tft display good or bad made in china

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

TFT stands for thin-film transistor, which means that each pixel in the device has a thin-film transistor attached to it. Transistors are activated by electrical currents that make contact with the pixels to produce impeccable image quality on the screen. Here are some important features of TFT displays.Excellent Colour Display.Top notch colour contrast, clarity, and brightness settings that can be adjusted to accommodate specific application requirements.Extended Half-Life.TFT displays boast a much higher half-life than their LED counterparts and they also come in a variety of size configurations that can impact the device’s half-life depending on usage and other factors.TFT displays can have either resistive or capacitive touch panels.Resistive is usually the standard because it comes at a lower price point, but you can also opt for capacitive which is compatible with most modern smartphones and other devices.TFT displays offer exceptional aspect ratio control.Aspect ratio control contributes to better image clarity and quality by mapping out the number of pixels that are in the source image compared to the resolution pixels on the screen.Monitor ghosting doesn’t occur on TFT displays.This is when a moving image or object has blurry pixels following it across the screen, resembling a ghost.

TFT displays are incredibly versatile.The offer a number of different interface options that are compatible with various devices and accommodate the technical capabilities of all users.

There are two main types of TFT LCD displays:· Twisted nematic TFT LCDs are an older model. They have limited colour options and use 6 bits per each blue, red, and green channel.

In-plane switching TFT LCDs are a newer model. Originally introduced in the 1990s by Hitachi, in-plane switching TFT LCDs consist of moving liquid pixels that move in contrast or opposite the plane of the display, rather than alongside it.

The type of TFT LCD monitor or industrial display you choose to purchase will depend on the specifications of your application or project. Here are a few important factors to consider when selecting an appropriate TFT LCD display technology:Life expectancy/battery life.Depending on the length of ongoing use and the duration of your project, you’re going to want to choose a device that can last a long time while maintaining quality usage.

Touch type and accuracy.What type of activities are you planning on using your device for? If it’s for extended outdoor use, then you should go with projected capacitive touch as this is more precise and accurate. Touch accuracy is important for industrial and commercial applications.

Image clarity.Some TFT displays feature infrared touchscreens, while others are layered. The former is preferable, especially in poor lighting conditions or for outdoor and industrial applications, because there’s no overlay and therefore no obstructions to light emittance.

The environmental conditions make a difference in operation and image clarity. When choosing a TFT for outdoor or industrial applications, be sure to choose one that can withstand various environmental elements like dust, wind, moisture, dirt, and even sunlight.

As a leading manufacturer and distributor of high-quality digital displays in North America, Nauticomp Inc. can provide custom TFT LCD monitor solutions that are suitable for a multitude of industrial and commercial indoor and outdoor applications. Contact us today to learn more.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

Initial iterations of IPS technology were characterised by slow response time and a low contrast ratio but later revisions have made marked improvements to these shortcomings. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists, although with the recent fall in price it has been seen in the mainstream market as well. IPS technology was sold to Panasonic by Hitachi.

Most panels also support true 8-bit per channel color. These improvements came at the cost of a higher response time, initially about 50 ms. IPS panels were also extremely expensive.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

It achieved pixel response which was fast for its time, wide viewing angles, and high contrast at the cost of brightness and color reproduction.Response Time Compensation) technologies.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Backlight intensity is usually controlled by varying a few volts DC, or generating a PWM signal, or adjusting a potentiometer or simply fixed. This in turn controls a high-voltage (1.3 kV) DC-AC inverter or a matrix of LEDs. The method to control the intensity of LED is to pulse them with PWM which can be source of harmonic flicker.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

The statements are applicable to Merck KGaA as well as its competitors JNC Corporation (formerly Chisso Corporation) and DIC (formerly Dainippon Ink & Chemicals). All three manufacturers have agreed not to introduce any acutely toxic or mutagenic liquid crystals to the market. They cover more than 90 percent of the global liquid crystal market. The remaining market share of liquid crystals, produced primarily in China, consists of older, patent-free substances from the three leading world producers and have already been tested for toxicity by them. As a result, they can also be considered non-toxic.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

Richard Ahrons (2012). "Industrial Research in Microcircuitry at RCA: The Early Years, 1953–1963". 12 (1). IEEE Annals of the History of Computing: 60–73. Cite journal requires |journal= (help)

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

TFT displays have become increasingly common in our daily lives. They are used in cars, laptops, tablets, and smartphones, as well as in industrial applications and many more. But what are TFT displays and why are they so important?

A TFT (Thin Film Transistor) display is a type of display technology that uses a thin layer of transparent material to produce an image on the screen. The display is made up of thin layers of organic material called organic transistors, which are stacked together on a glass substrate and covered with a thin layer of plastic or metal oxide.

TFT displays are also used in many other industrial applications, such as industrial control systems, medical devices, automotive infotainment systems, and more.

The basic concept behind a TFT display is simple: it uses light to create an image on a screen. Light passes through the glass substrate and the organic transistors until it reaches the top layer of the display.

The organic transistors turn on and off in response to the electrical charge of light passing through them. As they do so, they produce voltages that are then sent through wires connected to each pixel of the screen to create an image.

The number of pixels that can be displayed depends on how many organic transistors are used in each pixel or subpixel (a single-pixel is made up of multiple subpixels). For example, a 4-inch (10 cm) display has a pixel pitch of 0.0625 inches (1.57 mm).

The basic design of a TFT display has remained unchanged for more than 20 years. In this design, the sub-pixels are arranged in a grid pattern, with each subpixel connected to its neighbor by wires that form rows and columns.

In 1982, Sanyo introduced the world’s first 16-inch (40 cm) LCD with a resolution of 640×480 pixels. This was followed by the introduction of 30-inch (76 cm) screens in 1984 and 40-inch (100 cm) screens in 1985.

The first large format TFT display was introduced in 1987 by NEC Corporation, which used a 1024×768 pixel screen for its PC monitor line, called CRT Professional Display System or “Videotronic” system. The technology was licensed to NEC’s competitors such as Hitachi and Toshiba for use in their own monitors and televisions. The system was marketed as “Super Video” and replaced the aging “Videotron” CRT monitors that were still being used at the time. The first LCD TV was also produced in 1987 by Sony.

In 1989, Sharp’s first TFT-LCD TV set was introduced with a resolution of 576×320 pixels, while the world’s first large format high definition screen with a resolution of 1024×768 pixels was introduced by NEC in 1994.

Over the years, TFT display technology has developed by leaps and bounds. It has been used in tablets, smartphones, notebooks, game consoles, and computer monitors. The technology is also used in digital cameras, camcorders, MP3 players, and GPS devices.

What does the TFT display technology comprise? From far, you can easily assume TFT to be a single unit. But in reality, it comprises different components that work together.

The backlight of the TFT display is a very important component. It provides the light for the pixels and is also responsible for illuminating the display. The light emitted by a backlight can be controlled by varying the amount of current running through it.

When it comes to LCD displays, there are two types of backlights; Active matrix and Passive matrix. Active matrix backlight has several layers of electrodes, which are used to control the amount of current flowing through them.

Whereas, Passive matrix backlight consists of one electrode layer that acts as a switch between off and on states. The active matrix backlights are more expensive than passive-matrix ones because they require more power to operate.

The pixel is the smallest unit in a TFT display. It is the basic unit of information that is displayed on the screen. The pixel consists of three sub-elements, namely; Red, Green, and Blue (RGB).

The number of sub-pixels that are used in each pixel varies with different display technologies. In full-color LCDs, there are three types of sub-pixel: red, green, and blue (RGB). Full color TFT displays use a combination of Red, Green, and Blue (RGB) sub-pixels to represent full color.

The backplane and frontplane are connected by a number of flexible printed circuits. The PCBs are usually connected to each other with wires made from metals such as copper or aluminum. These wires are used to supply power, data, and control signals between the backplane and the front-plane.

The light that is transmitted through each TFT is controlled by applying voltages of different values to each pixel in turn. To do this, a control circuit called a driver circuit is required. The driver circuit controls the voltage applied to each pixel with reference to a set of parameters known as “pixel information”.

This information includes color, brightness, and other characteristics that define how an individual pixel should be operated for display purposes. The parameters also include how many red, green and blue sub-pixels are used to produce each pixel.

The control system can be further divided into 3 sub-systems: the interface, the timing, and the data transfer system (DTS). These systems work together to provide all of the necessary functions for controlling TFT displays from external sources such as computers, printers, or TVs.

This is another component of a TFT display system. It consists of a liquid crystal material sandwiched between two glass plates. This material is responsible for controlling the light by changing its refractive index.

-Wide viewing angle: The viewing angle of the TFT display is larger than that of the CRT set. It is generally considered to be the best choice for applications requiring an extended viewing angle.

-Transparency: TFT display has better transparency than CRT set, which makes it more suitable for applications requiring high transparency such as window displays and computer monitors.

-High resolution: TFT display can produce higher resolution than CRT display. For example, the pixel density of TFT is about 3 million pixels per square inch (PPI), which is about three times that of conventional liquid crystal displays (LCDs) whose pixel density is about 100 ppi.

-Reliability: Since it uses no moving parts, the TFT screen does not need any maintenance or repair, and therefore the reliability is higher than that of LCDs and plasma displays.

-Power saving: TFT display consumes much less power than CRT. The power consumption of a mainstream TFT display is about 1/10 that of a typical LCD. In some applications, the power consumption can be reduced to 1/100 or less of that of a CRT.

-High brightness: The picture displayed on the screen can be bright enough to be seen in bright sunlight without any need for glare reduction filters.

-Compatibility: Since it uses no moving parts, the TFT screen does not have any mechanical problems such as screen flicker and image sticking problems found in plasma displays and LCDs.

-High resolution: Although the pixel density of TFT is about 3 million pixels per square inch (ppi), the resolution is more than 100 ppi which makes it more suitable for many applications where high resolution is needed.

-Consistency: Since it uses no moving parts, the image displayed on the TFT display is not affected by temperature and humidity, which makes it more consistent than LCDs and plasma displays.

-Cost: The cost of a TFT display is lower than that of LCDs and plasma displays. For example, in some applications where image quality is not critical, the cost of a TFT display may be only a few tens to a few hundreds of dollars while the cost of LCDs or plasma displays may be several thousand to several tens of thousands.

-Excellent color display: We can’t deny the fact that TFTs have a superior color display. This simply means that the color of pixels can be accurately reproduced.

-Very thin: When compared with LCDs and plasma displays, which are very thick, TFTs are very thin and lightweight. In addition, the cost of mounting a large size TFT screen to a wall panel is relatively low.

-No ghosting: ‘Ghosting’ refers to the fact that the display shows a bright spot on the screen when the screen is turned off. TFT screens do not show ghosting. TFTs produce a sharp image even when they are turned off.

-No geometric distortion: Geometric distortion refers to the shape of the display on a flat surface. TFTs produce a sharp image even when they are turned off.

-No radiation: TFTs do not emit any harmful radiation, and there is no need for shielding or shielding materials to protect people from harmful radiation.

Considering that TFTs use less power, it is possible to reduce energy consumption by up to 50% compared with LCDs. In addition, if you use LED backlights in TFT displays, you can reduce power consumption by up to 75% compared with conventional backlights.

The screen quality of a product can be improved by reducing scratches on the screen surface caused by friction between the screen surface and fingers or objects that come into contact with it during daily use (e.g., keys). In addition, the life cycle of a product can be increased by reducing the possibility of product damage due to scratches on the screen surface.

If a product uses a backlight, there is a high possibility that the color of the screen will be affected after some time due to dust or dirt that comes into contact with it. But it is possible to prevent this problem by using TFTs with LED backlights, which have no problems such as those caused by dust and dirt.

It is possible to reduce power consumption and extend product life by reducing backlight power consumption and extending product life. In addition, if you use LEDs for backlights, you can reduce power consumption by up to 75% compared with conventional backlights.

Workability refers to the ease with which you can operate a product. When working with a screen that has TFTs, it is possible to increase the amount of information that can be displayed at one time. It is also possible to reduce the number of times you must change settings on a product by increasing its usability.

Design refers to what you can create with the use of a product. Using TFTs, it is possible to create products that have a thin profile and are lightweight, which makes them more convenient for transportation and storage.

In addition, when designing products, it is easier to reduce the number of parts needed for each surface by integrating multiple functions into one part or module (i.e., an IC chip).

Human interface refers to what you touch when using a product or what you see on the screen when using a product (e.g., buttons and other controls). By integrating the TFTs into the display part of a product, it is possible to make the human interface easier.

Amoled refers to a technology that replaces the traditional liquid crystal display (LCD) with an organic light-emitting diode (OLED). Modern TFTs are similar to Amoled in terms of their structure, but they differ from Amoled in terms of their performance.

The TFTs of the present invention have superior characteristics compared to Amoled, such as high contrast ratio and response speed. The TFTs also have superior characteristics compared to conventional display devices such as CRT and plasma display panels, which cannot be achieved by these conventional display devices.

IPS refers to a technology that replaces the traditional liquid crystal display (LCD) with in-plane switching technology. The IPS display has superior features to TFT due to its high contrast ratio, wide viewing angle, and high response speed.

There are certain limitations to TFTs. For example, there is a limit to the size of the display and the resolution of the image that can be displayed on a display. Also, because TFTs are considered to be a kind of organic semiconductor displays, they have a short life span and therefore need frequent replacement.

Because of their high resolution, TFT displays are used in display monitors. The type of TFT used in display monitors can be categorized as either active matrix or passive matrix. Active matrix TFTs use a thin film transistor (TFT) as its active component, whereas passive matrix uses a liquid crystal display (LCD).

TFTs are also being used in portable electronic devices such as mobile phones, personal digital assistants (PDAs), and cameras. These devices require high-resolution screens because the user must be able to view accurate images and text on the screen. TFTs are also being used in laptops, which have a much larger screen size than many other portable electronic devices.

Because of their size and high resolution, laptop computers use passive matrix TFT displays instead of LCDs for larger displays than those found on smaller-sized portable electronics devices that use LCDs for their displays (e.g., mobile phones and PDAs).

TFT displays are used in front-projection TVs. The type of TFT used in front-projection TVs can be categorized as either active matrix or passive matrix. Active matrix TFTs use a thin film transistor (TFT) as its active component, whereas passive matrix uses a liquid crystal display (LCD).

Head-mounted displays (HMDs) use liquid crystal on silicon technology to create small, inexpensive, low-power VR headsets that can be worn on the head. Some HMDs use active matrix TFT technology while others use passive matrix TFT technology. Active matrix HMDs use shorting bars or glass electrodes to control each pixel; passive matrix HMDs use a liquid crystal material that allows for the creation of an image by controlling the voltage applied to each pixel.

TFTs are used in projectors to create the on-screen image from the input signal. TFTs are used in both active matrix and passive matrix projectors. Active matrix projectors use shorting bars or glass electrodes to control each pixel, while passive matrix projectors use a liquid crystal material that allows for the creation of an image by controlling the voltage applied to each pixel.

CCDs are used in digital cameras and DV camcorders to capture still images and video, respectively. CCDs use a single array of photosites that each receives an electrical charge during exposure to light, resulting in an electrical signal that is output as an image. TFTs are used in CCDs as display circuits for previewing pictures.

TFTs are used in the display of gaming systems such as consoles, personal computers, and hand-held devices. TFTs are also used in the display of mobile telephones and in digital signs.

There are many factors to consider when buying a TFT display. The most important factors are the size of the display, the resolution of the display, and whether or not it is touch-sensitive.

It is also vital to consider where you are buying your TFT display system. A good place to buy a TFT display is from an authorized dealer or an online store. You should also consider whether or not the TFT display system you are looking for has a warranty.

At ICRFQ, we can connect you to the best TFT display suppliers and manufacturers in China. Just contact us and we will do what a reliable sourcing agent should do!

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

TFT LCD touch displays are becoming more prevalent every day, in devices that range from consumer electronics to industrial and medical equipment. While design concepts for the use of TFT touch displays are well established, engineering and product design teams often come up against problems that are hard to solve. Following best practices on how to use TFT LCD touch screen can reduce a lot of "hair-pulling".

If the applied ground approach for a device equipped with a TFT touch display doesn’t follow best practices, a variety of issues can arise. Common challenges associated with grounding:

In general, there are two key considerations: keeping ground connections as short as possible, and keep impedance to a minimum. This requirement is particularly critical in ground connections between display housing and touch controller. The diameter of the ground connection also has an effect, though it is less important than length.

Another important attention for grounding design is to avoid ground loops. Star topology for ground distribution, can avoid a situation where two points that are both intended to be at ground, have a potential between them.

Any floating conductive parts near touch sensor can cause erratic behavior in touch function. So they all should the same ground potential as the touch controller.

To address those issues, you need to follow best practices, including physical device assembly and grounding design. And those are just the top challenges, engineer will encounter a range of additional challenges, like longevity, slim design, and so on. Partnering with a hardware provider like Topway, who can advise you at every step along your path to market, is critical. With deep bench of expertise and 20+ years experience on TFT LCD industry, Topway offers you that guidance and ability to speed your time to market.

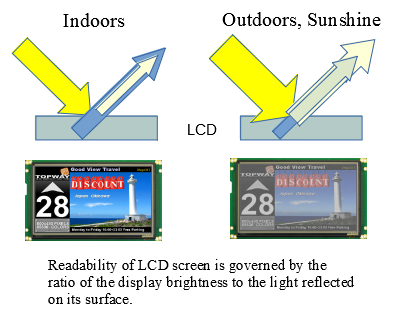

There are more and more TFT displays used in outdoor applications, such as automobile display, digital signage and kiosks. High ambient light in outdoor environment often causes wash-out image and renders the screen not readable. Readability & sustainability of TFT display under direct sunlight is becoming vital. Topway Display has been developing sunlight readable LCD display solution for years. The company understands the ins and outs of sunlight readable TFT LCD.

Visibility is the ease with which a viewer can detect an object, or in more scientific term: the relationship between luminance contrast and human eye’s threshold. Therefore, the higher an object’s contrast is, the better is its visibility.

For an LCD to be readable in outdoor environment with very bright ambient light, the LCD screen’s brightness needs to exceed the intensity of light that is reflected from the display surface. To be comfortably viewed by human eyes, the LCD’s brightness needs to exceed its reflected light by a factor of 2.5 at minimum. Naturally, to make an LCD sunlight readable, we can work on two areas, increasing brightness or reducing reflectance.

On a clear day in direct sunlight, the ambient brightness is about 6000 cd/m2. And a typical TFT LCD with touch screen reflects about 14% of ambient light, which is around 840 cd/m2. These days, most LCD displays use LED backlight as light source. It is not too difficult to increase an LCD’s brightness to 800 ~ 1000 Nits, to overpower the bright reflected sunlight. Thus, you have a sunlight readable TFT LCD.

However, this method requires more backlight LEDs and/or higher driving current. The drawbacks are high power consumption, more heat dissipation, increased product size and shorter LED backlight lifespan. Apparently, increasing backlight to make TFT LCD sunlight-readable is not a very good solution.

Transflective TFT LCD is a TFT LCD with both transmissive and reflective characteristics. A partially reflective mirror layer is added between LCD and backlight. This change turns part of the reflected ambient light into LCD’s light source, increasing the TFT display’s brightness. However, transflective TFT LCD is more expensive than transmissive one. At the same time, the partially reflective mirror layer will block some of the backlight, making it not ideal in indoor or low ambient light environment.

What causes light reflection? When light traveling in one transparent medium encounters a boundary with another transparent medium, a portion of the light bounces off the border. Through the simplest version of Fresnel’s equation, we can calculate the amount of reflected light.

The total reflectance on a TFT LCD with touch panel is the sum of reflected light on any interface where two materials meet. As an example, between polarizer and display glass, the difference in index of refractions for the two materials is very small, around 0.1. So the reflected light on this interface is only 0.1%. As Fresnel’s equation points out, we should focus reflection reduction on air interfaces. For air, its index of refraction is 1; for glass, it is 1.5. And that results in a reflectance of 4.5%. Therefore, the three air interfaces contribute majority of TFT LCD’s reflectance, at about 13%.

The quick and easiest thing we can do to reduce air-glass interface reflectance is to use an Anti-Reflection and Anti-Glare film or apply AR coating. An external film with AR properties not only reduces reflected light, but also brings other benefits.

For food industry application, shattered glass is a serious problem. An LCD screen with external film solves this issue nicely. As for automotive applications, in an accident, broken LCD with top AR film won’t produce sharp edge glass that could harms auto occupant. Nevertheless, a top film always reduces TFT LCD’s surface hardness. And it is susceptible to scratches. On the other hand, AR coating retains LCD’s hardness and touch performance. But it comes with a bigger price tag.

Another quick and easy way to tackle reflectance is to affix a linear polarizer on the top of TFT screen. When ambient light gets to the top polarizer, only half of the light passes through. Which results in reflection light cutting to half. This is a very low cost way to increase TFT LCD’s contrast, such that making it more sunlight readable.

Laminating a circular polarizer in TFT LCD will get rid of a lot of reflectance. That is because when ambient light passes through circular polarizer it gets circularly polarized. And when it is reflected, the polarization direction flips by 180 degrees. So when reflected light comes back to the circular polarizer, nothing goes through to viewer’s eyes.

This method is very effective for an LCD display with resistive touch panel. We know resistive touch LCD has two air gaps: air gap between two ITO layers and air gap between touch panel and LCD display. Reflectance caused by the two air gaps is very high. Applying circular polarizer blocks off most of the reflected light, and makes the LCD display sunlight readable.

The disadvantage of such solution is its cost. Since we need not only a circular polarizer, but also a retarder film on the top of LCD display, making sure light originates from within LCD is not blocked by external circular polarizer.

Add AR films on both interfaces of internal air gap. The add-ons can reduce this area’s reflection from 8.5% to 2%. And since the AR films are not outside facing, they are much cheaper than the one used outside. Keeping the air gap also retains the ease of service, in case either touch panel or LCD display needs to be repaired.

The most effective way is to eliminate air gap totally, by using optical bonding. In plain language, we fill air gap with special optical adhesive, to smooth out the area’s refraction index differences. Such that reflectance caused by internal air gap drops from 8.5% to 0.5%. Optical bonding is expensive but effective way to improve TFT LCD sunlight readability. It enhances durability and resistance to impact. Moreover, no air gap means no moisture condensation and fogging.

There are many ways to make TFT LCDsunlight readable. They all have their own pros and cons. With 20+ years" LCD design and manufacturing experience, Topway knows how to create the best sunlight readable TFT LCD for challenging environments. Leave us a message and let"s start the conversation of creating suitable sunlight readable TFT LCD for your project.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Despite been one of the pioneers in FPD manufacturing business in China, CEC Panda had been in a very tough position in the past a few years, especially from 2019-2020:Firstly, CEC Panda’s FPD business stock, known as Huadong Tech (000727) is moved to special treatment category with limited stock growth per day.

Since there have been many professional analysis about this trading, and its potential impacts on FPD industry in China, this article was focused on providing more background stories on CEC Panda’s display business, and readers can move to Omdia, Cinno, DSCC, Sigma Intel for more professional details about this business reconstructions.

There is an individual subsidiary for each production line, and the entire FPD business was placed under a holding company called Hudong Tech, a public listed company in China.Gen 8.5 TFT-LCD line in Nanjing is placed under Nanjing CEC Panda Display Tech.

Besides those 3 lines listed above, CEC Panda also has certain connections to following FPD projects:Gen 8.6 TFT-LCD from CHOT: Many people in the management were worked in CEC Panda Nanjing lines.

Huadong Tech has been in tough financial position for years since 201 with many loss in its FPD business. Since 89.62% of revenue in Huadong Tech was from its display business, it is reasonable to evaluate CEC Panda’s FPD operation based on financial indicators from Huadong Tech.From 2018 Q1 – 2020 Q2, operation income were negative.

Huadong Tech did not have enough saving in its Deferred account meaning it would be hard for it to compensate its profitability via withdrawing cash from deferred account.

By comparing the periodic cost between Huadong Tech and BOE from 2018Q1-2020Q2:Huadong Tech had its operating cost higher than revenue meaning it was hard for this company to generate any revenue in the first place. In the same time, operation cost/revenue ratio was less than 88% in BOE’s case. The high cost might be due to the Oxide process in Huadong Tech. Oxide is very sensitive to light, and an extra light shade is needed in array phase. In the meantime, the material cost for IGZO would be higher than traditional a-SI.

Even with poor operating performance, Huadong Tech still has its value to BOE and TCL who can use Huadong Tech’s lines to fill their strategic purpose.From BOE’s perspective, having Huadong Tech in hand means BOE will have the capability to make VA LCD, and get into Samsung’s supply Chain.

On TCL’s side, having IPS technology from Huadong Tech can be profitable since IPS would be a good fit to IT and monitor panel market. In the meantime, if TCL has Huadong Tech in hand, it will not only be able to stop BOE getting into Samsung’s supply Chain, this merge can also help TCL to compete with BOE to be the largest panel maker in China.

After years of fast expansion, FPD business was in hot competition in 2018-2019. But with Korea panel makers quitting LCD production, and the stimulation from COVID-19, panel prices have been kept increasing in the past a few months.

Even with huge increase in panel prices, most of panel makers still had some lost in 2020 Q2. Since the ASP of LCD panels will keep increasing, panel makers are expected to make good income in Q3 and Q4 in 2020.

For many Chinese panel makers, their expansion plans might be restarted when they have good income in following quarters. And Panel makers in Taiwan might be the next players to be forced out.

Statistically speaking, it will cost almost 2 years to build new display factory including months of planning ahead, 10-12 months of ground construction, 6 months of installation and 6 months ramping up. It means many panel makers will have good income at least in the next 2 years. But, if Chinese panel makers keep expansion, new price war might be here again.

Every aspect of your day involves interacting with an LCD Display Touch Screen. They are used in numerous places, including mobile phones, automated teller machines, kiosks, ticket vending machines, and factories. LCD display touch screens have dominated the market for years, and their dominance shows no signs of abating any time soon. Mechanical engineers are always working to enhance their hardware and software algorithms to render traditional input devices like keyboards and mice unnecessary.

An LCD display touch screen"s adaptability means it may be used in almost any setting, including those that are noisy, chaotic, or even dirty because of the high volume of traffic expected. This has numerous positive implications for many different types of businesses.

Because of their intended use in commercial and industrial settings, these displays are equipped with safeguards to prevent damage over time. Touchscreens used in commercial and industrial settings are made to last for years, even when subjected to extreme temperatures, humidity, and pressure. LCD touch screen displays can be configured to the precise characteristics required by a wide variety of applications, making them ideal for supermarkets, restaurants, stores, warehouses, distribution centers, hospitals, and even military and maritime activities.

LCD display touch screen ultra-compact and lightweight design. The liquid crystal display takes up only a third as much room as the bulkier CRT display, uses less power, and stays cool under pressure. When compared to cathode ray tube (CRT) displays, this device has a significantly lower power usage. The liquid crystal display generates zero thermal energy and emits zero harmful radiation, making it a safe and healthy choice. The display is gentle on the eyes. The lack of flickering on an LCD panel means less strain on the eyes and a more comfortable viewing experience than with CRT technology.

Therefore, it is crucial that these multipurpose systems can continue functioning normally and at peak efficiency even in the harshest environmental conditions, with as little system failure and hardware damage as possible. They might be responsible for saving someone"s life.

One of your least tech-savvy employees should be able to set up these devices with ease. You can save yourself a ton of time and money by not having to hire a computer professional to set up your portable industrial computer monitor because it is very similar to setting up a personal or office computer.

A-TOPS Electronics Co., Ltd., founded in 1998, is an industry leader in LCD display R&D and production. We have a distinct competitive advantage when it comes to producing individualized and specially designed products for our clients in addition to the more commonplace industrial displays.

When it comes to meeting the unique requirements of our customers, A-TOPS is always looking for new methods to improve and broaden our product offerings. We contribute to the value plus quality and service that our customers need to flourish in today"s competitive market by offering expert solutions at a fair price and prompt, helpful customer service.

Lately I’ve been seeing some surprisingly appealing bikes come out of CFMOTO, a Chinese motorcycle manufacturer and brand. One that caught my eye is the CFMOTO 700CL-X Sport, which I hope to flog around a track soon.

It’s easy to find out about the history of American and European motorcycle companies (and relatively easy to find out about Japanese ones), but very hard to figure out much about Chinese companies in general.

To many people around the world, saying “China” or “Chinese-made” tends to evoke instant emotional reactions based on a lot of our own experience and things we hear.

It is of course OK to have emotions. Particularly about motorcycles — it’s a very personal subject! But it’s also useful to have some facts surrounding those emotions so we know exactly what we’re talking about.

I’ve lived in China, speak Chinese (Mandarin), and have visited Hangzhou (where CFMOTO is based) a few times, so I have a personal connection to it. I’m not an authority on CFMOTO or China (far from it!), but in my time in that very interesting place, I have learned it’s useful to not make generalisations about a massive country and complex society.

Well, I am. That’s why I created this site — as an outlet. I love learning and sharing what others might find useful. If you like what you read here, and you’re a fraction as obsessed as I am, you might like to know when I’ve published more. (Check the latest for an idea of what you’ll see.)

CFMOTO was founded in 1989. Its headquarters are in Hangzhou, the capital of Zhejiang province — a relatively beautiful city, famous for its central lake (the West Lake), and known for being one of the major tech centres and a startup hub of China.

Hangzhou is 200 km from Shanghai and very accessible from Shanghai’s main airport by high-speed train — you can get there in thirty minutes. Economically, Hangzhou is a very important city in China, and a place where a lot of factories and tech companies are based.

If you have access to the Shanghai stock exchange, then CFMOTO would have been a good stock to own before 2020. Since early 2020, its value has basically quadrupled.

CFMOTO is becoming an important brand because they do a lot of manufacturing, and because their motorcycles are becoming genuinely well-accepted in the international motorcycle marketplace.

As of 2021, according to their website, CFMOTO has around 1800 employees, with 200 members in their R&D team. These numbers may be out of date, but it shows it’s a sizeable company. They currently produce over 600,000 motorcycles a year as of 2021, mostly for China.

You might be wondering where the name “CFMOTO” comes from. Firstly, that’s how they write it — all capitals (not “CFMoto” as some magazines report it).

You pronounce these fore characters zhèjiāng chūnfēng according to the Pinyin pronunciation system. Literally it means “Zhejiang (a region) Spring Wind Power”. It’s a poetic name (as are many Chinese company names), but translated it might confuse non-Chinese speakers into thinking it’s a wind power company, that focuses on the wind of spring!

Because non-Chinese speakers often find it hard to pronounce Chinese company names, a typical approach is to use acronyms for either company names or the founders’ names. In this case, they took CF from chunfeng, and call it CFMOTO for international audiences.

CFMOTO has sold the 650NK (the naked bike) since 2012, and revamped it significantly in 2017, along with releasing the 650GT (a sports tourer) and 650MT (an adventure tourer).

The 650 class of motorcycles are all powered by a 649cc liquid-cooled eight-valve parallel twin. The engines have a bore and stroke of 83.0 x 60.0 mm, and a compression ratio of 11.3:1.

In terms of engine dimensions and design, it’s very similar to that in the Kawasaki ER-6 or Z650/Ninja 650 bikes. They also have a 83.0/60.0mm bore and stroke, though the Kawasakis run a milder compression ratio of 10.8:1.

The 650 class of motorcycles make around 52 kW (70 hp) at 8750 rpm, which is lively without being aggressively sporty. They’re also sold in a learner restricted version, which makes around 41 kW (55hp), for compliance in markets like Australia and New Zealand that have power restrictions as well as capacity restrictions.

Seeing the 650 and 400 class engines (which also share similarities), I thought that Kawasaki and CFMOTO may have had a manufacturing partnership, but I haven’t found any evidence for this. Kawasaki still manufactures in Japan.

The CFMOTO 800MT is based around the 799cc LC8c parallel twin that came from KTM. This is a result of their partnership (see below). It’s a cracker of an engine, making (in the 800MT) 70 kW or 95 hp, and with a lot of character from its 285 degree crankshaft, helping it mimic the delivery of KTM’s V-twins.

The CFMOTO 800MT Touring comes with fully adjustable KYB suspension, a quickshifter, a big TFT screen, fog lights, radial-mounted J.Juan brakes with Cornering ABS as standard, and so much more. On other brands’ bikes, these are usually expensive add-ons.

It’s a high-spec luxury tourer based on a 1279cc liquid-cooled V-twin that makes a peak of 105 kW (140 bhp) at 8500 rpm, and a huge 1290 Nm (89 ft-lb) of torque at 7000 rpm.

The engine is based on the KTM LC8 V-twin that first appeared in the RC8 superbike. Of course it’s detuned and made more suitable for a long-distance tourer.

The bike has a ton of high-spec gear, like semi-active WP electronic suspension, big 12.3 inch TFT display, Brembo radial-mounted calipers, and cornering ABS. It even has a multimedia sound system.

Aside from the motorcycles above, CFMOTO has made a plethora of smaller motorcycles for the international markets. These include single cylinder bikes in the 150, 250, and 300 range, and possibly a future twin in the 400 range.

Generally speaking these motorcycles serve their purpose and even look quite good at times. They only suffer from limited brand perception (always influenced by China/global relations) and lower resale value.

The significant phase of the partnership started in 2014 when KTM started manufacturing KTM 200 and 390 Dukes for KTM in China. They’re sold under the CFMOTO KTMR2R brand. (For global markets KTM partners with Bajaj in India to manufacture its 390 Duke and RC 390 for international audiences. And the new 2022 KTM RC 390 has some amazing specs!)

CFMOTO is also starting to sell its own-brand of motorcycles using the LC8c engine in 799cc configuration, starting with the CFMOTO 800MT — which is incredible value for money, offering a level of tech and options usually found on bikes costing 30-50% more.

KTM is also transferring technology for the LC8 V-twin engine, including the 990 and 1080 V-Twin models. The first fruit of this, interestingly, is a 1279cc LC8-derived engine, to power the 1250 TR-G tourer. It makes 105 kW or 140 bhp.

CFMOTO has a few other partnerships for accessories. The most significant of these is with Total Lubrifiants SA, a French company (SA stands for Société Anonyme, and translates conceptually to “Public Limited Company”).

CFMOTO and Total have had a limited partnership since 2012. But since 2021, Total Hi-Perf will be the recommended lubricants for CFMOTO’s overseas network.

Inevitably, when people hear the word “China” these days — particularly in the belligerent environment of the 2010s and 2020s — their minds may turn to politics. I’d love to not touch this topic, but I know someone will write to me about it or comment about it.

It’s natural to want to vote with your wallet, and many people do so. I vote with my wallet constantly, preferring some manufacturers, sellers, or brands over others based on not just the product, but my perception of the company’s values.

I can’t really provide a concise summary here about the “China question” as it’s a deep topic and I always feel there’s more nuance to every point, but I want to provide some talking points.

Firstly, buying from a Chinese company is more strongly related to supporting the host government indirectly than is buying from, for example, an American or European manufacturer.

China isn’t a pure communist country, no matter the rhetoric. Ever since Deng Xiaoping’s reforms in the 1980s, China has taken on many market economy characteristics, through privatisation of national industries and allowing entrepreneurs to make money. “To get rich is glorious” became an axiom of that period:《致富光荣》. Not very communist! They call it a “socialist market economy”.

Nonetheless, despite the increasingly open markets, China still has a centrally planned economy. Even though in every country (including western democracies) companies need the blessing of regulatory authorities to exist (to have licenses to manufacture, export and so on), China’s central planning means that the fate of the Party and companies are closely intertwined. See this article in Britannica for an overview.

So in that sense, buying from a Chinese company means you more directly support the CCP and PRC compared to the degree to which buying from a European or American motorcycle manufacturer means supporting their host governments.

After living for years in China, I have many Chinese friends, both there and abroad. They helped me gain a lot of insight into the diversity of Chinese culture globally and how everyone relates to the country and to the PRC’s government. There’s a wonderful poetic saying in Chinese: 《海内存知己,天涯若比邻》, which loosely translated means “To have a close friend in distant lands makes far-flung realms seem close together.”

If you want to get more of a background on China and its role, I recommend the following newsletters. They tend to draw from multiple sources. There’s more in there than I could ever hope to know or summarise.

If you want to buy a new monitor, you might wonder what kind of display technologies I should choose. In today’s market, there are two main types of computer monitors: TFT LCD monitors & IPS monitors.

The word TFT means Thin Film Transistor. It is the technology that is used in LCD displays. We have additional resources if you would like to learn more about what is a TFT Display. This type of LCDs is also categorically referred to as an active-matrix LCD.

These LCDs can hold back some pixels while using other pixels so the LCD screen will be using a very minimum amount of energy to function (to modify the liquid crystal molecules between two electrodes). TFT LCDs have capacitors and transistors. These two elements play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy while still generating vibrant, consistent images.

Industry nomenclature: TFT LCD panels or TFT screens can also be referred to as TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology.

IPS (in-plane-switching) technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but has more enhanced features and more widespread usability.

These LCD screens offer vibrant color, high contrast, and clear images at wide viewing angles. At a premium price. This technology is often used in high definition screens such as in gaming or entertainment.

Both TFT display and IPS display are active-matrix displays, neither can’t emit light on their own like OLED displays and have to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light-emitting diodes) to generate their light hence utilizing less power and requiring less depth by design. Neither TFT display nor IPS display can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to produce the color consumers see. If you use a magnifier to inspect your monitor, you will see RGB color in each pixel. With an on/off switch and different level of brightness RGB, we can get many colors.

Wider viewing angles are not always welcome or nee

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey