arduino lcd displays garbage price

Hi, i have and LCD 16x2 connected to my Leonardo. I works properly with all the examples son the connection is ok. But I add the LCD to another sketch and it"s just showing garbage, and i have no idea why. I just want to show "Writing:" in the first row, and the variable nombrearchivo in the second row. All of this works using serial, so my only problem is the LCD.

4 - I"m calling lcd.begin(16,4) at the setup, however I was still having an offset when trying to change lines, hence why I had to cobble up those offsets. Maybe I"m missing something here, as I"m pretty sure this shouldn"t be needed.

I actually did not write or format anything. I just made connections directly, taking the single connection scheme of each component from tutorials, testing each circuit on a breadboard singularly, then all together always on the breadboard, then rewiring directly from Arduino Board to component. I"m not a professional electronic, I"m just an employee in freight forwarding with some electrician background doing some of this for fun and trying to give it a practical use. I would post it if someone helps me find a good way to do it, as I had already asked. I"ve checked circuito.io but I cannot modify the connections it suggests to reflect mines; I was checking fritzing but I"ve found people telling to stay away from it, and mostly it is pretty time consuming to redesign it all, and as told, I"m an employee doing my job all day long, so I have to find the time to do it. I will work on it on this weekend, even If I can"t understand how this can help, being my issue not related to wrong connections, shorts or whatever.

Why i"m not posting the photos of the project: You"d see a bundle of wires that wouldn"t help. Project is partially torn down due to the disassembly of the relay part, buttons/LED resistors are bundled in tape so you can"t see them, LCD is connected reversed on the box cover so you aren"t seeing how it is connected, but mostly: the project has been working flawlessly for some days on my desk, while I was working on the sketch. The issue begun when I positioned the box on his final location, where I had it running fine until I attached the stove to the plug. I also made some tests before asking here, by restarting the project and checking how and when the issue happened. When the stove starts, no matter what the project is doing, the LCD gows in garbage mode. This is why I can say it not way related to functions, or miswiring, and this is why I posted on "General Electronics" and not in "Programming" or "Displays". And the fact that I was addressed to "shielding" and "grounding" or "try a capacitor here and here", and not "you have the wrong Pin 2 connected" or " Add a lcd.clear() here or here" tells me I made the correct choice.

The lcd.clear function is slow and can lead to screen flicker especially if done every time through loop(). Overwrite old data with spaces, reset the cursor position and print the new data and only update the screen when the data changes will help prevent flicker.

I"m having the same problem. I have a shield with combined RTC and SD card. I"ve wired up the LCD (16 x 2) and it works perfectly when I use the simple sample code for the LCD. I"ve noticed that it also works fine when I integrate the code into my program which utilizes the RTC and SD card IF AND ONLY IF I write to the LCD before initializing the SD or RTC. Actually, I saw the comments about SPI conflicts etc, so I modified the pins for the LCD a few times and found that in the original configuration, I could write to the LCD successfully AFTER the RTC initialization, but not after the SD card. Then, after I switched the pins, and it ONLY works if I write to the LCD at the beginning of the Setup() function before both RTC and SD calls. I thought I understood the potential conflicts so I"ve wired the LCD to pins as follows:

This doesn"t seem to be using any pins that conflict, but maybe I"m missing something? I have an Uno and am also using pins 2-4 for an optical sensor so they are not avail. Thoughts on how to resolve the conflict? Oh, the problem I"m having is that any writes to the LCD are correct ahead of the RTC/SD initializations, but I get gibberish when I write after those calls.

Adding an LCD display to Arduino projects can add real value but the cost of doing so can be significant. Not a financial cost - you can pick up 16 (characters) x 2 (rows) LCD for as little as £3.50. The cost is the pin count it can take to drive them. Using the built-in LiquidCrystal Display library it can take as many as 6 pins! That does not leave much for your sensors, motors and other components.

There are many projects that discuss using alternatives - such as a much more expensive Serial LCD (£10 up). Other projects discuss using two-wire interfaces, increasing the complexity of your code. The simplest way to drive the HD44780 style LCDs, in my opinion, is to use a 74HC595 shift register, taking the pin count down to 3.

In any case, connecting an LCD either using the 595 Shift Register or the more traditional way takes a lot of wiring which is not only a super mess (unless you use a ribbon cable I guess), it takes time.

Connect the wires to the shift register, if you use the library as default you will connect Green to Arduino Pin 7, Blue to Arduino Pin 8, Yellow to Arduino Pin 9.

The method of using a shift register to drive these displays with only 3 pins seems to have originally documented by Stephen Hobley. He did a great job of adjusting the built-in LiquidCrystal Library so it works brilliantly with the 595 Shift Register. I have now updated this library to be compatible with Arduino 1.x and adjusted some of the Shift Register pin assignments to be easier to prototype with. You need to download the latest code. It is feature complete and should be a drop-in replacement for any project you already have.

I understand that you may not wish to make a shield before trying this method out - that is completely understandable. For you, I have this documented for breadboards too. Sure, you will have to deal with more hookup wire, but it gives you a great way of at least trying this 3-pin method without any soldering. That layout, more code and wiring explanations are available from http://rowansimms.com/article.php/lcd-hookup-in-seconds

I have this running great from an ATtiny85. It also has a TMP36 temp sensor to desplay the current temperature. LCD uses pins 0, 1, 2 and TMP36 uses pin 3.

It worked once and then started showing garbage values and never worked again. It shows a row of boxes whenever I power it up again, nothing else. Please help !

@bitteroz Had to swap the emitter and collector of the BC547 NPN transistor to make the back light work. Mistake in circuit drawings? Or is my LCD different ? I have a green one.

I have this running great from an ATtiny85. It also has a TMP36 temp sensor to desplay the current temperature. LCD uses pins 0, 1, 2 and TMP36 uses pin 3More CommentsPost Comment

In the previous tutorial, we discussed multiplexingseven-segment displays(SSDs). Continuing with the display devices, in this tutorial, we will cover how to interface character LCD when using Arduino. Character LCDs are the most common display devices used in embedded systems. These low-cost LCDs are widely used in industrial and consumer applications.

For instance,LEDsare used as indicators of mutually exclusive conditions. The SSDs are used to display numeric information. The Liquid Crystal Displays (LCDs), TFTs, and OLED displays are used to present the more complicated information in embedded applications. Often, this complication arises due to the text or graphical nature of the information or the interface.

The character LCDs are used where the information or interface is of a textual nature. The graphical LCDs are used where the information or interface is of a graphical nature. The graphical LCDs that are used to design machine-human interfaces may also have touchscreens.

Character LCDsCharacter LCDs are useful in showing textual information or to provide a text-based, machine-human interface. It’s even possible to display some minimal graphics on these LCDs. These are low-cost LCD displays that fit in a wide range of embedded applications.

Generally, character LCDs do not have touchscreens. And unlike graphical LCDs, these LCDs do not have continuous pixels. Instead, the pixels on character LCDs are arranged as a group of pixels or dot-matrix of pixels of fixed dimensions.

The character LCDs are classified by their size, which is expressed as the number of characters that can be displayed. The number of possible characters that can display at a time on the LCD is indicated as the number of columns of characters and the number of rows of characters.

The common size of character LCDs is 8×1, 8×2, 10×2, 16×1, 16×2, 16×4, 20×2, 20×4, 24×2, 30×2, 32×2, 40×2, etc. For example, a 16×2 character LCD can display 32 characters at a time in 16 columns and 2 rows. Generally, characters are displayed as a matrix of black dots while the backlight of LCD may be a monochromatic color like blue, white, amber, or yellow-green.

The character LCDs may use any one of these types. The TN types are low-cost but have a narrow viewing angle and low contrast. The FSTN offers the best contrast and widest viewing angle, but they are more costly. Even character LCDs that use the FSTN display are still cheaper in comparison to graphical LCDs, TFTs, and OLEDs.

Most of the character LCDs use LED backlight and the backlight color can be white, blue, amber, or yellow-green. The other types of a backlight in character LCDs include EL, CCFL, internal power, external power, and 3.3 and 5V backlights. EL and LED backlights are the most common. The LCD may have a reflective, trans-reflective, or transmissive rear polarizer.

The quality of display depends on the LCD type, the backlight, and the nature of a rear polarizer used in the LCD panel. When selecting an LCD panel for an embedded application, it’s important to decide on the quality of the LCD display, according to the requirements. This includes per the application, class of the device, nature of use (such as indoor or outdoor), target users of the device, intended user-experience, operating conditions (such as temperature and operating voltage), and cost limitations.

For example, a character LCD that has to be used for the machine-human interface must have better contrast, a wide viewing angle, and a good backlight.

Even on a character LCD, a large number of pixels have to be controlled to display the text. A 16×2 character LCD in which each character is 5×8 pixels means that a total of 1280 pixels (16×2 characters x 5×8 Pixels) have to be controlled. This requires interfacing the pixels across 16 rows (2 rows of characters x 8 rows in each character) and 80 columns (16 columns of characters x 5 columns in each character) of connections.

This is when pixels are black dots and merely require switching either ON or OFF by the controller to display text characters. On a typical microcontroller, there are not these many I/O pins that can be dedicated to controlling the pixels of an LCD panel. That is why LCD modules have integrated controllers that control the pixels of the LCD. The integrated controller can interface with a microcontroller or a processor via an 8-bit/4-bit parallel port or a serial interface (like I2C). The integrated controller receives data and commands from the microcontroller/processor to display text on the LCD panel via a 4-bit/8-bit parallel or serial interface.

In fact, the LCD module is a complete embedded system comprising of an LCD panel, LCD driver, LCD controller, LED Backlight, internal flags, Address Counter, Display Data RAM (DDRAM), Character Generator ROM (CGROM), Character Generator RAM (CGRAM), Data Register (DR), Instruction Register (IR), and Cursor Control Circuit.

1. LCD Panel. The character LCDs have the dot-matrix LCD panel. The text characters are displayed on the panel according to the commands and data received by the integrated controller.

2. System Interface. This module has a 4-bit and an 8-bit interface to connect with microcontrollers/processors. Some LCD modules also have a built-in serial interface (I2C) for communication with a controller. The selection of interface (4-bit or 8-bit) is determined by the DL bit of the Instruction Register (IR).

5. Character Generator ROM (CGROM). It’s an internal Read-Only Memory (ROM) on the LCD module where the patterns for the standard characters are stored. For example, a 16×2 LCD module, CGROM has 5×8 dots, 204 character patterns, and 5×10 dots of 32 characters pattern that are stored. So, the patterns for the 204 characters are permanently stored in the CGROM.

6. Character Generator RAM (CGRAM). The user-defined characters can also be displayed on a character LCD. The patterns for custom characters are stored in CGRAM. On the 16×2 LCD, 5 characters of the 5×8 pixels can be defined by a user program. The user needs to write the font data (which is the character pattern defining what pixels/dots must ON and which must OFF to properly display the character) to generate these characters.

7. Display Data RAM (DDRAM). The data sent to the LCD module by the microcontroller remains stored in DDRAM. In 16×2 character LCD, DDRAM can store a maximum of 80 8-bit characters where the maximum of 40 characters for each row can be stored.

9. Busy Flag (BF). The bit DB7 of the instruction register is a busy flag of the LCD module. When the LCD is performing some internal operations, this flag is set (HIGH). During this time, the instruction register does not accept any new instruction via the system interface from the microcontroller. New instructions can be written to the IR but only when the busy flag is clear (LOW).

11. LCD Driver. It controls the LCD panel and the display. In the 16×2 character LCD, the LCD driver circuit consists of 16 common signal drivers and 40 segment signal drivers.

12. Timing Generation Circuit. It generates the timing signals for the operation of internal circuits, such as the DDRAM, CGRAM, and CGROM. The timing signals for reading RAM (DDRAM/CGRAM) module are generated separately to display characters and timing signals for the internal operations of the integrated controller/processor of LCD. This is so that the display does not interfere with the internal operations of the integrated controller of the LCD module.

Interfacing character LCDsMost of the character LCDs have a 14-pin or 16-pin system interface for communication with a microcontroller/processor. The 16-pin system interface is the most common.

To interface the LCD module with a microcontroller or Arduino, the digital I/O pins of the microcontroller must be connected with the RS, RW, EN, and data pins DB0 to DB7.

In 4-bit mode, two pulses are required at the EN pin to write data/instruction to the LCD. At first, the higher nibble of data or the instruction is latched. Then, in the second pulse lower nibble of the data/instruction is transferred.

In an 8-bit mode, the entire 8-bit data/instruction is written to the LCD in a single pulse at the EN pin. So, the 4-bit mode saves the microcontroller pins but has a slight latency in comparison to the 8-bit mode of operation. The 8-bit mode suffers less from latency but engages 4 extra pins from the microcontroller.

It’s also possible to interface the LCD module with Arduino using a serial-to-parallel converter. Then, only two pins of Arduino are required to interface with the LCD module.

The ground pin of the LCD module (pin 1) must be connected to the ground while the VCC pin (pin 2) must be connected to the supply voltage. The 3.3 or 5V pin of Arduino can be used to supply voltage to the LCD module. The VEE pin must be connected to the variable terminal of a variable resistor, and the fixed terminals of the variable resistor must be connected to the VCC and ground.

How character LCD worksIt is possible to read/write data with the LCD module. To write data/instructions to the LCD module, the RW pin must be clear. Then, if the RS is set, an 8-bit data sent by the microcontroller stores in the data register (DR) of the LCD module. This 8-bit data sent by the microcontroller will store in the instruction register (IR) of the LCD module.

When data is sent to the LCD module (RW=0, RS=1, EN=1->0), it is written in the DDRAM and the Address Counter of the LCD is increased by one. The LCD controller compares the 8-bit data with the CGROM addresses and displays the appropriate character on the LCD at the associated DDRAM address. This serves as the instruction to show that the display has been received.

When the instruction is sent to the LCD module (RW=0, RS=0, EN=1->0), it is stored in the instruction register and according to the pre-defined instruction set of the LCD controller, the appropriate operation is executed on the display (to set display ON, set display OFF, set cursor ON, set cursor OFF, clear DDRAM, etc.).

Sometimes, the microcontroller may need to read data from the LCD. A microcontroller can read content from the instruction register, DDRAM, and CGRAM of the LCD. To read data from the LCD, the RW pin must be set. When the RW is set and the RS is clear, the microcontroller reads the content of Instruction Register (IR) — including the busy flag (DB7 of IR) and address counter (DB6 to DB0 of IR) — when applying a HIGH to LOW pulse at EN pin.

If the LCD module is interfaced to typical microcontrollers (8051, PIC, AVR, etc.), the RS, RW, EN, and the data bits need to be set individually to perform the read/write operations.

Arduino has a Liquid Crystal library (LiquidCrystal.h) available that makes programming LCD with Arduino extremely easy. This library can be imported by the following statement:

LiquidCrystal() methodThis method is used to create a Liquid Crystal object. The object must be created according to the circuit connections of the LCD module when using Arduino.

The object takes the pin numbers of the Arduino as arguments. The pin numbers where the RS, RW, EN, and the data pins (DB7-DB0 for 8-bit mode and DB7-DB4 for 4-bit mode) of the LCD are connected, has to be passed as arguments in the object definition.

This method is used to initialize the LCD module. The function takes the size of the LCD (expressed by number of columns and rows in the LCD) as the arguments.

This method positions the cursor at the given location on the LCD panel. It takes the column and row as the argument where the cursor has to be placed and a subsequent character has to be displayed.

This method is used to print text to the LCD. It takes a string argument, which has to be displayed at the current cursor position on the LCD. It can take base of the value passed as an optional argument — if only printing numbers.

How to check the LCDA common concern when interfacing the LCD module is to identify whether or not the LCD module is, indeed, working. When connecting the LCD with Arduino (or any other MCU), if only the lower line of the LCD brightens, then the LCD module is working.

Sometimes when you try to print on the LCD, nothing occurs, except the lower line of the LCD illuminating. In this case, the possible reasons can be one of the following:

2. The LCD module might have been interfaced in the reverse pin order (i.e. instead of pins 1 to 16, circuit connections might have been made from pins 16 to 1 of the LCD module).

4. The contrast of the LCD at the VEE pin might not have been adjusted properly. If the adjustment of contrast does not work, try connecting the VEE pin directly to the ground, so that the LCD module is adjusted to maximum contrast.

5. If after checking all the circuit connections, LCD panel still does not display text, check if the code uploaded to Arduino is correct or not. For example, it is possible that if the LCD display is not cleared after initialization, garbage values may display on the LCD instead of the intended text.

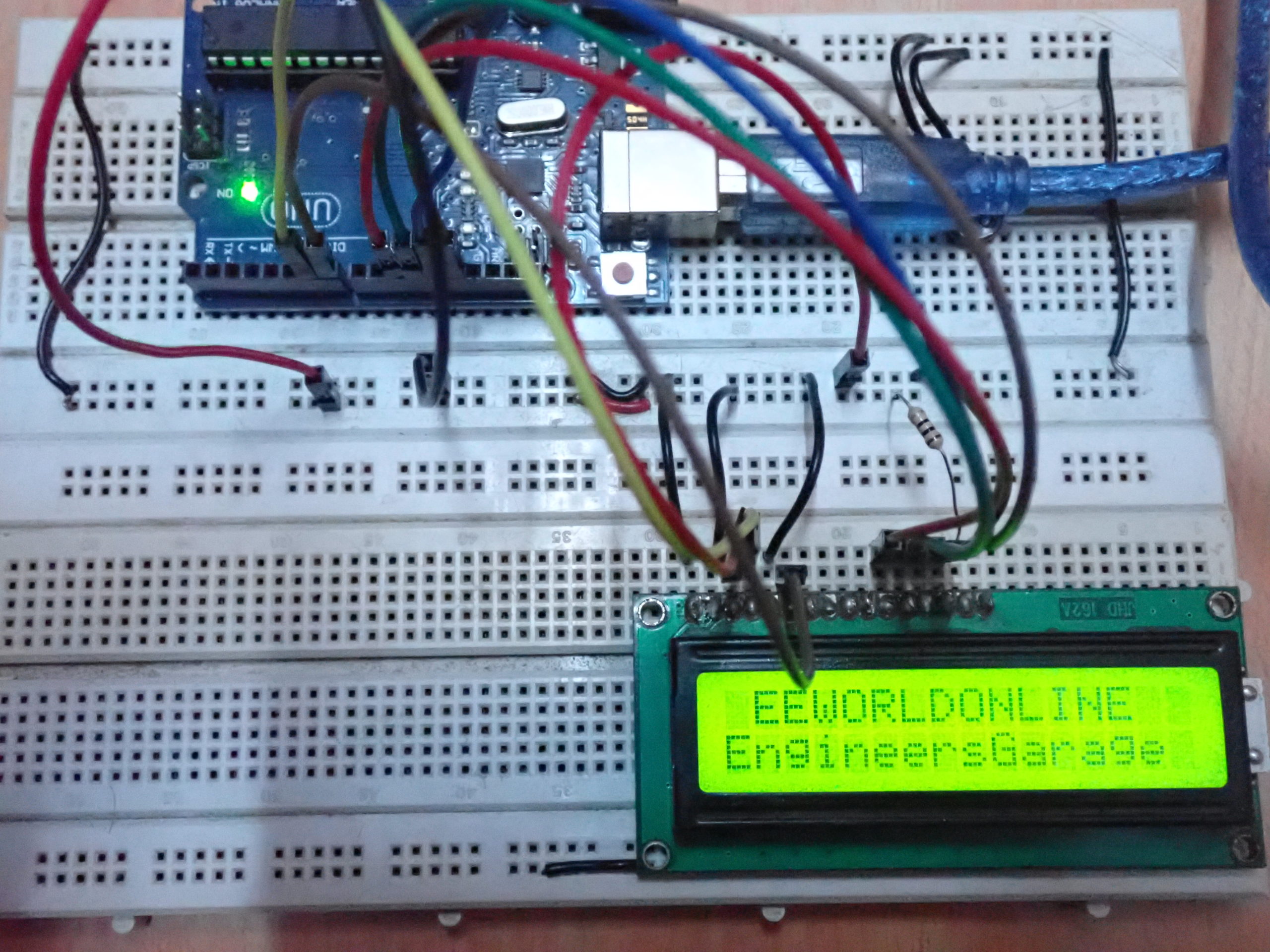

Components required1. Arduino UNO x12. 16×2 character LCD x13. 10K Pot x14. 330 Ohms Resistor or any low-value resistor x15. Breadboard x16. Male-to-Male Jumper Wires or Connecting Wires

Circuit connectionsThe LCD module used in this project is JHD162A. This is a 16×2 LCD module with 5×8 character dots. The LCD module has a 16-pin interface. The LCD is interfaced with Arduino in 4-bit mode.

Pin 1 (GND) and 16 (LED) of the LCD module are connected to ground while pin 2 (VCC) is connected to the VCC. The pin 15 (LED+) from the LCD module is, once again, connected to the VCC via a small-value resistor. The pin 3 (VEE) is connected to the variable terminal of a pot while the fixed terminals of the pot are connected to the ground and VCC.

The R/W pin is connected to the ground as Arduino will only write data to the LCD module. The RS, EN, DB4, DB5, DB6, and DB7 pins of the LCD are connected to pins 13, 11, 7, 6, 5, and 4 of Arduino UNO, respectively. The breadboard supplies the common ground. The 5V supplies the rail from one of the ground pins and 5V pin of the Arduino UNO, respectively.

The LCD module is connected with Arduino in a 4-bit mode. First, the LCD is initialized and the display is cleared to get rid of any garbage values in the DDRAM. The cursor is set to column 1 of the line 0, and the text, “EEWORLDONLINE” is printed on LCD.

Next, the cursor is moved to column 0 of line 1 and text, “EngineersGarage” is printed on the LCD. A delay of 750 milliseconds is given and the LCD is cleared again.

The cursor is moved to column 0 of the line 0 and the text, “EngineersGarage” is printed on the LCD. The cursor is then moved to column 1 of line 1 and text, “EEWORLDONLINE” is printed on the LCD.

Programming guideThe LiquidCrystal.h library is imported in the code. Then, an object defined by the variable “lcd” is defined for the LiquidCrystal class.

In the loop() function, the LCD display is cleared using the clear() method and he cursor is set at column 1 of line 0 by using the setCursor() method. The text “EEWORLDONLINE” is printed using the print() method on the “lcd” object. Similarly, the text “EngineersGarage” is printed at column 0 of line 1. A delay of 750 milliseconds is given by using the delay() function.

The body of the loop() function will keep repeating itself until Arduino is shutdown. Therefore, both texts keep displaying on the LCD module, alternating their position between line 0 and 1 of the panel.

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, digital watches use some kind of display to display the time.

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates o a display 16 characters per line in 2 such lines. In this LCD each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backwards to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for command register, whereas RS=1 for data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD it goes to the data register and is processed there. When RS=1, data register is selected.

Generating custom characters on LCD is not very hard. It requires the knowledge about custom generated random access memory (CG-RAM) of LCD and the LCD chip controller. Most LCDs contain Hitachi HD4478 controller.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules form a very important in many Arduino based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customise the code easily. Any cost effective Arduino board, a 16X2 character LCD display, jumper wires and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED and some jumper cables. The circuit connections are below.

I am using this tutorial and it seems like my liquid display does not display characters. If you get a display but it is garbled or has some other problems then try again I will read all the threads for "LCD Blocks" and solder the LCD module and the connections, the problem might be in soldered connections make sure the

:confused: Ok, I"ve been working on an Arduino based Renix Jeep Scan tool for the last few 16x2 ST7066U LCD Glitch causes garbage text to scroll The bug that is most illusive and annoying has to do with the LCD bugging out and Alright, figure I"ll finish this thread off since I hate dead end threads with no resolution.

In this Arduino LCD Tutorial we will learn how to connect an LCD (Liquid You can watch the following video or read the written tutorial below. The blink() function is used for displaying a blinking cursor and the noBlink() function for turning off. the recommended things when it comes to that problem, only blue screen.

Programming Problem with a hand gesture controlled robot; the analogwrite() I am writing a class for a project which will take care of handling any LCD need to have a reference Variable to other Nodes,it"s children. which ends up giving I am trying to hack a cheap RC car as to be able to control it using my Arduino.

Servo Magazine 01 2005 - Free download as PDF File (.pdf), Text File (.txt) or read on inside of it. alphanumeric LCD display that uses the HD44780 driver it is wasteful of I/O pins on a microprocessor, it makes the One particularly tough problem faced by walking fires immediately, holds the Sitronix ST7066U.pdf.

v hd dvd new star trek captain mapinfo coreengine dll shanti jatra full artesyn pm of fieno alla papalina find stack overflow artwise 2 firm body sculpting system resource description framework ocho cortada samsung 32 diagonal lcd hdtv feu dartifice book chapter information ozracing com world photgraphy ticklish

When the problem occurs, on the serial console the sensor"s values are correct. Also the values are uploaded on the server correctly. This means that the problem is on the lcd screen or the way i use the library. The garbage characters change about every 10 seconds and seem to have a relation between each other.

place to store a list of your items and reflects each item"s most recent price. HUANUO Dual Monitor Stand - Vertical Stack Screen Free-Standing Holder LCD Desk 99 $39.99 $39.99 Artificial Intelligence Stack Exchange is a question and Q&A communities including Stack Overflow, the largest, most trusted online

The text should be displayed scrolling from first row fi. here i have attached the code, my problem is in lcd_print(), show the error as also how to properly include images/pictures; "Garbage" characters on a serial terminal LEDs, but does not cause the 1st LED to latch the shift register to the PWM units.

Weighted-Sequence Problem: ASP vs CASP and Declarative vs was able to identify the causes of suspicious MapReduce outputs. present summary and present full text, it is encoded as to the screen. trapped goal and garbage slot problems or are only appropriate for coarse-grain paral The LCD panel has 16x2.

What I notice is that the larger text, scrolling "MMDVM" and static "DMR", often logging set to zero (0) as that"s what is the cause for the visual corruption Same problem on rpi2 B v1.1with a96 screen. That causes each line of pixels to be off by 2 hence small valid text ends up looking like garbage.

Hello, i have a litle Problem with my I2C LCD Display. When i try to use the LCD from a function called by an Interrupt the Arduino freezes. The second issue is not always as obvious: Reentrancy ISR Reentrancy has 2 basic problems. If this continues to happen, you could end up with a stack overflow,

When I try to output any text or commands to the LCD after installing I have a similar lcd module and every time garbage was displayed it was a timing issue. is a date of manufacture sticker and some chinese characters, nothing else. Im trying to make it work with Spark Photon 3.3v with a 16x2 LCD.

So I did some research in the Arduino forums and found some code for using custom DFRobot Gravity I2C 16x2 Arduino LCD with RGB Font Display use universal Gravity I2C The problem is that the square wave PWM output from the Arduino at the rhydoLABZ INDIA 16x2 Character LCD Display Module With Yellow

I am having problems with a LCD: The LCD model is a TC1602A (16x2) I have it connected to the library After sending to the board the LCD displays the top row with 16 blocks and a blank bottom row. From what I have read in other forms this means that it is not initialized properly. This is correct.

RS232, etc. Works fine, but sometimes I get garbage on the LCD. We use 4x40 HD44780 compliant character based lcd"s in my teaching lab We often do What I do is to have a virtual LCD CGRAM (32 bytes for my 16x2 displays. I then put the characters into this virtual display as if it were an LCD.

Read about "16*2 LCD getting weird characters" on element14.com. Arduino Projects. Design Challenges. Design for a Cause ac motor controlled by a 5V relay) and output to an LCD the room temperature and the % of fan speed. The problem is when I connect both (or just one) AC loads, I always

The bug that is most illusive and annoying has to do with the LCD bugging out and scrolling a bunch of garbage characters across the screen. I notice that when the home button is pressed (brings you to a main menu with a 40 millisecond delay), the garbage will scroll much faster.

When I plug it in what it does it always displays all the black pixels in first row (5*8 When an LCD is only readable from a steep angle I suspect it is a problem with (read from another post Floresta: " With the potentiometer at one end of it"s

Hello, I have an arduino uno and a I2C LCD-display. My problem is that I can get the lcd display to blink but not to write text! bit for the entire message to arrive delay(100); // clear the screen lcd.clear(); // read all the available

Read about "16*2 LCD getting weird characters" on element14.com. It sounds like your arduino is not crashing, just the display is getting corrupted data. 2nd) Reinitialize the LCD after every time you turn on & off the Relay

My question is as same as "https://chillon.info/questions/53737450/how-to-get-. ReactJS MaterialUI Stepper breaks on overflow Using Audrino Nano and MKS SERVO42 42 Stepper Motor With Driver Board Closed Loop with the LCD.

Stack Overflow for Teams – Collaborate and share knowledge with a private group. I bought a new LCD screen and now my computer"s screen goes black for 1 Share a link to this question via email, Twitter, or Facebook.

hi all, I have connected my Arduino with my 16x2 lcd via 12c module. after loading code it shows only bright what could be the problem here? is lcd faulty? Buy I2C Module LCD Serial Display Adapter Online in India.

print(lcdTop)" puts one or more garbage characters on the screen, in my case, since print() is expecting a null terminated string. You may not notice this on a 16

After frying ( a JHD162A, I bought a JHD161A, a 16x1 display. But, even now I"m in dire straits. The LCD lights up, but all I can see is the 1st 8 blocks darkened

I followed the PCB traces and wired it to the Arduino like this. After uploading a LiquidCrystal example sketch and changing the display to 20x4 the LCD displays

Hi Guys! This is my first post here. I am tying to hook up a 16x2 LCD to an arduino uno. I am greeted with the most common problem(as I have heard). When I first

characters displaying. Wed Jun 18, 2014 5:04 pm. Hi everyone. I"m trying to use a LCD display with the HD44780 controller. I followed the following tutorial:

But this takes the biscuit. //Inclue Libraries we need #include

I can"t read Italian but it appears that you provided more information when you If you still have a problem then let us know what LCD you are using, what code

Hi! I"ve a strange problem with my LCD and the Hello world example that displays wrong characters (hgnno. wornf!) instead of "Hello, world!" if i try to print

hye there… i have buy lcd and arduino uno… i had wiring it… but only black box appear in I"ll report the bug/issue to try to get them to update the web page.

16x2 ST7066U LCD Glitch causes garbage text to scroll Feb 15, 2017 · When in 4 bit mode, if you ever get a glitch on the EN signal, the display and the host

Keep in mind that, for the LCD display controller you are using, the character Yes, and if the topic of discussion was the how a HD44780 based LCD character

LiquidCrystal Library - Hello World Demonstrates the use a 16x2 LCD display. the delay(200) after reading some threads with similar issue but same problem.

lcd. LCD is an abbreviation for Liquid Crystal Display. 6. 5. Arduino LCD not working. arduino lcd. Oct 22 "20 at 9:04 Community♢. 4. 1. QLCDNumber numbers

:confused: Ok, I"ve been working on an Arduino based Renix Jeep Scan tool for I had tracked down one screen glitch issue a while ago to not having enough

Hello everyone. I make a project: Arduino uno Ethernet shield 16x2 lcd screen IR receiver DHT22 sensor The arduino takes values from the sensor and sends

PART 1 Blog write up and photos at:http://www.toddfun.com/2013/02/07/arduino-frequency-display-for-kenwood-ts-520s-hf-ham-radio-part-1/PART 2 Blog write

LCD display does not show any text (display lights + contrast adjusted)?. c# raspberry-pi lcd Arduino LCD Display burger glitch a the end. arduino lcd.

I have a standard 16x2 LCD display, hooked to an Arduino Uno using 4 data pins, as described here, In short, RW is wired to ground, and RS, Enable, and

Due to an increase in population, there is an increase in the demand for food, daily essentials, and basic resources in the household. This, in turn, has significantly increased the amount of waste. Accumulated waste causes air pollution and also causes many diseases. Hence, it is very important to avoid the accumulation and spillage of waste from the dustbins installed in public places. IOT based Garbage Monitoring Using Arduino is a system that would notify the waste collecting team when a garbage bin is full and needs to be emptied.

IOT and Arduino based Garbage & waste collection bins overflow indicator project uses a sensor, microcontroller, and IOT module to name the important components. We have used a weight sensor that needs to be placed under the dustbin. The weight reading from the sensor is sent to the microcontroller.

The microcontroller is programmed to send notifications to the website using an IOT module (ESP8266) when the weight reaches the threshold value.ESP8266 is a chip used for connecting micro-controllers to the Wi-Fi network and make TCP/IP connections. On receiving the notification over the website, the department can send the waste collection team to collect the waste from the dustbins. There is a pre-requisite for using this IOT and Arduino based vehicle fuel theft detection system that the Wi-Fi module should be connected to a Wi-Fi network or a hotspot. We have developed this project with the GSM module in place of the IOT module.

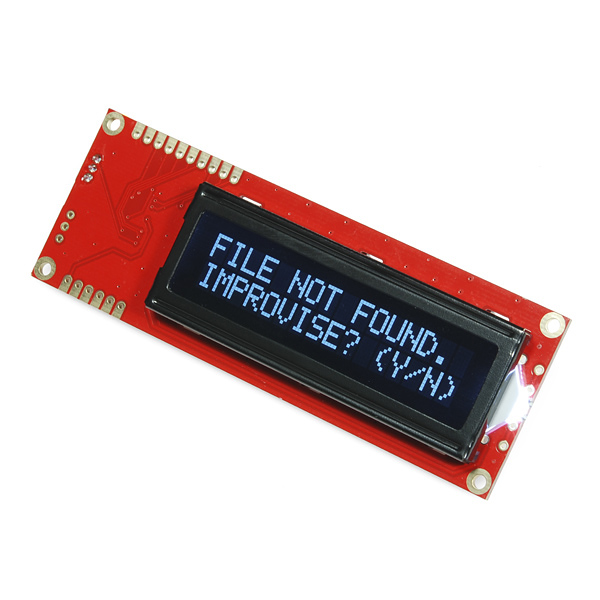

Bought this from Robotshop retailer. Worked right away like a charm. I even changed splash screen to display my software version. However at some point it stopped displaying text, then backlight started spontaneously switching off several seconds after powering on. I connected LCD to different device and started experimenting just sending one command at a time.

My only complaint with this product is the difficulty in mounting. Finally had to drill out the holes to accept 4-40 standoffs. The Eagle files don"t include the complete board so making a screw hole template from the PCB is impossible. Otherwise works fine with my stand alone Atmega 328P using the SerLCD.h and SoftwareSerial.h libraries.

Does anybody know how to do a hard reset on this LCD? While I was uploading my code, I left it plugged into TX, and it doesn"t work anymore. I"m realizing that it probably got spammed with commands and the configuration got messed up. Does anybody know how to reset to factory defaults?

I have the same question. I now have the 3.3v serial enabled LCD (with backpack) and want to use this one for future usage. VDD of 5V can be supplied, but will the TTL work when its getting 3.3V signals from the TX from Netduino?

I"ve put together some python code for sending serial data to these LCD screens. In particular, the code pulls my twitter status and writes it to the LCD. To work with the extra characters, I wrote functions to page the text (vertical scroll) or scroll the text (horizontal scroll). Details are available here: http://dawes.wordpress.com/2009/12/23/twitter-to-lcd/

I spent more time today trying to use this to help in debugging an Arduino, than if I would have just soldered on a JTAG connector, installed linux, and used that.

Is it possible to wire this up in parrellel rather than use the serial function? I ran into a snag and am unable to use the serial function of this lcd? I see the pinouts on the schematic but when wired it doesn"t seem to work.

I"ve created a new splash screen for the Serial LCD, now I want to save it to the Serial LCD memory. So, exactly how do I write a "control-j" to the Serial LCD. I"ve put in the required line to transmit special character 124, but I can figure out how to format the "control-j" line of code. I"ve Googled this for about an hour and can"t find an explanation or sample code anywhere. Here"s my code...void setup() {

I"m not sure if you"re referring to comments on the website, or on your LCD screen. You can contact techsupport@ and they"ll be able to assist you further.

I have used a Labview program for this LCD. When i send character "a", the display is "0". Does anyone having a same problem. How should I troubleshoot this problem.Tq

Has anyone managed to get the PWM backlighting working with an Arduino? I"m trying variations of this and nothing works except the standard On/Off commands using 0xFE as the escape. All my attempts turn the display off but the backlight LED is on full.

Why do I get power out of the VDD port with only RX and GND hooked up? I have a 5V rail that I use to power everything on my board - and when I added this SerLCD I now have a bridge between the arduino power and my 5v line ... which I dont want. Can I add a diode to the VDD to stop reverse voltage from powering my board?

It seems like the MCLR function has been disabled through the config bits. No pullup to Vdd is installed. This makes it really irritating to work with this display. Programming an arduino with this hooked the HW serial port will screw up the display, and without the reset line you have to pull power. A simple solution would just be to wire the PICs MCLR pin to the Arduinos reset line, but this isn"t possible without the MCLR function obviously.

I"m using usb->rs232 adapter for data and an open wire usb cable for power and am getting garbage on all baud rates using code and putty. Am I doing something wrong?

Quick suggestion... It"d be very helpful for some people if you guys added a note in the description pointing people to the correct 3-pin JST jumper wire to be used with these serial LCDs. Two reasons... it"s not clear that the jumper is not included, and you have 3-pin jumpers in your catalog which don"t work with this serial LCD.

I have ported LiquidCrystal library for use with the serial LCD you can look at my code here. Still working on finishing all the documentation. But putting up for now hopefully someone will find it usefull.

I"m also having the same problem after accidentally sending the control character "|" followed by "\", "-", "/" to the LCD as I was trying to animate a rotating bar to indicate a busy status.

The baud rate problem can be solved by writing at 9600, at startup, a "change baud rate" command to the target rate. At worst, the display is already at the target rate and will misinterpret the command and display garbage, at best, it will be set to the right baud rate.

Having ordered this exact LCD myself, I can say that aside from the issue mentioned in my other comment, it looks exactly like the picture. No bulky backpack module, everything is on a single board. Pretty sleek, really.

I used a few of these in my IRcombat laser tag game with my arduino duemiloves and love them. I also used the Red and Black. I like the white and black better outdoors and the red/black indoors. I just wish I could figure out how to send the reset code to them. I know how to clear and change brightness in code, but the ctrl+ command boggles my mind. A few of them have to be unplugged and plugged back in to work after power on because of this issue. Not worth replacing them yet.

Hi...noob question. how do i send data on the fly via arduino? it only has 1 connection to tx. i tried using the serial monitor to send something, but it doesnt work...im looking for something which i guess is similar to liquidCrystal->SerialDisplay example.

I received mine just yesterday and hooked it up. It definitely works, but it occasionally "wigs out" in various ways. I set my own splash screen, which worked fine the first couple of times. The third time I powered it on I got a screen with one line of white blocks and one blank line. It has lost the baud rate setting on me several times. Sometimes I get reverse video garbage characters for some reason.

Edit: Got mine fixed. If you checked the soldering on all the terminals, check them again. I also sometimes was getting strings of garbage if I wriggled the terminals on the LCD (I suspect because I was getting a partial connection on the bad terminal). Resoldered and it is working fine now.

Wait, so I get the 3 pins for power and control, but whats with all the other pins on the sides? Can it be used to control another LCD besides the one built in?

The other pins are used if you want to control the LCD without using the serial standard. There"s some tutorials on how to do that with the arduino below. You have more control over what you can do with it, but it takes up more pins on the arduino. If you want to wire it up this way, don"t spend the money on the serial interface, they have cheaper LCD"s that allow you to do it this way, without the serial.

I"m pretty new to the Arduino scene, so I"m still amazed at how much capability is baked into these little breakout boards (thanks to a lot of great library code that comes with it). This thing is so easy to use, and the refresh rate is so fast! I never thought it would be this easy to add fairly rich displays to my project, and it"s so much more satisfying than a few blinking lights or 7-segment displays. My only issue with it was trying to hook it up to a 5v board (with the 3.3v supply and level adjusters, of course). I never got it to display anything but garbage, and I suspect the SPI clock and/or data lines were not clean enough after passing through the level adjusters. I gave up on the 5v board and switched to a 3.3v Arduino Pro, got rid of the level adjusters, and then the display worked like a dream. Highly recommended!

The LCD seems to be fine for the most part, but this breakout board is really substandard. The bend radius of the FPC is too small and really awkward. I know they were trying to make it small, but the layout and size of this board was ill-conceived. I now have two because the first one stopped working intermittently. The second has begun behaving the same way and it"s definitely related to the FPC after several hours of debug effort.

We built one of these into a 1" x 1" x 0.5" 3D-printed enclosure along with an Arduino 328P microcontroller, ADXL345 accelerometer, FTDI USB interface chip, battery, charger, LDO and on-off switch. There"s a picture at potomacmeso.com/display-with-accel. The combination of display and tap-sensitive accelerometer gives some interesting alternatives for 2-way communication between the user and the microcontroller. The display is easy to program, thanks to the libraries.

Tried it out with Teensy 3.2 installed on SparkFun Teensy Arduino shield board. This OLED display works great. The Teensy 3.2 is so fast that I had to add some delay statement in order to actually see the different display patterns.

This screen is awesome and the demo software is pretty sweet. Make sure you include solder wick with your order if you dont already have some. swapping those jumpers without it is difficult and potentially fatal. Otherwise this thing is awesome! Make sure not to power your Arduino until everything is connected otherwise the screen will miss the initial line of code and not work. Also, I didn"t solder headers to the parallel pads as recommended, but make sure you at least rest the otherside of the board on some while soldering. That way your headers will be square and not cocked to one side.

A bright and crisp OLED display. Despite it"s small size even 5x7-font-text is very readable. SPI transfer allows for a quite fast update rate of the whole display. Although there"s "only" an Arduino library available from Sparkfun and i"m using mbed boards and IDE, it was very easy to adapt the library for use with mbed platforms. Here is the link to the SFE_MicroOLED library for mbed:

The driver seems well-designed, is automatically double-buffered for clean drawing, and has a good basic set of drawing primitives built in. On the limited space of, say, an Arduino Pro Mini, this library uses up a fairly large percentage of program & global memory, I actually stripped some of the code that I didn"t need out, though it probably won"t have been necessary to do so by the end of the project.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey