adjusting backlight on lcd panel free sample

© Copyright Han-Kwang Nienhuys, 2008. The text and accompanying images may not be redistributed. This includes placing the images on other websites, either as a copy or through hotlinking. Read more...

The view direction is the right direction marked with Φ which is with respect to the X-axis. The original location is the center point of the display panel surface, the Z axis is Normal, the X-axis is Horizontal and Y-axis is Vertical.

Normally it was defined 4 angles to correspond with 3, 12, 9, and 6 o’clock respectively. So, you can find the 6 o’clock or 12 o’clock parameter in the LCD datasheet.

Viewing Angle is the angle with respect to the Z-axis in a certain direction and marked by θ (θU means upper View Angle). LCD Viewing Angle describes the maximum watching angle, and it is one of the key indicators with the display module.

The LCD bias angle is the angle perpendicular from which the display is best viewed. (See Fig.2) This angle is determined when the display is designed and can be set at any angle or orientation. The orientation of the bias angle of LCD displays is often stated with reference to a clock face. If the offset is above the display, it is referred to as a 12:00 or Top view.

The LCD viewing angle is the angle formed on either side of the bias angle, where the contrast of the display is still considered acceptable. Generally, this contrast is specified as 2:1 for monochrome LCD and 10:1 for color LCD.

For example, assume the display is a 12:00 (topview) type. When the display is viewed from 25 degrees above the vertical, it will be at its maximum contrast and best look. If the viewer moves their eyes further above the display by an additional 30 degrees, they will see a contrast reduction, but the display will still be readable. Moving the view position any further above the display will reduce the contrast to an unacceptable degree.

Adjusting the contrast voltage, VL, effects the Bias Angle to some extent, but not the Viewing Angle. A top view 12:00 display can be optimized for a bottom view 6:00 viewing position by adjusting the contrast voltage. A 12:00 display set for a 6:00 viewing position will not have as great a contrast as a 6:00 display set for 6:00 viewing position and vice versa.

Generally, displays are optimized for straight-on viewing. Either a 6:00 or 12:00 module may be used, and the contrast voltage can be adjusted slightly to optimize the display for that viewing position. In the above example, the viewing angles of both 6:00 and 12:00 modules actually overlap the perpendicular (or straight on) viewing position.

Generally, a 10K ohm potentiometer is then connected between VDD and VSS in a single supply module, or from VDD to the negative rail in a dual supply module. The wiper of the pot is connected to the VL input of the module. (See Fig.3)

The LCD is positioned at the nominal viewing position and the pot is adjusted to obtain the desired LCD appearance. The voltage on the VL pin is now measured and a pair of resistors are chosen to produce this voltage in the production units.

By adjusting driving voltage and contrast is the most cost-effective way to improve the viewing angle. Different viewing angles need different driving voltage. It is compromising. In discussing the best viewing angle, we have to fix the voltage angle first.

– The higher the efficiency, the better of the contrast. It is especially important for negative display. Changing from 98% to 99.9% polarizer will do the work.

– Positive LCD to Negative LCD (When the LCD is used indoor or dark environment, the contrast will increase a lot, but it will not display well with ambient light only, it is also more expensive)

When a LCD is high density with the segments/icons or very crowded, some customers also complains the viewing angle or contrast are not good. The reason is for crowded display, the layout can be long and thin. The voltage drop along the layout can be big. The solutions are:

Want to find out more about LCD, OLED & TFT solutions? – Check out our knowledge base, where ypu can find tips on electronics operating temperature and differences between LCD and TFT!

Adjusting the display settings on a new computer is easy to do. It"s important to know how to adjust the brightness on Windows 10 and Windows 11 because if you get eye strain or headaches, the display brightness could be the culprit. Fortunately, you can adjust the levels manually or automatically based on parameters like battery life or the surrounding light.

If the slider is unavailable, it will be due to one of two things. If you"re using an external monitor, use the buttons on that to change the brightness. Otherwise, you need to update the display driver.

If you"re not using a portable device (like a laptop), you may not be able to adjust your brightness in Windows 10 or Windows 11. That"s because your external monitor controls the brightness.

If this applies to you, consult your monitor"s documentation for guidance on adjusting the brightness because the exact instructions will vary per monitor. You should have buttons on your monitor that bring up an on-screen display, which you can navigate through to alter the brightness.

Your display driver manufacturer will have its own control panel from where you can control brightness. For example, there"s the Intel Graphics Control Panel and the NVIDIA Control Panel. Which one you"ll use or have depends on what graphics card you have.

Lowering your brightness can help you squeeze more juice from your portable device"s battery. Windows 10 and Windows 11 have a battery saver feature that limits notifications and background activity, and this can also automatically lower your brightness.

Also, you can manually enable the battery saver at any time from this screen by turning the Battery saver toggle On (Windows 10) or selecting Turn on now (Windows 11).

Ideally, your monitor brightness should match the surrounding light since this reduces eye strain and unnecessary battery drain. One way to help with this is to have the brightness automatically change based on your ambient light.

Your computer keyboard might have shortcuts to turn your brightness up and down. If you"re using a laptop, it almost certainly will. Check out the function keys—brightness is commonly represented by a sun icon. It"s a handy keyboard productivity trick.

The exact key combination will depend on your keyboard model. For example, you may need to hold down or activate the Fn key and then press the corresponding function key simultaneously.

If you want a quick way to adjust your brightness on Windows 10 or Windows 11, rather than fiddling around in menu screens, there are two quick shortcuts you can use.

You can quickly adjust the brightness through the Action Center icon in the taskbar (or press Win + A.) Then, use the brightness slider to adjust the level. The further right the slider, the brighter the screen.

Want a good third-party utility? Check out the Windows 10 Brightness Slider. Despite the name, it works on both Windows 10 and 11. This lightweight utility will add a brightness icon in your system tray, which you can then click to adjust your brightness on a slider, much like how the volume icon works.

Head over to the GitHub project, download the file, and open it. It"ll automatically go into your tray. If you want it always to be there, right-click the icon and click Run At Startup.

If you want, you can change your brightness using Command Prompt. The other methods listed here are more intuitive, but you can use this if they"re unavailable for some reason.

With brightness sorted, you may want to check out your monitor"s color temperature. The light from our screens apparently causes sleep problems, and thus you can use programs like f.lux or Windows"s Night Light feature to help combat it.

LCD displays don’t emit light by themselves. They need a light source, and LED backlights are now dominating the market. In this article, Orient Display’s Bill Cheung provides a complete overview of LED backlight technology, discussing different types, driver technologies, color deviation, brightness options and more.

LCD (liquid crystal display) has long been the dominant technology in the display world. Certainly, there are some emerging competing display technologies—such as OLED (Organic Light Emitting Diode) [1] and micro-LED—that have the potential to threaten LCD’s position in the market. But both are currently only used for niche and high-end markets.

An LCD display can’t emit light by itself. In order to have an LCD display [2] used in a dim environment, a backlight has to be used as the light source. There are a few different technologies that are able to produce backlight ranging from EL (electroluminescent), CCFL (cold cathode fluorescent lamps) and LED (light emitting diode). However, a breakthrough in blue LED technology by Shuji Nakamura [3] led to LED backlights dominating the market.

One of the greatest benefits of LED backlighting is its long lifetime. Normally, LED lifetime can be measured with half-life when the original brightness decreases by 50%. With different LED chip manufacturing materials, technologies and environment used, the LED life can vary from 20,000 hours to well over 100,000 hours.

LED backlights have low power consumption and produce much less heat than other backlight technologies, which extends the durability and performance of the other display components. Furthermore, this reduces the risk of fire and explosion. LED backlights are also driven with DC (direct current) and low voltage (can be as low as 1.5V), which are good for battery drive and emit no interference to the circuitry. With the development of LED technology, the LED chips become small. So, it is possible to produce very thin backlight (0.5mm thick or thinner).

Although white LED is the most popular color, LED backlight can be made into different single colors, bi-colors and tri-colors [4] (Figure 1) (Figure 2). With RGB LED backlight color mixing, normal 8 color LED backlight can be produced (Figure 3).

LED backlight can be classified as bottom (array) lit and side (edge) lit backlights, and each have their plusses and minuses. The advantages of the bottom lit (array) backlight are that it is uniform and bright. Its disadvantage is high current draw, thickness, heat dissipation and cost. Meanwhile, the advantages of the side lit backlight are its thinness, flexibility in design, low current and lower cost. The main disadvantage of the side lit backlight is its non-uniformity—hot spots can be seen from most of the side lit backlight from certain angle. Figure 4 compares the bottom lit and side (edge) lit backlight LCD types.

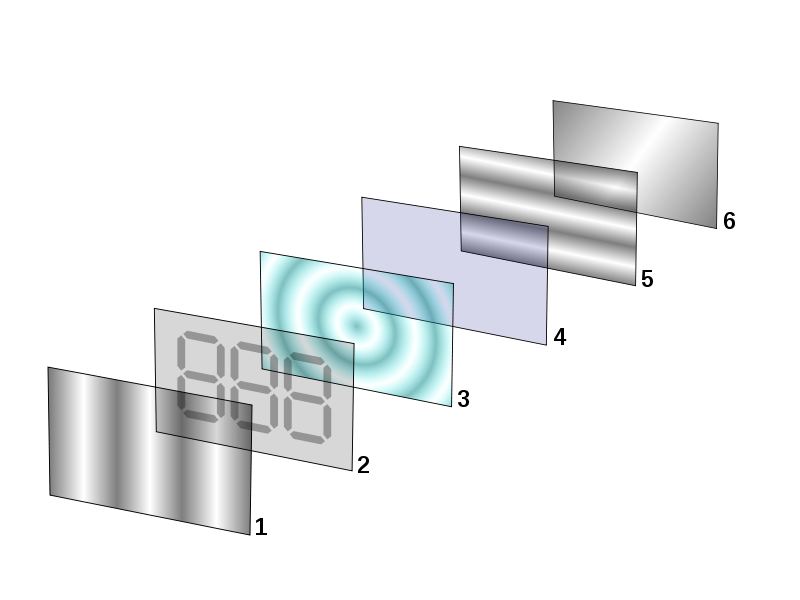

Now let’s look at LED backlight structures. An LED backlight can be simplified into layers starting with a LED chip, light guide, diffusor and reflector (Figure 5). This is the lowest cost structure. Except for some very low current efficiency LCD displays—such as utility meters, battery-powered clock, watch, GPS and so on—most LCD displays need backlights to be visible in the dim lighting. Most often the backlight is actually at the back of the LCD. In rare cases, this light can be done as front light. The traditional LCD structure with LED backlight shown in Figure 6.

Direct current driving: This is the simple and low-cost way to drive a LED backlight, however, be mindful of the current limit otherwise the LED life can deteriorate quickly. The solution is simply to add a current limiting resistor in the circuit. Current limitation resistors value calculation formula: R = (V0– Vf)/If.Also be mindful of reverse drive, otherwise, the LED chip can break down easily.

LED driver with constant current: The advantage of constant current LED driver is that it will be the best option to use when building your own fixture or working with high powered LED because they avoid violating the maximum current specified for the LEDs, therefore avoiding burnout/thermal runaway. They are easier for designers to control applications, and help create a more consistent bright light.

LED driver with constant voltage: Using a constant voltage LED driver makes sense when using an LED or array that has been specified to take a certain voltage. This is helpful because constant voltage is a much more familiar technology for design and installation engineers. Moreover, the cost of these systems can be lower, especially in larger scale applications.

There are a variety of ways to connect a backlight and LCD module electrically. It can be done with wires that are soldered on the LCD or LCD module. It can be connected using pins, which can be soldered onto the LCD or LCD module. A third way is to use a FPC (flexible printed circuit), which can be soldered or plugged in a ZIF (zero insertion force) connector. And finally, there is the connector method. With this method you use connectors which can be plugged into mating connectors.

As the LED is manufactured via the semiconductor process, there are some color deviations that can be a quality control issue. One way to solve the issue is through a process of selection and sorting after manufacturing the LEDs. The LEDs are sorted into different categories or bins. How this sorting is done and what each bin actually contains is defined differently by each LED manufacturer. The backlight manufacturer can choose from which bin they take the LEDs for backlight color hue.

Some customers might request very fine binning by the LED manufacturer, which can be very expensive since only a very small percentage of the LEDs manufactured would meet the requirements for a specific bin. Figure 7 shows an example of the bin selection from Nichia, the most renowned LED manufacturer in the world. Figure 8 shows the 1931 CIE chromaticity diagram. And Figure 9 shows the color deviations (bin definition) by Cree for a qualified production lot.

In actual LED backlight production, most customers will accept the LED color for two big categories: white with yellowish (warm) and white with bluish (cold). Of course, the LED brightness will also need to be defined. For general application, most customers will accept a brightness tolerance of 70 percent.

It is extremely hard to estimate the LED backlight lifetime or MTBF (mean time between failures) because there are so many variable factors. However, the most important is the temperature on the LED chip. The factors that can affect the LED chip temperature include: surrounding temperature, humidity, driving current, voltage, backlight design (how many LED chips to be used, how close to each other, heatsink design), backlight manufacturing process (type and thickness of adhesive), quality of the LED chip and so forth.

To test the LED life is also very time consuming, requiring at least 1,000 hours. That’s the reason why no LED manufacturers can guarantee LED backlight life and most backlight manufacturers also are reluctant to provide lifespan data. As for LCD manufacturers, they need to discuss it with the customer to understand the applications and provide suggestions. It is normal that the LCD datasheet lists the typical life time and avoids providing a minimum lifetime. From Figure 10, we can see that over room temperature, the current needs to decrease as the temperature increases. At over 85°C, the LED is not usable.

To estimate LED backlight lifetime, you can use ballpark estimation or theoretical calculation. Let’s first examine the ballpark method. To take white LED as example, the nominal biasing current is 20mA. If we use a safe lifetime estimation, we can estimate using Table 1.

Now let’s use the theoretical calculation approach. As we previously mentioned, LED life is affected by a lot of factors: surrounding temperature, humidity, driving current, voltage, backlight design (how many LED chips to be used, how close to each other, heatsink designed), backlight manufacturing process (type and thickness of adhesive), quality of the LED chip and so on. LED chip manufacturers are not willing to give absolute values of LED chip lifetimes, but there is a theoretical calculation that we can use.

Temperature is the determination factor for LED chip life, while LED chip manufacturers use LED junction temperature to predict LED chip life more accurately. An example is:

Where Tjis PN junction temperature (°C); Ts1 is solder temperature cathode side (°C); Rthj-s1 is thermal resistance of junction to Ts1 measuring point (°C/W); W is IF × VF; and, for Nichia NS6W083A Tj Max = 120°C, Rthj-s1= 10°C/W.

Finally, let’s look at ways to increase LED backlight brightness. There are many ways to increase LED backlight brightness, but all these measures are balanced with performance and cost. Here are some of the methods:

For the LCD module side, using better aperture opening ratio, anti-reflection coating on surface, optical bonding. This results in higher cost. Actually, this measure is not to increase LED backlight brightness directly but to increase to the visibility to users.

Using 3M film [6]: BEF (brightness enhancement film or prism film), DBEF (dual brightness enhancement film), DBEF II, ESR (enhanced specular reflector) and so on. These increase costs a lot, but these high-performance films are essential in tight power management like mobile phones and other battery-powered applications.

Note: We’ve made the May 2020 issue of Circuit Cellaravailable as a free sample issue. In it, you’ll find a rich variety of the kinds of articles and information that exemplify a typical issue of the current magazine.

Would you like to write for Circuit Cellar? We are always accepting articles/posts from the technical community. Get in touch with us and let"s discuss your ideas. Sponsor this Article

Bill Cheung is an engineering lead and marketing manager at Orient Display, an LCD and display technology provider with over two decades of industry experience in delivering cutting edge display solutions. You can browse Orient Display"s knowledge base [7] to learn more about LCDs.

Does your display look a little off? Not just too bright or too dim but perhaps some colors don"t look as accurate as they should or the image tends to look a bit washed out at times. If so, then it"s time to calibrate your display.

You can either calibrate your display by eye or by using a device called a color calibrator -- or colorimeter -- that you stick on the front of your display. If you have a colorimeter, then I"m going to assume you know how to use it and don"t need to read a blog post on the topic. If you haven"t plunked down $100 or more on a colorimeter, then I"m also going to assume you don"t have any immediate plans to purchase such a device and would like to go about calibrating your monitor by eye.

Thankfully, it"s easy to make adjustments by eye. If you don"t get your display as fine tuned as you might with a colorimeter, as long as the image looks good to you, then I would classify the mission as accomplished.

The quickest and easiest way to calibrate your display is to stare at a number of test patterns and use your monitor"s onscreen display (OSD) controls to adjust the contrast, brightness, color levels, sharpness, color temperature, and so on. A good resource for free test patterns is Lagom LCD monitor test pages. The site will lead you through a series of test patterns, which you use to adjust your monitor using the OSD controls -- the group of buttons located on the front or side of your display.

But what if you are using a laptop that doesn"t have such buttons, you ask? Both Windows and Mac OS X feature utilities that step you through various calibration settings.

When you have finished with your tweaks, the Display Color Calibration lets you compare your current settings with the previous calibration. Click Finish to move forward with your new calibration settings and Windows will make a pitch for you to turn on ClearType, which attempts to make text more readable. If you select this option, you will then jump through five quick test screens to fine tune ClearType for the clearest, crispest text.

To finish up, give your profile a name and click Done. Your new profile will now be listed as an option on the Color tab of the Display option in System Preferences.

The Arduino family of devices is features rich and offers many capabilities. The ability to interface to external devices readily is very enticing, although the Arduino has a limited number of input/output options. Adding an external display would typically require several of the limited I/O pins. Using an I2C interface, only two connections for an LCD character display are possible with stunning professional results. We offer both a 4 x 20 LCD.

The character LCD is ideal for displaying text and numbers and special characters. LCDs incorporate a small add-on circuit (backpack) mounted on the back of the LCD module. The module features a controller chip handling I2C communications and an adjustable potentiometer for changing the intensity of the LED backlight. An I2C LCD advantage is that wiring is straightforward, requiring only two data pins to control the LCD.

A standard LCD requires over ten connections, which can be a problem if your Arduino does not have many GPIO pins available. If you happen to have an LCD without an I2C interface incorporated into the design, these can be easily

The LCD displays each character through a matrix grid of 5×8 pixels. These pixels can display standard text, numbers, or special characters and can also be programmed to display custom characters easily.

Connecting the Arduino UNO to the I2C interface of the LCD requires only four connections. The connections include two for power and two for data. The chart below shows the connections needed.

The I2C LCD interface is compatible across much of the Arduino family. The pin functions remain the same, but the labeling of those pins might be different.

Located on the back of the LCD screen is the I2C interface board, and on the interface is an adjustable potentiometer. This adjustment is made with a small screwdriver. You will adjust the potentiometer until a series of rectangles appear – this will allow you to see your programming results.

The Arduino module and editor do not know how to communicate with the I2C interface on the LCD. The parameter to enable the Arduino to send commands to the LCD are in separately downloaded LiquidCrystal_I2C library.

The LiquidCrystal_I2C is available from GitHub. When visiting the GitHub page, select the Code button and from the drop-down menu, choose Download ZIP option to save the file to a convenient location on your workstation.

Before installing LiquidCrystal_I2C, remove any other libraries that may reside in the Arduino IDE with the same LiquidCrystal_I2C name. Doing this will ensure that only the known good library is in use. LiquidCrystal_I2C works in combination with the preinstalled Wire.h library in the Arduino editor.

Several examples and code are included in the Library installation, which can provide some reference and programming examples. You can use these example sketches as a basis for developing your own code for the LCD display module.

There may be situations where you should uninstall the Arduino IDE. The reason for this could be due to Library conflicts or other configuration issues. There are a few simple steps to uninstalling the IDE.

The I2c address can be changed by shorting the address solder pads on the I2C module. You will need to know the actual address of the LCD before you can start using it.

Once you have the LCD connected and have determined the I2C address, you can proceed to write code to display on the screen. The code segment below is a complete sketch ready for downloading to your Arduino.

The code assumes the I2C address of the LCD screen is at 0x27 and can be adjusted on the LiquidCrystal_I2C lcd = LiquidCrystal_I2C(0x27,16,2); as required.

Similar to the cursor() function, this will create a block-style cursor. Displayed at the position of the next character to be printed and displays as a blinking rectangle.

This function turns off any characters displayed to the LCD. The text will not be cleared from the LCD memory; rather, it is turned off. The LCD will show the screen again when display() is executed.

After 40 spaces, the function will loop back to the first character. With this function in the loop part of your sketch, you can build a scrolling text function.

Scrolling text if you want to print more than 16 or 20 characters in one line then the scrolling text function is convenient. First, the substring with the maximum of characters per line is printed, moving the start column from right to left on the LCD screen. Then the first character is dropped, and the next character is displayed to the substring. This process repeats until the full string has been displayed on the screen.

The LCD driver backpack has an exciting additional feature allowing you to create custom characters (glyph) for use on the screen. Your custom characters work with both the 16×2 and 20×4 LCD units.

A custom character allows you to display any pattern of dots on a 5×8 matrix which makes up each character. You have full control of the design to be displayed.

To aid in creating your custom characters, there are a number of useful tools available on Internet. Here is a LCD Custom Character Generator which we have used.

Over time, the image quality on your computer monitor can start to look a little lackluster or even too bright. Before you consider upgrading your entire system or getting a new monitor, there might be a much simpler, quicker, and economical solution — calibrate your monitor.

You could take your monitor to a professional to have it done, but doing it yourself is relatively quick and hassle-free and will greatly improve image quality. Manufacturers keep pumping out displays with new technologies like 4K UHD resolution, high dynamic range (HDR), and curved monitors, providing a veritable feast for the eyes — but only if they are properly calibrated.

Step 3: Make sure you’re calibrating in a room with moderate ambient lighting. The room doesn’t need to be pitch black, but you don’t want the sharp glares and color casts resulting from direct light.

Step 4: Familiarize yourself with your monitor’s display controls. They may be located on the monitor itself, on the keyboard, or within the operating system control panel.

Both MacOS and Windows have built-in calibration tools to help guide you step-by-step through the process, which is particularly helpful if you are new to monitor calibration. These free tools should be the first stop if you’re merely a casual image junkie or working on a tight budget. Keep in mind that the adjustments will be limited by the display type and model, though.

The assorted terms — gamma, white point, etc. — may seem a bit daunting at first glance, but each utility provides a relatively simple explanation of what they all mean. Realistically, you don’t need to know the ins and outs of the jargon to calibrate your monitor.

In older versions of Windows, you can find the Color Calibration utility in the Display section of the Control Panel, which is listed under Appearance and Personalization.

Step 2: Now that you are in the calibration tool, follow the on-screen instructions to choose your display’s gamma, brightness, contrast, and color balance settings.

Step 3: Once the calibration wizard is complete, make sure to choose the Current calibration, or return to the previous calibration if you are unsatisfied with the results. The new calibration will be stored as an .ics file, or color calibration file, and will show up as a new International Color Consortium (ICC) Profile in the Color Management settings app.

Step 4: The easiest way to open this app is to type "color management" in the search box and choose the first result. Once it’s open, you can select your monitor from the device list and see which ICC Profiles are available.

Step 1: In MacOS, the Display Calibrator Assistant is located in the system preferences under the Displays tab, in the Color section. If you are having trouble finding it, try entering calibrate in Spotlight to scan through your computer’s various folders and files. The results should show an option to open the utility in the System Preferences panel.

Step 2: Your Mac’s step-by-step instructions will walk you through the calibration process once you have found and opened the software utility. Just follow the on-screen instructions to choose:

Color adjustments: White point is a given, but Apple will try to detect your display and offer a number of other color calibrations at this point … or it may skip the rest of the adjustment options entirely. Native Apple displays may be more likely to have fewer color calibrations at this point (because Apple already calibrated them).

Step 3: This will create a new color profile for your display. If you couldn’t make the adjustments that you wanted to, then select this new profile and choose Open Profile. This will open a new window with all the tags associated with the color profile and their descriptions.

Step 4: You can choose each tag to see more information about them. Some tags will just be basic color data, but other tags can be altered to change specific color factors for the display.

Step 5: If you have a native display, look for the Apple display native information tag as a good place to start. As you can see, this can quickly become technical, so you will need to know your color data (phosphor values, response curves, etc.) to make accurate changes with this method.

There are a handful of web-based calibration tools that help you manually adjust your monitor settings. They can provide more precise, or more customized, calibration than the built-in utilities.

W4zt Screen Color Test: This simple webpage provides you with several color gradients and grayscale color boxes you can use for quick comparisons, along with an easy gamma test you can run. It’s nice to have so many tests on one page, making this solution great for fast and dirty calibration so you can move on.

The Lagom LCD Monitor Test Pages: Handy for both online and offline use, the Lagom LCD Monitor Test Pages not only allow you to adjust various things such as contrast and response time, but also allow you to download the images as a 120KB zip file, so you can check any monitor in-store that you are thinking about purchasing.

Calibrize 2.0: If you want a great tool that goes a little more in-depth than native calibration options, we suggest downloading Calibrize 2.0. It’s an excellent free wizard that carefully walks you through well-explained steps to help you calibrate color, grayscale, gamma, and similar settings on your computer.

While they’re better than a more temporary solution, built-in calibration utilities still have one major flaw: You. Since they rely on your specific color perception, what looks great to you might look thoroughly off to a friend.

The best way to avoid this problem and ensure that you calibrate your monitor correctly is by purchasing a calibrating device. You’ll need to spend a decent amount of money for the best control and precision. Still, there are affordable alternatives to help you achieve consistent color across all of your monitors.

If you’re looking for a calibration tool, we recommend either the X-Rite ColorMunki Smile ($99) or the Spyder5Elite ($200). Both devices boast a full-spectrum, seven-color sensor that can accurately display a range of standard and wide-gamut displays. If you have a bigger budget, you can look for upscale calibrators that have even more advanced options.

These devices are user-friendly, involving a simple three-step process of fastening the device to your screen, plugging it into a USB port, and opening the calibration software. When the software starts running, you just have to follow the setup procedure. It’s fairly intuitive, but if you have trouble, you can find tutorials online that will walk you through it.

Starting at $180, X-Rite’s i1Display is another solid device. Just like the Spyder series, each of these three options is configured with automated calibration software. The more money you spend, the more additional features and other benefits you’ll get from the device.

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

Sends data to data pins when a high to low pulse is given; Extra voltage push is required to execute the instruction and EN(enable) signal is used for this purpose. Usually, we set en=0, when we want to execute the instruction we make it high en=1 for some milliseconds. After this we again make it ground that is, en=0.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM is the main component in making custom characters. It stores the custom characters once declared in the code. CG-RAM size is 64 bytes providing the option of creating eight characters at a time. Each character is eight bytes in size.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

The wide range of conditions over which LCD monitors are used means that it is desirable to produce displays whose luminance (brightness) can be altered to match both bright and dim environments. This allows a user to set the screen to a comfortable level of brightness depending on their working conditions and ambient lighting. Manufacturers will normally quote a maximum brightness figure in their display specification, but it is also important to consider the lower range of adjustments possible from the screen as you would probably never want to use it at its highest setting. Indeed with specs often ranging up to 500 cd/m2, you will certainly need to use the screen at something a little less harsh on the eyes. As a reminder, we test the full range of backlight adjustments and the corresponding brightness values during each of our reviews. During our calibration process as well we try to adjust the screen to a setting of 120 cd/m2 which is considered the recommended luminance for an LCD monitor in normal lighting conditions. This process helps to give you an idea of what adjustments you need to make to the screen in order to return a luminance which you might actually want to use day to day.

Changing the display luminance is achieved by reducing the total light output for both CCFL- and LED-based backlights. By far the most prevalent technique for dimming the backlight is called Pulse Width Modulation (PWM), which has been in use for many years in desktop and laptop displays. However, this technique is not without some issues and the introduction of displays with high brightness levels and the popularisation of LED backlights has made the side-effects of PWM more visible than before, and in some cases may be a source of visible flicker, eyestrain, eye fatigue, headaches and other associated issues for people sensitive to it. This article is not intended to alarm, but is intended to show how PWM works and why it is used, as well as how to test a display to see its effects more clearly. We will also take a look at the methods some manufacturers are now adopting to address these concerns and provide flicker-free backlights instead. As awareness grows, more and more manufacturers are focusing on eye health with their monitor ranges.

Pulse Width Modulation (PWM) is one method of reducing the perceived luminance in displays, which it achieves by cycling the backlight on and off very rapidly, at a frequency you can’t necessary detect with the naked eye, but which could lead to eye issues, headaches etc. This method generally means that at 100% brightness a constant voltage is applied to the backlight and it is continuously lit. As you lower the brightness control the perceived luminance for the user reduces due to a number of possible controlling factors:

1) Frequency –The backlight is cycled on and off very rapidly, and this cycling typically occurs at a fixed frequency (in Hz). How fast this cycling occurs can impact whether flicker is visible or perceivable to the user, with higher frequencies being potentially less problematic. PWM has been known to operate at low frequencies of 180 – 240Hz for example which are likely to be more problematic than higher frequencies ranging up in to the Kilohertz range (e.g. 18,000Hz).

2) Modulation –The modulation of the cycling has an impact on the perceived brightness, and this describes the difference between the luminance in an “on” and in an “off” state. In some examples the backlight is completely turned off during the cycle so it is literally being turned on/off rapidly across the full brightness adjustment range. In those examples the luminance output is controlled really by the duty cycle only (see point 3). In other examples the backlight is not always being completely turned off but rather the voltage applied to the backlight is being rapidly alternated, resulting in less extreme differences between the on and off states. Often this modulation will be narrow in the high brightness range of the display, but as you reduce further, the modulation becomes wider until it reaches a point where the backlight is being switched completely off. From there, the change in the duty cycle (point 3) controls the further changes in the luminance output.

3) Duty Cycle – The fraction of each cycle for which the backlight is in an “on” state is called the duty cycle. By altering this duty cycle the total light output of the backlight can be changed. As you reduce the brightness to reach a lower luminance, the duty cycle becomes progressively shorter, and the time for which the backlight is on becomes shorter, while the time for which it is off is longer. This technique works visually since cycling the backlight on and off sufficiently fast means the user cannot see this flickering, because it lies above their flicker-fusion threshold (more on this later).

Above we can see graphs of a backlight’s output using “ideal” PWM for several cycles. The maximum output of this backlight in the example is 100 cd/m2, and the perceived luminance for the 90%, 50% and 10% cases are: 90, 50 and 10 cd/m2 respectively. The modulation percentage is the ratio between the minimum and maximum luminance during the cycle, and is 100% here, so it is being completely turned on and off. Note that during the duty cycle the backlight is at its maximum luminance.

The analogue (non-PWM) graphs corresponding to these perceived luminance levels would appear as shown below. In this case there is no modulation. This is the method used for flicker-free backlights which we will discuss more a little later.

The main reasons for the use of PWM is that it is simple to implement, requiring only that the backlight can be switched on and off rapidly, and also gives a large range of possible luminance.

CCFL backlights can be dimmed by reducing the current through the bulb, but only by about a factor of 2 because of their strict current and voltage requirements. This leaves PWM as the only simple method of achieving a large range of luminance. A CCFL bulb is in fact normally driven by the inverter to cycle on and off at a rate in the 10’s of kilohertz and well outside the range of flicker visible to humans. However, the PWM cycling typically occurs at a much lower frequency, around 175Hz, which can produce artefacts visible to humans.

The luminance of LED backlights can be adjusted greatly by altering the current passing through them, though this has the effect of altering the colour temperature slightly. This analogue approach to LED luminance is also undesirable since the accompanying circuits must take into account the heat generated by the LED’s. LED’s heat up when on, which reduces their resistance and further increases the current flowing through them. This can quickly lead to runaway current use in very high-brightness LED’s and cause them to burn out. Using PWM the current can be forced to hold a constant value during the duty cycle, meaning the colour temperature is always the same and current overloads are not a problem.

While PWM is attractive to hardware makers for the reasons outlined above, it can also introduce distracting visual effects if not used carefully. Flicker from LED backlights is typically much more visible than for older CCFL backlights at the same duty cycle because the LED’s are able to switch on and off much faster, and do not continue to “glow” after the power is cut off. This means that where the CCFL backlight showed rather smooth luminance variation, the LED version shows sharper transitions between on and off states. This is why more recently the subject of PWM has cropped up online and in reviews, since more and more displays are moving to W-LED backlighting units now.

Where the effect of flicker can really come into play is any time the user’s eyes are moving. Under constant illumination with no flickering (e.g. sunlight) the image is smoothly blurred and is how we normally perceive motion. However, when combined with a light source using PWM several discrete afterimages of the screen may be perceived simultaneously and reduce readability and the ability of the eyes to lock onto objects. From the earlier analysis of the CCFL backlighting we know that false colour may be introduced as well, even when the original image is monochromatic. Below are shown examples of how text might appear while the eyes are moving horizontally under different backlights.

It is important to remember that this is entirely due to the backlight, and the display itself is showing a static image. Often it is said that humans cannot see more than 24 frames per second (fps), which is not true and actually corresponds to the approximate frame rate needed to perceive continuous motion. In fact, while the eyes are moving (such as when reading) it is possible to see the effects of flicker at several hundred hertz. The ability to observe flicker varies greatly between individuals, and even depends on where a user is looking since peripheral vision is most sensitive.

So how fast is PWM cycling backlights on and off? This seems to depend on the backlight type used, with CCFL-based backlights nearly all cycling at 175Hz or 175 times per second. LED backlights have been reported typically running from 180 – 420Hz, with those at the lower end flickering much more visibly. Some have even faster frequencies of >2000Hz so it really can vary. While this might seem too fast to be visible, keep in mind that 175Hz is not much faster than the 100-120Hz flicker observed in lights connected directly to the mains power.

100-120Hz flickering of fluorescent lights has in fact been linked to symptoms such as severe eye strain and headaches in a portion of the population, which is why high-frequency ballast circuits were developed that provide almost continuous output. Using PWM at low frequencies negates the advantages of using these better ballasts in backlights because it turns an almost constant light source back into one that flickers. An additional consideration is that poor quality or defective ballasts in fluorescent backlights can produce audible noise. In many cases this is exacerbated when PWM is introduced since the electronics are now dealing with an additional frequency at which power usage is changing.

It is also important to distinguish the difference between flicker in CRT displays and CCFL and LED backlit TFT displays. While a CRT may flicker as low as 60Hz, only a small strip is illuminated at any time as the electron gun scans from top to bottom. With CCFL and LED backlit TFT displays the entire screen surface illuminates at once, meaning much more light is emitted over a short time. This can be more distracting than in CRTs in some cases, especially if short duty cycles are used.

The flicker itself in display backlights may be subtle and not easily perceptible for some people, but the natural variation in human vision seems to make it clearly visible to others. With the use of high-brightness LED’s on the rise it is becoming increasingly necessary to use short PWM duty cycles to control brightness, making flicker more of a problem. With users spending many hours every day looking at their monitors, shouldn’t we consider the long term effects of both perceptible and imperceptible flicker?

If you find PWM backlight flickering distracting or just want to see if reducing it makes reading on a monitor easier, I’d encourage you to try the following: Turn the brightness of your monitor up to maximum and disable any automatic brightness adjustments. Now use the colour correction available in your video card drivers or calibration device to reduce the brightness to normal levels (usually by adjusting the contrast slider). This will reduce the luminance and contrast of your monitor while leaving the backlight on as much as possible during PWM cycles. While not a long-term solution for most due to the decreased contrast, this technique can help to discover if a reduction in PWM usage is helpful.

A much better method of course would be to purchase a display not relying on PWM for dimming, or at least one which uses a much higher cycling frequency. Few manufacturers seem to have implemented PWM at frequencies that would limit visible artefacts (well above 500Hz for CCFL and above 2000 Hz for LED). Additionally, some displays using PWM do not use a 100% duty cycle even at full brightness, meaning they will always produce flicker. Several LED-based displays may in fact be currently available which do not use PWM, but until backlight frequency and modulation become listed in specifications it will be necessary to see the display in person. Some manufacturers promote “flicker free” monitors in their range (BenQ, Acer for example) which are designed to not use PWM at all and instead use a Direct Current (DC) method of backlight dimming. Other manufacturers such as Eizo talk about flicker free backlights but also list a hybrid solution for their backlight dimming, where PWM is used for some of the brightness adjustment range at the lower end. In fact it seems an increasingly common practice for a screen to be PWM free down to a certain point, and then fro PWM to be used to really drive down the minimum luminance from there.

An easy method of measuring the PWM frequency of a backlight would be ideal, and luckily it can be done using only a camera which allows manual control of the shutter speed. This can quickly and easily identify PWM frequencies in the lower range, but may not be suitable for high frequency PWM. It should be able to detect PWM up to at least 500Hz though, but anything above that may look like a solid block, suggesting no use of PWM, when in fact it might be just using a higher frequency. Further more complex methods such as our oscilloscope setup would be needed to validate flicker-free status for definite.

(Optional) Set the camera white balance by getting a reading off the screen while displaying only white. If not possible, then manually set the white balance to about 6000K.

Display a single vertical thin white line on a black background on the monitor (1-3 pixels wide should be fine). The image should be the only thing visible. Here is an example you may wish to save and use, show it full screen on your monitor.

Set the camera to use a shutter speed of 1/2 to 1/25 of a second. You may need to set the ISO sensitivity and aperture in order to capture enough light. Make sure the line is in focus at the distance you are holding it (lock the focus if needed).

Hold the camera about 2 feet in front of the monitor and perpendicular to (looking straight at) the front. Press the shutter button as you slowly move it horizontally across the screen (remaining perpendicular). You may need to experiment with moving the camera at different speeds.

Multiply this count by the inverse of the shutter speed. For example, if using a shutter speed of 1/25 of a second and 7 cycles are counted, then the number of cycles per second is 25 * 7 = 175Hz. This is the backlight cycle frequency.

What we are doing with this technique is turning a temporal effect into a spatial one by moving the camera during capture. The only significant source of light during the image capture is the thin line on the display, which is exposed onto consecutive columns on the sensor. If the backlight is flickering, different columns will have different brightness or colour values determined by the backlight at the time it was exposed.

A common problem when first attempting this technique is that the image is too dark. This can be mitigated by using a larger camera aperture (lower f/number) or increasing the ISO value. The shutter speed is not a factor in the exposure since we are using it only to control the total exposure time. The brightness of the image can also be adjusted by changing the speed at which the camera is moved, with a fast speed giving a darker image and more temporal resolution and a slow speed a brighter image with lower resolution. Another problem encountered is unevenly-spaced cycles in the final image, which is caused by the camera changing speed during exposure. Continuing to move the camera before and after the exposure helps to steady this. An image which looks particularly smooth may be due to it being out of focus. This can sometimes be helped by pressing the shutter button halfway to focus on the line target, then proceeding as normal.

Depending on the monitor several additional effects may be visible. CCFL-based backlights often show different colours at the start and end of each cycle, which means the phosphors used respond at different rates. LED-based backlights often use a higher cycling frequency than CCFL-based, and more rapid camera movement may be needed to easily see them. Dark stripes between cycles mean that the PWM duty cycle has been reduced to such an extent that no light is emitted for part of the cycles.

Using our oscilloscope and photosensor equipment it is possible to measure the PWM frequency and patterns far more accurately. While the above photo method is certainly suitable for a casual user, an oscilloscope can reveal more detail about the PWM operation and will be featured in all our reviews moving forward. We measure the luminance output of the screen at brightness settings of 100, 50 and 0%. This allows us to easily identify the backlight dimming technique, and if PWM is being used we can work out its frequency and comment on modulation, duty cycle etc.

Asus PA248Q – W-LED backlight. At 100% brightness we see a constant luminance output and a straight line, as there is no need for the backlight to be cycled. At 50% you can see PWM controls the backlight on and off. The modulation is always 100%, but the luminance reduction is controlled by the duty cycle which becomes progressively shorter. You can see much shorter “on” peaks in the 0% brightness graphs. We measure the frequency at 180Hz which is fairly typical.

BenQ GW2760HS – W-LED backlight. At all brightness settings the luminance output is a flat line, showing no PWM is being used. This is part of BenQ’s flicker free range.

The oscilloscope graphs can also allow us to examine the behaviour of the luminance output. Above is a typical W-LED backlight dimmed to 0% where PWM is used. You can see the changes between on and off are very steep and sudden, as the LED backlight is able to turn on and off very rapidly. As we’ve already discussed this can lead to potentially more noticeable flicker and associated issues as the changes are more pronounced.

The oscillographs for a typical CCFL display using PWM at 0% looks like the above. You can see the transitions from on to off are less sudden as the phosphors don’t go dark as quickly as with LED backlight units. As a result, the use of PWM may be less problematic to users.

As we said at the beginning, this article is not designed to scare people away from modern LCD displays, rather to help inform people of this potential issue. With the growing popularity in W-LED backlit monitors it does seem to be causing more user complaints than older displays, and this is related to the PWM technique used and ultimately the type of backlight selected. Of course the problems which can potentially be caused by the use of PWM are not seen by everyone, and in fact I expect there are far more people who would never notice any of the symptoms than there are people who do. For those who do suffer from side effects including headaches and eye strain there is an explanation at least.

With the long term and proven success of a technology like Pulse Width Modulation, and the many years of use in CCFL displays we can’t see it being widely changed at any time soon to be honest, even with the popular move to W-LED backlit units. It is still a reliable method for controlling the backlight intensity and therefore offering a range of brightness adjustments which every user would want and need. Those who are concerned about its side effects or who have had problems with previous displays should try and consider the frequency of the PWM in their new display, or perhaps even try and find a screen where it is not used at all in backlight dimming. Some manufacturers are proactively addressing this concern through the use of flicker free backlights, and so options are emerging which do not use PWM.

The first thing you want to adjust is the TV"s picture mode. This setting usually has the biggest impact on picture quality. Each picture mode has different default settings, and some of them behave differently from one another, even if you try and match the settings across modes.

If that is a concern, you should choose the ‘Game’ picture mode (or ‘PC’ on some models), or go into the TV’s settings and enable ‘Game’ mode. From there, the rest of the settings can be adjusted normally, and the picture will look very similar to what you get with ‘Movie’ or ‘Standard.’ On some models though, the PC or Game modes disable many of the TV"s picture enhancements, and some TVs even limit which picture modes are available.

For LED TVs, the backlight setting determines the brightness of the LEDs that are used to light the image. The higher the setting, the brighter the picture will be. There is no right answer for this setting. Each user needs to adjust this setting to their specific viewing conditions. If you"re in a bright room, for example, the TV has to be set to a brighter setting than if it was placed in a completely dark room. It also depends on personal preferences, as some people prefer a brighter or darker image.

Adjusting the backlight setting doesn"t have a significant impact on overall picture quality. It tends to brighten everything pretty much equally, so although blacks tend to let a bit more light through, whites are brighter as well, so the contrast ratio actually remains about the same. For LED TVs, don’t worry about using a high backlight setting, it won’t make your TV wear out sooner.

OLED TVs don"t have a backlight, so instead, look for a setting called "OLED Light" on LG TVs, or "Brightness" on Sony OLED TVs. Like the backlight setting above, you should adjust this to your viewing conditions. Unlike LED TVs though, higher backlight settings can have an impact on the life of your TV, so it isn"t recommended to leave this at the maximum for SDR content.

The ‘Brightness’ setting on a TV is used to adjust the depth of black on the screen. Set it too low and you will ‘crush’ the blacks, which means you’ll lose detail in darker images. Set it too high and the blacks won’t look dark enough.

Almost all TVs have this set correctly by default, so we recommend leaving it alone. If you want to try adjusting it using the pattern above, set the brightness to the minimum value and then increase it until you see the black portion on the left begins to lighten.

The contrast setting adjusts the amount of detail present in bright images. If contrast is set too high, whites could be ‘clipped,’ which means there is detail being lost in bright portions of an image. Too low, and the bright portions of the image won’t look bright enough.

This setting should be pretty close to correct by default, but sometimes needs a bit of tweaking. Just lower the contrast setting on your TV to the minimum, and then increase until only lines 230-234 appear. It’s very rare for a new TV to clip the whites, so it’s fine to set the value to the max if there is no loss in detail at that high setting. As you can see from the above images, there"s little difference between the correct setting and the maximum.

Adjusting a TV’s sharpness setting changes how it defines distinct objects on the screen. The proper sharpness setting will make things look about the same as they do in real life. Too much will exaggerate contours and lines. It"s very rare for a TV to have the option to remove sharpness from an image, which is why only two images are compared here.

Because high levels of sharpness make an image ‘pop,’ it’s not uncommon for a TV’s picture to be over-sharpened by default. To adjust this setting with the pattern, increase Sharpness to as high as it goes, and then decrease until the lines look normal and any geometric patterns in the lines (usually diamond-shaped) go away.

The ‘Color’ setting adjusts the level of saturation of colors in the TV’s images. Too little saturation will wash out the color of the image (extreme example at the above-left), and too much will oversaturate the picture (above-right).

Modern TVs almost always have this set correctly by default in their ‘Movie’ mode, and while the most basic way to modify it, which requires a blue filter, works pretty well, the best policy is to just leave this setting alone.

To adjust this setting with the pattern, look through a blue filter and adjust the color setting so that the blue box on the far left looks the same as the smaller gray boxes within.

This setting adjusts the amount of red and green tint to the image on the TV. Like the color setting, this is almost always correct by default, so there’s no need to adjust it yourself. Once again, if you decide to adjust this setting yourself, use a blue filter.

Adjusting the white balance means changing the amount of red, blue, and green in several different shades of gray. By correcting each of these shades, the overall color of the image is corrected to be as accurate as the TV can manage.

This can"t be adjusted without specialized equipment, so we don"t recommend trying to adjust this by eye. It also varies between units, even of the same model and size, so we don"t recommend copying someone else"s settings, including the values we provide on each review settings page.

Warmer color temperatures will make the picture look yellower, and cooler temperatures look bluer. We recommend using a warm temperature – that’s what professional calibrators use (it is the closest to the 6500k standard color temperature) - but you should choose whatever you like best.

This setting determines the amount of detail in blacks and shadows, with "Full" offering a bit more detail. It doesn"t really matter which setting you choose, as long as both devices are set to the same thing. As you can see in the above images, a mismatch will result in poor blacks.

Dynamic contrast is a software-based contrast enhancer. It doesn"t actually increase the absolute contrast of the picture (pure blacks and pure whites stay the same). Instead, it gives the impression of a greater contrast by darkening the shadows and brightening up the highlights. We recommend turning off this feature as it can cause color banding and changes the intended gamma curve.

Local

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey