arduino lcd touch screen code 2.8 factory

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The third example is a game. Actually it’s a replica of the popular Flappy Bird game for smartphones. We can play the game using the push button or even using the touch screen itself.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

As the code is a bit longer and for better understanding I will post the source code of the program in sections with description for each section. And at the end of this article I will post the complete source code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Now we need to make the buttons functional so that when we press them they would send us to the appropriate example. In the setup section we set the character ‘0’ to the currentPage variable, which will indicate that we are at the home screen. So if that’s true, and if we press on the screen this if statement would become true and using these lines here we will get the X and Y coordinates where the screen has been pressed. If that’s the area that covers the first button we will call the drawDistanceSensor() custom function which will activate the distance sensor example. Also we will set the character ‘1’ to the variable currentPage which will indicate that we are at the first example. The drawFrame() custom function is used for highlighting the button when it’s pressed. The same procedure goes for the two other buttons.

So the drawDistanceSensor() custom function needs to be called only once when the button is pressed in order to draw all the graphics of this example in similar way as we described for the home screen. However, the getDistance() custom function needs to be called repeatedly in order to print the latest results of the distance measured by the sensor.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

I have 2.8inch TFT SPI display (ILI9341 which work without problem). Problem is with touch panel (XPT2046) connected via SPI too. I attached connection (which I checked several times). I see correct value of push force, but X and Y coordinates are not real (most of time are 31 and sometimes can reach thousands). Why? Did anyone think of how to fix it?

The four sample codes: DisplayString, DrawGraphic, ShowBMP, and TouchPanel are used to display strings, graphics, pictures in BMP format, and touch pen functions.

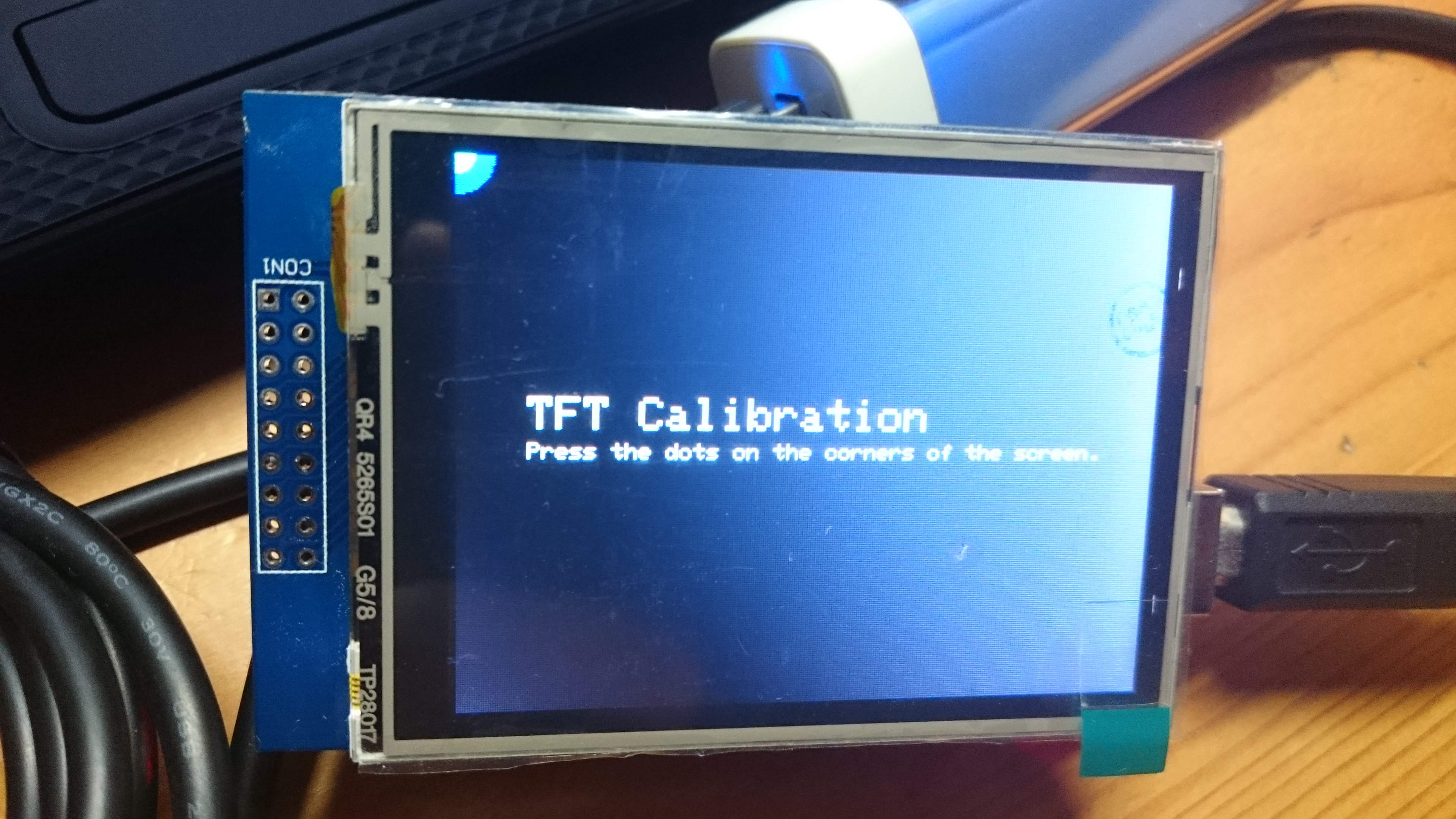

Before experimenting with the TouchPanel, the touchscreen must be calibrated according to the displayed prompts. Open the corresponding project, burn the program, and you will be prompted when running:

The demos are developed based on the HAL library. Download the program, find the STM32 program file directory, and open the STM32 with four project folders: DisplayString, DrawGraphic, ShowImage, and Touchscreen.

The four sample codes: DisplayString, DrawGraphic, ShowBMP, and TouchPanel are used to display strings, graphics, pictures in BMP format, and touch pen functions.

Before experimenting with the TouchPanel, the touchscreen must be calibrated according to the displayed prompts. Open the corresponding project, burn the program, and you will be prompted when running:

TFT Touch Shield V2.0 is a resistive touch screen, compatible with Arduino/Seeeduino/Arduino Mega/SAMD21 platforms. It can be used as display device or sketch pad. Compared with the previous version, 2.8""TFT Touch Shield V1.0, we upgraded the screen driver to a more professional chip, ILI9341 driver, providing different pin-saving SPI communication without sacrificing the data transmitting speed. Due to the communication method change, programs developed for the original version are needed for modification before being transplanted to the new version. With a SD card module integrated on this shield, this shield reserves capability for other expansions of your project.

Click to download the Touch Screen Driver,then please click on below button to download the library and install it, if you don"t know how to install an Arduino library, please refer to the tutorial (HOW TO INSTALL AN ARDUINO LIBRARY).

We recommend using Seeed_Arduino_LCD with internal flash chips larger than 128k. If you have a smaller flash device, I recommend using the TFT_Touch_Shield_V2.

Step1. Download and Install Seeed_Arduino_LCD. if you don"t know how to install an Arduino library, please refer to the tutorial (HOW TO INSTALL AN ARDUINO LIBRARY).

This is a versatile and Arduino/Seeeduino/Arduino Mega compatible resistive touch screen shield which can be used as display device, or sketch pad for user input/interface.

Compared with the previous version (2.8" TFT Touch Shield V1.0) we improved the screen driver with a professional chip (ILI9341) to provide the pin-saving SPI communication protocol without sacrificing the data transmission speed.

Function Description: The drawCircle function draws an empty circle with the center at the coordinates poX, and poY. The circle will be of radius r and the border color will be color. The color parameter is a 16-bit Red-Geen-Blue (RGB) integer, in the example code above the words YELLOW, CYAN, RED, and BLUE are defined as integers in the TFTv2.h file.

A color palette should be displayed on the right side of the screen to give the user different colors to choose from for his/her finger brush. The colors available in the palette are BLACK, RED, GREEN, BLUE, CYAN, YELLOW, WHITE, and GRAY1. Check out our artistic skills below!

The TFT Touch Shield"s backlight is on by default since its control circuit is directly powered by the 5V pin. If, however, you wish to control the backlight"s on/off state using the Arduino Digital I/O pin 7, a simple modification will have to be made:

Now controlling the backlight"s state is as easy as controlling an LED, upload the following code to the Arduino board to see how to toggle the backlight every 500ms (1/2 second):

I still remember when I post my first Instructable post years ago, it"s a project about Arduino, I made a phone with Arduino. It"s called ArduinoPhone, even today I can get some comments from it, and I am glad to help others to make their own phone with Arduino.

If you like Instructables and write instruction post, you will like this idea. I will share the process to make it, as well as the code, all things are open sources.

Combining Arduino and other shield modules, we make a mobile phone named Arduino Phone. Meanwhile, we printed a shell for it with the 3D printer. Although it"s not such fine as you think, even a little bit clunky, it"s still very cool. That is the point this is a cell phone made by ourselves.

While, we can"t install Arduino Phone Apps limited by Arduino. So, if you want to play Angry Birds, then you need to do some big modifications on Arduino Phone. :)

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big (7" diagonal) bright (14 white-LED backlight) and colorfu 800x480 pixels with individual pixel control. As a bonus, this display has a optional resistive touch panel with controller XPT2046 attached by default.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (Due/Mega 2560). This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

For 7 inch screen,the high current is needed.But the current of arduino uno or arduino mega board is low, an external 5V power supply is needed. Refer to the image shows the external power supply position on shield ER-AS-SSD1963.

If you"ve had a lot of Arduino DUEs go through your hands (or if you are just unlucky), chances are you’ve come across at least one that does not start-up properly.The symptom is simple: you power up the Arduino but it doesn’t appear to “boot”. Your code simply doesn"t start running.You might have noticed that resetting the board (by pressing the reset button) causes the board to start-up normally.The fix is simple,here is the solution.

Looking for a bigger screen to interface with the Arduino Uno? Bigger than the 2.4″ TFT LCD screen, this shield is able to display a little more information than the 2.4″ screen. In this tutorial, we’ll be looking at how we would interface the 2.8″ TFT LCD Touchscreen Shield with an Arduino Uno.

As this is an Arduino Shield, just attach the shield to the Arduino Board. (Uno, Mega, etc.) But in this tutorial, we’ll be connecting the shield to an Arduino Uno.

We’ll be using Adafruit’s GFX and TFTLCD library to interface the LCD shield with Arduino Uno. Download the library, extract the rspective folders and place it in your Arduino libraries directory.

Before using the TFT LCD Shield, we should first calibrate the touch screen. As there weren’t any calibration sketch provided in the librarie’s example, I wrote a simple calibration sketch to calibrate the touch screen. With this sketch, adapted from Adafruit’s tftpaint example sketch, it will display the offset that will remap the values of the raw values of the TFT resistors to the coordinates of the screen.

The values displayed at the end of the calibration will be used to determine the TS_MINX,TS_MINY, TS_MAXX & TS_MAXY variables. These variables are actually the resistance value of the TFT screen, which will be “converted” into coordinates relative to the screen:p.x = map(p.x, TS_MINX, TS_MAXX, 0, tft.width());

Upload the following code below to obtain the offset values. Remember to note down the respective values (TS_MINX,TS_MINY, TS_MAXX & TS_MAXY), as it is needed for the next section of the tutorial.// Paint example specifically for the TFTLCD breakout board.

After the calibration is done and the (maximum & minimum) X/Y resistance values recorded, we’ll proceed on to running the tftpaint demo. Open up tftpaint sketch from Adafruit’s TFTLCD examples.

When you draw something on the touch screen with the original sketch, the X coordinates will be inverted. To fix it, we’ll have to flip the mapping function from :// scale from 0->1023 to tft.width

After the changes has been made, save the sketch and upload to the Arduino. And Viola! You should be able to draw on the screen without too much offset.

Open up your serial monitor & see whther the library is able to detect the driver. If the Serial Monitor returns something like this:Unknown LCD driver chip: 0x00

You can try hard-coding the driver of the LCD Shield specific to the shield you have. You can figure it through these following methods:Turn to the back of the shield & look for the chip ID

After you have figured out the driver ID, we’ll hard code the driver ID. Modify this line of code (at line 92) from this:uint16_t identifier = tft.readID();

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big (2.8" diagonal) bright (4 white-LED backlight) and colorful (18-bit 262,000 different shades)! 240x320 pixels with individual pixel control. It has way more resolution than a black and white 128x64 display. As a bonus, this display has a resistive touchscreen attached to it already, so you can detect finger presses anywhere on the screen.

*Go to Australia post delivery time calculation to get various Australia post service in your area please use our shipping postcode Rosanna, 3074 as the "from" address - https://auspost.com.au/parcels-mail/delivery-times.html?ilink=tools-open-deliv-times.Shipping Destinations

This is a 2.8” TFT Resistive Touchscreen Display. The module, with a resolution of 320x240, adopts ILI9341 as driver IC and SPI (4-line) communication mode. The board integrates touch chip XPT2046, which converts the touch data collected by the AD to SPI data. The module also integrates an SD card slot allowing you to easily read the full-color bitmap. There are two modes of wiring supplied, normal pin header wiring and GDI. The latter one requires to work with a main controller board with a GDI interface (e.g. FireBeetle-M0). You can use it with only one FPC line plugging in, which reduces the complexity of the wiring. Furthermore, it features high resolution, wide viewing angle, and simple wiring, which can be used in all sorts of display applications, such as, IoT controlling device, game console, desktop event notifier, touch interface, etc.

* @brief Constructor When the screen uses hardware SPI communication, the driver IC is ILI9341, and the screen resolution is 240x320, this constructor can be called

This is UI control demo -- gesture. At the start, click the textbox. After the cursor appears in the text box, slide gestures on the screen (up, down, left, right, double click, single click). The instruction of the corresponding gestures will show in the textbox.

* @brief Constructor When the screen uses hardware SPI communication, the driver IC is ILI9341, and the screen resolution is 240x320, this constructor can be called

Touchscreen displays are everywhere! Phones, tablets, self-serve kiosks, bank machines and thousands of other devices we interact with make use of touchscreen displays to provide an intuitive user interface.

Today we will learn how touchscreens work, and how to use a common inexpensive resistive touchscreen shield for the Arduino. Future videos and articles will cover capacitive touchscreens, as well as a touchscreen HAT for the Raspberry Pi.

Although touchscreens seem to be everywhere these days we tend to forget that just a few decades ago these devices were just science fiction for most of us. For many people, the touchscreen concept was introduced 30 years ago in the television seriesStar Trek: The Next Generation.

Eric A Johnson, a researcher at the Royal Radar Establishment in Malvern UK is credited for describing and then prototyping the first practical touchscreen. HIs device was a capacitive touchscreen, and it’s first commercial use was on air traffic control screens. However, the touchscreens used then were not transparent, instead, they were mounted on the frame of the CRT display.

In 1972, a group at the University of Illinois filed for a patent on an optical touchscreen. This device used a 16×16 array of LEDs and phototransistors, mounted on a frame around a CRT display. Placing your finger, or another solid object, on the screen would break two of the light beams, this was used to determine the position and respond accordingly.

The first transparent touchscreen was developed atCERNin 1973. CERN is also home to the Large Hadron Collider, and this is where Tim Berners-Lee invented the World Wide Web.

The first resistive touchscreen was developed by American inventor George Samuel Hurst in 1975, although the first practical version was not produced until 1982.

In 1982 theUniversity of Toronto’sInput Research Group developed the first multi-touch touchscreen, a screen that could interpret more than one touch at the same time. The original device used a video camera behind a frosted piece of glass. Three years later the same group developed a multi-touch tablet that used a capacitive touchscreen instead.

The first commercial product to use a touchscreen was a point-of-sale terminal developed by Atari and displayed at the 1986 COMDEX expo in Las Vegas. The next year Casio launched theCasio PB-1000 pocket computerwith a touchscreen consisting of a simple 4×4 matrix.

LG created the world’s first capacitive touchscreen phone, theLG Pradaused a capacitive touchscreen and was released in early 2007. A few weeks later Apple released its first iPhone.

Most early touchscreen devices were resistive, as this technology is generally less expensive than capacitive screens. However, nowadays capacitive screens are more common, being used in the majority of smartphones and tablets.

Although they were invented after capacitive touchscreens, resistive touchscreens are probably the most common type used by hobbyists. The reason for that is the price and performance, resistive touchscreens are cheaper than capacitive ones and they are generally more accurate.

A resistive touchscreen consists of two thin layers of material, separated by a tiny gap. Spacers are used to maintain the gap and keep the two sheets apart.

In operation, the resistance between the two sheets is measured at different points. Pressing down upon the tip sheet will change that resistance, and by comparing the measurement points it can be determined where the screen was pressed. Essentially, it creates a pair of voltage dividers.

In a 4-Wire Analog touchscreen, there are two electrodes or “busbars” on each of the conductive layers. On one layer these electrodes are mounted on the two X-axis sides, the other layer has them on the two y-axes.

This is the most inexpensive method of designing a resistive touchscreen. The touchscreen display that we will be working with today uses this arrangement.

In a 5-Wire Analog touchscreen, there are four wires, one connected to a circular electrode on each corner of the bottom layer. A fifth wire is connected to a “sensing wire”, which is embedded in the top layer.

Touching any point on the screen causes current to flow to each of the bottom electrodes, measuring all four electrode currents determines the position that the screen was touched.

This 8-Wire Analog touchscreen uses an arrangement of electrodes identical to the 4-Wire variety. The difference is that there are two wires connected to each electrode, one to each end.

Capacitive touchscreens are actually older technology than resistive displays. They are commonly used in phones and tablets, so you’re probably familiar with them.

The capacitive touchscreen makes use of the conductivity of the human body. The touchscreen itself consists of a glass plate that has been treated with a conductive material.

The surface capacitive touchscreen is the most inexpensive design, so it is widely used. It consists of four electrodes placed at each corner of the touchscreen, which maintain a level voltage over the entire conductive layer.

When your finger comes in contact with any part of the screen, current flows between those electrodes and your finger. Sensors positioned under the screen sense the change in voltage and the location of that change.

This is a more advanced touchscreen technique. In a projected capacitive touchscreen transparent electrodes are placed along the protective glass coating and are arranged in a matrix.

One line of electrodes (vertical) maintain a constant level of current. Another line (horizontal) are triggered when your finger touches the screen and initiates current flow in that area of the screen. The electrostatic field created where the two lines intersect determine where it was touched.

The module we will be experimenting with today is a very common Arduino Shield, which is rebranded by many manufacturers. You can easily find these on Amazon, eBay or at your local electronics shop.

You can also just use the shield as an LCD display and ignore the two other components, however, if you intend on doing that it would be cheaper just to buy an LCD display without any touchscreen features.

You do need to be looking directly at the display for best color accuracy, as most of these inexpensive LCD displays suffer from distortion and “parallax error” when viewed from the side. But as the most common application for a device like this is as a User Interface (UI) this shouldn’t be a problem.

This shield uses a 4-wire analog resistive touchscreen, as described earlier. Two of the wires (one X and one Y) are connected to a couple of the analog inputs on the Arduino. The analog inputs are required as the voltage levels need to be measured to determine the position of the object touching the screen.

You should note that the microSD card uses the SPI interface and is wired for the Arduino Uno. While the rest of the shield will function with an Arduino Mega 2560, the SPI connections on the Mega are different, so the microSD card will not work.

The last paragraph regarding the microSD card may make you think that an Arduino Uno is the best choice for the Touchscreen Display Shield. And it you require the microSD card then it probably is a good choice.

But using an Arduino Uno with this shield does have one big disadvantage – a limited number of free I/O pins. In fact there are only three pins left over once the card has been plugged in:

If your product is self-contained and doesn’t need many (or any) I/O pins then you’ll be fine. But if you need more pins to interface with then an Arduino Mega 2560 is a much better choice. It has a lot of additional analog and digital pins.

So if you don’t require the microSD card, or are willing to hook up a separate microSD card, then the Arduino Mega 2560 is a better choice for most applications.

As there are three devices on the shield you will need libraries for each of the ones you want to use. TheSD Libraryis already installed in your Arduino IDE, so you will just need libraries for the display and touchscreen.

For the LCD you will have a lot of choices in libraries. Most of these shields come with a CD ROM with some sketches and libraries, so you can use the LCD libraries there. Bear in mind however that code on these CD ROMs tends to be a little dated, you may have better lick on the vendors website.

This useful resource contains code, libraries and datasheets for a wealth of LCD displays, both touchscreen and non-touchscreen. You’ll also find code for some common OLED displays as well.

I ran my touchscreen through all of the code samples I obtained from the LCD Wiki. It’s an interesting exercise, and by examining the sketch for each demo you can learn a lot about programming the display.

The first example is a very simple color “sweep” test. Navigate to theExample_01_Simple_testfolder and open the folder for your Arduino controller. Navigate down until you find the “ino” file and load it.

This test does not make use of any of the extra libraries, it drives the LCD directly. It is only a test of the LCD display, it does not make use of the touchscreen membrane.

You’ll find this example in theExample_02_clear_screenfolder, the sameclear_Screen.inoexample is used for both the Uno and Mega so there are no separate folders.

This example does use the custom libraries, and is a very good way to learn how to use them. You’ll note that theLCDWIKI_GUI.hlibrary is loaded, which is the graphics library for the LCD display.

Another library, LCDWIKI_KBV.h, is loaded as well. This is a hardware-specific “helper” library that provides an interface to the actual hardware for the other libraries.

When you run this example the results will be similar to the first one, a series of colors will sweep across the screen. In this case the colors are different, and they vary in speed.

A look at the loop will show how this is done. TheLCDWIKI_GUI.hlibrary has a “Fill_Screen” method that fills the screen with an RGB color. You can specify the color in both hexadecimal or decimal format, the example illustrates both ways.

The example itself is in a folder labeled “Example_03_colligate_test” and the code itself is in the colligate_test.ino file. I suspect a translation error resulted in the name!

This sketch uses a number of functions from theLCDWIKI_GUI.hlibrary, along with some custom functions to draw geometric shapes. It then displays a cycle of graphs, shapes, and patterns on the LCD display.

The result of running the sketch is the display screen fills with rows of hexadecimal values while the background alternates between blue and black and the orientation (or “aspect”) changes. If you stand back to see the “big picture” you’ll note that the color values form “number patterns”.

In addition to the graphics and “helper” libraries that have been used in the previous examples this sketch also uses theTouchScreenlibrary to read screen interaction. This was one of the libraries included in the original ZIP file.

Note that this demo will only work on the Arduino Uno, as the microSD card uses the SPI bus and is wired to the Arduino Uno SPI port. The Arduino Mega 2560 board uses different pins for SPI.

The image needs to be in bitmap format as this format defines several bytes for each individual pixel in the image. There are four 320×480 sample images included in the code sample, you can also use your own if you (a) keep them the same size and (b) give them the same names.

Another thing you will notice is the speed at which the images draw, which is not particularly impressive. The clock speed of the Arduino has a lot to do with this, as does the method used to extract each individual pixel from the image.

This example draws some small “switches” on the display. The switches are active and respond to touch. There are slide switches, a push button, some radio buttons and some text-based expandable menus to test with.

The Touch Pen example is actually a pretty decent little drawing application. You can draw whatever you want on the main screen area. A set of buttons allow you to set the stylus color and pen width.

While the sample code is a bit difficult to follow it’s worth the effort, as it shows you how to create a dynamic menu system. Touching the stylus color button, for example, will open a new menu to select colors. This is a handy technique that you’ll need to know when developing your own user interfaces.

The Calibration utility lets you calibrate the resistive touchscreen. It achieves this by placing a number of crosses on the screen. You can calibrate the screen by using the stylus to touch the center of one of the crosses as accurately as you can.

After you touch one of the cross points the sketch runs through a calibration sequence, during which time you need to continue to touch the cross point. You’ll be informed when it is finished.

After calibration, the sketch will display a number of calibration values for the resistive touchscreen. These values can be used in your future sketches to make the touchscreen more accurate.

The examples are a great way to demonstrate the capabilities of your touchscreen. But to really put your interface to work you’ll need to write your own interface code.

Writing a touchscreen interface can be challenging. I would suggest that you start by modifying one of the example codes, one that is closest to your desired interface.

For my experiment, I will be using an Arduino Mega 2560 to drive three LEDs. I used a Red, Green and Blue LED but really any colors will work – I just wanted my LED colors to match my button colors.

The digital I/O connector at the back of the Mega is still accessible even when the touchscreen display shield is installed, so I used three of those connections for the LEDs. I hooked up each LED anode through a 220-ohm dropping resistor and connected them as follows:

The sketch is based upon the telephone keypad sketch. I modified it to eliminate the other functions and just display three buttons. Then I added code to toggle the LEDs.

TheAdafruit TFTLCD Libraryis used. It uses the previous library to provide an easy method of drawing on the LCD display. It works with LCD displays that use driver chips like the ILI9325 and ILI9328.

TheTouchScreenlibrary comes in the code that you downloaded from the LCD Wiki or from the CD ROM included with your touchscreen shield. As its name implies it is used to interface with the touchscreen.

We also define some “human-readable” colors to use within our code, it’s a lot simpler and more intuitive than providing RGB values. I’ve includes all of the colors from the phone sketch I used as the basis for this code, so if you want to change button or background color you can easily do it.

Next, we define some touchscreen parameters. You can ‘fine-tune” your code here by using parameters from your own display, which you can obtain from the Calibration Sketch we ran from the sample code. Otherwise, just use the values here and you should be fine.

Now, still in the Setup, we set up the LCD display rotation and fill the background in black. Next step is to draw our buttons. Once we are done that the Setup is finished, and our screen should be displaying the three buttons on a black background.

The loop is where we will be monitoring the screen for keypresses. If we get one, and if its position corresponds to a button location, then we need to toggle the correct LED.

We start by triggering the touchscreen, which is done by toggling pin 13 on the Arduino high. If something is touching the screen we read it and assign it to a TSPoint object named “p”.

We then need to reset the pin modes for two of the touchscreen pins back to outputs. This is done as these pins get shared with other LCD display functions and get set as inputs temporarily.

Now we check to see if the pressure on the screen was within the minimum and maximum pressure thresholds we defined earlier. If it makes the grade then we determine where exactly the screen was pressed.

Now that we know where the screen was pressed we need to see if the pressure point corresponds to one of our buttons. So we cycle through the button array and check to see if the pressure point was within 10 pixels of our button location.

Load the code into your Arduino IDE and upload it to your Arduino Mega 2560. Make sure you have the correct processor-type set in your Arduino IDE, especially if you are used to working with the Uno!

This is a pretty simple demo but it does illustrate how to create a simple IDE. You can expand upon it to add more buttons, or to change the button colors or shapes. And, of course, you don’t have to light LEDs with your buttons, they can control anything that you can connect to your Arduino.

Touchscreen interfaces are used in a number of products, and now you can design your own devices using them. They can really make for an intuitive and advanced display and will give your project a very professional “look and feel” if done correctly.

This is not the only time we will look at touchscreen displays. Next time we’ll examine a capacitive touchscreen and we’ll explore the Adafruit Graphics libraries further to create some very fancy displays with controls and indicators.

Let"s learn how to use a touchscreen with the Arduino. We will examine the different types of touchscreens and will then create a simple interface using an inexpensive Arduino touchscreen shield.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey