of how transmissive and reflective LCD displays work in the sunlight. If we have a simple image, like a black and white pattern, then on a transmissive LCD display, even with 1000 candela brightness, the image probably will be lower quality than for a reflective LCD display; if we have sunlight, we have very strong light reflections on the surface of the screen. We have talked about contrast in more detail in the lecture Sunlight Readable Displays. So, reflective LCD displays are a better solution for outdoor applications than transmissive LCD displays, where you need a really strong backlight, 1000 candela or more, to be really seen outdoors.

To show you how the backlight of LCD displays is built, we took the picture above. You can see the edge backlight there, where we have LEDs here on the small PCB on the edge, and we have a diffuser that distributes the light to the whole surface of LCD screen.

In addition to the backlight, we have something that is called a frontlight. It is similar to backlight, it also uses the LEDs to put the light into it, but the frontlight needs to be transparent as we have the display behind. On the example on the picture above we can see an e-paper display. The e-paper display is also a TFT display variation, but it is not LCD (liquid crystal), it is a different technology, but the back of the display is the same and it is reflective. The example you see is the Kindle 4 eBook reader. It uses an e-paper display and a frontlight as well, so you can read eBooks even during the night.

Before you get a new monition for your organization, comparing the TFT display vs IPS display is something that you should do. You would want to buy the monitor which is the most advanced in technology. Therefore, understanding which technology is good for your organization is a must. click to view the 7 Best Types Of Display Screens Technology.

Technology is changing and becoming advanced day by day. Therefore, when you are looking to get a new monitor for your organization, LCD advantages, and disadvantage, you have to be aware of the pros and cons of that monitor. Moreover, you need to understand the type of monitor you are looking to buy.

That is why it is important to break it down and discuss point by point so that you can understand it in a layman’s language devoid of any technical jargon. Therefore, in this very article, let’s discuss what exactly TFT LCDs and IPS LCDs are, and what are their differences? You will also find out about their pros and cons for your organization.

The word TFT means Thin-Film-Translator. It is the technology that is used in LCD or Liquid Crystal Display. Here you should know that this type of LCD is also categorically referred to as active-matrix LCDs. It tells that these LCDs can hold back some pixels while using other pixels. So, the LCD will be using a very minimum amount of energy to function. TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the display monitor functions by using a very small amount of energy without running out of operation.

Now, it is time to take a look at its features that are tailored to improve the experience of the monitor users significantly. Here are some of the features of the TFT monitor;

No radiation, no scintillation, no harm to the user’s health. In particular, the emergence of TFT LCD electronic books and periodicals will bring humans into the era of a paperless office and paperless printing, triggering a revolution in the civilized way of human learning, dissemination, and recording.

It can be normally used in the temperature range from -20℃ to +50℃, and the temperature-hardened TFT LCD can operate at low temperatures up to -80 ℃. It can not only be used as a mobile terminal display, or desktop terminal display but also can be used as a large screen projection TV, which is a full-size video display terminal with excellent performance.

The manufacturing technology has a high degree of automation and good characteristics of large-scale industrial production. TFT LCD industry technology is mature, a mass production rate of more than 90%.

TFT LCD screen from the beginning of the use of flat glass plate, its display effect is flat right angles, let a person have a refreshing feeling. And LCDs are easier to achieve high resolution on small screens.

The word IPS refers to In-Plane-Switching which is a technology used to improve the viewing experience of the usual TFT displays. You can say that the IPS display is a more advanced version of the traditional TFT LCD module. However, the features of IPS displays are much more advanced and their applications are very much widespread. You should also know that the basic structure of the IPS LCD is the same as TFT LCD if you compare TFT LCD vs IPS.

As you already know, TFT displays do have a very quick response time which is a plus point for it. But, that does not mean IPS displays a lack of response time. In fact, the response time of an IPS LCD is much more consistent, stable, and quick than the TFT display that everyone used to use in the past. However, you will not be able to gauge the difference apparently by watching TFT and IPS displays separately. But, once you watch the screen side-by-side, the difference will become quite clear to you.

The main drawback of the TFT displays as figured above is the narrow-angle viewing experience. The monitor you buy for your organization should give you an experience of wide-angle viewing. It is very much true if you have to use the screen by staying in motion.

So, as IPS displays are an improved version of TFT displays the viewing angle of IPS LCDs is very much wide. It is a plus point in favor of IPS LCDs when you compare TFT vs IPS. With a TFT screen, you cannot watch an image from various angles without encountering halo effects, blurriness, or grayscale that will cause problems for your viewing.

It is one of the major and remarkable differences between IPS and TFT displays. So, if you don’t want to comprise on the viewing angles and want to have the best experience of viewing the screen from wide angles, the IPS display is what you want. The main reason for such a versatile and wonderful viewing angle of IPS display is the screen configuration which is widely set.

Now, when you want to achieve wide-angle viewing with your display screen, you need to make sure it has a faster level of frequency transmittance. It is where IPS displays overtake TFT displays easily in the comparison because the IPS displays have a much faster and speedier transmittance of frequencies than the TFT displays.

Now the transmittance difference between TFT displays and IPS displays would be around 1ms vs. 25ms. Now, you might think that the difference in milliseconds should not create much of a difference as far as the viewing experience is concerned. Yes, this difference cannot be gauged with a naked eye and you will find it difficult to decipher the difference.

However, when you view and an IPS display from a side-by-side angle and a TFT display from a similar angle, the difference will be quite evident in front of you. That is why those who want to avoid lagging in the screen during information sharing at a high speed; generally go for IPS displays. So, if you are someone who is looking to perform advanced applications on the monitor and want to have a wider viewing angle, then an IPS display is the perfect choice for you.

As you know, the basic structure of the IPS display and TFT displays are the same. So, it is quite obvious that an IPS display would use the same basic colors to create various shades with the pixels. However, there is a big difference with the way a TFT display would produce the colors and shade to an IPS display.

The major difference is in the way pixels get placed and the way they operate with electrodes. If you take the perspective of the TFT display, its pixels function perpendicularly once the pixels get activated with the help of the electrodes. It does help in creating sharp images.

But the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

As you already know the features of both TFT and IPS displays, it would be easier for you to understand the difference between the two screen-types. Now, let’s divide the matters into three sections and try to understand the basic differences so that you understand the two technologies in a compressive way. So, here are the difference between an IPS display and a TFT display;

Now, before starting the comparison, it is quite fair to say that both IPS and TFT displays have a wonderful and clear color display. You just cannot say that any of these two displays lag significantly when it comes to color clarity.

However, when it comes to choosing the better display on the parameter of clarity of color, then it has to be the IPS display. The reason why IPS displays tend to have better clarity of color than TFT displays is a better crystal oriental arrangement which is an important part.

That is why when you compare the IPS LCD with TFT LCD for the clarity of color, IPS LCD will get the nod because of the better and advanced technology and structure.

IPS displays have a wider aspect ratio because of the wide-set configuration. That is why it will give you a better wide-angle view when it comes to comparison between IPS and TFT displays. After a certain angle, with a TFT display, the colors will start to get a bit distorted.

But, this distortion of color is very much limited in an IPS display and you may see it very seldom after a much wider angle than the TFT displays. That is why for wide-angle viewing, TFT displays will be more preferable.

When you are comparing TFT LCD vs. IPS, energy consumption also becomes an important part of that comparison. Now, IPS technology is a much advanced technology than TFT technology. So, it is quite obvious that IPS takes a bit more energy to function than TFT.

Also, when you are using an IPS monitor, the screen will be much larger. So, as there is a need for much more energy for the IPS display to function, the battery of the device will drain faster. Furthermore, IPS panels cost way more than TFT display panels.

1. The best thing about TFT technology is it uses much less energy to function when it is used from a bigger screen. It ensures that the cost of electricity is reduced which is a wonderful plus point.

2. When it comes to visibility, the TFT technology enhances your experience wonderfully. It creates sharp images that will have no problems for older and tired eyes.

1. One of the major problems of TFT technology is that it fails to create a wider angle of view. As a result, after a certain angle, the images in a TFT screen will distort marring the overall experience of the user.

Although IPS screen technology is very good, it is still a technology based on TFT, the essence of the TFT screen. Whatever the strength of the IPS, it is a TFT-based derivative.

Finally, as you now have a proper understanding of the TFT displays vs IPS displays, it is now easier for you when it comes to choose one for your organization. Technology is advancing at a rapid pace. You should not be surprised if you see more advanced display screens in the near future. However, so far, TFT vs IPS are the two technologies that are marching ahead when it comes to making display screens.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

First, the ITO film layer needs to be deposited on the TFT glass, so that there is a smooth and uniform ITO film on the whole TFT glass. Then, using ionized water, the ITO glass is cleaned and ready for the next step.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

Have you ever wonder where TFT derive from? Why is TFT referred to as LCD? The phenomenon started in early days, when bulky CRT displays were thing of the past and LCD was its replacement, but as time progresses, there were still room for improvement, which leads to the birth of TFT’s.

TFT is a variant of an LCD which uses thin film transistor technology to improve an image quality, while an LCD is class of displays that uses modulating properties of liquid crystals to form what we call an LCD (liquid crystals display) which in fact does not emits light directly.

Even though LCDs were very energy efficient, light weight and thin in nature, LCD were falling behind to the CRT display, which then leads to a change in LCD manufacturing, where performance became a big problem.

For example, having a 2001 Mustang vs a 2014 Mustang, the dimensions and engine of the 2014 has been redesign for performance reasons, not mentioning user friendly, so does the LCD to TFT.

As the birth of TFT, the elements are deposited directly on the glass substrate which in fact the main reason for the switch was because TFTs are easier to produce, better performance in terms of adjusting the pixels within the display to get better quality.

LCDs became ineffective over a period of time, almost all aspect of watching a TV, playing video games or using a handheld device to surf the net became daunting, this phenomenon is known as high response time with low motion rate.

Another problem with LCD was crosstalking, in terms of pixelating, this happens when signals of adjacent pixels affects operations or gives an undesired effect to the other pixel.

As TFT’s become very popular throughout the century due to its elaborate low charge associate and outstanding response time, LCDs became a thing of the past, and TFT became the predominant technology with their wider viewing angles and better quality this technology will be around for a long time.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

TFT is an abbreviation for Thin Film Transistor, a flat panel display used to improve the operation and utility of LCD screens. In order to portray an appearance to the audience, a liquid crystal display (LCD) utilizes a crystalline-filled fluid to modify rear lighting polarized origin through the use of an electromagnetic force among two relatively thin metal wires such as indium oxide (ITO). However, color TFT displays are associated with this method, which can be employed in both divided and pixelated display systems.

With motion pictures displayed on an LCD, the intrinsic sluggish rate of increase between liquid phases over a significant number of pixel components can be an issue due to capacitance impacts, which can create a blurring of the visuals. Placing a high-velocity LCD control device inside the formation of a thin-film transistor immediately next to the cell component just on a glass screen, the issue of LCD picture speed may be substantially improved, and image blur can be eliminated for all useful purposes entirely.

Organic light-emitting diodes (AMOLEDs) are a type of flat light-emitting advanced technologies that are created by interspersing a succession of organic thin sheets over two conducting conductors. An electrical charge causes a brilliant light to be produced when the current flows. AMOLED displays are light-emitting screens that do not require a backlight, making them thinner and more energy-efficient than liquid crystal displays (LCDs) (which will need a white backlight).

Half-Life has been expanded. TFT displays have a far longer half-life than its LED equivalents, and they are available in a number of sizes, which might have an effect on the device"s half-life based on the phone"s usage as well as other variables. Touch panels for TFT screens can be either resistant or capacitance in nature.

Backlighting is unnecessary for AMOLEDs. LCDs produce images by selectively blocking parts of the illumination, whereas AMOLEDs produce light. AMOLEDs utilize less energy than LCDs since they don"t need backlighting. This is critical for battery-powered devices such as phones.

While AMOLED light-emitting sheets are lightweight, the substrate can also be elastic rather than stiff. AMOLED films are not limited to glass-like LEDs and LCDs.

AMOLEDs offer 170-degree ranges of vision. LCDs operate by obscuring the light. Hence they have intrinsic viewing obstacles. In addition, AMOLEDs have a substantially wider viewing spectrum.

AMOLEDs outperform LEDs. Since AMOLED organic coatings are less than LED inorganic crystal levels, AMOLED conducting and particle emitters layers can just be multi-layered. Also, LEDs and LCDs need glass backing, which absorbs light. AMOLEDs don"t need it.

Due to the fact that AMOLED displays inherently emit illumination, they do not need a backlight when used on a monitor screen. Conversely, LCDs require backlights since the liquid crystals themselves are incapable of producing light under their own. Direct light emission from AMOLED displays also allows for the developing of lightweight display devices than others using TFT LCDs.

LCD displays have a higher brightness than AMOLED panels. This is owing to the LCD"s usage of led backlight, which may provide a brilliant illumination of the entire display. Despite the fact that AMOLEDs produce high levels of brilliance from their illumination, they will never be able to match the intensity of LCD lighting.

LCD screens use less power than AMOLED displays, which provides a slight advantage. The amount of energy consumed by AMOLED displays is dependent on the intensity of the screen. Lowered luminance results in lower energy usage, however, it might not be the best solution because the contrast would suffer as a result of the decreased brightness. In some situations, such as when to use an AMOLED device in direct sunlight, it is not an optimal situation.

However, the backlit keys of TFT displays account for the majority of their power usage. TFT screens" efficiency is considerably improved when the backlight is set to a lesser brightness level than the default setting. For example, replacing the light of an LCD TV with just an Led flash will have no effect on the image quality, but will result in lower power usage than replacing the light of an AMOLED TV.

With the exception of phones, numerous other technologies make use of displays to allow customers to engage in direct communication with them. To determine whether or not TFT LCD will be able to withstand the development of AMOLED innovation, we should first review the benefits of LCD technology. The backlighting quality ensures that whites are strong and brightness is superb but will deplete a battery much more quickly than just an AMOLED display. Furthermore, the cost of LCD screens is a considerable consideration. In addition to being less expensive and more easily accessible, they are produced in standard industry sizes, allowing them to be purchased for innovative products with relative ease.

The DT010TFT is a 1 inch TFT LCD module with 80 x 160 RGB resolution. This small LCD screen uses a 4-wire Serial Protocol Interface (SPI) to communicate with the driver IC (Ilitek ILI9163) and has a 6 o"clock viewing angle. The single chip driver IC for this transmissive TFT LCD provides a full color display mode of 262K colors. This TFT LCD is ideal to be used as an indicator or to display simple icons and information. The 1" LCD module includes a color TFT-LCD panel, a driver IC, FPC, and a white LED backlight unit.

Please see the DT028CTFT for reference designs. The schematics between the B and the C are the same with the exception that the B does not have the IPS interface.

TOPWAY Color TFT Modules are designed to provide robust and easy to install display products for industrial applications. For many years in business, the broad design experience and the full range of iconic products made ...

VMD 3002 is a robust 10.4-inch TFT LCD monitor with enhanced brightness, projected capacitive touchscreen, and high performance loud speaker. It is designed with a single cable to consolidate ...

VMD 1001 is a 7-inch TFT LCD monitor with 4 wire resistant touch screen sensor. With the high brightness display and automatically brightness control, it is designed ...

VMD 2002 is an 8-inch TFT LCD monitor with 4 wire resistant touch screen sensor. With the high brightness display and automatically brightness control, it is designed ...

The HANNspree HP248WJB is a 23.8-inch Full HD monitor featuring an integrated 5Mpixel webcam, microphone array and stereo speakers for video conferencing and live-streaming. The TFT panel delivers ultra-wide ...

Distributor of component LCDs for equipment which provide high-contrast ratio, color saturation, luminance and performance enhancements such as advanced wide viewing (AWV) for true color fidelity, super-high brightness (SHB) and wide temperature range. Focus on industrial, instrumentation, hand-helds, medical and other low-to-medium volume markets. High-bright LED backlights for outdoor use. LVDS interfaces decrease EMI. Factory installed touch screen solutions. 3.5" to 12.1" QVGA, HVGA, VGA, WVGA, SVGA, XGA, WXGA. Also distributes other related products including LED drivers, lamps, indicators, LED assemblies, segment displays, LED mounts, LEDs, and light pipes. Distributor of electronic components, hardware and fasteners and provides design/value engineering support, fulfillment strategies, procurement services and transactional models to meet specific needs and priorities.

TFT stands for Thin-Film Transistor. TFT technology is a new standard these days for manufacturing displays, monitors, laptop screens, and other devices. TFT LCD displays can show crisp text, vivid colors, fast animations, and complex graphics.

TFT LCD monitors, also called flat panel displays, are replacing the old style cathode ray tubes (CRTs) as the displays of choice. Almost all LCD monitors today take advantage of the TFT technology.

Each pixel on a TFT display is backed by a tiny transistor. Transistors are so small these days, they need only a very minimal charge to control what they do. TFT displays are much more energy efficient than regular CRT screens that need a powerful light source.

TFT displays also allow for very fast re-drawing of the display, so the image has very little chance to flicker. This was not always the case with flat-panel monitors. Original passive matrix LCD displays were not able to refresh at very high rates and therefore could not keep up with fast moving images. A TFT monitor refresh rate is very high resulting in a display that can be used for video, gaming, and all forms of multimedia.

A TFT monitor delivers crisp text, vibra

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey