monochromatic lcd display factory

When looking for a cost-effective LCD display solution capable of displaying text, Icons or full graphics look no further than the Phoenix Display monochrome line.

Character LCD Display modules are an efficient and effective solution for displaying text only for a variety of applications in any number of products. Our in-house engineering team can assess and replace your current Character LCD Display or build a Custom LCD Display for use in your project or product. With 30+ standard character LCD Displays in stock, plus any custom solutions available, Phoenix Display can provide the display solution you want at the price you need.

When your project or product is in need of increased graphical content capabilities and performance, look to the graphic LCD Displays from Phoenix Display International.

Our Graphic LCD Display modules allow you to customize each individual pixel to display both text and graphical images simultaneously. Let our in-house team of engineers assess your current graphic LCD solution and suggest one of our standard models, or we can design a Custom LCD Display module capable of displaying both text and images in a monochromatic format

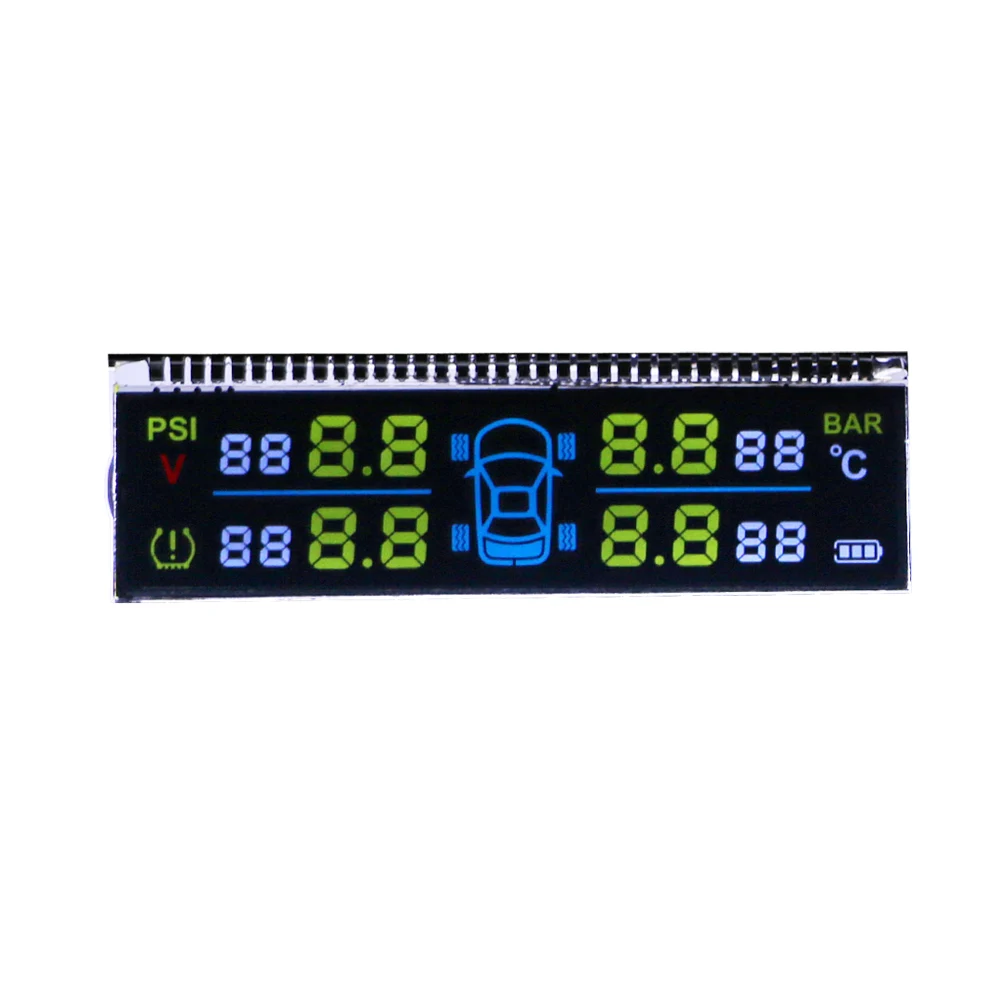

And finally PDI’s Monochrome TFT LCDs provide a high performance solution for industrial and automotive instrumentation, audio/visual displays and industrial devices that do not require full color. They offer an excellent contrast ratio, high resolution, wide viewing angles, fast response time, sunlight readability and wide operating temperatures.

Not EXACTLY what you need? We specialize in custom and semi-custom display solutions. Contact us about creating something that fits your exact specifications.

Explore the extensive selection of wholesale monochromatic lcd display LCD displays, TFT, and HMI that can be used across a range of industries, including domestic, medical, industrial, automotive, and many others. You can choose from a number of standard industry sizes and find the monoch romatic lc display that are applicable to your required use. If you would like options that allow a smaller environmental footprint due to low power consumption, you can browse the Chip-on-Glass (COG) LCDs. COGs are designed without PCBs so have a slimmer profile.

Browse cutting-edge monochromatic lcd display on Alibaba.com at reasonable prices. monochromatic lcd display in varying display size and resolution are accessible on the site. The merchandise are useful in automotive, medical, and industrial screen displays. monochromatic lcd display having multiple interface types and display technology are in stock. monochromatic lcd display on Alibaba.com have high resolution and luminance to display precise details. They have a capacitive touch for convenient use. They can show multiple characters per line. monochromatic lcd display can be manufactured to suit smaller wearable devices or large projectors. They can be integrated with smart home systems for face recognition and office equipment. They feature multiple interfacing types like MPU or RS232. They are sturdy, thanks to a toughened glass structure with a considerable operating temperature range. The life span.

Alibaba.com features a broad collection of smart and advanced monochromatic lcd display equipped with bright, capacitive screens for the most affordable prices. These monochromatic lcd display are made implying the latest technologies for a better, enhanced, and smart viewing experience. These products are of optimal quality and are sustainable so that they can last for a long time. Buy these monochromatic lcd display from the leading wholesalers and suppliers at discounted prices and fabulous deals. The smart and capacitive monochromatic lcd display offered on the site are applicable for all types of ads displaying, mobile screens, LCD monitors, and many more. You can use them both for commercial as well as residential purposes. These marvellous monochromatic lcd display are provided with bright and strong backlights available in distinct colors for a wonderful screen viewing experience. These monochromatic lcd display are.

Character Display 16x2 1602A LCD Display Mono color Quick Details Type:TN display, Mono LCD Display Size:16*2 Supplier Type:Manufacturer Place of Origin:Guangdong, China Brand Name:Risenta...

For product design engineers and manufacturers, a custom display and touch solution is the best approach to meet their unique application needs. Turning to us to be your monochrome LCD manufacturer means you’ll gain the experience and expertise of our in-house engineering team. Our talented engineers can develop customized solutions using a wide range of LCD technologies:Custom TN LCD displays

As we work with you to design a custom monochrome display, we’ll provide you with data-based recommendations and dedicated support. The know-how we bring to our clients has resulted in a proven track record of success, even with the most demanding applications.

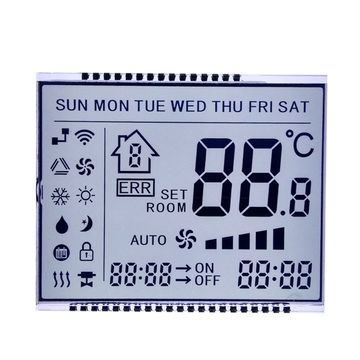

Dr Pan: Hello, Greg. Monochrome LCD Panel can be made with TN, HTN, STN, FSTN and VA technology. It can be divided into dot matrix and segment LCD on the basis of the display mode. Depending on the types of polarizers, it can be divided into transmissive LCD, reflective LCD and transflective LCD.

Let us look at the typical structure of monochrome LCD. From top to bottom, top polarizer, top ITO glass, ITO film,liquid crystal, ITO film,bottom ITO glass and bottom polarizer.

Dr Pan: Absolutely. First, it is cheaper. And usually, the colorful screens we can see are standard products, which do not need to be designed. Monochrome LCD screen is highly customized product. You can select the outer dimension, the view area, the connection type, the display mode, the view degree, the type of the polarizer and the driving mode according to your requirements.

Factory Custom Small-middle Size Monochromatic 7 Segment Liquid Crystal Display - Buy 7 Segment Lcd Display,Segment Lcd,Custom Lcd Display Product on Alibaba.com

A:We are professional manufactory, which specializes in TN, HTN, FSTN, STN monochrome LCD, LED backlights, LCD modules more than 6 years in Dongguan ! Our advanced full set equipments make sure good quality and competitive price!

Nowadays, LCD panels for smartphone displays are taking the back seat while tech companies move towards OLED screens, including Apple. Samsung Display, one of Apple’s suppliers for iPhone, iPad and Apple Watch displays, announced today that it is going to end LCD production in its China-based and South Korean factories by the end of 2020.

Reuters now reports that Samsung is moving on with its factories, but will still supply LCD display orders until the end of the year. The company has two LCD production lines in South Korea and two LCD-dedicated factories in China.

Additionally, Samsung’s spokesperson said that the company has not decided upon a specific plan for the China-based factories yet, but the ones in South Korea are to focus on “quantum dot” screens, which is an advanced technology producing pure monochromatic red, blue and green light, and therefore offering enhanced color schemes and brightness.

The production of LCD displays by Samsung has already been in decline since last year, as demand for LCD screens is continuously decreasing. In October, Samsung closed one of its LCD production lines in South Korea. Additionally, the company stated that it will invest around $10.72 billion in research and improvements for their production lines of quantum dot screens.

Manufacturers of low-cost 3D printers that use the masked stereolithography (MSLA) process are able to build their machines so cheaply because they’re using repurposed smartphone or tablet LCD panels to mask off the UV backlight. Considering the quality you get out of even the entry-level MSLA resin printers, we certainly aren’t complaining about this bit of thrift. But as [Jan Mrázek] explains in a recent blog post, there’s certainly room for improvement.

The problem is that those repurposed LCD panels are, as you’d expect, color displays. After all, even the bottom of the barrel mobile devices moved away from monochrome displays decades ago. But in this case, that’s not what you really want. Since the printer operates on a single wavelength of light, the color filters inside the LCD are actually absorbing light that could otherwise be curing the resin. So an MSLA printer with a monochrome screen would use less energy and print faster. There’s only one problem: it’s not very easy to find high-resolution monochrome displays in the year 2020.

But it was still worth a try. [Jan] pulls the display apart, removes the liquid crystals, scrapes off the color filters, and then puts it all back together again. His first attempt got him a monochrome display that actually worked, but with debris trapped inside the screen, the image was too poor to be useful. He tried again, this time trying harder to keep foreign material out of the crystals. But when he got it back together a second time, he found it no longer functioned. He thinks it’s possible that his attempt to clean up the inside of the display was too aggressive, but really there are so many things that could go wrong here it’s hard to pin down just one.

Long story short, manually creating monochrome displays for low-cost MSLA printers might not be a viable option. Until a better solution comes along, you might be interested in seeing some slightly less invasive ways of improving your resin print quality.

The general consumer typically has very limited knowledge about the different types of LCD panels on the market and they take all of the information, specifications, and features printed on the packaging to heart. The reality is that advertisers tend to take advantage of the fact that most people conduct very minimal research before making big technological purchases—in fact, they depend on this to sell higher quantities of commercial monitors. With that in mind, how exactly do you know if you’re actually getting a good quality product that’ll suit your needs? Reading up on all of the different types of industrial LCD monitors is a good place to start!

LCD stands for liquid-crystal display. Over the years, LCD technology has become ubiquitous with various commercial and industrial screen manufacturing. LCDs are constructed of flat panels that contain liquid crystals with light modulating properties. This means that these liquid crystals use a backlight or reflector to emit light and produce either monochromatic or coloured images. LCDs are used to construct all sorts of displays from cellphones to computer screens to flat-screen TVs. Keep reading to learn everything you need to know about the different types of LCD displays on the market.

Twisted Nematic LCDs are the most commonly manufactured and used types of monitors across a wide range of industries. They’re most commonly used by gamers because they’re inexpensive and boast faster response times than most of the other display types on this list. The only real downside to these monitors is that they possess low quality and limited contrast ratios, colour reproduction, and viewing angles. However, they suffice for everyday operations.

In Plane Switching displays are considered to be among the best of the best when it comes to LCD technology as they offer superior viewing angles, excellent image quality, and vibrant colour accuracy and contrast. They’re most commonly used by graphic designers and in other applications that require the highest possible standards for image and colour reproduction.

AFFS LCDs offers far superior performance and a wider range of colour reproduction than even IPS panel technology. The applications involved in this type of LCD display are so advanced that they can minimize colour distortion without compromising on the extremely wide viewing angle. This screen is typically used in highly advanced and professional environments such as in the cockpits of commercial airplanes.

Nauticomp Inc. is the leading designer and manufacturer of high-quality LCD panels and displays. All of our touchscreen displays are made to order and customized according to your specific needs and applications. To learn more about our products, please contact us today.

Quantum dot displays are an emerging technology with the potential to fundamentally change the competition between LCD and OLED display technologies. It builds upon traditional LCD display systems, optimizing performance, picture quality, and energy efficiency by incorporating a layer of quantum dots into the LCD matrix.

This article will explore the current impact of quantum dots on the display market, and their potential to fundamentally change the next generation of displays.

LCD screens use a backlight of LEDs or a series of LEDs mounted at the edges of a screen to diffuse white light through polarizing filters, a liquid crystal layer, and a color filter, to create an image on the display surface. Essentially, the image on the screen is created by blocking and filtering wavelengths of light from reaching the display surface. This results in significant energy wastage.

Quantum dots are photo-emissive nanocrystals which are capable of naturally emitting monochromatic light when excited by an energy source. In quantum dot-enhanced LCD displays, a layer of quantum dots is overlaid on a blue LED backlight, which emits all the blue light visible onscreen while supplying the energy required for red and green quantum dots to fluoresce their respective colors. These colors can be accurately tuned by controlling the size, shape, and chemical composition of the nanocrystals, thereby precisely altering their emitted wavelengths. This results in a more vibrant display and a wider color gamut, which is a prerequisite for modern displays utilizing Ultra-HD and HDR.

OLED displays are the leading competition for LCD technology, offering technically infinite contrast ratios and thinner, lighter displays. This technology comprises of an organic, carbon-based film sandwiched between two conductors, which emits light when a current is passed through the array. The self-emissive nature of this diode makes an LED backlight redundant. It also allows for representation of true black colors on the display surface, as each individual pixel can be switched off without being affected by the backlight of neighbouring pixels. This also results in class-leading efficiency levels.

However, low manufacturing yields and expensive material costs have affected the market price of OLED displays, particularly for large panels used in modern TVs. OLED production is becoming more stable, but marketing costs remain high. Quantum dot production is similarly expensive, but recent chemical developments could result in a large-scale manufacturing breakthrough for this emergent technology.

Current generations of quantum dot-enhanced LCD displays use quantum dots based on cadmium selenide or indium phosphide chemical compositions. These materials have limited availability and exorbitantly high costs in the region of $10.000 per KG. They also require an additional inorganic shell to reach sufficient levels of quantum efficiency. To resolve this, Avantama has developed quantum dots composed of cost-efficient cesium lead halide, which require no inorganic shell and offer an absorbance per gram of at least three times higher than quantum dots of other chemical compositions. These metal halide perovskite quantum dots currently yield the highest possible quantum efficiencies, thus the best peak brightness in LCD displays.

This technology will be instrumental to the next generation of LCD screens where color filters are replaced with thermally-efficient quantum dots. As mentioned above, color filters serve the function of omitting wavelengths of light to display color. This means that a high proportion of all light produced by the display’s LEDs is wasted. Naturally produced monochromatic light from a layer of quantum dot-pixels behind a liquid crystal display layer would drastically improve energy efficiency while offering best-in class optical performance. Avantama’s quantum dot products are already suitable to produce such color filter displays.

Current quantum dot displays utilise the photo-luminescent nature of these nanocrystals to produce high purity light by stimulating them with an LED-based light source. Future iterations could revolutionize that technology by exploiting the electro-luminescent aspect of quantum dots in the manufacturing of direct-view quantum dot displays, removing the liquid crystal display entirely. This would allow for unparalleled picture quality with a wider color gamut, exceptional contrast levels, improved viewing angles, and unrivalled levels of efficiency. This array, while similar in principle to OLED technology, would vastly alter the dynamic in display technology, making it difficult for OLED to become dominant in the display market.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey