nodecmu tft lcd display to esp32 supplier

The TFT display is a kind of LCD that is connected to each pixel using a transistor and it features low current consumption, high-quality, high-resolution and backlight. This 2.8-inch full color LCD has a narrow PCB display. The resolution is 320×280 pixels and it has a four-wire SPI interface and white backlight.

As you all know the are a few variants of the 1.8" TFT on the internet. With the genuine Adafruit lcd-s there are usually no problems. But when using fake ones(usually from Aliexpress) you have to make some adjustments.

Bodmers TFT_eSPI library is very awsome and rich funcionality. And the best part is that he made it to handle the pixel offsets depending on wich kind of 1.8" TFT you are using.

Then uncomment the tft height an width. And then in my case(REDTAB) uncomment for eg: #define ST7735_REDTAB. After this save it for the moment and compile sketch and upload to board. To be sure i have defined the parameters in the sketch too.This is a bit long procedure, cause you have to compile and upload the sketch every time to board untill the offset is gone, but it is worth the experimenting. For editing the h. files i strongly suggest Wordpad. Images included.

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

After uploading the code, open the Serial Monitor at a baud rate of 115200. Press the ESP32 EN button. The I2C address should be displayed in the Serial Monitor.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

Then, you need to set the display address, the number of columns and number of rows. You should use the display address you’ve found in the previous step.

To display a message on the screen, first you need to set the cursor to where you want your message to be written. The following line sets the cursor to the first column, first row.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

The messageToScroll variable is displayed in the second row (1 corresponds to the second row), with a delay time of 250 ms (the GIF image is speed up 1.5x).

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

Then, in the setup(), create a custom character using the createChar() function. This function accepts as arguments a location to allocate the char and the char variable as follows:

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

We hope you’ve found this tutorial useful. If you like ESP32 and you want to learn more, we recommend enrolling in Learn ESP32 with Arduino IDE course.

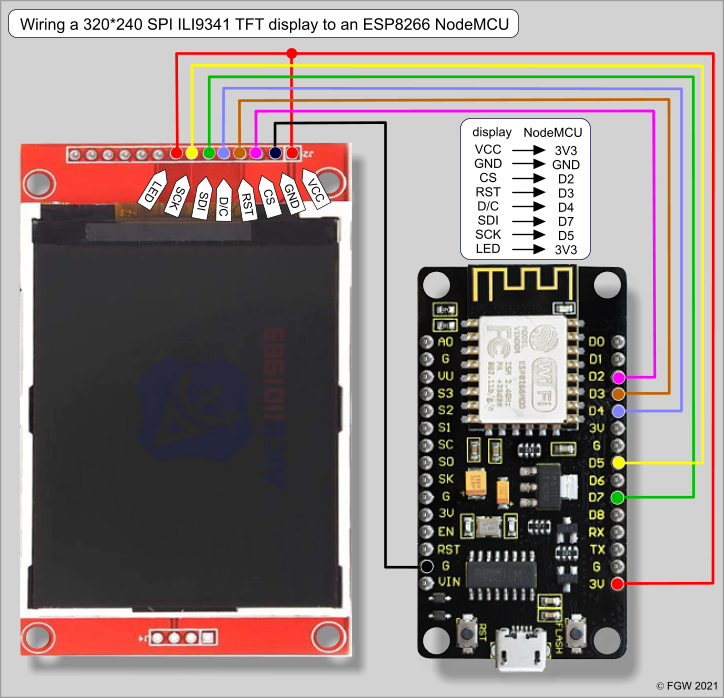

Connecting a colour screen over SPI to ESP32 based MCU’s is a straight forward process and is extremely similar to using one with the Arduino or ESP8266. Firstly though you need to ensure that you have set up your ESP32 to work with the Arduino IDE, see this articleif you have not already done so and then come back here.

The ScreenThe screen I chose is shown below, finding one very similar will probably make your build easier, but as long as your screen is an SPI screen using the ST7735 driver chip then you should be good to go.

As can be seen from the connections it accepts both 5V and 3.3V with the 5V side having a pre-soldered pin header. This particular one was ordered from Ali-Express and had a picture of a cartoon boy on the screen. I suspect buying any with the same pin connections will give you the same screen as the one above.

For my new Froggerproject (after the Space Invaders one), I wanted a screen where I could directly port the Arcade graphics and screen layout without too much messing about re-designing graphics. But for the price point I wanted this proved impossible. Most arcade games of the early 80’s did not go above 256 pixels in any give direction so porting the graphics should be easy I thought. At half the resolution (128×128) I hope that transferring the graphics will not be too tedious and that in most cases I can simply reduce the number of pixels in each image by half.

Due to the planned game being more advanced than Space Invaders I needed a processor with more memory and speed than the Arduino could offer. Enter the ESP32 was the obvious choice, it has more power than the ESP8266 (not that that was an issue) and more importantly it has loads of input pins, cool! Wifi is also available but will not be required for this project unless we implemented a World High Score Table perhaps! I’m using a NodeMCU development board which brings out all the ESP32’s pins to headers and enables the board to be plugged into a 5V USB power source. It also adds a USB controller chip to handle program transfers with the host computer.

Connections – very careful now!Looking at the back we can see +3v3 (this screen can be powered from 5v as well), several grounds (Gnd) and SCL/SDA. This shouldmean that this device is an I²C device and can be easily connected to our Arduino. Err… Think again. This screen gave me no end of problems as connecting it to the I²C connections and running any demo I could find on the internet did not get anything on the display. I went back and looked at the listing for this device, it stated SPI Bus not I²C ! So it began to become apparent that this screen had an SPI interface. SCL and SDA would logically seem to be SPI clock and data (MOSI) respectively but other pin labels didn’t match normal SPI protocol labels. Reading several resources for other different screens and looking at the source code for the examples in the Arduino IDE Examples library lead me to find the correct connections to power and use this screen.

Power is self explanatory. LED adds a little extra brightness to the screen but it does still work if not connected. I’ve seen resistors added in series here and even variable ones to vary the brightness but I’ve ran it directly connected on this screen with no issues and wouldn’t want it dimmer as its not ultra bright. Connect it to the 5V pin of the NodeMCU to get 5V from the USB connection, this will make the screen nice and bright and clear. SCL is the SPI clock and goes to the NodeMCU’s hardware SPI pin (pin GPIO18). SDA is actually the SPI MOSI connection and goes to the NodeMCU’s SPI MOSI pin (GPIO23). RS is a Regsiter Select pin for ST7735 driver chips, this maps to a variable called TFT_DC in the Adafruitcode (explained later) that I was using for testing. This controls whether we are sending a command to the ST7735 chip or actual data. I think that Adafruit call it DC meaning Data Control, but I’m not sure. On some boards it may even be referred to as A0. For our purposed we connect it to GPIO2. RST is the screen reset and and is connected to pin GPIO4. These last two can connect to any NodeMCU pins that are not used for other functions. CS is Chip Select (usually referred to as Slave Select in the SPI protocol) and again can connect to any pin but I use the official SPI SS for the ESP32, GPIO5. If this is pulled low then this device can receive or send data on the SPI bus. If only one device in your design you could pull this low permanently and not use GPIO5.

Driver CodeWhen presented with this board (as mentioned above) it was difficult to work out where wires should go and what driver software I needed for the display. Looking at the solitary chip on the board and Googling revealed nothing. So I went back to the sellers listing and found buried deep in a sub-page description the phrase “7735 drive”. Googling this revealed Adafruit had written some drivers for this chip for a board they had created (which also had an SD card slot on it as well). It was not surprising I didn’t find the 7735 chip on the board as this chip is designed to by embedded onto the back of the screen. It was being armed with this source code and other web pages dealing with different chip sets but similar displays that I managed to work out (with a little trial and error) the connections talked about previously above. Initially I used the Adafruit driver code but gave issues with this screen (as it was designed to work with the one they sell). Look below.

Also when the screen orientation is rotated (in software) so you can write to the display any way up then more things either correct themselves or mess up again.

Fixing the ST7735 driver to work with this screen.So we have some work to do still to make this work well with our display. The driver we have used to get this up and running was not designed for this display exactly. Things appear clipped and off screen. There were other issues with colour (i.e. red was blue and blue was red amongst other colour problems) and other graphics routines were not correct. I won’t bore you with all the tiny re-writes I did but just supply you with the new driver for this particular display. This driver is very specific, i.e. only targeting this display and resolution but it may well work with many other similar displays. At the time of writing I have no other displays to test with but will be expanding the driver code as and when required. The full driver code is available from the link below, add it into your Arduino in the usual manner (Adding libraries to the Arduino IDE.)

Load up the example code that should now be available at “Files->Examples->XTronical ST7735 Library->GraphicsTestESP32”. This is basically the Adafruit example with just some tiny changes (It goes through all the tests for each rotational position of the screen) so that it uses the new driver file and slightly altered initialisation routine.

//#define ILI9488_DRIVER // WARNING: Do not connect ILI9488 display SDO to MISO if other devices share the SPI bus (TFT SDO does NOT tristate when CS is high)

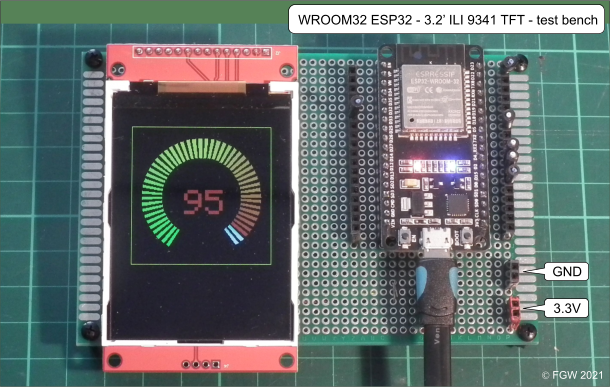

Many Arduino projects require adequate display of what is being monitored. Think of time, temperature, humidity, pressure, sound, light, voltages, or combinations of recorded data in a weather station. With the addition of fast and capable ESP32 microcontroller boards to my personal ‘fleet’ my collection of good old Arduino Unos with their TFT display shields seemed prone to gather dust. The ESP32 combines well with TFT displays through a 4-pin SPI interface* while the Uno shields have parallel interfaces that feature 28 pins of which a minimum of 13 is necessary for the daily display business (see figure 2). A parallel interface is generally faster than a SPI interface. The prospect of a bunch of shield displays with fast parallel interface parked forever in a deep drawer was a stimulus for me to start a project to connect these shields to an ESP32. Fortunately there are several solutions available of which I selected the one proposed by Alberto Iriberri Andrés at https://www.pangodream.es/ili9341-esp32-parallel. However, the nightmarish prospect of connecting shield after shield with an ESP with unwieldy Dupont jumper wires inspired me to create a Uno-shield compatible parallel ESP32 TFTdisplay workbench for the purpose of checking all my Uno TFT shields, one by one. Here follows the design, wiring, and the results with a collection of parallel Uno shield type displays.

The market is swamped with TFT shields that can be placed directly on the pin sockets of an Arduino Uno. These shields feature parallel interfaces. They have in common that there are four pin header blocks through which one can stick such a shield very handy right onto a Uno (fig. 2). The displays mounted on these shields have different pixel dimensions and, more important, different controller chips. Most commonly used are ILI9341, ILI9481 and ILI 9486 chips. The best performing TFT shields are equipped with 3V-5V voltage converters (e.g. the shield shown in fig 2) but there are plenty of cheap shields available that lack a voltage regulator and therefore accept only 3V.

Controllers need their own specific driver to make the display work correctly. A major effort to supply the Arduino world with adequate drivers for ESP8266 and ESP32 microprocessors running smoothly with the above ILI controllers has been undertaken in recent years by the electronics engineer known as Bodmer: the TFT_e_SPI.h library.

So what I needed is a board that accomodates an ESP32 and that has enough space to accommodate a variety of small (2.4 inch) and large (3.95 inch) Uno TFT shields.

The base board consists of a doule-sided soldering board fastened with four nylon spacers on a piece of cardboard. Mounted on this base are two 15-pin parallel socket headers to accommodate an ESP32 microcontroller board and the four socket headers to accommodate the Arduino Uno TFT shields to be tested. As screen diagonals of TFT shields in my ‘arsenal’ vary between 2.4 inch and 3.95 inch, a 12080 mm double-sided soldering board with 4230 holes was selected for this purpose. The positioning of the socket headers is shown in figure 3. There are also two 2-pin pin headers to allow to select the proper voltage to power the display being tested (with jumpers).

12080 mm double-sided soldering board featuring 4230 holes, two 15-pin socket headers, two 6-pin socket headers, two 8-pin socket header, one 3-pin socket header, one black 2-pin socket header (black), two 2-pin headers (red), four nylon bolts, four nylon spacers and four nylon nuts, ESP32-WROOM32 microcontroller board with 30 pins, wire, two jumpers.

The positioning of pins on the original Arduino Uno does not follow the uniform 2.54 mm (0.1 inch) pitch rule. Any Uno parallel TFT shield therefore will not immediately fit a standard soldering board. On the back of each shield are jumper blocks labeled J1 through 4 (figure 2). We call J1 here the ‘SD jumper block’, J2 the ‘parallel jumper block’, J3 the ‘control jumper block’ and J4 the ‘power block’. Part of the SD jumper block is occupied by the parallel data interface. Some manoevering makes it clear trhat the J2-J3-J4 blocks fit the holes of the soldering board while the parallel jumper block (J1) is the outlier. Fortunately, the pins in all blocks follow the 2.54 mm pitch rule. It is J1 as a whole that is half a unit positioned ‘out of pitch’. Through this unorthodoxy, say asymmetry, a TFT shield fits an Arduino in only one way. Very clever. The present soldering board was adapted to this configuration by cutting a narrow sleeve where the pins of the J1 parallel jumper block should be, just wide enough to let the pins of the corresponding socket header through. Then an extra piece of soldering board was prepared and fastened with wire and solder under the sleeve, taking care that the J1 accepting socket header would exactly match jumper block J1.

The design is quite simple: two parallel rows of 15-pin socket headers serve as a mounting point for the ESP32 (figures 2,3). These sockets are positioned in the upper left corner of the board to leave as much area as possible to position the TFT shields. Here, TFT shields are oriented landscape. The bench is designed only for displaying data and graphs only, with no SD card reader support.

All Uno TFT shields have three pins that deal with power (3V3, 5V, GND), five pins that are necessary for display control and eight pins connected with the parallel data transfer interface, i.e., there is a total of 16 pins that need to be wired (figure 2). In addition I planned three ‘free’ pins of the ESP32 available via pin sockets for input-output puposes: pins D2, D5 and D15 (figure 4).

With so many wires it is necessary to bring order in the assembly of the bench. One can distinguish (1) power wires, (2) TFT control wires, (3) parallel interface wires, (4) additional wiring. One by one the groups of wires were mounted on the soldering board.

The group of control wires originates from pins D26, D27, D14, D12 and D13 and connect to the socket header that accomodates TFT shield jumper J1 (figure 5).

There are eight data pins on the TFT shields, marked LCD_D0 through LCD_D07. LCD-00 and LCD_01 are pins on jumper block J3 while the remaining LCD_nn pins can be found on jumper block J2. These pins must be connected to, respectively, pins RX2, D4, D23, D22, D21, D19, D18 and TX2 (figure 6).

Bodmer’s TFT_eSPI library is different than other libraries, e.g. Adafruit_GFX and U8G2 in the sense that there is no ‘constructor’. Pin definitions for each type of controller are in TFT_eSPI systematics stored in a separate Setup_nn.h file that is placed in a folder with the name ‘User_Setups’. In turn, the specific Setup_nn.h is called in another stetup file named User_Setup_Select.h. Consider the systematics as a kind of two-stage rocket. Both stages need to be edited befor launch. The first stage is User_Setup_Select.h and the second stage is Setup_nn.h.

An example of the specific Setup_nn.h file for one of my ILI9341 shields (the one shown in figure 1) is named ‘Setup_FW_WROOM32_ILI9341_parallel_TFT_016.h’. This is a file editable with any ASCII editor.

Figure 1 shows one of my Uno TFT shields mounted on the bench, running the example ‘TFT_graphicstest_one_lib,’ that can be found in the Arduino IDE under File, Examples, TFT_eSPI, 320×240, of course after correct installation of Bodmer’s TFT_eSPI library. With an ESP32. My own ‘ESP32_parallel_Uno_shield_TFT_radar_scope.ino’ runs fine: the downloadable demo sketch which mimics an aviation traffic controller’s radar scope with a sweeping beam. I created this sketch in 2017 as a demo for one of my first Arduino Uno TFT shields**. The body of that demo was used for the present demo sketch.

Testing my complete collection showed marked differences between shields. I tested shields with ILI341, ILI9481, ILI8486 and ILI9488 controllers, with mixed results. Best performance was achieved with ILI9341 controller equipped shields. Shields that lack a voltage regulator appeared to be dedicated 3V3 shields as they would not perform, or produce an upload error, if the 5V jumper was closed. One 3V3 shield needed the 3V3 jumper closed during upload while after upload it needed 5V to lighten up the screen. Some but not all shields accepted closed 3V3 and 5V jumpers during uploading and running sketches. One ILI9481-powered shield behaved very peculiar: only if both 3V3 and 5V jumpers were open during upload the sketch would be accepted and then be visible on screen only with the 5V jumper closed.

The experiences with the TFT shields lead to the following rule of thumb: first try to figure out the correct controller (this on an Arduino Uno with David Prentices’ ‘MCUFRIEND_kbv.h’), then checking the User_Setup_nn.h file icreated for this shield n the TFT_eSPI library system, and then try to upload first with the 3V3 jumper closed, then again (if necessary) with the 5V jumper closed, and finally with both jumpers closed.

Tags: ESP32 Dev Module, ESP32 development board,ESP32 Development board with WiFi and Bluetooth,ESP32-DevKitC V4 development board, ESP-WROOM-32 module with ESP32‑D0WDQ6 chip, Espressif Systems, ESP32-based development board, ESP32 modules, ESP32-WROOM-32, ESP32-WROOM-32U, ESP32-WROOM-32D, ESP32-SOLO-1, USB-UART bridge, IOT,ESP-WROOM-32 Dev Module, ESP32 DEVKITV1,Installing the ESP32 Board in Arduino IDE,Uploading sketch,1.8" SPI TFT LCD, 128x160 module, SD card, ST7735R, ST7735S, Adafruit, Adafruit_ST7735, Adafruit_GFX, ST7735B, HY-1.8 SPI, S6D02A1, Adafruit_QDTech, KMR-1.8 SPI, TFT_ILI9163, Arduino Esplora, SainSmart

In this project, you needed these parts (Dear visitors. You can support our project buy clicking on the links of parts and buying them or donate us to keep this website alive. Thank you):

This color display uses SPI to receive image data. That means you need at least 4 pins - CLOCK, DATA IN, TFT CS and D/C. If you"d like to have SD card usage too, add another 2 pins - DATA OUT and card CS.

LITE - this is the PWM input for the backlight control. Connect to 3-5VDC to turn on the backlight. Connect to ground to turn it off. Or, you can PWM at any frequency.

MISO(or SD_MISOorSDO) (Master In Slave Out) - this is the SPI Master In Slave Out pin, its used for the SD card. It isn"t used for the TFT display which is write-only

MOSI (or DIN or SD_MOSIorSDA) (Master Out Slave In) - this is the SPI Master Out Slave In pin, it is used to send data from the microcontroller to the SD card and/or TFT

TFT_CS (Chip Select or Slave Select) - the pin on each device that the master can use to enable and disable specific devices. This is the TFT SPI chip select pin

Card_CS (or SD_CS) (Chip Select or Slave Select) - the pin on each device that the master can use to enable and disable specific devices. Used if you want to read from the SD card.

RST (or RESETorRES) - this is the TFT reset pin. Connect to ground to reset the TFT! Its best to have this pin controlled by the library so the display is reset cleanly, but you can also connect it to the Arduino Reset pin, which works for most cases.

You can find more information (datasheets, schematics, pins descriptions, functional desgn descriptions) about each board (made by Espresiff Systems) by pressing Getting startedlink close to each board here.

ESP32-WROOM-32 - ESP32-WROOM-32 module soldered to the development board. Optionally ESP32-WROOM-32D, ESP32-WROOM-32U or ESP32-SOLO-1 module may be soldered instead of the ESP32-WROOM-32.

BOOT button - Download button: holding down the Bootbutton and pressing the EN button initiates the firmware download mode. Then user can download firmware through the serial port.

There are two ways to wire up these displays - one is a more flexible method Software SPI (you can use any pins on the ESP32) and the other Hardware SPI is much faster (4-8x faster, but you are required to use the hardware SPI pins)

The ESP32 is currently being integrated with the Arduino IDE like it was done for the ESP8266. There’s an add-on for the Arduino IDE that allows you to program the ESP32 using the Arduino IDE and its programming language.

Select COM port that the board is attached to (if you don’t see the COM Port in your Arduino IDE, you need to install the ESP32 CP210x USB to UART Bridge VCP Drivers)

Open, compile and upload the to your ESP32 development board. If everything went as expected, you should see a “Done uploading” message. (You need to hold the ESP32 on-boardBootbutton while uploading).

esp3218spitftlcdspitftbitmap. The display can load images bigger or smaller than the display size (160 x 128 px), but for better results, edit your image size to 160 x 128 px.The image should be in .bmp format. To do that, you can use a photo editing software and save the image as .bmp format. If you want to later use your own image, use an image editing tool and crop your image to no larger than 160 pixels high and 128 pixels wide. Save it as a 24-bit color BMP file - it must be 24-bit color format to work, even if it was originally a 16-bit color image - becaue of the way BMPs are stored and displayed! You can download example here. If you need to use own picture - modify the name of the bmp file in this sketch.

Adafruit_GFX library. Download, unzip and add to libraries in our PC, for example C:\Users\toshiba\Documents\Arduino\libraries. This link you can find in Preferences of Adruino IDE program which installed in your PC. You can read about it here.

Adafruit_ST7735 library. Download, unzip and add to libraries in our PC, for example C:\Users\toshiba\Documents\Arduino\libraries. This link you can find in Preferences of Adruino IDE program which installed in your PC. You can read about it here.

mySD library. Download, unzip and add to libraries in our PC, for example C:\Users\toshiba\Documents\Arduino\libraries. This link you can find in Preferences of Adruino IDE program which installed in your PC. You can read about it here.

This module is the 3.2” version of the ESP32 touchscreen display, based on ESP32-WROVER, with a built-in 2M pixel OV2640 camera. The LCD is 320x240 TFT, with driver is ILI9341, it uses SPI for communication with ESP32, the SPI main clock could be up to 60M~80M, make the display smooth enough for videos; and the camera OV2640 with pixel 2M, with this camera, you can make applications such as remote photography, face recognition…

While the camera not used, you can freely use all these pins with the breakout connectors, to connect the ESP32 display with sensors/ actuators, suitable for IoT applications.

This ST7735S 1.8" TFT Display features a resolution of 128×160 and SPI (4-wire) communication. Integrated with an SD card slot, it allows to easily read full-color bitmaps from the SD card. The module provides users with two wiring methods: pin header wiring and GDI (General Display interface). You can directly use an FPC cable to connect the display to any controller with GDI interface like FireBeetle-M0. Plug and play, easy to wire. Besides, the display supports low refresh rate and offers good display effect and strong versatility. It can be used in applications like sensor monitoring and alarm, Arduino temperature monitor, fan controller, etc.

This product is a breakout module that features SPI communication mode and onboard GDI interface, which could reduce the complexity of wiring. It can easily display the read content from the SD card.

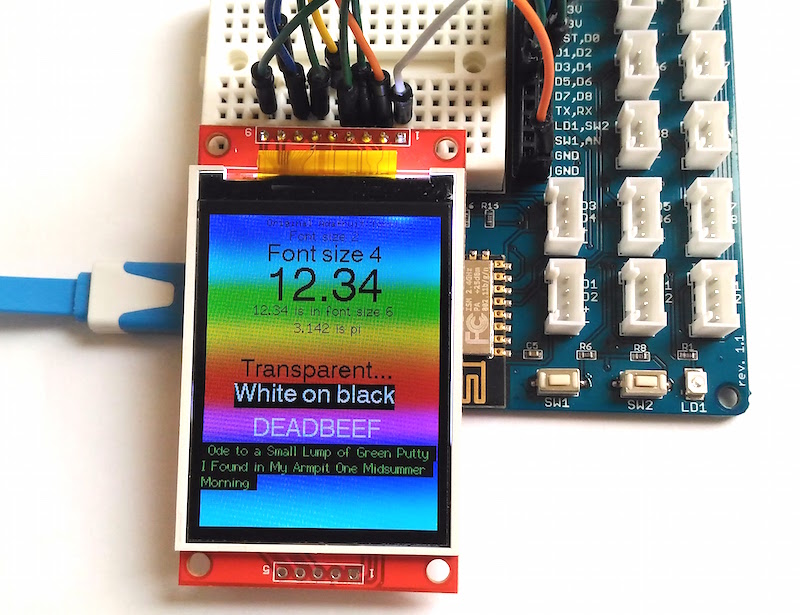

The BasicTest.ino code shows us the basic display functions of the screen: text display, number display, drawing lines, drawing rectangles and other demos.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In IoT, LCD is rarely required, but some times its useful to monitor errors and connection related issues. In this tutorial we are interfacingI2C LCD with ESP8266 or ESP32.Both code examples are given.

This library is tested for different types of LCD displays like 16×2, 16×4, 20×2, 20×4 with both ESP32 and ESP8266, it also works with other ESP modules.

ESP8266 with 20×4 i2c, 1602 LCD adaptable to others, tested with ESP-201 and ESP-01 Compatible with the Arduino IDE 1.6.6 Library https://github.com/agnunez/ESP8266-I2C-LCD1602

This is simple code to display text, cursor and scrolling text. Upload this code it will demonstrate many functions of library such as scrolling, display on off, cursor positioning

I2C is a serial protocol for two-wire interface to connect low-speed devices like microcontrollers, EEPROMs, A/D and D/A converters, I/O interfaces and other similar peripherals in embedded systems. It was invented by Philips and now it is used by almost all major IC manufacturers.

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

After uploading the code, open the Serial Monitor at a baud rate of 115200. Press the ESP32 EN button. The I2C address should be displayed in the Serial Monitor.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

Then, you need to set the display address, the number of columns and number of rows. You should use the display address you’ve found in the previous step.

To display a message on the screen, first you need to set the cursor to where you want your message to be written. The following line sets the cursor to the first column, first row.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

The messageToScroll variable is displayed in the second row (1 corresponds to the second row), with a delay time of 250 ms (the GIF image is speed up 1.5x).

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

Then, in the setup(), create a custom character using the createChar() function. This function accepts as arguments a location to allocate the char and the char variable as follows:

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

We hope you’ve found this tutorial useful. If you like ESP32 and you want to learn more, we recommend enrolling in Learn ESP32 with Arduino IDE course.

Simply put: that TFT requires a lot of GPIO pins - 10 at an absolute bare minimum, but better if you have more available. The ESP8266 doesn"t have many IO pins - and some of them are very sensitive about what they can be connected to without affecting the boot process.

If you are careful with your GPIO selection it may be possible to work with that screen. There are no specific requirements for what pins need to be connected to where (as far as hardware functionality goes), so it"s up to you to find the right combination that doesn"t cripple the boot process (stay away from GPIOs 0, 2 and 15 if you can).

ESP-LCD is a multimedia smart-control solution built around ESP32-S2-HMI-DevKit-1 and an LCD capacitive touch screen. With ESP-LCD, users can easily realize a hardware network, and achieve remote or smart-touch control, data visualization, music playback, recording, etc. ESP-LCD is suitable for several smart-control scenarios involving smart clocks, air-quality detectors, smart audio control, and various other applications based on touch screens.

ESP32-S2-HMI-DevKit-1 is a development board based on the ESP32-S2-WROVER module. It has a 4.3-inch TFT-LCD, and a capacitive touch panel with a resolution of up to 480×800 and an initial start-up time that is less than 200 ms. ESP32-S2-HMI-DevKit-1 has various components, including a light sensor, a temperature and humidity sensor, a MEMS sensor, a micro-SD card connector, a TWAI® interface (compatible with CAN 2.0) etc. On top of that, it also supports functions, such as LVGL GUI development, music playback, and recording.

Based on ESP-IDF, users can easily migrate their applications to other ESP SoCs. The complete C runtime library enables users to seamlessly switch from any PC platform to ESP-IDF in order to use standard input and output, memory allocation, file system, and other functions.

For development guidance, a piece of demo code is provided, including examples of GUI development, audio acquisition, storage and playback, file system, sensor use, low-power consumption modes, etc.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey