how to glue lcd screen brands

This is the only option and is available in many sizes. The glass touchscreen on majority of phones/tablets do not come in direct contact with the actual LCD, it is connected via ribbon connector.

For Samsung phones you have to use a UV activated liquid adhesive but it must dry crystal clear and you do need to purchase a UV light to activate the glue.

I have no idea what type of adhesive Apple products use but I am sure it would cost a lot and you probably will need a vacuum type screen seperator machine.

If your device is cost effective to repair, you are familiar with delicate electronics and have patience then I would try it but you have to purchase screen repair tools from someplace such as eBay that sells these sets for cheap.

LOCA or Liquid Optically Clear Adhesive is kind of special UV glue or sealant used to bond display / LCD Screen and touch screen panels. It is also called UV Glue. Most technicians prefer to use LOCA Glue or UV Glue over other glue or sealants because it improves contrast by many times. It also prevents loss of light from the display and hence increases the life of Mobile Phone Battery.

In order to replace a faulty, broken or damaged glass / touch panel (PDA) of LCD Screen of a mobile phone or smartphone, you will need following Mobile Phone Repairing Tools:

Separating the glass from the LCD should be done very carefully to avoid any unwanted damage. Special care must be undertaken if the glass is cracked. Never try to take off the glass without the right tools and equipment. It can damage the LCD which can be very costly to replace.

The glass and LCD are strongly bonded together with LOCA glue. The glue must be heated to loosen the bond. It can be done using a Hot Air Gun / Heat Gun. Technicians with some practice can easily do it. However, in most authorized service centers and professional service centers, they use LCD separator machine.

Use a Hot Air Gun or LCD Separator Machine, to give heat to the LCD to Loosen the bond of the LOCA glue. In both cases, a temperature of 200-300 Degree C is OK.

Gradually and evenly heat the front side of the phone. Use the Infrared Thermometer to check the temperature before trying to remove the glass. Make sure there is neither too much heat nor too little heat. Too much heat will burn the LCD screen while too little heat might crack it.

Start removing the glass from the top of the screen where speaker is located. Use the metal spudger to carefully separate the glass from the LCD screen. Move the spudger along the top edge and make enough space for the putty knife to slip in.

Reheat the surface and using the putty knife, carefully pry the glass away. After removing the Glass, use the Goof Off or Hot Blade to remove existing melted LOCA glue and clean the LCD screen using lint-free wipes. Some service centers and technicians also use automated LOCA removing machine.

LOCA glue is available in the form of liquid. It is not as thick as other adhesives. Apply just enough glue on to the screen in a “X” pattern with a “-” in the middle of “X”. Make sure not to apply too much or too little glue and see that there is no air bubble.

The adhesive will gradually spread across the screen and to the edges on its own without you having to apply any pressure. If there is any bubble, apply gentle pressure on the LCD and guide the bubble to the edge.

LOCA Glue do not cure or dry on its own. You have to dry it using UV light. Always Use a branded UV light that is about 30 to 40 Watts. You can also use a UV nail dryer. But do not use Flashlight UV lights.

Curing or Drying time of the Glue is generally 1 to 2 minutes. It also depends on the Wattage of the UV light source and the distance between the UV light source and the LCD Screen or Glass.

Afghanistan, Africa, Albania, Andorra, Armenia, Austria, Azerbaijan Republic, Bahrain, Bangladesh, Belarus, Belgium, Bhutan, Bosnia and Herzegovina, Brunei Darussalam, Bulgaria, Cambodia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Georgia, Germany, Gibraltar, Greece, Guernsey, Hong Kong, Hungary, Iceland, India, Indonesia, Iraq, Ireland, Israel, Italy, Jersey, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Liechtenstein, Lithuania, Luxembourg, Macau, Macedonia, Malaysia, Maldives, Malta, Middle East, Moldova, Monaco, Mongolia, Montenegro, Nauru, Nepal, Netherlands, Norway, Oman, Pakistan, Philippines, Poland, Portugal, Qatar, Republic of Croatia, Romania, Russian Federation, San Marino, Saudi Arabia, Serbia, Singapore, Slovakia, Slovenia, Somalia, South Korea, Southeast Asia, Spain, Sri Lanka, Svalbard and Jan Mayen, Sweden, Switzerland, Taiwan, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Arab Emirates, United Kingdom, Uzbekistan, Vatican City State, Vietnam, Yemen

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller"s listing for full details.See all condition definitionsopens in a new window or tab

• Apply this glue in the required area of the LCD screen, clear up the other area of screen, adhesive the front glass (make sure use mold to align correctly, you can purchase the mold in our store). Make sure complete screen expose to the light after spreading the glue and wait for few minutes till process finish.

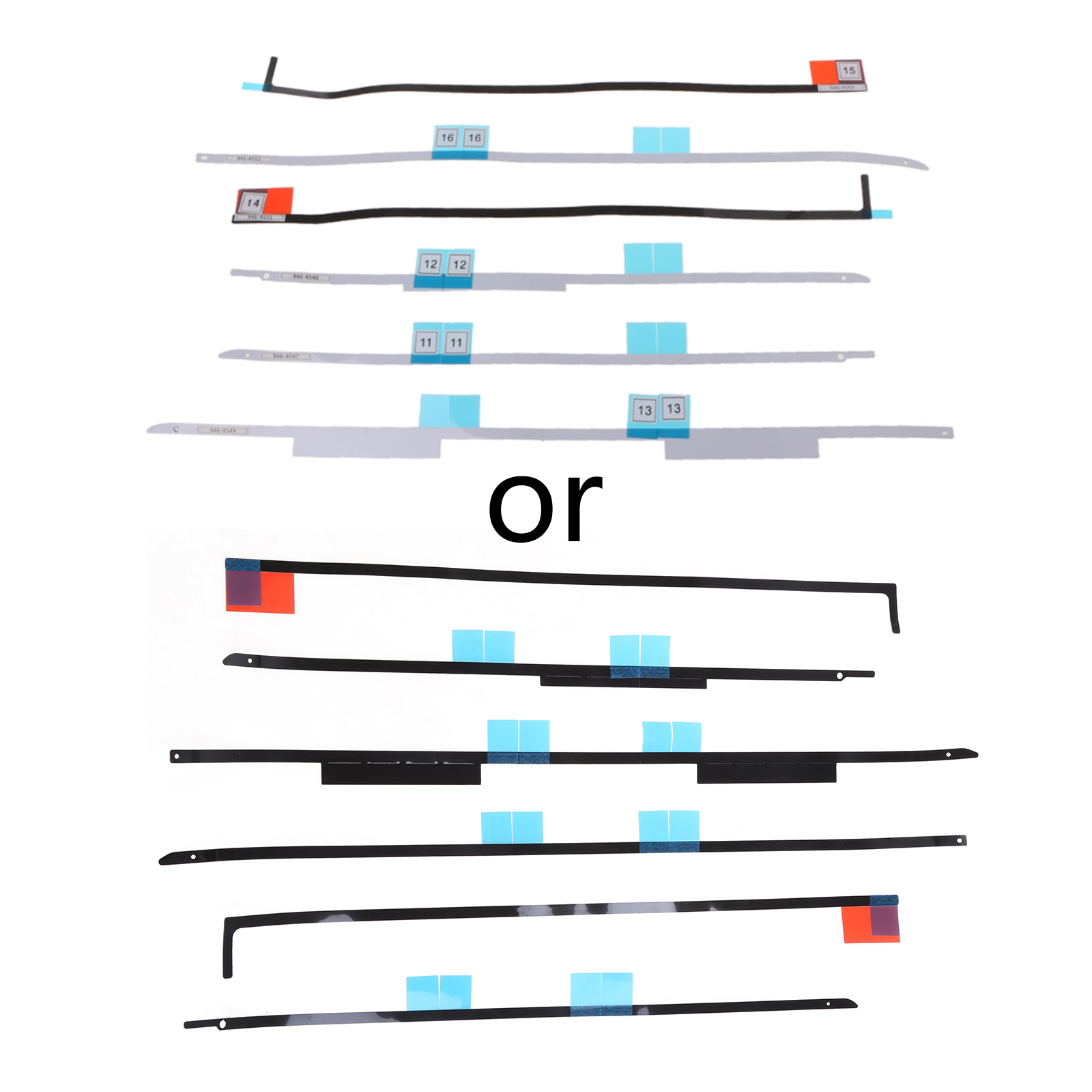

• To fix the Touch Screen Digitizer, this is the excellent choice to repair you"re old broken, damaged, faulty screens. Supporting frame sticker for your device. Replace broken and unusable supporting frame with this new one.

• We will not be held responsible for any damages to your cellphone that you may cause during the changing of replacement parts. Professional Installation highly recommended using repair Touch panel screen and LCD screen.

• It can be used at all Smartphone Digitizer LCD Outer Glass LENS etc. Now you can re-manufacturer broken screen back to resell condition. The professional skill required to finish this task. Each item will be checked and in good condition before shipping.

• 100% SATISFACTION GUARANTEE! Very easy use of LOCA (Liquid Optical Clear Adhesive) gum or glue for glass/screen touch replacement could be very interesting. Make sure the outcome looks professional and clean at a glance.

Any problem or question, please feel free to contact us for the first time, we will resolve for you as soon as possible. We are always here to serve you!

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Alibaba.com offers a splendid collection of durable, powerful, and optimal quality repair glue for mobile phone lcd touch screen for varied distinct uses in many commercial sectors. These efficient and rigid quality repair glue for mobile phone lcd touch screen are made from the finest quality materials for superior efficacy and bonding that is capable of holding things together precisely. These repair glue for mobile phone lcd touch screen are user friendly and come with longer shelf life. You can order these proficient products from the leading wholesalers and suppliers on the site who are vetted to deliver quality products only.

The brilliant and robust repair glue for mobile phone lcd touch screen available on the site are made of high-quality materials such as silicone, polysiloxane, filler, crosslinker, tackifier, and many other efficient materials that make these products safe yet very powerful. The distinct categories of repair glue for mobile phone lcd touch screen put up for sale are in the form of a smooth paste and are premium quality weather-resistant products. You can use these repair glue for mobile phone lcd touch screen in any conditions due to high weather resistance, UV protection, and hydrolysis resistance.

Alibaba.com offers several unique repair glue for mobile phone lcd touch screen available in distinct pack sizes, consistencies, efficacies, and composition to meet your individual requirements. These proficient repair glue for mobile phone lcd touch screen are waterproof, have better temperature tolerance, higher movement capacities, and prevents corrosion on the metals. You can use these repair glue for mobile phone lcd touch screen in the manufacturing industry, garment industry, construction industry, for tiles, ceramics, etc, depending on your requirements.

Alibaba.com can help you find perfect products by offering repair glue for mobile phone lcd touch screen that fits into your budget. These products are ISO certified and available as OEM orders. You can also go for customized packaging when ordering in bulk.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Loca glue, also known as UV glue, is an optically-clear liquid adhesive. This type of glue is used on a wide range of electronic equipment, especially with touch panels found in today’s smartphones. This liquid sticks the touch panel, or in this case the digitizer, to the LCD. It is used by many well known leading companies such as Apple for their iPhones and Samsung for their Galaxies.

It is used for a variety of reasons such as its ability to dry within minutes. Durability is another key factor as devices go through a lot of abuse everyday and the screen must be able to withstand it. Furthermore, LOCA has high transmittance, low shrinkage, and anti-aging characteristics.

Searching high and low on the internet, I can conclude that information on LOCA glue is very limited. This is why I decided to create this piece. Since there is little info on the subject, besides a Wikipedia page, I began contacting manufacturers of this UV glue. Here are my findings: The chemical composition of LOCA glue is Urethane Acrylic. Water base

Earlier, if a smartphone got cracked, repair shops would simply switch out the screen assembly. The problem with this was that in most cases the LCD was not damaged at all. Yet, it was impossible to separate the cracked glass from it.

The introduction of LCD separator machines allowed an even disbursement of heat that a heat gun could not achieve. Profits from glass only repairs were almost double of what one would make if they just switched out an assembly.

The short and simple answer is no. When doing glass only repairs, you must use optically clear adhesive. Why? Well for one thing it is in the name; ‘optically clear’. LOCA glue acts as a barrier between the glass and the LCD. Older versions of smartphones used to use regular adhesive around the border of the LCD.

The problem with this is that not only is the touch signal not as responsive, it also leaves room for dust to get in between. Therefore this type of UV glue was introduced. For the iPhone, Apple began using it with the iPhone 4. This liquid glue makes it ideal for filling in any tiny gaps in the displays that might have been caused by the cracked screen. It won’t leave any noticeable mark that can be later identified.

If you attempt to use any other glue, the quality will not be the same. LOCA glue allows minimum reflection to occur. It allows light to travel from the LCD and out from the glass with minimal light being lost in between.

While keeping this thing in mind, LOCA suppliers try to match the refractive index of glass and clear plastic used in displays to minimize the color loss. Furthermore, LOCA glue is highly heat resistant which prevents condensation or fogging on the lens that can be caused by the hot display .

Another reason not to use any other glue is that it might not dry clear. I have heard many cases where when the glue has dried, it gives off a yellow hue. You do not want this! LOCA glue dries crystal clear and stays that way, even as the phone ages.

If you are going to do glass only repairs, use the right adhesive. Liquid optically-clear adhesive is the perfect ideal bonding agent for all LCD display devices.

Separating the glass from the LCD can be quite tricky, especially if the glass is severely cracked. If you attempt to take the glass off without the right tools, you will damage the LCD. The bond between the glass and LCD is very strong. The LOCA glue must be heated in order to loosen this bond. This can be done with a heat gun, however this is not the best tool for the job.

Heat must be dispersed as evenly as possible through out the glass. You need to have a consistent temperature throughout to avoid damaging the LCD. This can be done using an LCD separator machine, a tool that is like a hot plate. Take a look at the video below done by JCD Repair, a professional repair shop that knows what they are doing.

In the video, the Samsung Galaxy is placed on a LCD separator machine. Notice how he checks the temperature through out the glass to ensure that it is consistent. He is aiming for 225 degrees. Since the phone cools down fairly quickly, you must put it back onto the hot plate to maintain the right temperature.

In regards to what tool to use to get between the LCD and glass, there are two that I would recommend. In the video, he is using a tool that is very similar to the iSesamo. This is basically a thin piece of metal. The other tool I would recommend is molybdenum wire. This wire is thin, but strong and heat resistant.

Note the differences between an iPhone repair verse a Samsung Galaxy repair. With Samsung Galaxies, you will want to use the iSesamo tool as the glass is glued to the case itself. With iPhones, the display assembly can be separated. This means you can place the assembly back onto the hot plate, clamp it down, and run the molybdenum wire between the glass and the LCD.

When doing these repairs, the loca glue will still be on the LCD display even after the glass has been taken off. The adhesive is very durable and strong. In order to remove it from the display you will have to use a product that can remove adhesive, and not damage the screen. There are many solutions out there that claim to be able to remove LOCA, but many of them actually do not work.

There are two alternatives to the plastic razor and the wipes. I suggest you first practice removing the glue with the method above before moving onto these tools. There are two tools that you can try out. The first is a

only have to finish off the job using the wipes to ensure a clean surface. It works just like a hot plate, except it focuses the heat all onto the blade.As you can see from above, the hot blade goes right through the glue without much effort. It takes off most off it, and you

LOCA glue is all liquid and not as dense as other glues that you may have used before. Therefore you cannot just smear it onto the LCD. This part of the repair takes a lot of practice. The LOCA must be applied in the pattern shown above to avoid pesky little bubbles that could result in dropping the new screen too fast onto the LCD.

It is also important not to put too much of the glue. If you put too much, it can go onto the edges and get into the LCD itself. After you apply the glue onto the screen, make sure to close the lid on the container. Never put any extra LOCA back into the container as that will cause contamination.

A common issue that a lot of beginners run into when trying to do glass only repairs is that the LOCA glue gets in between the backlight within the LCD. This causes the screen to look spotty in places when it is turned on. The only true way to prevent this is by not putting more adhesive then you need. However this takes time to master. Chances are it is going to happen to you. So how do you prevent it all together?

You must take the backlight off the LCD. It is soldered on so it requires at least some knowledge on how to desolder/ solder. You have two choices; you can either do the entire screen replacement and then replace the backlight with the new one. Alternatively, you can avoid the need to replace it with a new one by prepping for the repair beforehand. Desolder the backlight from the LCD.

Once you are sure that the glue has been cured, carefully remove the tape. If any uncured glue got onto the back of the LCD, do not smudge it. Carefully wipe the spot. If you do this wrong, the LOCA will be smeared all over the LCD.

The fascinating thing about this bonding glue is that it doesn’t dry normally. You must dry it using a uv light. The uv light causes a chemical reaction in the photons that get bonded within the loca. This results in a great bond between the glass and lcd. The great part about this is that if you mess up applying the glue, you can always take it off as it does not dry on you.

You can use any UV light on the market to cure the LOCA glue. However I recommend you use one that is at least 30W. The less watts, the longer it will take to dry. Curing time takes 30 seconds to 2 minutes. UV cure rate is dependent on the strength of the bulb, as well as the distance between the light source and the gap size between the LCD and the glass.

Put the assembly under the UV light with the glass facing up. After 2 minutes, remove it and inspect it. The glass should not be moving away from the LCD. Flip it over and use a lint free rag to wipe any excess glue that can be on the sides. I then put it back under the UV light, with the glass facing down for 1 minute. This ensures that both sides are cured.

There are a lot of UV lights on the market for LOCA repairs. Which one should you choose? As mentioned before, try to get one with at least 30W. However you can still get weaker UV lights, you just have to cure it for a longer time. I do not recommend you get one of those flashlight UV lights. For one thing, you will have to be holding this in the air for a few minutes.

The flashlights also focus their lights on a specific area of the screen and not the entire assembly. This means you will have to move it around to ensure the entire screen is cured.

Personally I use a UV nail dryer. These work best because they are stationary. All you do is slide the assembly in and you can do other things while the LOCA glue cures. Inside the dryer, the walls are mirrored, allowing the light to bounce back and cover every part of the assembly. This results in an even cure that the flash light does not provide.

Techniques to repair dents on frames of the iPhone, iPads (this is done in order to properly install and prevent damage during the installation of the screen. Failure to do this can cause the screen to unglue or to crack)

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey