connect tft display to arduino factory

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

No! For about the price of a familiar 2x16 LCD, you get a high resolution TFT display. For as low as $4 (shipping included!), it"s possible to buy a small, sharp TFT screen that can be interfaced with an Arduino. Moreover, it can display not just text, but elaborate graphics. These have been manufactured in the tens of millions for cell phones and other gadgets and devices, and that is the reason they are so cheap now. This makes it feasible to reuse them to give our electronic projects colorful graphic displays.

There are quite a number of small cheap TFT displays available on eBay and elsewhere. But, how is it possible to determine which ones will work with an Arduino? And what then? Here is the procedure:ID the display. With luck, it will have identifying information printed on it. Otherwise, it may involve matching its appearance with a picture on Google images. Determine the display"s resolution and the driver chip.

Find out whether there is an Arduino driver available. Google is your friend here. Henning Karlsen"s UTFT library works with many displays. (http://www.rinkydinkelectronics.com/library.php?i...)

Download and install the driver library. On a Linux machine, as root, copy the library archive file to the /usr/share/arduino/libraries directory and untar or unzip it.

Load an example sketch into the Arduino IDE, and then upload it to the attached Arduino board with wired-up TFT display. With luck, you will see text and/or graphics.

For prototyping and testing:A solderless breadboard male-to-male jumpers male-to-female jumpers 22 gauge insulated hookup wire, solid Graph paper, for planning and sketching wiring diagrams and layouts

We"ll begin with a simple one. The ILI9163 display has a resolution of 128 x 128 pixels. With 8 pins in a single row, it works fine with a standard Arduino UNO or with a Mega. The hardware hookup is simple -- only 8 connections total! The library put together by a smart fella, by the name of sumotoy, makes it possible to display text in multiple colors and to draw lines.

Note that these come in two varieties, red and black. The red ones may need a bit of tweaking to format the display correctly -- see the comments in the README.md file. The TFT_ILI9163C.h file might need to be edited.

It is 5-volt friendly, since there is a 74HC450 IC on the circuit board that functions as a level shifter. These can be obtained for just a few bucks on eBay and elsewhere, for example -- $3.56 delivered from China. It uses Henning Karlsen"s UTFT library, and it does a fine job with text and graphics. Note that due to the memory requirement of UTFT, this display will work with a standard UNO only with extensive tweaking -- it would be necessary to delete pretty much all the graphics in the sketch, and just stay with text.

on the far side of the display. It has 220x176 resolution (hires!) and will accept either 3.3 or 5 volts. It will work hooked up to an Uno, and with a few pin changes, also with a Mega. The 11-pin row is for activating the display itself, and the 5-pin row for the SD socket on its back.

This one is a 2.2" (diagonal) display with 176x220 resolution and parallel interface. It has a standard ("Intel 8080") parallel interface, and works in both 8-bit and 16-bit modes. It uses the S6D0164 driver in Henning Karlsen"s UTFT library, and because of the memory requirements of same, works only with an Arduino Mega or Due. It has an SD card slot on its back

This one is a bit of an oddball. It"s a clone of the more common HY-TFT240, and it has two rows of pins, set at right angles to one another. To enable the display in 8-bit mode, only the row of pins along the narrow edge is used. The other row is for the SD card socket on the back, and for 16-bit mode. To interface with an Arduino ( Mega or Due), it uses Henning Karlsen"s UTFT library, and the driver is ILI9325C. Its resolution is 320x240 (hires!) and it incorporates both a touch screen and an SD card slot.

Having determined that a particular TFT display will work with the Arduino, it"s time to think about a more permanent solution -- constructing hard-wired and soldered plug-in boards. To make things easier, start with a blank protoshield as a base, and add sockets for the TFT displays to plug into. Each socket row will have a corresponding row next to it, with each individual hole "twinned" to the adjacent hole in the adjoining row by solder bridges, making them accessible to jumpers to connect to appropriate Arduino pins. An alternative is hard-wiring the socket pins to the Arduino pins, which is neater but limits the versatility of the board.

The key to an effective DIY shield is a neat and logical layout. Sketching the prospective shield on quadrille (graph) paper may be helpful. A multitester or continuity tester might be useful for detecting wiring and soldering errors.

In step 5, you mention that the TFT01 display can"t be used with the UTFT library on an Arduino Uno because of its memory requirements. It can - all you have to do is edit memorysaver.h and disable any display models you"re not using.

I think you should add a disclaimer that the code might make the Arduino Uno unprogrammable afterward (due to use up the two 0 and 1 pin) and link to how to fix it: https://stackoverflow.com/questions/5290428/how-to-reset-an-arduino-board/8453576?sfb=2#84535760

Not at all - it was your Instructable that got me going with the display to begin with! We all build off each other"s work, to the benefit of everyone.0

Tho I realize this is quickly becoming legacy hardware, these 8,16 bit parallel spi with 4 wire controller 3.2in Taft touch display 240x380. It has become very inexpensive with ally of back stock world wide so incorporating them into any project is easier then ever. Sorry to my question. I’m having difficulty finding wiring solution for this lcd. It is a sd1289 3.3 and 5v ,40 pin parallel 8,16 bit. I do not want to use a extra shield,hat or cape or adapter. But there’s a lot of conflicting info about required lvl shifters for this model any help or links to info would be great .. thank you. I hope I gave enough information to understand what I’m adoing

#1 you need a data sheet for the display and pinout and the i/o board attached to the cable.Than before you buy check for a driver for this chip Raydium/RM69071.if no driver lib are you able to write one and do you have the necessary tools to work on this scale to wire it up ..if you answer no than search for an arduino ready product.WCH0

hooking up and adding a lib is no piece of cake insure the screen you buy is arduino ready and sold by a reputable shop with step by step directions...WCH0

I"m sorry that I can"t help you with this. You"ll have to do your own research. See if you can identify the chipset and find out if there"s an Arduino driver for it.0

Thanks for the wealth of knowledge! It is amazing at what is possible with items the average person can easily acquire. I hope to put some of your tips to use this winter as I would like to build sensors and other items for home automation and monitoring. Being able to have small displays around the house in addition to gathering and controlling things remotely will help the family see room conditions without going to the computer. The idea of a touchscreen control for cheap is mind blowing.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big (4.3" diagonal) bright (8 white-LED backlight) and colorfu 480x272 pixels with individual pixel control. As a bonus, this display has a optional resistive touch panel with controller XPT2046 attached by default and a optional capacitive touch panel with controller FT5206 attached by default, so you can detect finger presses anywhere on the screen and doesn"t require pressing down on the screen with a stylus and has nice glossy glass cover.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (UNO/Due/Mega 2560).

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

If you"ve had a lot of Arduino DUEs go through your hands (or if you are just unlucky), chances are you’ve come across at least one that does not start-up properly.The symptom is simple: you power up the Arduino but it doesn’t appear to “boot”. Your code simply doesn"t start running.You might have noticed that resetting the board (by pressing the reset button) causes the board to start-up normally.The fix is simple,here is the solution.

We covered the basics of accelerometer previously inUsing Arduino with Parts and Sensors – Accelerometer Part 1andUsing Arduino with Parts and Sensors – Accelerometer Part 2. Today we’ll be testing KX022-1020 accelerometer using TFT liquid crystal panel. We’ll discuss how to control the TFT LCD in more detail in the next article. In addition, we’ll further exploreArduino Create. For more information about Arduino Create, please refer back tothisarticle.

Let’s briefly review what accelerometer is. An accelerometer is a sensor that can detect the state of motion, such as “tilt,” “shock,” “vibration” and so forth. Accelerometers are classified into one axis, two axes, and three axes. For example, one axis detects one direction (vertical only); two axes detects two directions (vertical and horizontal); and three axes three directions (vertical, horizontal and height).

Now, let’s test the accelerometer. Download the library from the “Software” section at the bottom of theaccelerometer page from theRohm Sensor Evaluation Kit website.

We’ll continue using Arduino Create Web Editor as we did in our lasttutorial. To add the library, you can upload the zip file by selecting it from “Libraries” on the left menu and clicking on “ADD ZIP LIBRARY.”

After adding the library, attach the accelerometer to the Sensor Shield (I2C I/F) and try running the sample program. The accelerometer should be set to 1.8V or 3.0V.

Now the sample program is working fine, let’s try to display the values on a 1.8 inch TFT LCD monitor. Although this TFT liquid crystal monitor has a resolution slightly smaller than 126 x 160 px, it’ll be quite useful when displaying numbers or letters with Arduino etc.

In the past, we used 7-segment LED to display numerical values only. But this time, I tried to display the graph along with the values obtained from the accelerometer.

When using the TFT monitor, the connection method and the library used in the program may be different depending on the specification of each TFT monitor. The TFT monitor used in this tutorial is a monitorSainSmart ST7735R. In addition to Arduino, the monitor is also compatible with Raspberry.

In order to use the monitor to run the program in Arduino, we’ll have to modify the downloaded library a little bit.We’ll go over how to control the TFT LCD in more detail in the next article. Once everything is set, you will be able to output numerical values in the monitor as shown in the video below:

In the next part, we’ll create a simple device using the same accelerometer and TFT monitor. We’ll show how to create graphs and display the values obtained from the accelerometer on the TFT monitor.

In electronics world today, Arduino is an open-source hardware and software company, project and user community that designs and manufactures single-board microcontrollers and microcontroller kits for building digital devices. Arduino board designs use a variety of microprocessors and controllers. The boards are equipped with sets of digital and analog input/output (I/O) pins that may be interfaced to various expansion boards (‘shields’) or breadboards (for prototyping) and other circuits.

The boards feature serial communications interfaces, including Universal Serial Bus (USB) on some models, which are also used for loading programs. The microcontrollers can be programmed using the C and C++ programming languages, using a standard API which is also known as the “Arduino language”. In addition to using traditional compiler toolchains, the Arduino project provides an integrated development environment (IDE) and a command line tool developed in Go. It aims to provide a low-cost and easy way for hobbyist and professionals to create devices that interact with their environment using sensors and actuators. Common examples of such devices intended for beginner hobbyists include simple robots, thermostats and motion detectors.

In order to follow the market tread, Orient Display engineers have developed several Arduino TFT LCD displays and Arduino OLED displays which are favored by hobbyists and professionals.

Although Orient Display provides many standard small size OLED, TN and IPS Arduino TFT displays, custom made solutions are provided with larger size displays or even with capacitive touch panel.

WF43WTYBEDSG0 is a 4.3-inch IPS TFT-LCD display with a Capacitive Touch screen, made of resolution 480x272 pixels. This module is built-in with BT815 controller IC, and it supports SPI and QSPI interfaces. The QSPI interface can achieve four times data rate compared with the current SPI interface and make a smoother display accordingly. The series of BT815/6 controller IC with EVE (Embedded Video Engine) technology simplifies the system architecture, Eve technology is a revolutionary concept that utilizes an object-oriented approach to creating high-quality human-machine interfaces (HMI). This new technology supports display, audio and touch, enabling engineers to quickly and efficiently design HMI and provide a powerful solution for high-resolution displays that reduce material costs.

WF43WTYBEDSG0 is adopted IPS panel which is having the advantage of wider view angle of Left:80 / Right:80 / Up:80 / Down:80 degree (typical), contrast ratio 800:1 (typical value), brightness 400 nits (typical value), glare surface panel, aspect ratio 16:9. The PCAP touch screen is built-in with ILI2130 IC, supporting I2C interface and multi-touch function.

We offer the TFT module WF43WTYBEDSG0#000 designed to support the Arduino board. The control signal for WF43WTYBEDSG0 is 3.3V; it has a built-in storage device (FLASH 32M). The control signal of WF43WTYBEDSG0#000 is 5V; without a built-in storage device (FLASH); but with a MicroSD Socket, pins CON1~CON4 are designed for SPI control (such as for Arduino Uno Rev3). WF43W model can be operating at temperatures from -20℃ to+ 70℃ and storage temperatures from -30℃ to +80℃.

If you receive a product with a manufacturing defect, please notify us within the 3 days of you receive the product, supported by proper pictures and description. Once our support team accept the return, we will provide a replacement or a complete refund including the return shipping cost. Please note that if your item is already soldered or modified in manner we will not be able to take it under return.

We ship to all over India with free shipping on all prepaid orders. For Cash on Delivery orders INR 70 will be charged for orders below INR 599 and INR 20 will be charged for the orders above 599. Please contact to our support team at support@quartzcomponents.com for any question related to shipping.

A number of display devices like LEDs, 7-segments, character and graphic displays can be attached to microcontrollers to create an interface between the user and an electronic system for displaying data or controlling the system. Sometimes you may need to add colorful images or graphics to your project, that’s where the TFT color displays come in handy.

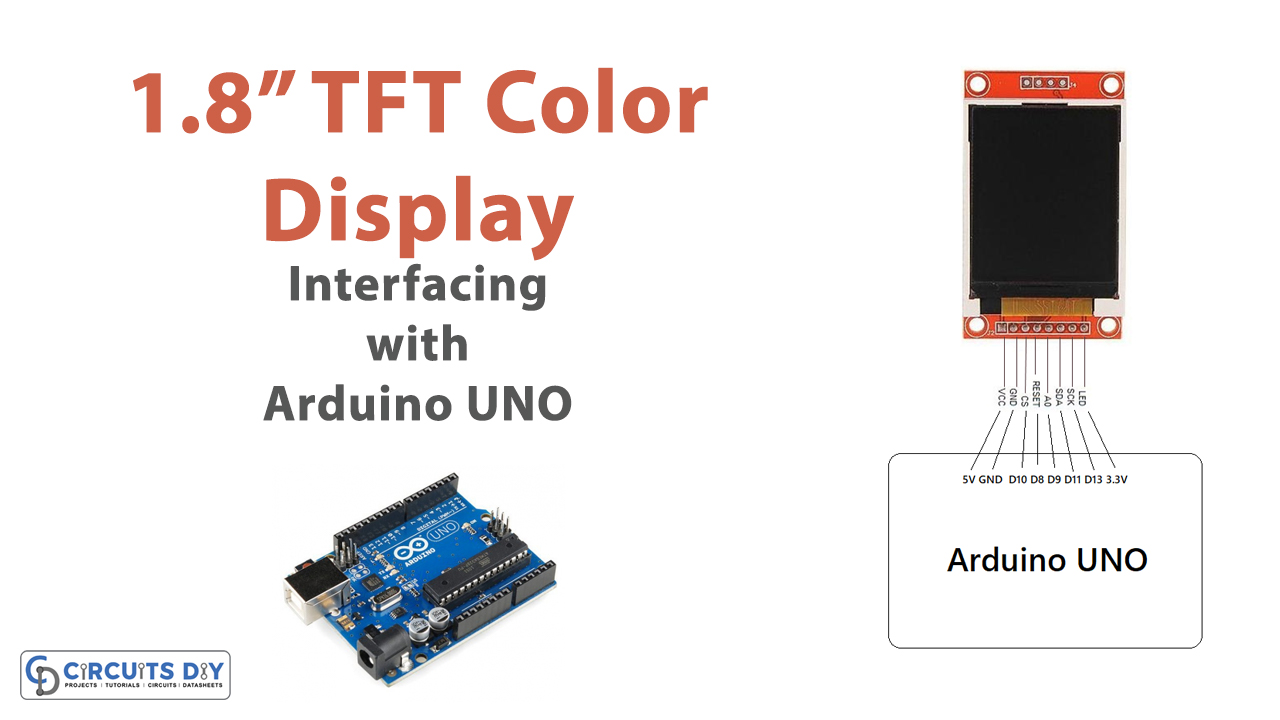

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. In this tutorial we are going to show how to interface a 1.44″ TFT color display based on the ST7735 driver. It has 128×128 color pixels and can display full 16-bit color.

This is the type of display am using but they come with various pin configurations. However all the displays will have the major pins stated below and should be connected to the Arduino board as follows:

This TFT display uses 3.3V but comes with an on board voltage regulator therefore the VCC can be connected to the Arduino 5V. However for best practice it’s better to use the 3.3V.

Most code Libraries for this TFT ST7735 display with Arduino are programmed with the SDA and SCL pins connected to Arduino pins 11 and 13 respectively. Make sure you don’t change that order otherwise the display may not work.

There are a number of libraries that have been developed to run the TFT ST7735 color display using Arduino but I found the Adafruit-ST7735-Librarythe best to use. Make sure you have this library installed in your IDE.

tft.fillRoundRect(x,y,w,h,r,t); function draws a filled Rectangle with r radius round corners in x and y location and w width and h height and t color.

There are many other functions and commands which you can use to program the TFT color display but the above are the commonest. You will meet many more with practice.

Before we can write our personal code we need to first test the display using the already made code examples from the installed library. This is done by going to File>Examples>Adafruit ST7735 and ST7789 Library. Then you can select any of the examples and upload it to the setup to see if the display works fine.In the diagram below I have shown how to access the graphics test code.

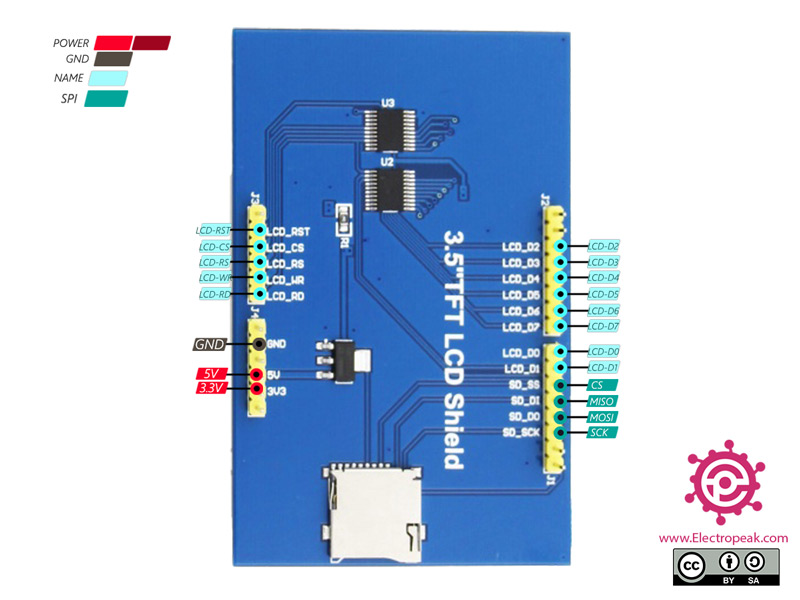

The component TFT supports a 2.8 inch TFT display with a resolution of 240*320 pixels.The display is not soldered on the board, but there is a 14 pin connector for a TFT display. The ILI9341 has been tested.

There are four sample projects for the Arduino IDE which could be downloaded: TFT-Box3D (download here), TFT-Graphic-Test (download here), TFT-HelloWorld (download here) and TFT-HowToUseFonts (download here). And there are two examples for the Arduino IDE for using the touch functionality which could be downloaded: TFT-TouchBtn (download here) and TFT-TouchDraw (download here).

There are two dip switches for the component: SW311 and SW314. If you want to use the TFT display all switches on SW311 have to be on on. If you additonally want to use the touchpad of the display all switch of SW314 have to be on. The following two tables shows the functions and the potential conflicts with other components

In order to use the component you need the Ucglib in Version 1.5.2. This version could be downloaded from GitHub. Additionally you could download from this site..

After the download it"s necessary to add both libraries to your Arduino IDE. Open Sketch > Include Library > Add .ZIP Library ... and select the downloaded archive. Do it for both libraries.

There are four sample projects for the Arduino IDE which could be downloaded: TFT-Box3D (download here), TFT-Graphic-Test (download here), TFT-HelloWorld (download here) and TFT-HowToUseFonts (download here).

And there are two examples for the Arduino IDE for using the touch functionality which could be downloaded: TFT-TouchBtn (download here) and TFT-TouchDraw (download here).

This is SainSmart UNO R3 and 2.8 inch TFT LCD module with the TFT LCD shield kit For arduino enthusiasts.It includes one pcs of sainsmart UNO R3, one pcs of 2.8 inch TFT LCD display and a TFT LCD shield. We will provided you the whole document including the example project of arduino UNO(R3) with the kit. We will supply you the technical support after your purchase.

The SainSmart Uno R3 is a microcontroller board based on the ATmega328 . It has 14 digital input/output pins (of which 6 can be used as PWM outputs), 6 analog inputs, a 16 MHz ceramic resonator, a USB connection, a power jack, an ICSP header, and a reset button. It contains everything needed to support the microcontroller; simply connect it to a computer with a USB cable or power it with a AC-to-DC adapter or battery to get started.

1.0 pinout: added SDA and SCL pins that are near to the AREF pin and two other new pins placed near to the RESET pin, the IOREF that allow the shields to adapt to the voltage provided from the board. In future, shields will be compatible with both the board that uses the AVR, which operates with 5V and with the Sainsmart Due that operates with 3.3V. The second one is a not connected pin, that is reserved for future purposes.

SainSmart 2.8" TFT LCD Display is a LCD touch screen module. It has 40pins interface and SD card and Flash reader design. It is a powerful and mutilfunctional module for your project.The Screen include a controller ILI9325, it"s a support 8/16bit data interface , easy to drive by many MCU like arduino families,STM32 ,AVR and 8051. It is designed with a touch controller in it . The touch IC is XPT2046 , and touch interface is included in the 40 pins breakout. It is the version of product only with touch screen and touch controller.

Voltage type: 5v or 3v voltage input voltage,input is selectable. Because TFT can only work under 3.3 V voltage, so when the input voltage VIN is 5V, need through the 3.3 V voltage regulator IC step down to 3.3V , when the input voltage of 3.3 V, you need to use the zero resistance make J2 short , is equivalent to not through the voltage regulator IC for module and power supply directly.

This is SainSmart TFT LCD Extend shield for UNO(R3) .Using this shield can help you out of the bothers to use other cables. You just need to plug the module to arduino UNO(R3) through this shield.

If you connect the touch screen LCD with UNO R3, the touch screen function will be useless . If you want to use the touch function, please connect the LCD with Mega2560 (R3) or Due (R3).

2.The LCD is compatible for arduino family,but the Shield is just for the arduino UNO R3. If you need the LCD Extend shield for other arduinos, you need another shield which is also provided from our store.

Thank you for your purchase. We hope you are happy with your purchase. However, if you are not completely satisfied with your purchase for any reason, ELEGOO provides a straightforward warranty that is processed in the most hassle-free way possible. Please refer to the chart below for the warranty timelines of various products, as warranty periods differ according to models.

All returns for refund must be postmarked within fourteen (14) days of the date the item was delivered to the designated shipping address. All returned items must be in new and unused condition, with all parts & accessories included and all original tags and labels attached.

All returns for exchange must be postmarked within thirty (30) days of the date the item was delivered to the designated shipping address. All returned items must be in new and unused condition, returned with all parts & accessories included and all original tags and labels attached.

To return an item, please email customer service at service@elegoo.com / euservice@elegoo.com to obtain the address information you need regarding of returning the products. Please place the item securely in its original packaging, and mail your return through a trackable method.

After receiving your return and inspecting the condition of your item, we will process your return. Please allow at least 7 days from the receipt of your item to process your return. We will notify you by email when your return has been processed and refund you the payment via Paypal.

Regarding defective or damaged products, please don"t hesitate to contact us at the customer service channels below to acquire technical support, refund or exchange.

When contacting our customer service team, buyer must provide sufficient proof of purchase (order number from online purchases made through ELEGOO, Amazon or other ELEGOO"s authorized resellers), tell us which product you purchased, and describe the problem as clearly as possible through text, images or short videos. This will help our team to process your inquiries and help you solve the problems more efficiently.

TFT LCD screens combined with Human Machine Interface (HMI) technology result in exciting project ideas applicable to a wide variety of industries. STONE HMI TFT LCD Arduino project ideas. After all, HMI is a smart technology that uses touch to draw out information from both the human user and the display machine.

And when high-quality display screen modules such as STONE Tech’s TFT LCD products are laden with HMI technology, the result is outstanding machine performance capable of bringing out the best in every customer and business.

Now, this article will feature STONE HMI. Furthermore, we will also present some exciting project development initiatives carried out by the company using its vast range of TFT LCD modules paired with HMI technology, and the TFT LCD Arduino project.

Human Machine Interface (HMI) is an interface or dashboard that lets human users interact with a machine. HMI allows users to monitor and control a machine through the use of different touch technologies.

The interface with which HMI works consists of both hardware and software. These two work together to let users input signals using direct or indirect touch (such as by using a special screen stylus) on the machine display. Once the touch signals have been inputted, the machine recognizes them and sends them to the software to begin interpretation. The machine then responds by showing the desired information to the human user.

Information that a user can get from an HMI machine greatly varies depending on the setting with which the machine is used. Here are some examples of common HMI machines and the data it presents to its daily users:

Medical equipment in hospital settings uses HMI to display pertinent information regarding a patient. For instance, a ventilator machine can display data such as vital signs and a selection of possible breathing patterns for the patient. It can also alert medical practitioners when there is a problem with the patient or the machine through alarms and sounds.

Another HMI machine used in daily life is the car dashboard. An on-board car control panel using an intelligent touch screen can be used to display important car information like speed, gas levels, and time. The screen dashboard can also be used to toggle many functions like turning the AC and beam on or off using a single touch.

HMIs are user-friendly by nature. Graphics and colors can easily be added to the display to communicate with the end-users. Any problems arising from the HMI screen can also be detected easily using color codes, alarms, and sounds. Furthermore, you’ll need only a few touches to fix any issues detected by an HMI device.

HMI greatly improves productivity when used in industrial settings. These interactive screens and machines help automate several tasks. While these tasks could be carried out by a human worker, using an HMI machine gets the job done in less time, translating to more work finished by the day’s end.

Several HMI machines have the innate ability to record data. This is especially useful in adjusting machine settings or troubleshooting any mechanical issues. Automatic data gathering can be programmed into the HMI software, allowing the machine’s screen and hardware to capture data through a series of commands.

Using HMI machines in workplaces such as factories and corporate offices increases worker satisfaction. This is because the HMI technology allows workers to interact easily with the machine, automating some of their work and providing them more efficiency.

What makes HMI a good choice for industrial use is that it is fully flexible and customizable to fit several industrial needs. The TFT LCD screen sizes can be tailor-made to suit the HMI’s application. Furthermore, the software that comes with the machines can be adjusted as well.

Another exciting opportunity for HMIs is their ability to connect with the Internet, much like an Internet of Things (IoT) device. This allows greater opportunities for productivity such as remote controlling and network monitoring.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

There is also a downloadable design software called STONE Designer. This is a completely free GUI design software you can use to create responsive digital module-ready user interfaces.

STONE TFT LCD modules come with a microcontroller unit that has a cortex-m4 32-bit CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to it.

You can also use a peripheral MCU to serially connect STONE’s HMI display via TTL. This way, your HMI display can supply event notifications and the peripheral MCU can then execute them. Moreover, this TTL-connected HMI display can further be linked to microcontrollers such as:

Each customizable TFT-LCD HMI display module comes with free access to STONE’s dedicated design software. STONE TOOLBox software is an easy-to-use program that allows you to set up graphical user interface functions such as:

STONE TOOLBox features a drag-and-drop mechanism and comes with simple instructions. Hence, even beginning engineers can quickly and seamlessly create an impressive user interface within minutes.

Intricate and intuitive interfaces will require a bit more steps. Nevertheless, using the TOOLBox program allows you to save time on developing HMI projects due to its ease of use.

HMI projects can quickly be done with Stone’s HMI-ready display modules. As previously mentioned, STONEprovides complete modules that include hardware and a free downloadable GUI design software – everything you need to get started on your HMI concept.

With faster project timelines comes greater production savings. Stone’s modules are cost-effective and since they have superior quality, you’re assured of a quick return on investment (ROI) with fewer costs on maintenance and repairs in the long run.

STONE creates modules that are easy to assemble if you’re doing an HMI project. Add to that its user-friendly GUI software that lets you seamlessly create GUIs for your new HMI device.

Also, STONE manufactures several TFT LCD touch screen sizes that range from 3.5 to 15.1 inches. Customized options are also available depending on your needs. There are also plenty of options and models for each screen size.

Indeed, STONE produces a plethora of HMI-ready TFT LCD screens. You won’t have a hard time finding the right display module compatible with your microcontroller projects.

Over the years, Stone’s modules have been used to create numerous projects featuring its reputable HMI technology. These project ideas cater to a wide variety of fields and industries.

STONE developed an oxygen monitor for an Italian customer. The monitor uses Stone’s 7-inch TFT LCD screen and was connected to an oxygen tank for medical use.

The finished product displays information about the connected oxygen tank such as concentration levels and other advanced data. All these data are displayed on a streamlined interface developed using TOOLBox software.

Communication between the module and the device was established via an MCU connected to a serial port. The device also used the UART interface and TTL.

The end-product featured a touch screen display where fan functions such as speed, dose, and RF are controlled. Moreover, the resulting fan control board can operate at temperatures ranging from -20°C to 70°C, making it a simple yet heavy-duty device.

STONE’s display screen was connected to the Arduino development board through UART. But this required a level conversion achieved by the MAX3232. Meanwhile, the same Arduino board was wired to the MAX30100 module through an IIC interface.

Some modifications to the MAX30100 module were made, specifically to the IIC pull-up resistor. The remainder of the project was finished using Arduino codes to finally create a responsive display for heart rate and blood oxygen monitoring.

This project aims to create a fingerprint door lock that can enter, scan, compare, and delete fingerprints. It utilized an STM32 development board, fingerprint identification module, and Stone’s STVC050WT-01 LCD display.

STONE LCD screen’s role here is to display the fingerprint module’s status. As with all other projects, STONE TOOLBox software was used to generate the user interface flashed on the screen. Meanwhile, Stone’s LCD screen was connected to the development board and fingerprint identification module with MCU through UART-TTL signals.

The idea for this project is a real-time display of pictures collected by the camera on the LCD display screen. The TFT LCD STONE module used for this project is a 7-inch serial display module with 800×480 resolution. A camera module, development board, and some wires are needed to complete the project.

The user interface was designed using STONE TOOLBox and Adobe Photoshop. Then, the hardware parts were wired together; some parts needed welding. After that, a simple program was written following MCU to the command control TFT-LCD module.

This particular project used a STONE serial LCD touch display screen. This functions as the main display for the coffee machine. With the screen installed, you can:

RGB lamps that can be controlled through a touch display – this is the aim of this project idea. STONE’s 7-inch TFT LCD display module in STVC070WT-01 was used to connect and control an RGB lamp.

Last but not least is a basic appliance controller made using STONE’s 7-inch TFT LCD touch screen and an STM32 development board. The touch screen controls lights for various parts of the house. The finished product also collects data about humidity, temperature (indoor and outdoor), and air quality.

This project resulted in a simple electronic scale made by connecting STONE’s 5-inch touch screen to a development board, an ADC conversion module, and a pressure acquisition module. The finished product can:

STONE TOOLBox and graphics software such as Adobe Photoshop was used to design the user interface. Meanwhile, the hardware pieces were wired together and an MCU code was written for the electronic scale to be functional.

STONE’s TFT LCD intelligent touch modules can be paired with Arduino technology to automate a variety of processes. This project clearly demonstrates this.

Here, a sensor directly connected to Arduino Uno is monitored by the display screen in real-time. Moreover, two light bulbs connected to Arduino are directly controlled by the display screen as well.

This project is all about making a car display dashboard using a 10.1-inch STONE LCD touch screen. The on-board display interface for a used car contains the following:

We presented an overview of what HMI technology is, how it works, and which applications use it. Also, we covered Stone’s range of HMI-capable TFT LCD display modules. Furthermore, we discussed a lengthy list of exciting project ideas made using Stone’s superior quality HMI displays.

STONE Technologies is truly your best bet for powering your HMI-driven development ideas(projects based on TFT LCD Arduino, STM32, ESP, etc.). Take inspiration from the actual examples we’ve shown you and build your very own HMI display device today.

This guide is about DWIN HMI Touch Screen TFT LCD Display. HMI Means Human-Machine Interface. DWIN is specialized in making HMI Touch screen displays that are compatible with all microcontrollers like Arduino, STM32, PIC, and 8051 families of Microcontrollers.

This is a Getting Started tutorial with 7-inch DWIN HMI TFT LCD Display. We will see the architecture, features, board design, components, and specifications. We will also learn about the TTL & RS232 interfaces. Using the DGUS software you can create UI and with SD Card you can load the firmware on display memory.

You can change the TTL Interface mode or RS232 mode from here. Just solder these two terminals as shown here to enable TTL Interface. By default, the module is in RS232 Interface.

On the LCD board, you can see the flip-open connector. Just flip open the connector and insert the FCC cable. Keep in mind that the blue ends should be on top. Now you can just press the lock so the FCC cable is locked.

In the same way, another end of the FCC cable is connected to the HDL by keeping the blue end on the top. Now here we have a male-to-male USB cable. So, one end is connected to this HDL board and another END is connected to your PC.

One of the method to load the firmware to the T5L DWIN LCD Display is by using the SD Card. An SD Card of up to 16GB can be used to download the firmware files. We can easily insert the Micro SD card into the SD Card slot on the backside.

But we need to format this SD card in a FAT32 file system. You can insert the SD Card into your computer using the SD Card Adapter and perform a quick format.

Under the Download, section Go to tools and Download the DGUS-DWIN Graphic utilized software i.e DGUS software and XR21X Driver. This driver is for the HDL662B board.

Inside the XR21X folder, there are driver files. You need to install the driver on your PC to establish the communication between HDL662B and your PC. Double-click the executable file to launch the driver installer. Now click on Install to install the driver on your Windows PC.

We don’t need to install this DGUS software. Under this DGUS folder, you can see some executables files. Which includes tools like the ICL tool, font generating tool, image resizing tool, etc. inside this DGUS Software.

Extract the firmware folder, you will get different folders inside it. We need the firmware for Capacitive Touch Screen. The firmware folder is named as ‘WTC‘.

After copying the file, remove the SD Card from your computer and insert it into the SD Card slot of DWIN LCD Display. Then power the display using the USB Cable. The firmware downloading process will start automatically.

Here, select all these files which are available in the DWIN_SET folder as shown here. After that, select the COM port of the HDL board. You can see the COM port from Device Manager on Windows. Now you can click on Start downloading button.

The next part of this tutorial includes creating UI and interfacing DWIN LCD Display with Arduino. For that you can follow the DWIN LCD Arduino Interfacing Guide.

The 2.4 inch TFT LCD Touch Display Shield is a Bright, 4 white-LED backlight, on by default but you can connect the transistor to a digital pin for backlight control. So spice up your Arduino UNO project is a beautiful large touchscreen display shield with a built-in microSD card connection. This TFT display is big (2.4″ diagonal) bright (4 white-LED backlights) and colorful (18-bit 262,000 different shades)!

2.4 inch TFT LCD Touch Display Shield for ArduinoUno is fully assembled, tested and ready to go. Add the touch display without wiring, no soldering! Simply plug it in and load up a library – you ‘ll have it running in under 10 minutes! Works best with any classic Arduino ATMEGA328 Board.

The 2.4 inch TFT LCD Touch Display comes with 240×320 pixels with individual pixel control. It has way more resolution than a black and white 128×64 display. As a bonus, this display has a resistive touchscreen attached to it already, so you can detect finger presses anywhere on the screen.

Display worked perfect! No dead pixels, backlight was bright and touch screen had minimal lag and was very responsive. Recommended if you need a touchscreen.

This touch display works 100% right out of box . Touch screen and SD card reader functions works as designed. You just "plug and play" into the UNO module.

This project involves yet another Arduino-compatible display which can be used as an output to display any information in the form of graphics, text or animations. Since this is a 1.3" 240x240 IPS (In-Plane Switching) TFT display module, it does offer a high-resolution colour display with fine graphics, and that is one of the things which I really enjoy about this display. It is also very easy to program, as it runs on the STT789 display, which is helpful to know, as the Adafruit ST7789 library supports this display, and is what we will be using today. The code used below is a fairly complex code at first, which showcases this display"s capabilities and what it can do, in terms of functionality. For the wiring, a 6-pin wiring configuration is used with the SPI interface to the Arduino, which will be shown below. Finally, for this project, here are the components which you will need:1 1.3" 240x240 IPS TFT Display Module

This project is fairly straightforward to set up so make sure you start by unplugging any power source feeding into your Arduino to prevent any shorts while wiring. Firstly, take a jumper wire and connect the GND pin on the display to any of your Arduino"s GND pins and follow that up by connecting the VCC pin from the display to the 3v3 pin of your Arduino to supply a +3.3 volt power supply to the module. +5v will have a possibility to damage the display. Now, for the i2c connections, hook up the SCL (Serial Clock) pin of the display to A13 (analog pin 13) on the Arduino and the SDA (Serial Data) pin to A11 (analog pin 11). For the RES (Reset) pin, connect it up to A8 (analog pin 8) as well as the DC (Data/Command) pin to A9 (analog pin 9). The hardware part is finally done!

This code may seem slightly intimidating at first, due to its length and much newer functions, but once it is broken down, it isn"t so hard anymore. In the first three lines, we declare libraries for running this display, the graphics used, and for the interface used, which is the SPI interface. In the next three lines, the RST (Reset) and DC (Data/Command) pins are defined, which are connected to A8 (analog pin 8) and A9 (analog pin 9). In the next line, we initialize the Adafruit ST7789 library for use with this display and we follow that by defining the value of pi as a float variable in that next line. We will be using this float variable later on for graphics and calculations needed. Thevoid setupsection is now here where we first start by begining serial communication with a baud rate of 9600 bauds and printing a test message which is "Hello! ST7789 TFT Test!". In regards to the display, we address that our display module is of 240x240 resolution and we set the rotation of our display in the next line. If your display is flipped, removetft.setRotation(2). From there, we print the text "Initialized" as our display is now correctly set up. After that, we count up the seconds from the startup with themillis()function and store it in an unsigned 16-bit integer, namedtime, for use later. We then fill up the TFT screen with a black colour. Since we already started the stopwatch which counts up, we can always reset the stopwatch back to zero by using subtracting thetimefunction with themillis().To end off this section, we set a delay for 500 milliseconds before moving on. This section onwards will only be for the animations, graphics and images displayed on the screen, and we start off by filling the screen with a black background and writing some text with a white colour before a 1-second delay. Proceeding that, we execute a print test which basically is already programmed to print out a set of text in different font colours and sizes. We end this test by setting a delay for 4 seconds. From this point, the rest of the code is responsible for printing out the different graphics, which can be composed of shapes, pixels and text. All the different graphics and its individual code are mentioned at the end of the code so I recommend really going through this program to learn all the commands, which can help you build your own demo code, even with your own personal images being displayed. This project is now done!

a leading manufacturer and distributor in PCB design and manufacturing. They have amazing prices and excellent quality in their services, so don"t miss out on them! Plus, PCBWay has an amazing website, online Gerber viewer function and a gift shop so make sure to check out their links below:

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey