lcd module vex supplier

VEX Robotics is educational robotics for everyone. VEX solutions span all levels of both formal and informal education with accessible, scalable, and affordable solutions. Beyond science and engineering principles, VEX encourages creativity, teamwork, leadership, and problem solving among groups. It allows educators of all types to engage and inspire the STEM problem solvers of tomorrow!

Visit our new website www.idesignsol.ca. Free Shipping on orders over $250. Authorized VEX Robotics dealer in Canada only. Please note: some products may no longer be available in your region. Please email us for questions or concerns. If you"re waiting on a VEX order you placed with us, and you reside in the US, your order will be fulfilled. Additional Note: For any items that you are ordered on PRE-ORDER or out of stock, you are agreeing to our Pre-Order Policy as detailed on our Terms & Conditions page.

@sabarrett328 I have a lot of V4 parts and discontinued parts available, including the LCD screen, IME’s, and the VEX Speaker. If you need ANYTHING in related to V4, even spare motors if you need them, I have it and I am willing to ship it to you for free. Contact me by PM and we can discuss further about this.

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

Normally it was defined 4 angles to correspond with 3, 12, 9, and 6 o’clock respectively. So, you can find the 6 o’clock or 12 o’clock parameter in the LCD datasheet.

Viewing Angle is the angle with respect to the Z-axis in a certain direction and marked by θ (θU means upper View Angle). LCD Viewing Angle describes the maximum watching angle, and it is one of the key indicators with the display module.

The LCD bias angle is the angle perpendicular from which the display is best viewed. (See Fig.2) This angle is determined when the display is designed and can be set at any angle or orientation. The orientation of the bias angle of LCD displays is often stated with reference to a clock face. If the offset is above the display, it is referred to as a 12:00 or Top view.

The LCD viewing angle is the angle formed on either side of the bias angle, where the contrast of the display is still considered acceptable. Generally, this contrast is specified as 2:1 for monochrome LCD and 10:1 for color LCD.

Generally, displays are optimized for straight-on viewing. Either a 6:00 or 12:00 module may be used, and the contrast voltage can be adjusted slightly to optimize the display for that viewing position. In the above example, the viewing angles of both 6:00 and 12:00 modules actually overlap the perpendicular (or straight on) viewing position.

Generally, a 10K ohm potentiometer is then connected between VDD and VSS in a single supply module, or from VDD to the negative rail in a dual supply module. The wiper of the pot is connected to the VL input of the module. (See Fig.3)

The LCD is positioned at the nominal viewing position and the pot is adjusted to obtain the desired LCD appearance. The voltage on the VL pin is now measured and a pair of resistors are chosen to produce this voltage in the production units.

– Positive LCD to Negative LCD (When the LCD is used indoor or dark environment, the contrast will increase a lot, but it will not display well with ambient light only, it is also more expensive)

When a LCD is high density with the segments/icons or very crowded, some customers also complains the viewing angle or contrast are not good. The reason is for crowded display, the layout can be long and thin. The voltage drop along the layout can be big. The solutions are:

Want to find out more about LCD, OLED & TFT solutions? – Check out our knowledge base, where ypu can find tips on electronics operating temperature and differences between LCD and TFT!

After successfully creating a project in VEXcode V5 to move the arm mounted on the VEX V5 Workcell, it is time to examine things closer and relate them to the industrial robots used in manufacturing. In this reading we will explore the following topics: a manufacturing robot’s controller, operating systems, motion control, and robot dynamics.

In this example, you will learn how to use VEX Gyroscope and VEX LCD Display to create an application where the robot turns by an angle selected by the user. In this application, the LCD screen displays three angles 45, 90 and 120 corresponding to the left, center and right LCD buttons. The user can select either of the three angles by pressing the corresponding LCD button or can select a combination of two or more angles by pressing the corresponding buttons together. The 4-wheeled robot then takes a turn in the anti-clockwise direction until the turn angle specified by the user is completed. To make the robot turn, the left and right motors are provided with speed input such that the motors rotate in opposite direction. The figure below illustrates this application.

Below is a figure of a 4-wheel robot platform with gyroscope sensor and LCD display and two DC motors connected to the two wheels and attached to the VEX microcontroller.

1. The two DC motors drive the left and right set of wheels on the robot platform. The motors are installed on the robot with the motor shafts facing outwards to enable connecting the wheels to the shafts. Connect the left DC motor and right DC motor to motor pins 4 and 3 respectively on the VEX microcontroller. Use the Motor Controller 29 cables to establish the connection between the motor leads and the pins on the VEX microcontroller. Connect them as described on Page 4 of the VEX Microcontroller and VEXnet Joystick User Guide.

2. Mount the VEX Gyroscope sensor on the front towards the center of the 4-wheel robot platform. Connect a 3-wire cable to the gyroscope such that the black wire of the cable is plugged into the pin near the "B" printed on the sensor as shown in the figure below. Plug the other end of the 3-wire cable into analog port 1 of the VEX microcontroller.

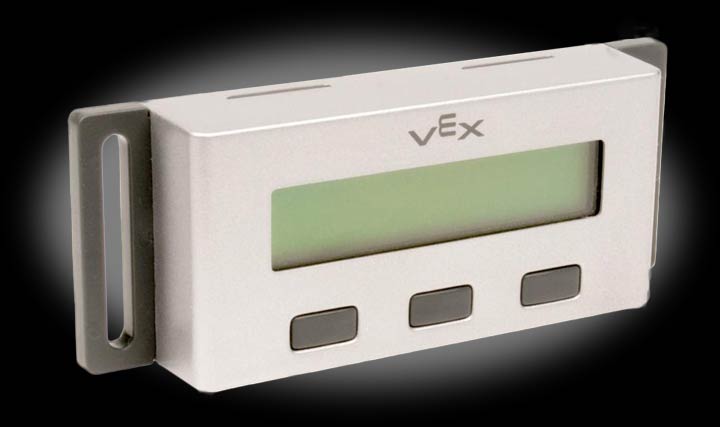

3. Mount the VEX LCD Display on the 4-wheel robot platform. Plug the 3-pin ends of the serial Y-cable to the LCD Display, with the yellow wire connected to the RX port and the white wire connected to the TX port of the LCD Module. Plug the 4-pin end of the serial Y-cable into UART1 port on the VEX microcontroller.

The VEX gyroscope sensor output is affected by external factors such as temperature, mechanical vibration and motor magnetic field influence. This variation in gyroscope output is referred to as drift. The drift in gyroscope value can be corrected and the sensor can be calibrated to provide accurate readings using the Calibration multiplier parameter for the Gyroscope block. A default value of "196" for Calibration multiplier is used for the purpose of calibrating the gyroscope. This value may need to be increased or decreased for the gyroscope used so that the readings are accurate. In this task, you will learn how to calibrate the gyroscope sensor so that its angle output matches with the physical turn angle of the robot. The 4-wheeled robot is made to turn by an angle of 90 degrees in anti-clockwise direction with the help of the gyroscope reading. Based on how the robot rotates, i.e. beyond 90 degrees or less than 90 degrees, the Calibration multiplier parameter is increased or decreased until the gyroscope output angle matches with the physical turn angle made by the robot.

The value for the parameter Analog port for the Gyroscope block is chosen as per the hardware connection in Task 1. The parameter Calibration multiplier for the Gyroscope block has a default value of "196". The parameter Motor Channel for the Left Motor block is chosen as "4" and for the Right Motor block as "3" as per the hardware connections in Task 1. Similarly, the value for the parameter UART port for the LCD screen is chosen as "UART1".

In this model, the output of Gyroscope block is provided as input to the LCD Screen block. This will cause the Gyroscope block output to be displayed on the LCD Display. The output of Gyroscope block increases for anti-clockwise rotation and decreases for clockwise rotation.

9. Disconnect the USB cable from the VEX microcontroller and connect the VEXnet key to the VEX microcontroller. Place the robot on a sheet which has a right angle drawn on it similar to what is shown in the figure below.

10. Turn ON the VEX Microcontroller and the Gamepad to pair the VEXnet keys. Do not move the robot after turning ON the microcontroller for proper initialization of the gyroscope sensor. Once the VEXnet keys are paired, the robot begins to turn in the anti-clockwise direction. The LCD Display displays the output of Gyroscope block. When the robot stops turning, observe the value displayed on the LCD Display and measure the physical angle by which the robot has turned.

11. If the physical turn angle made by the robot is less than what is read by the gyroscope as observed from the LCD Display, decrease the value of the parameter Calibration multiplier for the Gyroscope block. If the physical turn angle made by the robot is more than what is read by the gyroscope, increase the value of the parameter Calibration multiplier.

In this task, you will learn how to use the LCD Display to display the robot turn angles and choose the desired angle of turn by pressing the appropriate LCD button. You will also learn how to use gyroscope to turn the robot by the specified number of degrees.

The value for the parameter Analog port for the Gyroscope block is chosen as per the hardware connection in Task 1. The three LCD Button blocks in the model have the values "Left", "Center" and "Right" respectively for the parameter Button. The LCD Button blocks and the LCD Screen blocks in the Enabled Subsystems have the value of "UART1" for the parameter UART port as per the hardware connections in Task 1. Similarly, the parameter Motor Channel for the Left Motor block is chosen as "4" and for the Right Motor block as "3".

The outputs of the three LCD Button blocks corresponding to the three buttons are provided as inputs to the Stateflow Chart. The Stateflow® chart implements the logic to output the angle of turn based on the button(s) pressed using various states. The default output "Angle" of the Stateflow chart is zero. It also includes the logic to reset the angle of turn to zero when the required degree of turn is completed. The implementation of the logic to output the angle of turn or reset the angle of turn is shown in the figure below.

The inverted comparison output is used as the external signal to reset the Gyroscope block output. This causes the gyroscope reading to be reset when no angle is selected via pressing the LCD buttons or the selected angle of turn is completed.

5. Disconnect the USB cable from the VEX microcontroller and connect the VEXnet key to the VEX microcontroller. Place the robot on the ground. Turn ON the VEX microcontroller and the Gamepad to pair the VEXnet keys. Do not move the robot while the VEXnet keys are in the process of pairing. Once the VEXnet keys are paired, the LCD screen displays the turn angle options. Select the desired angle by pressing the corresponding LCD button(s). You will then observe that the robot begins to turn and stop once the specified angle of turn is completed.

GREENVILLE, Texas, April 13, 2015 -- The 2015 VEX Robotics World Championship kicks off this week! Presented by the Robotics Education and Competition (REC) Foundation and the Northrop Grumman Foundation, this season finale event showcases the largest and fastest growing educational competitive robotics program in the world! On April 15-18, over 15,000 participants from over 27 countries will come together to put their engineering expertise to the test as they seek to be crowned the 2015 VEX Robotics World Champions.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey