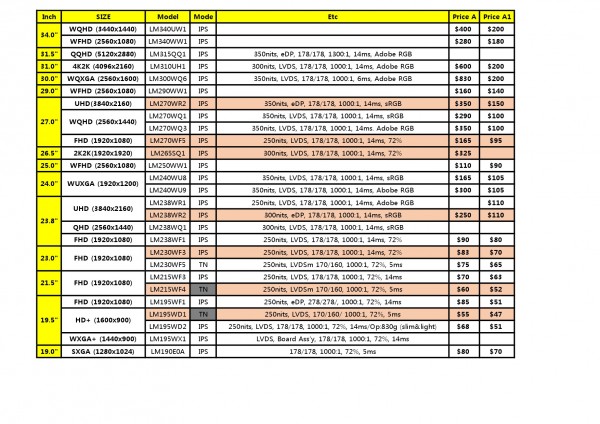

lcd panel generations pricelist

Prices for all TV panel sizes fluctuated and are forecast to fluctuate between 2020 and 2022. The period from March 2020 to July 2021 saw the biggest price increases, when a 65" UHD panel cost between 171 and 288 U.S. dollars. In the fourth quarter of 2021, such prices fell and are expected to drop to an even lower amount by March 2022.Read moreLCD TV panel prices worldwide from January 2020 to March 2022, by size(in U.S. dollars)Characteristic32" HD43" FHD49"/50" UHD55" UHD65" UHD------

DSCC. (January 10, 2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) [Graph]. In Statista. Retrieved January 27, 2023, from https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars)." Chart. January 10, 2022. Statista. Accessed January 27, 2023. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. (2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars). Statista. Statista Inc.. Accessed: January 27, 2023. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "Lcd Tv Panel Prices Worldwide from January 2020 to March 2022, by Size (in U.S. Dollars)." Statista, Statista Inc., 10 Jan 2022, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC, LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) Statista, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/ (last visited January 27, 2023)

LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) [Graph], DSCC, January 10, 2022. [Online]. Available: https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

LCD panel prices have risen for 4 months in a row because of your home gaming? Since this year, the whole LCD panel market has smoked. Whether after the outbreak of the epidemic, LCD panel market prices rose for four months, or the panel giants in Japan and South Korea successively sold production lines, or the Chinese mainland listed companies frequently integrated acquisition, investment, and plant construction, all make the industry full of interesting.

LCD panel prices are already a fact. Since May this year, LCD panel prices have risen for four months in a row, making the whole industry chain dynamic. Why are LCD panels going up in price in a volatile 2020? The key factor lies in the imbalance between supply and demand.

The price of LCDS for large-size TVs of 70 inches or more hasn’t budged much. In addition, LTPS screens and AMOLED screens used in high-end phones have seen little or no increase in price.

As for October, LCD panel price increases are expected to moderate. The data shows that in October 32 inches or 2 dollars; Gains of 39.5 to 43 inches will shrink to $3;55 inches will fall back below $10; The 65-inch gain will narrow to $5.

During the epidemic, people stayed at home and had no way to go out for entertainment. They relied on TV sets, PCS, and game consoles for entertainment. After the resumption of economic work and production, the market of traditional home appliances picked up rapidly, and LCD production capacity was quickly digested.

However, due to the shutdown of most factories lasting 1-2 months during the epidemic period, LCD panel production capacity was limited, leading to insufficient production capacity in the face of the market outbreak, which eventually led to the market shortage and price increase for 4 consecutive months.

In fact, the last round of price rise of LCD panels was from 2016 to 2017, and its overall market price has continued to fall since 2018. Even in 2019, individual types have fallen below the material cost, and the whole industry has experienced a general operating loss. As a result, LCD makers have been looking for ways to improve margins since last year.

A return to a reasonable price range is the most talked about topic among panel makers in 2019, according to one practitioner. Some manufacturers for the serious loss of the product made the decision to reduce production or even stop production; Some manufacturers planned to raise the price, but due to the epidemic in 2020, the downstream demand was temporarily suppressed and the price increase was postponed. After the outbreak was contained in April, LCD prices began to rise in mid-to-late May.

In fact, the market price of LCD panels continued to decline in 2018-2019 because of the accelerated rise of China’s LCD industry and the influx of a large number of local manufacturers, which doubled the global LCD panel production capacity within a few years, but there was no suitable application market to absorb it. The result of excess capacity is oversupply, ultimately making LCD panel prices remain depressed.

Against this background, combined with the impact of the epidemic in 2020, the operating burden of LCD companies in Japan and South Korea has been further aggravated, and it is difficult to make profits in the production of LCD panels, so they have to announce the withdrawal of LCD business.

business in June 2022. In August, Sharp bought JDI Baishan, a plant in Ishikawa prefecture that makes liquid crystal display panels for smartphones. In early September, Samsung Display sold a majority stake in its SUZHOU LCD production plant to Starlight Electronics Technology, a unit of TCL Technology Group. LGD has not only pulled out of some of its production capacity but has announced that it will close its local production line in 2020. According to DSCC, a consultancy, the share of LCD production capacity in South Korea alone will fall from 19% to 7% between 2020 and 2021.

It is worth mentioning that in industry analysis, in view of the fact that Korean companies are good at using “dig through old bonus – selling high price – the development of new technology” the cycle of development mode, another 2020 out of the LCD production capacity, the main reason may be: taking the advantage of China’s expanding aggressively LCD manufacturers, Korean companies will own LCD panel production line hot sell, eliminating capacity liquid to extract its final value, and turning to the more profitable advantage of a new generation of display technologies, such as thinner, color display better OLED, etc. Samsung, for example, has captured more than 80% of the OLED market with its first-mover advantage.

From the perspective of production capacity, the launch of LCD tracks by major manufacturers in Japan and South Korea must reduce some production capacity in the short term, which to some extent induces market price fluctuations. In the long run, some of the Japanese and Korean LCD production capacity has been bought by Chinese manufacturers, coupled with frequent investment in recent years, the overall capacity is sure to recover as before, or even more than before. But now it will take time to expand the production layout, which more or less will cause supply imbalance, the industry needs to be cautious.

The LCD panel industry started in the United States and then gradually moved to Japan, South Korea, China, and Taiwan. At present, the proportion of production capacity in The Chinese mainland has reached 52% in 2020, and there are leading LCD panel products in China represented by BOE, Huxing Optoelectronics. Meanwhile, the production capacity layout of BOE, Huike, Huxing Optoelectronics, and other manufacturers has been basically completed, making industrial integration a necessity.

On the one hand, South Korean enterprises out of the LCD track, the domestic factory horse enclosure, plant expansion action. While LCDs may not sell as well as “upstart” flexible screens, respondents believe they are still strong enough in the traditional home appliance market to warrant continued investment. Zhao Bin, general manager of TCL Huaxing Development Center, has said publicly that the next-generation display technology will be mature in four to five years, but the commercialization of products may not take place until a decade later. “LCD will still be the mainstream in this decade,” he said.

On the other hand, there is no risk of neck jam in China’s LCD panel industry, which is generally controllable. In mainland China, there will be 21 production lines capable of producing 32-inch or larger LCD panels by 2021, accounting for about two-thirds of the global total. In terms of the proportion of production capacity, the Chinese mainland accounted for 42% of the global LCD panel in 2019, 51% this year, and will continue to climb to 63% next year.

Of course, building factories and expanding production cannot be accomplished overnight. In the process of production capacity recovery, it is predicted that there will be several price fluctuations, and the cost may be passed on to the downstream LCD panel manufacturers or consumers when the price rises greatly, which requires continuous attention.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Before microLED technology becomes mature for commercial use, miniLED-backlit LCD panels will compete with OLED panels for application to high-end automotive displays.

Display panel makers" production utilization rates are expected to remain at low levels while panel prices will stay stable in the first quarter of 2023, according to industry sources.

TFT-LCD panel maker Innolux has undertaken zero-waste and zero-pollution automation of its liquid crystal extraction process, according to the company.

Although LCD panel makers have recently seen a short-term surge of their capacity utilization rate to 60-70%, up from 60% in September 2022, most makers in the line believe demand for their products will remain weak in 2023.

As it will take time for the sagging global economy to recover, panel demand from the primary application sectors, such as LCD TVs, monitors, notebooks, tablets and smartphones, will likely continue declining instead of picking up in 2023, according to industry sources.

Samsung has struck LTAs for the supply of TV panels with AU Optronics (AUO), China Star Optoelectronics Technology (CSOT) and HKC, according to industry sources.

LG Display (LGD) may continue to scale down its LCD TV panel production, having closed its 7.5G fab in Paju, South Korea, at the end of 2022, according to industry sources.

Price for handset panels have dropped further in the first quarter of 2023, while quotes for TV and IT display products hold steady, according to industry sources.

Despiting the rising popularity of OLED panels among notebook brands, miniLED-based displays have also been expanding their presence in the notebook market.

While LCD panels have been dominantly used in automotive displays, demand for higher-quality in-vehicle displays will lead to competition between OLED and LCD panels, according to Taiwan-based LCD DDI (display driver IC) and TDDI (touch & display driver integrated IC) design houses.

More panel makers, including BOE Technology and Sharp, have begun churning out OLED displays for notebook applications as notebook brands have added more OLED-based models to their offerings.

China-based BOE Technology has reportedly obtained a large order for flexible OLED panels for iPhone 15 series, to be launched by Apple in 2023, according to industry sources.

Panel makers Innolux and Giantplus have reported mixed results for 2022. Innolux experienced an over 30% revenue decline, while Giantplus, specializing in small- and medium-size panels, generated slight revenue growth.

Taiwan Surface Mounting Technology (TSMT), an LCD surface-mount technology (SMT) solutions provider, has disclosed plans to initiate its capacity expansion projects overseas in 2023.

Samsung Electronics plans to launch 89-inch microLED TVs with microLED panels based on LTPS (low-temperature polysilicon) TFT glass backplanes in the third or fourth quarter of 2023, according to South Korea-based media The Elec.

Beginning next year, Chinese display makers will start the full-fledged operation of large-sized tenth-generation or later liquid crystal display (LCD) panel factories. As a result, some experts say that an increase in global flat panel display production capacity may extend the current LCD oversupply period.

According to market researcher IHS Markit on December 7, China"s large display makers such as BOE which is the largest display manufacturer of China, China Star (CSOT) and Foxconn, will put seven 10-generation LCD factories to work one by one from next year to 2020.

As a result, IHS Markit predicts that global LCD panel supply growth will reach 59% per annum on average over the next five years to 2022. The proportion of 10G or later LCD panel production will also climb from 4% this year to 26% in 2020, according to IHS Markit. Purchases of flat panel display production equipment are also expected to exceed US$ 20 billion next year.

It is forecast that the LCD oversupply which began at the end of 2015 is expected to continue for at least five years. The price of a 55-inch LCD panel which rose above US$ 228 in 2015 dropped to US$ 200 in 2016 and then sank to US$ 180 in December of this year, according to market research firm WitsView.

As LCD panel prices have tumbled due to increased supply, the premium TV market is also moving rapidly towards large-screen models. Display panel manufacturers are competing to build a 10.5th-generation plant optimized for 65-inch and 75-inch displays. As 8th-generation and 8.6th-generation plants which account for the majority of large-area LCD production lines are optimized to produce 55-inch and 58-inch panels, respectively, they are less efficient at producing larger LCD panels.

BOE started the full-scale operation of its 8.5th-generation production line this year, and will start running its 10th-generation plant in the first half of next year. China Star (CSOT) and CEC-Panda are also in the process of building large LCD production lines. In the third quarter, BOE of China dethroned LG Display which has been at the top spot for 31 consecutive quarters while ranking first with a market share of 21.7% (based on shipment) in the 9-inch or larger display panel market.

Currently, LG Display is enjoying 90% of its total sales in the LCD sector and making its profit structure centered on the large organic light emitting diode (OLED) business. However, the company already missed investment timing for nearly half a year such as a delay in investment in the establishment of an 8G OLED factory in Guangzhou in China. Thus, a lot of attention is being paid to how LG Display will tackle this matter.

“As 10.5th-generation plants will be put into full operation, prices of 65-inch or larger panels will slide more than 5% each year, while demand will increase 2.5-fold to 40 million units per year,” an industry observer said. “65-inch or larger TVs will become the mainstream in the future.”

SEOUL/TOKYO -- Samsung Electronics intends to manufacture liquid crystal display panels through the end of 2022, reversing plans to end production due to an unexpected spike in demand.

But the change in plan also highlights Samsung"s difficulty in developing next-generation displays, and the tech giant"s outlook after the pandemic-driven demand fizzles remains uncertain. Compatriot and rival LG Display has also postponed plans to end production of LCD panels.

In China. The biggest LCD panel manufacturer in the world now. BOE has G4 (Chengdu), G5 (Beijing), G5.5 (Ordos), G6 (Hefei, Chengdu, Mianyang, Dalian), G8 (Beijing, Hefei, Chongqing), Fuqing, Dalian, Chongqing) and 10.5 (Hefei) production lines.

In Taiwan. One of the daughter company of Foxconn/Hon Hai. In 2010, it bought the then famous LCD manufacturer, ChiMei, then changed its name to Innolux. It has G7.5 production lines.

In Korea and China. It is used to be the 2nd biggest TFT LCD manufacturers. LG also planned to stop the production but delayed the plan after the price increased. LG has G7.5 and G8.5 (Guangzhou) production lines.

In Korea. It used to be the biggest TFT LCD manufacturers before it was dethroned by BOE in 2019. Because of tough competition, Samsung planned to stop the production in 2021 but delayed because the price increase during the pandemic. Samsung has G7 and G8.5 production lines.

In Japan and China. The pioneer and queen of LCD industry. Because of high cost and tough competitor, Sharp was acquired by Foxconn/Hon Hai in 2016. Sharp has G8, G8.5(Suzhou), G10, G10.5 (Guangzhou) production lines.

Fans of TV gear love to debate the merits of flat-panel technologies. In the past, this meant comparing Quantum Dot LED (or QLED TV as it’s most commonly known) and Organic LED, otherwise known as OLED TV. But 2022 was the year a new display technology called Quantum Dot OLED or QD-OLED, made its official debut, and it has already started to reshape the TV landscape thanks to new models from Sony and Samsung, and computer monitors from Dell’s Alienware brand.

Picture improvements aside, it’s also possible that over time, QD-OLED TVs may prove less expensive to buy than similarly sized OLED TVs. We’ll discuss this in more detail later. Since QD-OLED TVs are essentially an evolution of OLED, it’s expected that some of the clever things we’ve seen LG do with its OLED panels, like transparent displays and rollable displays, will soon be possible with QD-OLED, too.

From there, the purified white light passes through the LCD matrix (which is responsible for the images you see, and how bright or dark areas of the screen are) and, finally, through the color filter, which converts the white light into the right amounts of red, green, and blue so that we see true color images.

But it has drawbacks, too. No matter how hard the LCD matrix tries, it can’t block 100% of the light from coming through in dark scenes, so you never get that perfect, inky black that you see on an OLED TV. The LCD matrix also creates problems for off-angle viewing because it tends to “tunnel” light straight outward from the screen.

QLED also has to use more energy to create the brightness you see because the combination of the LCD matrix and the color filter diminishes the light the LED backlight generates. This makes QLED TVs less energy efficient than OLED TVs.

That sounds remarkably simple compared to QLED TV, and it is. Thanks to the emissive nature of the basic element of OLED TV — the OLED pixel — this one ingredient can take care of brightness and image creation, essentially fulfilling the roles of both the LED backlight and the LCD matrix in QLED TV.

Without an LCD matrix, viewing angles with OLED TV are as near-perfect as we’ve ever seen. You can sit wherever you like and still see the same levels of brightness, contrast, and color.

OLED panels are also susceptible to something known as burn-in. If you display the same kind of content on an OLED TV for tons of consecutive hours — say a lower info banner on a news channel, or a control panel in a video game — it can cause those pixels to age at a faster rate than the pixels that are constantly displaying different images.

Finally, because the large-format OLED panel market is effectively a monopoly, with just one company — LG Display — manufacturing and selling them to companies like LG, Sony, Philips, and Vizio, it will remain more expensive than QLED for some time to come.

At the moment, OLED TVs create their light and color starting point with white light. They do this by combining blue and yellow OLED material to create a blend that comes very close to pure white. Why do this instead of using red, green, and blue OLED material? The answer has to do with the complexities of manufacturing OLED panels at the 50-inch to 88-inch sizes of today’s TVs while keeping costs as low as possible.

To give you a sense of just how expensive a true RGB OLED panel is, Sony makes a 4K, 55-inch monitor for the broadcast and film industries that uses this technology. It costs nearly $28,000.

When viewing HDR content, the panels turbocharge these white subpixels to deliver HDR’s higher brightness. But there’s a limit to how hard you can drive those white subpixels. Push them too far and not only do you reduce the panel’s life, but that extra brightness can also wash out the color of the other subpixels, something that is especially noticeable when displaying small features like text, which can often look less crisp.

To deal with the technical hurdles of OLED brightness, QD-OLED TVs take a page out of QLED TV’s handbook. Using the same principle that lets a QLED TV turn a blue backlight into a pure white light using red and green quantum dots, a QD-OLED panel uses just blue OLED material as the basis of each pixel.

At the moment, Samsung Display — a division within Samsung that develops display technologies but doesn’t sell final products like TVs or monitors — is the only company manufacturing QD-OLED panels. It sells these panels to companies like Sony, Dell’s Alienware division, and Samsung Electronics (the Samsung division that makes and sells TVs). We expect other companies will join the ranks of Samsung Display’s QD-OLED customers now that the first highly positive reviews are in.

Remember when we said that quantum dots use light energy at almost 100% efficiency to produce their own light? Well, it turns out that quantum dots aren’t picky about their diet. They can also be energized using electricity for what’s known as quantum dot electroluminescence, or QDEL. In our opinion, it’s QDEL panels that should be referred to as “QD Displays,” not QD-OLED panels, but this isn’t the first time the industry has chosen a confusing tech name, and it certainly won’t be the last.

However, today the scenario is completely changed. There are various TV display technology options available, making decision-making tough. Whenever you visit any electronic store to purchase a new TV, you will be bombarded with jargon such as QLED, OLED, LED, Nano Cell, LCD, etc.

LCD stands for Liquid Crystal Display. It is a particular flat panel that either allows or blocks the passage of light. In this technology, liquid crystal technology is used. This technology combines liquid crystals and polarizers to create images on the screen.

Generally, LCD TVs have three polarized glass panels known as substrates. It contains liquid crystals in between them. These panels are in red, blue, and green colours. Whenever electric current passes through these substances, the crystals rotate and align to let the light pass through the other substrate. In this way, we can see colours and images.

Usually, most people think that LED displays are a new format, but the truth is that they have been around for a long time. LED stands for light-emitting diode. LED TVs are an updated version of the LCD generation. When it comes to technology, both LED, and LCD TVs use the same one.

The impressive thing about OLED TV is that it does not need a backlight to illuminate the screen area like LCD and QLED. Therefore, it can be very thin and flexible. OLED TVs produce less heat and consume less power than LCDs and LEDs.

The next on the list is Nano Cell. It is a type of LCD/LED TV from LG. In Nano Cell technology, nanoparticles are used at individual pixels. They absorb unwanted light and enhance the primary red, green, and blue colours on the screen.

In a nutshell, these are some different types of TV display technologies you will probably explore in any electronic store. Hopefully, this article has cleared your all doubts, and now you understand the basic difference between each, like QLED vs OLED, OLED vs LED, Nano Cell vs OLED, OLED vs LCD, etc. Therefore, the next time you want to upgrade your TV, note down all the desirable points and select the best one you feel.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey