tft display vs led backlit free sample

In market, LCD means passive matrix LCDs which increase TN (Twisted Nematic), STN (Super Twisted Nematic), or FSTN (Film Compensated STN) LCD Displays. It is a kind of earliest and lowest cost display technology.

LCD screens are still found in the market of low cost watches, calculators, clocks, utility meters etc. because of its advantages of low cost, fast response time (speed), wide temperature range, low power consumption, sunlight readable with transflective or reflective polarizers etc. Most of them are monochrome LCD display and belong to passive-matrix LCDs.

TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy without running out of operation.

Normally, we say TFT LCD panels or TFT screens, we mean they are TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology. TFT is active-matrix LCDs, it is a kind of LCD technologies.

TFT has wider viewing angles, better contrast ratio than TN displays. TFT display technologies have been widely used for computer monitors, laptops, medical monitors, industrial monitors, ATM, point of sales etc.

Actually, IPS technology is a kind of TFT display with thin film transistors for individual pixels. But IPS displays have superior high contrast, wide viewing angle, color reproduction, image quality etc. IPS screens have been found in high-end applications, like Apple iPhones, iPads, Samsung mobile phones, more expensive LCD monitors etc.

Both TFT LCD displays and IPS LCD displays are active matrix displays, neither of them can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to make LCD showing colors. If you use a magnifier to see your monitor, you will see RGB color. With switch on/off and different level of brightness RGB, we can get many colors.

Neither of them can’t release color themselves, they have relied on extra light source in order to display. LED backlights are usually be together with them in the display modules as the light sources. Besides, both TFT screens and IPS screens are transmissive, it will need more power or more expensive than passive matrix LCD screens to be seen under sunlight. IPS screens transmittance is lower than TFT screens, more power is needed for IPS LCD display.

Confused about LED vs. LCD vs. TFT? Here"s everything you need to know. Creating or upgrading a device display or screen can involve a lot of different things, but it often comes down to one major question - what kind of display should you get?

So, there are 3 common displays LED, LCD and TFT available in the market. All terms refer to the flat-panel display, or screen, of a computer monitor or television set. In this article, we are going to differentiate between them. It will help you to choose a better one.

LCD stands for liquid crystal display. Works by adjusting the amount of light blocked. Usually has a backlight but might not (clocks, calculators, Nintendo Gameboy). The green-black ones can be very cheap and are a mature technology. Response time can be slow. An LCD display uses the light balancing qualities of crystals. Today LCDs are used in a great number of products and applications. Your TV, computer screen, calculator, cell phone and the dreaded alarm clock are all made of an LCD flat panel. Color LCDs produce the color based on two techniques: Passive matrix and active matrix. Passive matrix is the cheapest technology of the two. The other technology is called an active matrix or TFT. Active matrix displays produce really sharp and clear images.

This is a type of LCD with a thin film transistor attached to each pixel. All computer LCD screens are TFT since the early 2000s; older ones had slower response times and poorer color. Cost is now very good; power consumption is fairly good but dominated by the backlight. Has to be manufactured out of glass. The TFT layer is embedded in the screen itself, it reduces crosstalk between pixels. Crosstalk happens when a signal sends to a pixel also affects the pixel next to it. This makes the TFT technology the technology offering the best resolution and image quality. It also makes it a bit more expensive. Today TFTs have become the standard when producing LCD screens.

LED stands for a light emitting diode. As the name suggests, emits light rather than blocking it like LCD. Used for red/green/blue/white indicator lights everywhere. Some manufacturers advertise "LED" displays that are TFT screens with a white LED backlight, which is just confusing. Ones that are real LED screens are usually OLED.

Some devices actually have backlights made from Red, Green and Blue LEDs, normally referred to as RGB LED, which tend to have better color reproduction than any other display.

LED screen is just like saying that it is a plastic screen. You still have the WHOLE screen illuminated all the time and LED is "good" only for being more eco-friendly and probably more bright at max setting if you ever need this.

An LCD panel is, in fact, 2 layers of glass with some volume of Liquid Crystal in between. These two form the panel itself. The 2 layers are usually called Color Filter Glass (above) and TFT glass (below).

A standard TFT has a whole "lamp" behind it, illuminating the whole screen all the time. This way, you cannot have a true black, as it is still illuminated and stay grayish.

TFTs are a type of active matrix display that controls individual pixel updates several times per second on the screen to update the image relative to the content source.

TFT displays use more electricity than regular LCD screens, so they not only cost more in the first place, but they are also more expensive to operate.

LCDs use fluorescent lights while LEDs use those light emitting diodes. The fluorescent lights in an LCD are always behind the screen. On an LED, the light emitting diodes can be placed either behind the screen or around its edges.

Let us start with the basics first; refresh the knowledge about TN and LCD displays in general, later we will talk about TFTs (Thin Film Transistors), how they differ from regular monochrome LCD displays. Then we will go on to the ghosting effect, so we will not only discuss the technology behind the construction of the TFT, but also some phenomena, like the ghosting effect, or grayscale inversion, that are important to understand when using an LCD TFT display.

Next, we will look at different technologies of the TFT LCD displays like TN, IPS, VA, and of course about transmissive and transflective LCD displays, because TFT displays also can be transmissive and transflective. In the last part we will talk about backlight.

Let us start with a short review of the most basic liquid crystal cell, which is the TN (twisted nematic) display. On the picture above, we can see that the light can be transmit through the cell or blocked by the liquid crystal cell using voltage. If you want to learn more about monochrome LCD displays and the basics of LCD displays, follow this link.

What is a TFT LCD display and how it is different from a monochrome LCD display? TFT is called an active display. Active, means we have one or more transistors in every cell, in every pixel and in every subpixel. TFT stands for Thin Film Transistor, transistors that are very small and very thin and are built into the pixel, so they are not somewhere outside in a controller, but they are in the pixel itself. For example, in a 55-inch TV set, the TFT display contains millions of transistors in the pixels. We do not see them, because they are very small and hidden, if we zoom in, however, we can see them in every corner of each pixel, like on the picture below.

On the picture above we can see subpixels, that are basic RGB (Red, Green, Blue) colors and a black part, with the transistors and electronic circuits. We just need to know that we have pixels, and subpixels, and each subpixel has transistors. This makes the display active, and thus is called the TFT display. TFT displays are usually color displays, but there are also monochrome TFT displays, that are active, and have transistors, but have no colors. The colors in the TFT LCD display are typically added by color filters on each subpixel. Usually the filters are RGB, but we also have RGBW (Red, Green, Blue, White) LCD displays with added subpixels without the filter (White) to make the display brighter.

Going a little bit deeper, into the TFT cell, there is a part inside well known to us from the monochrome LCD display Riverdi University lecture. We have a cell, liquid crystal, polarizers, an ITO (Indium Tin Oxide) layer for the electrodes, and additionally an electronic circuit. Usually, the electronic circuit consists of one transistor and some capacitors to sustain the pixel state when we switch the pixel OFF and ON. In a TFT LCD display the pixels are much more complicated because apart from building the liquid crystal part, we also need to build an electronic part.

That is why TFT LCD display technologies are very expensive to manufacture. If you are familiar with electronics, you know that the transistor is a kind of switch, and it allows us to switch the pixel ON and OFF. Because it is built into the pixel itself, it can be done very quickly and be very well controlled. We can control the exact state of every pixel not only the ON and OFF states, but also all the states in between. We can switch the light of the cells ON and OFF in several steps. Usually for TFT LCD displays it will be 8-bit steps per color, so we have 256 steps of brightness for every color, and every subpixel. Because we have three subpixels, we have a 24-bit color range, that means over 16 million combinations, we can, at least theoretically, show on our TFT LCD display over 16 million distinct colors using RGB pixels.

Now that we know how the TFT LCD display works, we can now learn some practical things one of which is LCD TFT ghosting. We know how the image is created, but what happens when we have the image on the screen for a prolonged time, and how to prevent it. In LCD displays we have something called LCD ghosting. We do not see it very often, but in some displays this phenomenon still exists.

If some elements of the picture i.e., your company logo is in the same place of the screen for a long period of time, for couple of weeks, months or a year, the crystals will memorize the state and later, when we change the image, we may see some ghosting of those elements. It really depends on many conditions like temperature and even the screen image that we display on the screen for longer periods of time. When you build your application, you can use some techniques to avoid it, like very rapid contrast change and of course to avoid the positioning the same image in the same position for a longer time.

You may have seen this phenomenon already as it is common in every display technology, and even companies like Apple put information on their websites, that users may encounter this phenomenon and how to fix it. It is called image ghosting or image persistence, and even Retina displays are not free of it.

Another issue present in TFT displays, especially TN LCD displays, is grayscale inversion. This is a phenomenon that changes the colors of the screen according to the viewing angle, and it is only one-sided. When buying a TFT LCD display, first we need to check what kind of technology it is. If it is an IPS display, like the Riverdi IPS display line, then we do not need to worry about the grayscale inversion because all the viewing angles will be the same and all of them will be very high, like 80, 85, or 89 degrees. But if you buy a more common or older display technology type, like the TN (twisted nematic) display, you need to think where it will be used, because one viewing angle will be out. It may be sometimes confusing, and you need to be careful as most factories define viewing direction of the screen and mistake this with the greyscale inversion side.

On the picture above, you can see further explanation of the grayscale inversion from Wikipedia. It says that some early panels and also nowadays TN displays, have grayscale inversion not necessary up-down, but it can be any angle, you need to check in the datasheet. The reason technologies like IPS (In-Plane Switching), used in the latest Riverdi displays, or VA, were developed, was to avoid this phenomenon. Also, we do not want to brag, but the Wikipedia definition references our website.

We know already that TN (twisted nematic) displays, suffer from grayscale inversion, which means the display has one viewing side, where the image color suddenly changes. It is tricky, and you need to be careful. On the picture above there is a part of the LCD TFT specification of a TN (twisted nematic) display, that has grayscale inversion, and if we go to this table, we can see the viewing angles. They are defined at 70, 70, 60 and 70 degrees, that is the maximum viewing angle, at which the user can see the image. Normally we may think that 70 degrees is better, so we will choose left and right side to be 70 degrees, and then up and down, and if we do not know the grayscale inversion phenomena, we may put our user on the bottom side which is also 70 degrees. The viewing direction will be then like a 6 o’clock direction, so we call it a 6 o’clock display. But you need to be careful! Looking at the specification, we can see that this display was defined as a 12 o’clock display, so it is best for it to be seen from a 12 o’clock direction. But we can find that the 12 o’clock has a lower viewing angle – 60 degrees. What does it mean? It means that on this side there will be no grayscale inversion. If we go to 40, 50, 60 degrees and even a little bit more, probably we will still see the image properly. Maybe with lower contrast, but the colors will not change. If we go from the bottom, from a 6 o’clock direction where we have the grayscale inversion, after 70 degrees or lower we will see a sudden color change, and of course this is something we want to avoid.

To summarize, when you buy older technology like TN and displays, which are still very popular, and Riverdi is selling them as well, you need to be careful where you put your display. If it is a handheld device, you will see the display from the bottom, but if you put it on a wall, you will see the display from the top, so you need to define it during the design phase, because later it is usually impossible or expensive to change the direction.

We will talk now about the other TFT technologies, that allow us to have wider viewing angles and more vivid colors. The most basic technology for monochrome and TFT LCD displays is twisted nematic (TN). As we already know, this kind of displays have a problem with grayscale inversion. On one side we have a higher retardation and will not get a clear image. That is why we have other technologies like VA (Vertical Alignment), where the liquid crystal is differently organized, and another variation of the TFT technology – IPS which is In-Plane Switching. The VA and IPS LCD displays do not have a problem with the viewing angles, you can see a clear image from all sides.

Apart from the different organization of the liquid crystals, we also organize subpixels a little bit differently in a VA and IPS LCD displays. When we look closer at the TN display, we will just see the subpixels with color filters. If we look at the VA or IPS display they will have subpixels of subpixels. The subpixels are divided into smaller parts. In this way we can achieve even wider viewing angles and better colors for the user, but of course, it is more complicated and more expensive to do.

The picture above presents the TN display and grayscale inversion. For IPS or VA technology there is no such effect. The picture will be the same from all the sides we look so these technologies are popular where we need wide viewing angles, and TN is popular where we don’t need that, like in monitors. Other advantages of IPS LCD displays are they give accurate colors, and wide viewing angles. What is also important in practice, in our projects, is that the IPS LCD displays are less susceptible to mechanical force. When we apply mechanical force to the screen, and have an optically bonded touch screen, we push the display as well as squeeze the cells. When we have a TN display, every push on the cell changes the image suddenly, with the IPS LCD displays with in-plane switching, different liquid crystals organization, this effect is lesser. It is not completely removed but it is much less distinct. That is another reason IPS displays are very popular for smartphones, tablets, when we have the touchscreens usually optically bonded.

If we wanted to talk about disadvantages, there is a question mark over it, as some of them may be true, some of them do not rely on real cases, what kind of display, what kind of technology is it. Sometimes the IPS displays can have higher power consumption than others, in many cases however, not. They can be more expensive, but not necessarily. The new IPS panels can cost like TN panels, but IPS panels definitely have a longer response time. Again, it is not a rule, you can make IPS panels that are very fast, faster than TN panels, but if you want the fastest possible display, probably the TN panel will be the fastest. That is why the TN technology is still popular on the gaming market. Of course, you can find a lot of discussions on the internet, which technology is better, but it really depends on what you want to achieve.

Now, let us look at the backlight types. As we see here, on the picture above, we have four distinct types of backlight possible. The most common, 95 or 99 per cent of the TFT LCD displays on the market are the transmissive LCD display type, where we need the backlight from the back. If you remember from our Monochrome LCD Displays lecture, for transmissive LCD displays you need the backlight to be always on. If you switch the backlight off, you will not see anything. The same as for monochrome LCD displays, but less popular for TFT displays, we have the transflective LCD display type. They are not popular because usually for transflective TFT displays, the colors lack in brightness, and the displays are not very practical to use. You can see the screen, but the application is limited. Some transflective LCD displays are used by military, in applications where power consumption is paramount; where you can switch the backlight off and you agree to have lower image quality but still see the image. Power consumption and saving energy is most important in some kind of applications and you can use transflective LCD displays there. The reflective type of LCD displays are almost never used in TFT. There is one technology called Low Power Reflective Displays (LPRD) that is used in TFT but it is not popular. Lastly, we have a variation of reflective displays with frontlight, where we add frontlight to the reflective display and have the image even without external light.

Just a few words about Low Power Reflective Displays (LPRD). This kind of display uses environmental light, ambient light to reflect, and produce some colors. The colors are not perfect, not perfectly clear, but this technology is becoming increasingly popular because it allows to have color displays in battery powered applications. For example, a smartwatch would be a case for that technology, or an electrical bike or scooter, where we can not only have a standard monochrome LCD display but also a TFT LCD color display without the backlight; we can see the image even in

strong sunlight and not need backlight at all. So, this kind of TFL LCD display technology is getting more and more popular when we have outdoor LCD displays and need a low power consumption.

On the picture above, we have some examples of how transmissive and reflective LCD displays work in the sunlight. If we have a simple image, like a black and white pattern, then on a transmissive LCD display, even with 1000 candela brightness, the image probably will be lower quality than for a reflective LCD display; if we have sunlight, we have very strong light reflections on the surface of the screen. We have talked about contrast in more detail in the lecture Sunlight Readable Displays. So, reflective LCD displays are a better solution for outdoor applications than transmissive LCD displays, where you need a really strong backlight, 1000 candela or more, to be really seen outdoors.

To show you how the backlight of LCD displays is built, we took the picture above. You can see the edge backlight there, where we have LEDs here on the small PCB on the edge, and we have a diffuser that distributes the light to the whole surface of LCD screen.

In addition to the backlight, we have something that is called a frontlight. It is similar to backlight, it also uses the LEDs to put the light into it, but the frontlight needs to be transparent as we have the display behind. On the example on the picture above we can see an e-paper display. The e-paper display is also a TFT display variation, but it is not LCD (liquid crystal), it is a different technology, but the back of the display is the same and it is reflective. The example you see is the Kindle 4 eBook reader. It uses an e-paper display and a frontlight as well, so you can read eBooks even during the night.

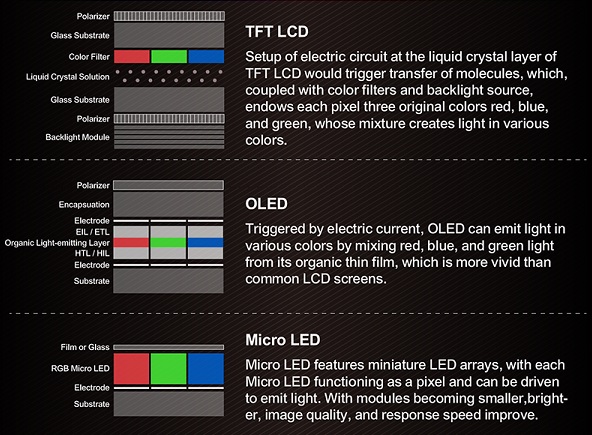

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Low power consumption and flexible: OLED doesn"t rely on backlight and consumes less power. OLED is essentially created on plastic film. It is bendable and easy to process.

High contrast and vivid color: OLED emits light itself, can produce very bright image with beautiful color. And because OLED can be turned off, it can produce true black.

Stroboscopic effect: most OLED screen uses PWM dimming technology. Some people who are easy perceive stroboscopic frequency may have sore eyes and tears.

Micro LED, sometimes called μLED is made up of tiny LED, measure less than 100μm. Another way of looking at this is that MicroLEDs are simply traditional LEDs shrunk down and placed into an array.

Replacing organic material with inorganic GaN material eliminates the need of polarizing and encapsulation layer, found in OLED. Micro LED is smaller and thinner, consumes less power.

![]()

TFT displays are also known as an “Active Matrix TFT LCD module” and have an array of thin film transistors fabricated on the glass that makes the LCD. There is one of these transistors for each pixel on the LCD. See our blog post RGB and Color Depth for more on how TFTs show color.

LCDs use voltage applied to a field of microscopic liquid crystals to change the crystal’s orientation. The orientation of the crystals changes the polarization of the liquid crystal creating light or dark pixels on the display.

These pixels are arranged to create characters or graphic images. This type of display may be sunlight-readable and may have a backlight, which allows it to be viewed in dark areas.

Beautiful, complex images: All of our TFT modules are full-color graphic displays. Unlike standard monochrome character displays, you can create complex images for an imaginative user experience.

Thin and light: These are ideal display modules for handheld devices, communications equipment, information displays, and test and measurement equipment.

Single Supply: Most of the TFTs use an integrated controller with built-in voltage generation so only a single 3.3v supply is needed for both the panel power and logic voltage.

Many of the LCD controllers on board our graphic LCD display modules also include a CGROM (character generator ROM) which allows for easy character information as well as full bit-mapped graphic information to be shown.

Some of the graphic LCD displays have the ability to render graphics in grayscale, enabling you to show images and elements of your UI (user interface) with more depth and definition.

Because OLEDs are emissive, these displays can always be used in dark environments. There is usually a software command or hardware setting that will allow OLEDs to be dimmed.

Some OLED displays are bright enough to be sunlight readable–these models will typically take more current and may have a shorter rated lifetime. Additionally, OLEDs have extremely wide viewing angles.

What makes OLEDs useful for display construction is that they can be fabricated in bulk. Using OLED fabrication techniques, all the diodes can be made at the same time, at a much lower cost. OLEDs also come in a wide variety of colors.

LCD: liquid crystal display. Works by adjusting the amount of light blocked. Usually has a backlight but might not (clocks, calculators, Nintendo Gameboy). The green-black ones can be very cheap and are a mature technology. Response time can be slow.

TFT: is a type of LCD with a thin film transistor attached to each pixel. All computer LCD screens are TFT since early 2000s; older ones had slower response times and poorer colour. Cost is now very good; power consumption is fairly good but dominated by the backlight. Has to be manufactured out of glass.

LED: light emitting diode. As the name suggests, emits light rather than blocking it like LCD. Used for red/green/blue/white indicator lights everywhere.

Some manufacturers advertise "LED" displays that are TFT screens with a white LED backlight, which is just confusing. Ones that are real LED screens are usually OLED.

OLED: organic LED (rather than silicon or germanium based like regular LEDs). Comparatively recent technology, so cost still quite variable and not available in really large sizes. In theory can be printed on plastic, resulting in lighter flexible displays with good brightness, good power consumption and good response time.

Focus Displays offers a wide range of standard full color TFT displays. 64 million unique colors, high brightness, sharp contrast, -30C operating temperature, and fast response time are all good descriptions of a TFT display. This is why TFT technology is one of the most popular choices for a new product.

Thin Film Transistor (TFT) display technology can be seen in products such as laptop computers, cell phones, tablets, digital cameras, and many other products that require color. TFT’s are active matrix displays which offers exceptional viewing experiences especially when compared to other passive matrix technologies. The clarity on TFT displays is outstanding; and they possess a longer half-life than some types of OLEDs and range in sizes from less than an inch to over 15 inches.

CCFL’s are still available, but are becoming a legacy (obsolete) component. TFT displays equipped with a CCFL require higher MOQs (Minimum Order Quantities) than displays with LED backlights.

Red, Green and Blue (RGB) backlights are built with either a single LED that produces red, green and blue colors or with three separate Red, Green or Blue LEDs.

Backlight brightness (Luminance) is measured in nits. A nit being the amount of light that one candle delivers in a 1 square meter box. The intensity of the LED backlight can be critical when operating in low light or in direct sun light and is usually controlled by adjusting the DC voltage. In many applications this is accomplished through pulse-width modulation (PWM)

The majority of TFT displays contain a touch panel, or touch screen. The touch panel is a touch-sensitive transparent overlay mounted on the front of the display glass. Allowing for interaction between the user and the LCD display.

Some touch panels require an independent driver IC; which can be included in the TFT display module or placed on the customer’s Printed Circuit Board (PCB). Touch screens make use of coordinate systems to locate where the user touched the screen.

Resistive touch panels are the lowest cost option and are standard equipment on many TFT modules. They are more common on smaller TFT displays, but can still be incorporated on larger modules.

Contrast ratio, or static contrast ratio, is one way to measure the sharpness of the TFT LCD display. This ratio is the difference between the darkest black and the brightest white the display is able to produce. The higher the number on the left, the sharper the image. A typical contrast ratio for TFT may be 300:1. This number ratio means that the white is 300 times brighter than the black.

TFT LCD displays are measured in inches; this is the measurement of the diagonal distance across the glass. Common TFT sizes include: 1.77”, 2.4”, 2.8”, 3”, 4.3”, 5”, 5.7”, 5.8”, 7”, 10.2”, 12.1 and 15”.

As a general rule, the larger the size of the glass the higher the cost of the display, but there are exceptions to this rule. A larger display may be less expensive than a smaller display if the manufacture produces higher quantities of the larger displays. When selecting your color display, be sure to ask what the cost is for one size smaller and one size larger. It may be worth modifying your design requirements.

TFT resolution is the number of dots or pixels the display contains. It is measured by the number of dots along the horizontal (X axis) and the dots along the vertical (Y axis).

The higher the resolution, the more dots per square inch (DPI), the sharper the display will look. A higher resolution results in a higher cost. One reason for the increase in cost is that more driver chips are necessary to drive each segment.

Certain combinations of width and height are standardized and typically given a name and a letter representation that is descriptive of its dimensions. Popular names given to the TFT LCD displays resolution include:

Transmissive displays must have the backlight on at all times to read the display, but are not the best option in direct sunlight unless the backlight is 750 Nits or higher. A majority of TFT displays are Transmissive, but they will require more power to operate with a brighter backlight.

Transflective displays are readable with the backlight off provided there is enough ambient light. Transflective displays are more expensive than Transmissive also there may be a larger MOQ for Transflective. However, Transflective displays are the best option for direct sunlight.

Drivers update and refresh the pixels (Picture Elements) of a display. Each driver is assigned a set number of pixels. If there are more pixels than a single driver can handle, then an additional drivers are added.

A primary job of the driver is to refresh each pixel. In passive TFT displays, the pixel is refreshed and then allowed to slowly fade (aka decay) until refreshed again. The higher the refresh frequency, the sharper the displays contrast.

The controller does just what its name suggest. It controls the drivers. There is only one controller per display no matter how many drivers. A complex graphic display with several thousand pixels will contain one controller and several drivers.

The TFT display (minus touch screen/backlight) alone will contain one controller/driver combination. These are built into the display so the design engineer does not need to locate the correct hardware.

If you do not see a Thin Film Transistor (TFT) Display module that meets your specifications, or you need a replacement TFT, we can build a custom TFT displays to meet your requirements. Custom TFTs require a one-time tooling fee and may require higher MOQs.

Ready to order samples for your TFT design? Contact one of our US-based technical support people today concerning your design requirements. Note: We can provide smaller quantities for samples and prototyping.

LCD displays don’t emit light by themselves. They need a light source, and LED backlights are now dominating the market. In this article, Orient Display’s Bill Cheung provides a complete overview of LED backlight technology, discussing different types, driver technologies, color deviation, brightness options and more.

LCD (liquid crystal display) has long been the dominant technology in the display world. Certainly, there are some emerging competing display technologies—such as OLED (Organic Light Emitting Diode) [1] and micro-LED—that have the potential to threaten LCD’s position in the market. But both are currently only used for niche and high-end markets.

An LCD display can’t emit light by itself. In order to have an LCD display [2] used in a dim environment, a backlight has to be used as the light source. There are a few different technologies that are able to produce backlight ranging from EL (electroluminescent), CCFL (cold cathode fluorescent lamps) and LED (light emitting diode). However, a breakthrough in blue LED technology by Shuji Nakamura [3] led to LED backlights dominating the market.

One of the greatest benefits of LED backlighting is its long lifetime. Normally, LED lifetime can be measured with half-life when the original brightness decreases by 50%. With different LED chip manufacturing materials, technologies and environment used, the LED life can vary from 20,000 hours to well over 100,000 hours.

LED backlights have low power consumption and produce much less heat than other backlight technologies, which extends the durability and performance of the other display components. Furthermore, this reduces the risk of fire and explosion. LED backlights are also driven with DC (direct current) and low voltage (can be as low as 1.5V), which are good for battery drive and emit no interference to the circuitry. With the development of LED technology, the LED chips become small. So, it is possible to produce very thin backlight (0.5mm thick or thinner).

Although white LED is the most popular color, LED backlight can be made into different single colors, bi-colors and tri-colors [4] (Figure 1) (Figure 2). With RGB LED backlight color mixing, normal 8 color LED backlight can be produced (Figure 3).

LED backlight can be classified as bottom (array) lit and side (edge) lit backlights, and each have their plusses and minuses. The advantages of the bottom lit (array) backlight are that it is uniform and bright. Its disadvantage is high current draw, thickness, heat dissipation and cost. Meanwhile, the advantages of the side lit backlight are its thinness, flexibility in design, low current and lower cost. The main disadvantage of the side lit backlight is its non-uniformity—hot spots can be seen from most of the side lit backlight from certain angle. Figure 4 compares the bottom lit and side (edge) lit backlight LCD types.

Now let’s look at LED backlight structures. An LED backlight can be simplified into layers starting with a LED chip, light guide, diffusor and reflector (Figure 5). This is the lowest cost structure. Except for some very low current efficiency LCD displays—such as utility meters, battery-powered clock, watch, GPS and so on—most LCD displays need backlights to be visible in the dim lighting. Most often the backlight is actually at the back of the LCD. In rare cases, this light can be done as front light. The traditional LCD structure with LED backlight shown in Figure 6.

Direct current driving: This is the simple and low-cost way to drive a LED backlight, however, be mindful of the current limit otherwise the LED life can deteriorate quickly. The solution is simply to add a current limiting resistor in the circuit. Current limitation resistors value calculation formula: R = (V0– Vf)/If.Also be mindful of reverse drive, otherwise, the LED chip can break down easily.

LED driver with constant current: The advantage of constant current LED driver is that it will be the best option to use when building your own fixture or working with high powered LED because they avoid violating the maximum current specified for the LEDs, therefore avoiding burnout/thermal runaway. They are easier for designers to control applications, and help create a more consistent bright light.

LED driver with constant voltage: Using a constant voltage LED driver makes sense when using an LED or array that has been specified to take a certain voltage. This is helpful because constant voltage is a much more familiar technology for design and installation engineers. Moreover, the cost of these systems can be lower, especially in larger scale applications.

As the LED is manufactured via the semiconductor process, there are some color deviations that can be a quality control issue. One way to solve the issue is through a process of selection and sorting after manufacturing the LEDs. The LEDs are sorted into different categories or bins. How this sorting is done and what each bin actually contains is defined differently by each LED manufacturer. The backlight manufacturer can choose from which bin they take the LEDs for backlight color hue.

Some customers might request very fine binning by the LED manufacturer, which can be very expensive since only a very small percentage of the LEDs manufactured would meet the requirements for a specific bin. Figure 7 shows an example of the bin selection from Nichia, the most renowned LED manufacturer in the world. Figure 8 shows the 1931 CIE chromaticity diagram. And Figure 9 shows the color deviations (bin definition) by Cree for a qualified production lot.

In actual LED backlight production, most customers will accept the LED color for two big categories: white with yellowish (warm) and white with bluish (cold). Of course, the LED brightness will also need to be defined. For general application, most customers will accept a brightness tolerance of 70 percent.

It is extremely hard to estimate the LED backlight lifetime or MTBF (mean time between failures) because there are so many variable factors. However, the most important is the temperature on the LED chip. The factors that can affect the LED chip temperature include: surrounding temperature, humidity, driving current, voltage, backlight design (how many LED chips to be used, how close to each other, heatsink design), backlight manufacturing process (type and thickness of adhesive), quality of the LED chip and so forth.

To test the LED life is also very time consuming, requiring at least 1,000 hours. That’s the reason why no LED manufacturers can guarantee LED backlight life and most backlight manufacturers also are reluctant to provide lifespan data. As for LCD manufacturers, they need to discuss it with the customer to understand the applications and provide suggestions. It is normal that the LCD datasheet lists the typical life time and avoids providing a minimum lifetime. From Figure 10, we can see that over room temperature, the current needs to decrease as the temperature increases. At over 85°C, the LED is not usable.

To estimate LED backlight lifetime, you can use ballpark estimation or theoretical calculation. Let’s first examine the ballpark method. To take white LED as example, the nominal biasing current is 20mA. If we use a safe lifetime estimation, we can estimate using Table 1.

Now let’s use the theoretical calculation approach. As we previously mentioned, LED life is affected by a lot of factors: surrounding temperature, humidity, driving current, voltage, backlight design (how many LED chips to be used, how close to each other, heatsink designed), backlight manufacturing process (type and thickness of adhesive), quality of the LED chip and so on. LED chip manufacturers are not willing to give absolute values of LED chip lifetimes, but there is a theoretical calculation that we can use.

Temperature is the determination factor for LED chip life, while LED chip manufacturers use LED junction temperature to predict LED chip life more accurately. An example is:

Finally, let’s look at ways to increase LED backlight brightness. There are many ways to increase LED backlight brightness, but all these measures are balanced with performance and cost. Here are some of the methods:

For the LCD module side, using better aperture opening ratio, anti-reflection coating on surface, optical bonding. This results in higher cost. Actually, this measure is not to increase LED backlight brightness directly but to increase to the visibility to users.

Bill Cheung is an engineering lead and marketing manager at Orient Display, an LCD and display technology provider with over two decades of industry experience in delivering cutting edge display solutions. You can browse Orient Display"s knowledge base [7] to learn more about LCDs.

The wide range of conditions over which LCD monitors are used means that it is desirable to produce displays whose luminance (brightness) can be altered to match both bright and dim environments. This allows a user to set the screen to a comfortable level of brightness depending on their working conditions and ambient lighting. Manufacturers will normally quote a maximum brightness figure in their display specification, but it is also important to consider the lower range of adjustments possible from the screen as you would probably never want to use it at its highest setting. Indeed with specs often ranging up to 500 cd/m2, you will certainly need to use the screen at something a little less harsh on the eyes. As a reminder, we test the full range of backlight adjustments and the corresponding brightness values during each of our reviews. During our calibration process as well we try to adjust the screen to a setting of 120 cd/m2 which is considered the recommended luminance for an LCD monitor in normal lighting conditions. This process helps to give you an idea of what adjustments you need to make to the screen in order to return a luminance which you might actually want to use day to day.

Changing the display luminance is achieved by reducing the total light output for both CCFL- and LED-based backlights. By far the most prevalent technique for dimming the backlight is called Pulse Width Modulation (PWM), which has been in use for many years in desktop and laptop displays. However, this technique is not without some issues and the introduction of displays with high brightness levels and the popularisation of LED backlights has made the side-effects of PWM more visible than before, and in some cases may be a source of visible flicker, eyestrain, eye fatigue, headaches and other associated issues for people sensitive to it. This article is not intended to alarm, but is intended to show how PWM works and why it is used, as well as how to test a display to see its effects more clearly. We will also take a look at the methods some manufacturers are now adopting to address these concerns and provide flicker-free backlights instead. As awareness grows, more and more manufacturers are focusing on eye health with their monitor ranges.

Pulse Width Modulation (PWM) is one method of reducing the perceived luminance in displays, which it achieves by cycling the backlight on and off very rapidly, at a frequency you can’t necessary detect with the naked eye, but which could lead to eye issues, headaches etc. This method generally means that at 100% brightness a constant voltage is applied to the backlight and it is continuously lit. As you lower the brightness control the perceived luminance for the user reduces due to a number of possible controlling factors:

1) Frequency –The backlight is cycled on and off very rapidly, and this cycling typically occurs at a fixed frequency (in Hz). How fast this cycling occurs can impact whether flicker is visible or perceivable to the user, with higher frequencies being potentially less problematic. PWM has been known to operate at low frequencies of 180 – 240Hz for example which are likely to be more problematic than higher frequencies ranging up in to the Kilohertz range (e.g. 18,000Hz).

2) Modulation –The modulation of the cycling has an impact on the perceived brightness, and this describes the difference between the luminance in an “on” and in an “off” state. In some examples the backlight is completely turned off during the cycle so it is literally being turned on/off rapidly across the full brightness adjustment range. In those examples the luminance output is controlled really by the duty cycle only (see point 3). In other examples the backlight is not always being completely turned off but rather the voltage applied to the backlight is being rapidly alternated, resulting in less extreme differences between the on and off states. Often this modulation will be narrow in the high brightness range of the display, but as you reduce further, the modulation becomes wider until it reaches a point where the backlight is being switched completely off. From there, the change in the duty cycle (point 3) controls the further changes in the luminance output.

3) Duty Cycle – The fraction of each cycle for which the backlight is in an “on” state is called the duty cycle. By altering this duty cycle the total light output of the backlight can be changed. As you reduce the brightness to reach a lower luminance, the duty cycle becomes progressively shorter, and the time for which the backlight is on becomes shorter, while the time for which it is off is longer. This technique works visually since cycling the backlight on and off sufficiently fast means the user cannot see this flickering, because it lies above their flicker-fusion threshold (more on this later).

The luminance of LED backlights can be adjusted greatly by altering the current passing through them, though this has the effect of altering the colour temperature slightly. This analogue approach to LED luminance is also undesirable since the accompanying circuits must take into account the heat generated by the LED’s. LED’s heat up when on, which reduces their resistance and further increases the current flowing through them. This can quickly lead to runaway current use in very high-brightness LED’s and cause them to burn out. Using PWM the current can be forced to hold a constant value during the duty cycle, meaning the colour temperature is always the same and current overloads are not a problem.

While PWM is attractive to hardware makers for the reasons outlined above, it can also introduce distracting visual effects if not used carefully. Flicker from LED backlights is typically much more visible than for older CCFL backlights at the same duty cycle because the LED’s are able to switch on and off much faster, and do not continue to “glow” after the power is cut off. This means that where the CCFL backlight showed rather smooth luminance variation, the LED version shows sharper transitions between on and off states. This is why more recently the subject of PWM has cropped up online and in reviews, since more and more displays are moving to W-LED backlighting units now.

It is important to remember that this is entirely due to the backlight, and the display itself is showing a static image. Often it is said that humans cannot see more than 24 frames per second (fps), which is not true and actually corresponds to the approximate frame rate needed to perceive continuous motion. In fact, while the eyes are moving (such as when reading) it is possible to see the effects of flicker at several hundred hertz. The ability to observe flicker varies greatly between individuals, and even depends on where a user is looking since peripheral vision is most sensitive.

So how fast is PWM cycling backlights on and off? This seems to depend on the backlight type used, with CCFL-based backlights nearly all cycling at 175Hz or 175 times per second. LED backlights have been reported typically running from 180 – 420Hz, with those at the lower end flickering much more visibly. Some have even faster frequencies of >2000Hz so it really can vary. While this might seem too fast to be visible, keep in mind that 175Hz is not much faster than the 100-120Hz flicker observed in lights connected directly to the mains power.

It is also important to distinguish the difference between flicker in CRT displays and CCFL and LED backlit TFT displays. While a CRT may flicker as low as 60Hz, only a small strip is illuminated at any time as the electron gun scans from top to bottom. With CCFL and LED backlit TFT displays the entire screen surface illuminates at once, meaning much more light is emitted over a short time. This can be more distracting than in CRTs in some cases, especially if short duty cycles are used.

The flicker itself in display backlights may be subtle and not easily perceptible for some people, but the natural variation in human vision seems to make it clearly visible to others. With the use of high-brightness LED’s on the rise it is becoming increasingly necessary to use short PWM duty cycles to control brightness, making flicker more of a problem. With users spending many hours every day looking at their monitors, shouldn’t we consider the long term effects of both perceptible and imperceptible flicker?

A much better method of course would be to purchase a display not relying on PWM for dimming, or at least one which uses a much higher cycling frequency. Few manufacturers seem to have implemented PWM at frequencies that would limit visible artefacts (well above 500Hz for CCFL and above 2000 Hz for LED). Additionally, some displays using PWM do not use a 100% duty cycle even at full brightness, meaning they will always produce flicker. Several LED-based displays may in fact be currently available which do not use PWM, but until backlight frequency and modulation become listed in specifications it will be necessary to see the display in person. Some manufacturers promote “flicker free” monitors in their range (BenQ, Acer for example) which are designed to not use PWM at all and instead use a Direct Current (DC) method of backlight dimming. Other manufacturers such as Eizo talk about flicker free backlights but also list a hybrid solution for their backlight dimming, where PWM is used for some of the brightness adjustment range at the lower end. In fact it seems an increasingly common practice for a screen to be PWM free down to a certain point, and then fro PWM to be used to really drive down the minimum luminance from there.

(Optional) Set the camera white balance by getting a reading off the screen while displaying only white. If not possible, then manually set the white balance to about 6000K.

Display a single vertical thin white line on a black background on the monitor (1-3 pixels wide should be fine). The image should be the only thing visible. Here is an example you may wish to save and use, show it full screen on your monitor.

What we are doing with this technique is turning a temporal effect into a spatial one by moving the camera during capture. The only significant source of light during the image capture is the thin line on the display, which is exposed onto consecutive columns on the sensor. If the backlight is flickering, different columns will have different brightness or colour values determined by the backlight at the time it was exposed.

Depending on the monitor several additional effects may be visible. CCFL-based backlights often show different colours at the start and end of each cycle, which means the phosphors used respond at different rates. LED-based backlights often use a higher cycling frequency than CCFL-based, and more rapid camera movement may be needed to easily see them. Dark stripes between cycles mean that the PWM duty cycle has been reduced to such an extent that no light is emitted for part of the cycles.

Asus PA248Q – W-LED backlight. At 100% brightness we see a constant luminance output and a straight line, as there is no need for the backlight to be cycled. At 50% you can see PWM controls the backlight on and off. The modulation is always 100%, but the luminance reduction is controlled by the duty cycle which becomes progressively shorter. You can see much shorter “on” peaks in the 0% brightness graphs. We measure the frequency at 180Hz which is fairly typical.

BenQ GW2760HS – W-LED backlight. At all brightness settings the luminance output is a flat line, showing no PWM is being used. This is part of BenQ’s flicker free range.

The oscilloscope graphs can also allow us to examine the behaviour of the luminance output. Above is a typical W-LED backlight dimmed to 0% where PWM is used. You can see the changes between on and off are very steep and sudden, as the LED backlight is able to turn on and off very rapidly. As we’ve already discussed this can lead to potentially more noticeable flicker and associated issues as the changes are more pronounced.

The oscillographs for a typical CCFL display using PWM at 0% looks like the above. You can see the transitions from on to off are less sudden as the phosphors don’t go dark as quickly as with LED backlight units. As a result, the use of PWM may be less problematic to users.

As we said at the beginning, this article is not designed to scare people away from modern LCD displays, rather to help inform people of this potential issue. With the growing popularity in W-LED backlit monitors it does seem to be causing more user complaints than older displays, and this is related to the PWM technique used and ultimately the type of backlight selected. Of course the problems which can potentially be caused by the use of PWM are not seen by everyone, and in fact I expect there are far more people who would never notice any of the symptoms than there are people who do. For those who do suffer from side effects including headaches and eye strain there is an explanation at least.

With the long term and proven success of a technology like Pulse Width Modulation, and the many years of use in CCFL displays we can’t see it being widely changed at any time soon to be honest, even with the popular move to W-LED backlit units. It is still a reliable method for controlling the backlight intensity and therefore offering a range of brightness adjustments which every user would want and need. Those who are concerned about its side effects or who have had problems with previous displays should try and consider the frequency of the PWM in their new display, or perhaps even try and find a screen where it is not used at all in backlight dimming. Some manufacturers are proactively addressing this concern through the use of flicker free backlights, and so options are emerging which do not use PWM.

The Capacitive touch panel is activated with anything containing an inductive load such as a finger or stylus. It allows for multi-touch options. When using the capacitive touch screen, the display needs a separate controller to interface with the touch panel. The display for capacitive touch is brighter since the touch panel is transparent.

The Transmissive polarizer is best used for displays that run with the backlight on all the time. This polarizer provides the brightest backlight possible. If you have a need for a bright backlight with lower power drain, transmissive is a good choice for this TFT LCD display.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

The ISL98611A is a high efficiency display power supply and LED driver for small size displays such as smart phones. It integrates a boost regulator, LDO, and inverting charge pump that are used to generate two output rails for the display power: +5V (default) and -5V (default). It also integrates a boost regulator and 3-channel current sinks for the LED backlight driver. The ±5V output voltages can be adjusted from ±4. 5V up to ±6V. The ISL98611A extends the battery life of mobile devices by delivering greater than 87% efficiency for the display power function. For a backlight driver ISL98611A uses nonsynchronous rectification and by using a 3-channel topology ISL98611A provides more than 90% efficiency. ISL98611A integrates all compensation and feedback components, which minimizes BOM count and reduces the solution PCB size. This product drives backlight LEDs with excellent current matching even at very low LED current (±2. 2% down to 1mA), improving the brightness uniformity of LCD displays. It includes analog, PWM and hybrid dimming to maximize LED efficiency while eliminating color shift issues. The ISL98611A is offered in a 2. 33x2. 61mm2 WLCSP package, and the device is specified for operation across the -40°C to +85°C ambient temperature range.

An LED-backlit LCD is a liquid-crystal display that uses LEDs for backlighting instead of traditional cold cathode fluorescent (CCFL) backlighting.TFT LCD (thin-film-transistor liquid-crystal display) technologies as CCFL-backlit LCDs, but offer a variety of advantages over them.

While not an LED display, a television using such a combination of an LED backlight with an LCD panel is advertised as an LED TV by some manufacturers and suppliers.

LED-backlit LCDs are not self-illuminating (unlike pure-LED systems). There are several methods of backlighting an LCD panel using LEDs, including the use of either white or RGB (Red, Green, and Blue) LED arrays behind the panel and edge-LED lighting (which uses white LEDs around the inside frame of the TV and a light-diffusion panel to spread the light evenly behind the LCD panel). Variations in LED backlighting offer different benefits. The first commercial full-array LED-backlit LCD TV was the Sony Qualia 005 (introduced in 2004), which used RGB LED arrays to produce a color gamut about twice that of a conventional CCFL LCD television. This was possible because red, green and blue LEDs have sharp spectral peaks which (combined with the LCD panel filters) result in significantly less bleed-through to adjacent color channels. Unwanted bleed-through channels do not "whiten" the desired color as much, resulting in a larger gamut. RGB LED technology continues to be used on Sony BRAVIA LCD models. LED backlighting using white LEDs produces a broader spectrum source feeding the individual LCD panel filters (similar to CCFL sources), resulting in a more limited display gamut than RGB LEDs at lower cost.

Using PWM (pulse-width modulation), a technology where the intensity of the LEDs are kept constant but the brightness adjustment is achieved by varying a time interval of flashing these constant light intensity light sources,

A first dynamic "local dimming" LED backlight was public demonstrated by BrightSide Technologies in 2003,Sony in September 2008 on the 40-inch (1,000 mm) BRAVIA KLV-40ZX1M (known as the ZX1 in Europe). Edge-LED lighting for LCDs allows thinner housing; the Sony BRAVIA KLV-40ZX1M is 1 cm thick, and others are also extremely thin.

LED-backlit LCDs have longer life and better energy efficiency than plasma and CCFL LCD TVs.mercury, an environmental pollutant, in their manufacture. However, other elements (such as gallium and arsenic) are used in the manufacture of the LED emitters; there is debate over whether they are a better long-term solution to the problem of screen disposal.

Because LEDs can be switched on and off more quickly than CCFLs and can offer a higher light output, it is theoretically possible to offer very high contrast ratios. They can produce deep blacks (LEDs off) and high brightness (LEDs on). However, measurements made from pure-black and pure-white outputs are complicated by edge-LED lighting not allowing these outputs to be reproduced simultaneously on screen.

Quantum dots are photoluminescent; they are useful in displays because they emit light in specific, narrow normal distributions of wavelengths. To generate white light best suited as an LCD backlight, parts of the light of a blue-emitting LED are transformed by quantum dots into small-bandwidth green and red light such that the combined white light allows a nearly ideal color gamut to be generated by the RGB color filters of the LCD panel. The quantum dors may be in a separate layer as a quantum dot enhacement film, or replace pigment-based green and red resists normally used in LCD color filters. In addition, efficiency is improved, as intermediate colors are no longer present and do not have to be filtered out by the color filters of the LCD screen. This can result in a display that more accurately renders colors in the visible spectrum. Companies developing quantum dot solutions for displays include Nanosys, 3M as a licensee of Nanosys, QD Vision of Lexington, Massachusetts, US and Avantama of Switzerland.Consumer Electronics Show 2015.quantum dot displays at CES 2017 and later formed the "QLED Alliance" with Hisense and TCL to market the technology.

Mini LED displays are LED-backlit LCDs with mini-LED–based backlighting supporting over a thousand full array local dimming (FALD) zones, providing deeper blacks and a higher contrast ratio.

LED backlights are often dimmed by applying pulse-width modulation to the supply current, switching the backlight off and on more quickly than the eye can perceive. If the dimming-pulse frequency is

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey