led vs lcd display difference factory

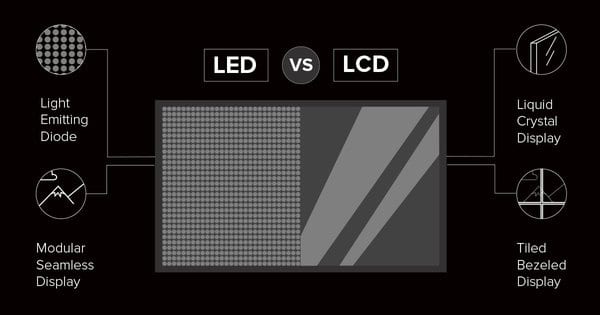

LCD and LED are popular technologies used to display texts and images. Both LCD and LED are extensively used in display screens in various electronic devices such TVs, computers, laptops, smartphones, etc. There are many differences between LCD and LED displays, where one of the major difference is that LCD uses the liquid crystal and cold cathode fluorescent lamp for the formation of image on the screen, whereas the LED uses a PN junction diode which emits light when the current passes through it that is used as backlight in the display.

In this article, we will explain the various differences between LED and LCD. Also, we have added a brief description of LED and LCD for your reference.

LCD stands for Liquid Crystal Display. The LCD is a combination of solid state and liquid state of matter which is used to produce display effect. It uses the liquid crystals for the formation of a visible image. The LCDs are super-thin technology displays which are commonly used in screens of TVs, laptop, smartphones and computer, etc. The LCD consumes less electricity and includes millions of colors.

LED stands for Light Emitting Diode. The LED is a specially designed PN junction diode which is capable for emitting light when electric current passes through it. This emitted light is then used in display technologies as backlight.

The LED is constructed by joining a P-type semiconductor with an N-type semiconductor. Basically, the LED is a heavily doped PN junction diode. When an electric current is passed through the LED, the recombination of holes and electrons takes place at the PN junction and light is emitted in this process.

The color of emitted light by an LED depends upon the semiconductor material used and the amount of doping. The LEDs have very long life and requires less maintenance. However, they are costlier than LCD. In the display technology the LED is used as the backlight and such a display is known as LED display.

Both LED and LCD are types of display technologies used for showing the texts and images. However, there are several differences between LCD and LED displays, which are highlighted in the following table −Basis of DifferenceLCDLED DisplayFull formLCD stands for Liquid Crystal Display.LED stands for Light Emitting Diode.

DefinitionThe ‘LCD’ is a combination of solid and liquid states of matter which is used to display the information in the form of texts and images.The ‘LED’ is a PN junction diode which emits visible light when the electric current flows through it. This light is then used as the backlight for displaying the information in the form of texts and images.

Response timeLCD has high response time, hence their switching speed is less.The response time of LED is less than LCD, thus the LED is better than LCD in terms of response time.

MaterialThe liquid crystals and glass electrodes are used for manufacturing of LCD.In case of LED, the gallium arsenide phosphide is used for manufacturing

The most significant difference between LCD and LED display is that the Liquid Crystal Display uses Cold Cathode Fluorescent Lamp to provide backlight while the LED Display uses Light Emitting Diode to provide the backlight for displaying the information.

Sometimes the distance between good and great seems like hardly any distance at all — such as liquid crystal displays (LCDs) versus light-emitting diode (LED) displays. Both are suitable for retail window signage, campus wayfinding or large video walls. But LCD and LED have significant differences, and their specific benefits are worth understanding so you can choose the best displays for your business needs.

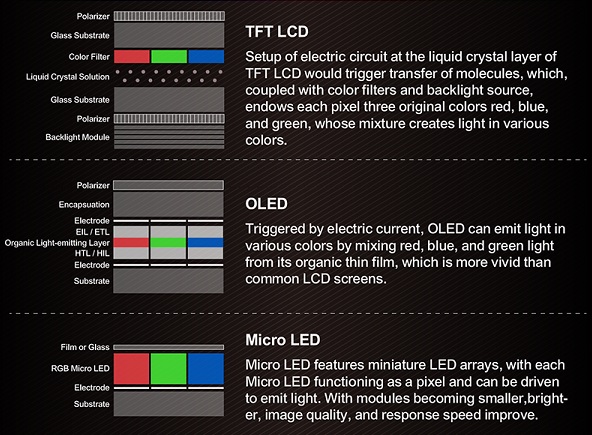

LCD is the broader category; LED is a subset. In other words, all LED displays are LCDs, but not all LCDs are LED. LCDs are made up of hundreds of thousands — even millions — of individual pixels built from liquid crystals. Each pixel is capable of displaying a color when it receives an electrical charge. Like a mosaic, the displayed image is built from tiny elements that combine to form the overall picture.

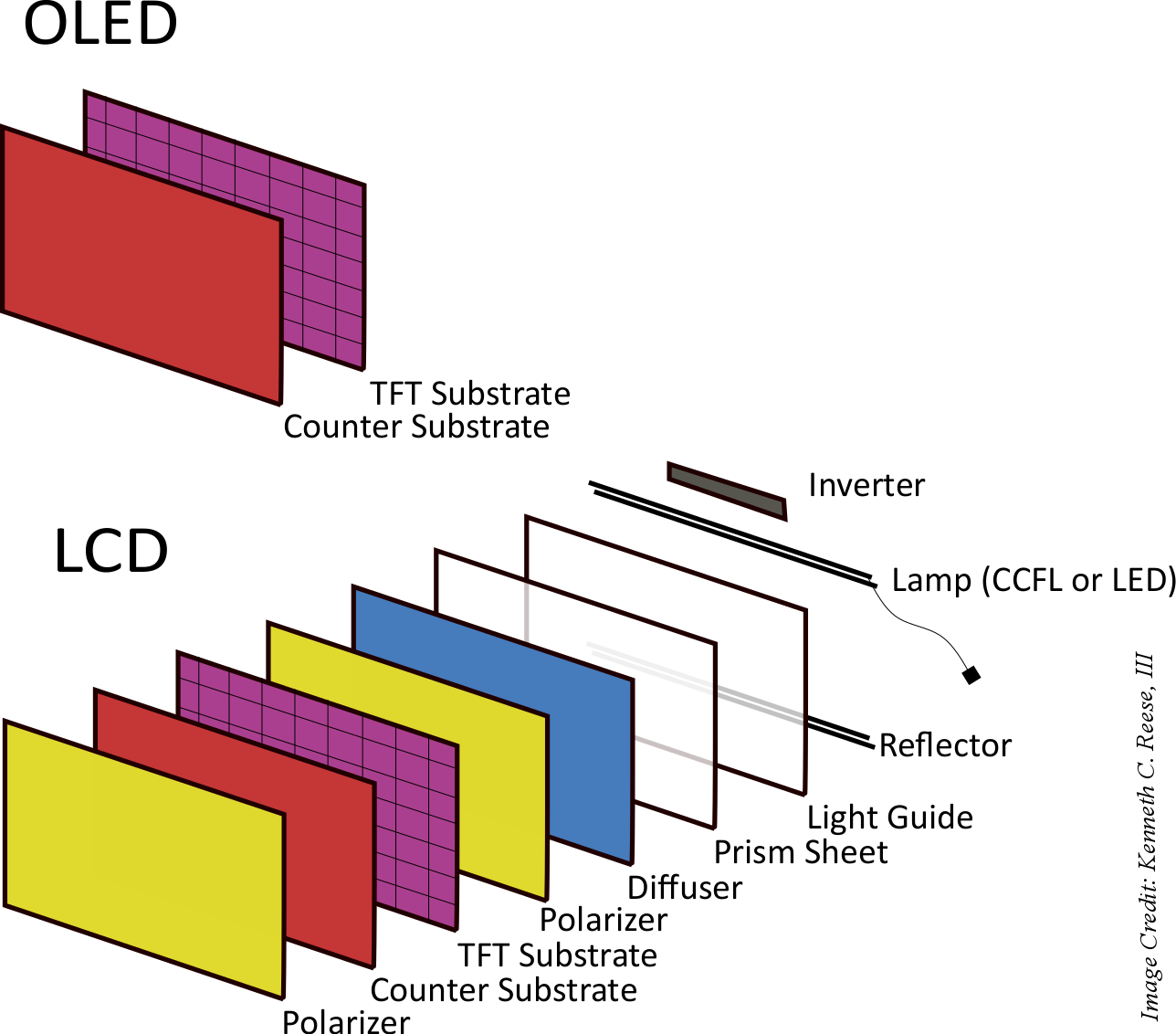

But the liquid crystals don’t produce any light of their own, so in order for the image to be illuminated, the liquid crystals need to be backlit. LCDs are illuminated by cold cathode fluorescent lamps (CCFLs), evenly positioned behind the pixels so that, at least in theory, every part of the screen is evenly lit and at consistent brightness.

Up to a point, LED displays are much the same. An LED screen also uses liquid crystals to generate color — or pure black (no color), by not charging a specific pixel. So LED displays have the same need for backlighting. But rather than CCFL, tiny individual lights (light-emitting diodes) illuminate the liquid crystals.

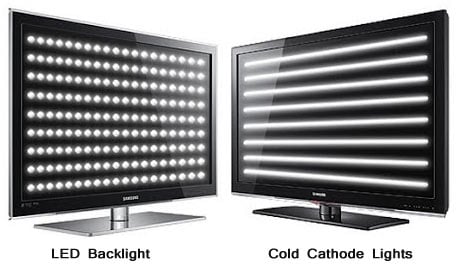

The individual LEDs can be arranged one of two ways: full-array or edge-lit. For edge lighting, the LEDs are arranged around the edges of the back of the screen. Full-array, on the other hand, calls for many LEDs to be lined up evenly across the back of the screen, where they can be arranged into zones (usually called “dimming zones” or “local dimming”).

Is LED just plain better than LCD? Well, for a while, LCD screens represented the cutting edge of digital signage. But now, about the only meaningful advantage of LCD over LED is price point. As LCD is becoming outdated, it tends to be less of an upfront investment. In every other respect, though, LED displays have the advantage.

No matter the arrangement of the backlighting, LED has a greater nit value than LCD, which means it’s brighter (“nit” comes from the Latin “nitere,” meaning “to shine”). The average nit value for LCDs is between 500 and 700 nits, while LEDs are typically between 1,200 and 2,400 nits. With greater brightness comes greater contrast, and all-day visibility on outdoor displays.

Despite the energy output, higher brightness doesn’t necessarily mean a shorter lifespan. In fact, LED displays have an average lifespan of 10 years — double the average five-year lifespan of LCDs. Factoring longevity into the cost of your signage, LED’s longer lifespan can make it cheaper than LCD in the long run.

Even with edge lighting, LED produces more vividly lifelike images than CCFL-backlit LCDs — and with sleeker hardware, thanks to their minimalist design. And while LCD bezels have drastically reduced over time, they’re still greater than zero. LED has no bezels at all.

Full-array backlighting requires a little more depth to the screen, but with discrete dimming zones, LEDs can be illuminated far more precisely — which, in turn, means more accurate and engaging visuals.

LED isn’t the first technology to realize miniaturization is the way forward. Even as screens get bigger, the next big step is made of smaller parts: microLEDs.

Up to 40 times smaller than regular LEDs, microLEDs allow backlighting to be even more precisely targeted, with many times more diodes. This, in turn, delivers a more accurate picture, with greater contrast and highly focused areas of brightness. Samsung’s The Wall is a spectacular example of what microLED is capable of.

Whether you need your digital signage to entertain, inform or simply impress, understanding the differences between LCD and LED will allow you to make a better-informed decision.

With best-in-class picture quality and exceptional durability,Samsung LED displayscan help your business deliver content that engages, informs and entertains.Samsung’s trade-in program makes it easy for businesses to upgrade their video wall with LED technology. Once you’ve chosen your displays, learn how you can configure and tailor their real-time messaging using an integrated CMSin this free guide.

In the world of digital signage, there are two prominent display technologies: LCD and LED. There’s also a considerable amount of misconception about these technologies and how they relate to each other or work together. The blame for much of this confusion can be attributed to the advent of LCD TVs with LED-backlighting technology, so let’s clear that difference up before we move on.

With any digital display, you must have a well working light source so that you can see the picture brightly. Until very recently, TVs have always been backlit—that is, illuminated from behind the display monitor. For a long period of time after television sets were invented, this was done by firing electrons through a “gun” to the screen (tube and projector TVs). In the early 2000s, LCD TVs were backlit by fluorescent bulbs. More recently, however, TV manufacturers began using LED technology as the light source for flat-screen LCD TVs, as this method provided more versatility and uniform picture lighting, therein lies some of the confusion.

As picture displays, there are many differences between LED display features and LCDs. Given advances in LED display technology—and drastically lower cost—both display types can be viable options for a variety of interior spaces. And of course, each has benefits, and each has limitations. To determine the best display for a digital signage project, it’s critical to understand exactly how each display type will perform and why one is better than the other in a given situation. It’s important to compare, not only cost, but also factors such as brightness, durability, size, resolution, vibrancy, and many more features that are on the market.

LED stands for light-emitting diode. By definition, LEDs provide their own light. Once reserved for large-scale, exterior digital displays, direct-view LED signage has emerged as a greatly improved, widely applicable medium, now suitable for virtually all display installations, both indoor or outdoor. In the digital signage industry, direct-view LED displays have now become the norm and work well together.

LCD stands for liquid crystal display. This type of display uses light-modulating properties of liquid crystals. As referenced above, liquid crystals don’t produce light directly; instead, they use a backlight to produce images on the screen. LCDs are used most often in interior applications, where users are in proximity to the screen. With this display technology, ambient light is usually limited and controlled.

Typically, LED displays have a higher up-front cost than LCDs; however, unlike LCDs, LED displays are rugged and durable, even in the most inhospitable environments. Additionally, they can be upgraded and retrofitted relatively easily. For total cost of ownership and longevity, the better option is the LED.

Brightness is typically measured in NITs. One NIT is equivalent to one candela per square meter. The brightness for LED displays ranges from hundreds to thousands of NITs. LCDs have a much lower brightness range feature. LED displays are able to compete in well-lit areas, both inside and outside. In contrast, competing light will severely impact an LCD; many times, this renders the picture unviewable.

While LED and LCD displays can both render most types of content, there are some drawbacks to LCDs. They can sometimes hold the “memory” of an image, and leave behind a residual imprint referred to as “image persistence.” It’s caused when a still image remains on the screen for too long. The colors become “stuck” in place. When the display tries to shift to another color, the crystals don’t want to budge. The result is a color that is slightly skewed from the intended one. LED displays do not encounter this issue.

Video walls are one of the most popular ways to use digital displays in interior spaces. From entertainment venues to other various retail spaces on the market, video walls have wide appeal. This makes the setup more complex than single screens, so it’s essential to have the right screens. LEDs are typically the preferred display for video walls. They are seamless, tiling together with no bezels. In a well-installed application, video walls have excellent uniformity and the widest viewing angles. LCDs can be tiled, but their bezels cause gaps and visual barriers. While there are LCDs with narrow bezels, small seams are still visible, unfortunately.

An LED display can be any size. There are no inherent limitations. They can also be curved, concave, or convex. They can even wrap completely around a pillar for a 360-degree effect. LCDs are typically only available in the standard sizing set by the manufacturer.

SNA Displays is a global manufacturing leader in LED video displays. We offer fully customizable LED products, thereby providing you with the most impact on your messaging. To learn more about how LED signage can power your digital display project, view our portfolio.

LCDs can be tiled, but their bezels cause gaps and visual barriers. While there are LCDs with narrow bezels, small seams are still visible. Thus it is not an ideal choice given such a condition.

An LED display can be any size. There are various creative LED displays including ball LED display, curved LED display, flexible LED display, foldable LED display and so on to meet the requirements for creative display, but LCDs are typically only available in the standard sizing set by the manufacture.

The possible higher initial price point: as the more complex production process, more durable quality and is released later than LCD panels, the initial price point of LEDs can be higher. But there is one thing that deserves to be noticed, the lifespan is longer and the future maintenance fee can be lower with high adaptability to different application scenarios. So in the long term, choosing a LED display may save you more money.

LCD stands for liquid crystal display. As what has been mentioned above, LCD doesn’t produce light directly, it has a backlight to help to produce images. LCD displays are usually used in the indoor environment and the ambient light is often limited and controlled.

Due to LCD has been in widespread use since the early ’70s where it first appeared in digital watches, the cost has been reduced so the price can be lower.

LCD monitors tend to have better viewing angles and anti-glare than edge-lit LEDs as if you like to kick back in your chairs or view the screen from different angles, because the edge-lit LED may lose visibility as you move away from the center viewing angle (please notice the full-array LED monitors don’t have such issue so it is the best choice for gaming).

1.Thicker and heavier structurebecause of the different backlight. There are two methods of LED backlight: direct and edge. The main advantage of edge lighting is that it can be used to make LED screens incredibly thin cause the LEDs are at the side and not behind the screen.

2.Many monitors can not support 4K. Nowadays, 4K videos are one of a trend, however, many LCD displays can not load such video sources so there are more limitations on the content.

3.More energy consumption. As compared with LED display of the same size, LCD may consume 20% to 50% electricity more than that of LED display screens.

4.Lower contrast results in a less clear image. As what we have discussed above, LED display has special lighting methods that can increase the contrast to display pictures more clearly.

This article introduces the differences between LED and LCD, and the advantages and disadvantages of both.When you try to make the best choice for your project, consider these different features carefully.

Generally speaking, an LED display holds advantages due to many functions it has, such as longer working life, lower consumption, easier maintenance, better display performance and so on.

These qualities contribute to the higher initial price point, while in the long run, the investment may be more cost-effective. But if you are looking for something cheaper just without many requirements, that may have you considering the LCD.

Differences between LCD and LEDare important to understand as they are both very co-related and it is possible to get confused between one and the other. LCD is the abbreviation for liquid crystal display while LED is the abbreviation for light-emitting diodes. They differ from one another in the fact that LCDs usually use fluorescent lights while lights use light-emitting diodes.

The structure of both LCD and LED is quite the same as the technology behind these screens is the same. The differing television types have two different layers of polarized glass and through this glass, the liquid crystals get blocked as well as pass the light. Thus, this is one of the key differences and similarities between LCD and LED.

Digital panel meters (or DPM) typically uses either an LCD (Liquid Crystal Display) or LED (Light-Emitting Diodes) to display information in an alphanumerical format. What are the differences between LCD’s and LED’s and how do you know which one to pick for your application? Read on to find out!

The Liquid Crystal Display (or LCD) is a form of visual display used in electronic devices in which a layer of a liquid crystal is sandwiched between two transparent electrodes. The application of an electric current to a small area of the layer alters the alignment of its molecules, which affects its reflectivity or its transmission of polarized light. Liquid crystals do not emit light directly. Instead, they use a backlight or reflector to produce images in color or monochrome.

To take it a step further, LCD displays also come in two different variations: Positive LCD and Negative LCD. Essentially, a positive LCD display features dark-colored or black numbers/letters on a light-colored background while a negative LCD display features light-colored numbers/letters on a dark background.

Light-Emitting Diode (or LED) is a semiconductor light source that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons. The color of the light is determined by the energy required for electrons to cross the bandgap of the semiconductor.

While the underlying technology is the main difference between LCD’s and LED’s, there are other features that set these 2 apart from each other and could help to determine which one is right for your application.

Color: DPMs traditionally have a red, green or amber/yellow display. LEDs are also available in blue or white. Tri-color (RGB) LEDs can be used to create any color. The color of a transmissive LCD is determined by the backlight LED. Therefore, color-changing digital displays are more easily implemented with LCD technology. Some high-end DPMs provide a full-color graphic display. These use LCD technology similar to what is used in a color TV.

Brightness: The typical LED display is significantly brighter than an LCD. So viewing in a bright room or in a crowded instrument cluster favors LED. The LED’s higher brightness coupled with higher contrast gives enhance readability over LCDs. However, in direct sunlight, a reflective LCD is more visible.

Viewing Angle: LED displays to have a much wider viewing angle than LCDs. When viewing an LCD display, the image clarity will become diminished when viewing the display off to the side from the center point in either direction.

Temperature: LEDs are semiconductors, so they have a wide temperature range. Other components in the meter will determine its operating temperature limits. The chemical action in the LCD slows down at low temperatures (typically <0°C), so it may require a heater for these situations. Depending on the type of LCD, the maximum temperature of an LCD meter may also be more restricted than an LED meter.

Burn-In Issues: Neither LCD nor LED displays to have burn-in issues. That is, an image is “burned in” to the display if left unchanged for an extended time. Because of this, both types of displays are considered suitable for static images, which are typical with digital panel meters.

Life: Either display type will provide years of continuous operation. However, LCDs can degrade in high humidity due to an imperfect seal between the glass plates.

Both LCD and LED technologies have their own set of advantages and disadvantages. Be sure to consider all of these factors when deciding on the right type of display for your DPM application.

At Weschler Instruments, we carry a wide selection of digital panel meters from an assortment of manufacturers in both LCD and LED displays. We also recognize that every application is different and can sometimes require custom input ranges/scales. Contact us today with your needs and one of our highly qualified salespeople will assist you.

One of the most common questions we’re asked when assisting businesses establish their digital signage systems is whether an LED or an LCD display is best for their business. The answer is always contextual to the clients’ needs. It starts by clarifying what the difference between the two actually is.

When we’re talking aboutconsumer products such as computer monitors and televisions the first thing to know is that an LED screenis an LCD screen, but an LCD screen is not always an LED screen. An LED monitor or television is just a specific type of LCD screen, which uses a liquid crystal display (LCD) panel to control where light is displayed on your screen.

For the display to be considered an LED screen, it means it is utilising ‘Light Emitting Diodes’ to generate the light behind the liquid crystals to form an image. A non-LED LCD screen has backlights (called fluorescent lamps) behind the screen that emit white light which cannot pass through the liquid crystals until an electric current is applied to the liquid crystals which then straighten out and allow light to pass through.

This is where it can get easy to divert away from giving clear advice on whether as LED or LCD display is best for your business, because consumer displays differ from commercial displays. We are not trying to give the reader direction on which monitor is best for their gaming set-up, but which screen type is ideal for communicating your business’ messages.

Commercial LED displays are typically referred to as Direct View LED. This is because they use LEDs as the individual pixels that make up the image itself. Using a surface array of LEDs removes any need for a liquid crystal display panel, which carries noticeable benefits for particular uses.

While LCD flat panels are available in resolutions of 1080P and 4K UHD, Direct View LED displays are measured by pixel pitch. Pixel pitch is the distance from the centre of one pixel cluster to the centre of the next pixel cluster in an LED screen. The smaller the pitch, the closer viewers can get to the display before they see the pixels themselves. Outdoor configurations may have a pitch of 10mm to 40mm, as they are viewed at longer distances.

For use indoors, where viewers would be closer to the display, a pitch of 10mm or less would be required, some have even sub-1mm pixel pitch. When considering Direct View LED displays, it is important to know the minimum viewing distance required. Multiplying the pixel pitch by 1,000 gives you a good rule of thumb for the minimum viewing distance.

Direct view LED displays can either use discrete oval LEDs which are basically one single self-contained diode, or Surface Mounted Device (SMD) LEDs. SMD LEDs contain 3 individual light-emitting diodes bunched together. Either way, it’s the light-emitting diodes that create the images you see on screen. This is explained in the image below, courtesy of LG Electronics

Commercial LCD screens are more closely related to their consumer counterparts like TVs but there are still differences to be aware of. It is not advised to simply purchase an LCD TV from your local electronics retailer and install it in a public setting and expect it to function as desired.

Both have been designed to be used differently. Commercial display manufacturers understand that their displays are going to be exposed to far different conditions than a living room television will be. The componentry in a commercial display is optimised to allow for the display to be on 24 hours a day, all year around. They take into account diverse environments such as hot kitchens, high foot traffic, and bad weather,ensuring the product won’t fail in such exposures. The addition of more durable and resistant technology means commercial LCD displays will typically be priced higher than their consumer cousins.

Brightness: When deployed in areas with strong ambient lighting, even the best LCDs can appear washed out and difficult to view, especially when from an angle. Direct view LEDs for outdoor applications can reach 9,000 nits, making them a brighter and better choice for most outdoor applications.

Contrast: Direct View LEDs can turn off pixels that aren’t being used which allows for a higher contrast and therefore a richer image in varied lighting conditions.

Size and shape: Direct view LED-based walls can be flat, curved, wrapped around pillars and more. With no size limit or set aspect ratio they can be used more flexibly than LCDs. Plus, panels have no bezels which means you can piece together Direct view LEDs to create large and uniquely shaped displays with no visible interruptions between units.

Lifespan and servicing: Most direct view LEDs are rated to last 10 years, compared to a typical 5 years for LCDs. Further, they can be easily replaced on-site, reducing maintenance costs.

Tougher: If you’re using an LCD for any outdoor application or one where the unit has to be protected from extreme temperatures or humidity, you’re going to need to include an enclosure and have an understanding of how to properly seal and vent the unit. Outdoor Direct view LEDs, on the other hand, are purpose-built to withstand harsh environments.

Price: The higher upfront cost of Direct LEDs could be the biggest sticking point when it comes to pitching a video wall. While prices have been steadily dropping, Direct view LEDs are still more expensive than LCD alternatives. However, make sure you consider the lifetime cost of the solution and other benefits mentioned above before you discount direct view LEDs.

Functionality: LCD screens can offer a wider range of functionality when it comes to set-up, display settings, and day-to-day control. There is also the addition of touch screen options for LCD displays which are a fairly sought-after feature these days.

Resolution: Whilst the fine pixel pitches available in direct view LEDs today make for impressively resolute images, LCD screens still boast are more uninterrupted image when viewed up close, particularly with the modern 4k displays. This makes them a better option for smaller retail stores, quick service restaurants or office meeting rooms.

As earlier stated, intended use for the display will determine which format you invest in. In outdoor environments or areas with high ambient lighting, brightness is the key concern. For indoor environments, the key concern is image quality and contrast. It’s also imperative to consider the usage environment and what the screen may be exposed to with regards to weather, temperature, humidity, direct contact and other factors. If you have a good understanding of your requirements for content, application, perception and budget then your first move should be to contact a supplier, like Black Lab Design, and we will be able to assist you with designing, building and installing the perfect digital display solution for your business.

While a standard LCD screen uses fluorescent backlights, an LED screen uses light-emitting diodes for backlights. LCD screens usually have superior picture quality, but they less brightness than the LED screens. And some backlight configurations create better images than the LED screens. So, LCD display is good for Indoor of Commercial Display and LED display is good for outdoor of Commercial Display.

In the traditional sense, Digital Signage Media Solution products in a broad sense refer to display terminals that publish information or product advertisements in public places. At present, these products are mainly used for "indoor" commercial advertising applications. The indoor display mainly uses LCD display technology, because of its high resolution, fine colors, stable product performance, and easy installation and maintenance. Due to the "outdoor" special use environment, commercial advertising display products are required to have high brightness, protection, and durability.

Outdoor Billboard Advertising has been around since the mid-nineteenth century and may seem a bit dated, but the advent of digital billboards has witnessed a sudden rise in the popularity of these displays. In fact, billboards and digital advertising are the only growing advertising areas, while the radio, television, and print advertising markets are shrinking. Many companies have discovered that the presence of huge displays can mean a huge impact, and they are using the functions of digital billboards in creative ways. For example, the billboard of a coffee chain can adapt to real-time weather conditions: on a cold day, it will show a cup of hot coffee and a doughnut; on a hot day, it will show a cup of iced coffee drink.

The COVID-19 has made 2020 a turning point for the entire industry. Due to the further development of LCD panel display technology, the cost of high-brightness products continues to drop, and many digital signage product suppliers are also turning their attention to the outdoor advertising market. During the period of low demand for traditional applications, we saw new opportunities for digital signage products in the outdoor advertising application market.

According to research by relevant institutions, due to the impact of the epidemic in the first half of the year, the shipments of outdoor digital signage machines dropped sharply. In order to improve corporate profitability, most digital signage product manufacturers are turning their attention to the rising demand for outdoor markets, mainly in the transportation sector (Bus stations and other land transportation platforms), and the fast-growing self-service ordering display in the fast-food (QSR) retail application scenario. Secondly, during the epidemic, many stores added Digital Signage with Hand Sanitizer that can display posters, videos, and highly interactive in order to attract traffic. The creation of digital stores also promoted the growth of digital signage demand to a certain extent. Furthermore, due to the need for prevention, control, and isolation, manufacturers have taken longer to develop products. Therefore, during the epidemic period, the maturity of display terminal technology is catalyzed. The LCD & LED display technological competition during the epidemic has promoted the maturity of the technology and the decline in market prices, thereby stimulating the overall market.

The lineup of public displays and signage displays for "outdoor" or "semi-outdoor" applications with a brightness of more than 1,000 nits is growing steadily. The above display products need to work for a long time in a complex environment, usually with 1000nit or more, and adjust the brightness according to the ambient light; work around the clock (24/7); adapt to changes in high temperature, independently adjust the machine temperature; three protection (Waterproof), Dustproof, Anti-collision) and other characteristics.

In recent years, LED direct light-emitting display products with high brightness, high contrast, high response speed, customization, and strong protection have been in large scenes, and the outdoor application market for long-distance viewing can be said to be booming. It has grown into the preferred display product for outdoor sports, transportation, and building advertising markets. In 2019, LCD and LED direct light-emitting display technologies have joined hands in the "semi-outdoor" market, especially in retail and public places. In recent years, small-pitch GOB LED Display Technology has matured and costs have fallen. , The price of this product has also recently begun to show a downward trend.

Digital Signage is generally a small-size display terminal device that needs to be viewed from a close distance. The advantage of LCD is its small size and delicate display. Therefore, before the birth of small-pitch LED displays, LCD was the mainstream display terminal product for digital signage. At the same time, the entire industry has been committed to reducing chip size and pixel pitch. With the improvement of product resolution, small-pitch LED display products have begun to enter the indoor market and begin to compete on the same stage with LCD splicing walls, industrial projections, and other products.

Although LCD occupies part of the digital signage market, its low-brightness characteristics limit its application in outdoor advertising scenes. Therefore, in order to seize the opportunity of outdoor digital signage, digital signage manufacturers have come in to introduce brightness higher than 4000nit and IP protection level Products higher than 56, but their price is close to or even higher than that of P2-P5 LED displays, and their protection level is far less than that of outdoor LED displays. Therefore, in the field of outdoor digital signage with P2-P5 dot pitch, LED displays have advantages in price, brightness, and protection performance. However, in the field of fine-pitch products with higher pixel specifications, its price advantage is still inferior to LCD products. Therefore, major companies in the LED industry are trying to reduce the price difference and seize more digital signage market share.

In addition to regular comparisons of LCD and LED technologies in terms of resolution and seam, OMDIA believes that analyzing brightness specifications can provide more interesting comparisons for these technologies in the "outdoor" market. People usually ask "Isn"t LED more advantageous in terms of brightness?" It seems to be. However, due to the advancement of LCD panel technology, LCD can now provide products with brightness above 4000 nits without any technical difficulties. Therefore, it is difficult to say that LEDs are stronger than LCDs in the outdoor market.

At present, the price of outdoor LED displays with a dot pitch in the range of 2-5mm has approached or is better than that of high-brightness LCD display products, but for small-pitch products with higher pixel specifications, the price is higher than LCD products. Therefore, the major companies in the LED industry are trying to reduce the price difference and grab more market share. It is foreseeable that the LED and LCD are outdoors, and the semi-outdoor competition will become more intense.

Starting in 2021, the growth rate of outdoor digital signage display products will gradually exceed that of indoors. With the emergence of new high-brightness products, outdoor display products will have more opportunities to appear in new outdoor application scenarios such as outdoor sports and hotel terraces.

With the maturity of LED display technology and the decline in the price of small pitches, the Commercial terminal advertising display market will become intensified, and spread to the small pitch field, digital signage, and other major fields, and the competition of major machine manufacturers will also increase. It"s getting more intense. As a high-brightness display terminal, LED display screens have been gradually decreasing in price in recent years, and the dot pitch has been shrinking, and the display size has been shrinking. It has a strong impact on the digital signage display market and has become a dark horse in this field.

Plasma TVs contain tiny pockets of gas, and when a voltage is applied to them, they turn into a plasma state. The voltage then strikes the mercury within the plasma to emit ultraviolet (UV) rays, which pass through phosphor cells to produce an image. Each pixel in the TV contains three phosphor cells: red, green, and blue, and these three colors combine to produce a color. Essentially, plasma TVs don"t require a backlight, and each pixel is self-emissive as it produces its own light.

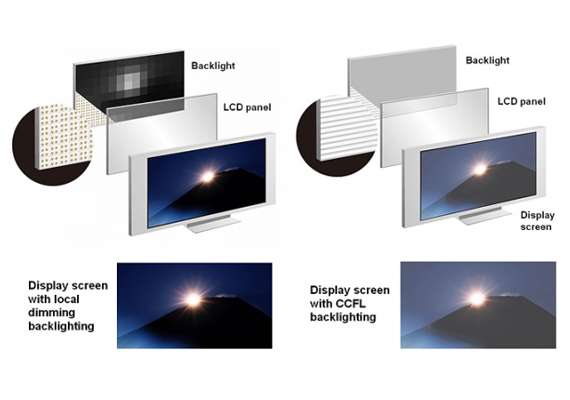

Unlike plasma TVs, LCD TVs use a backlight. Initially, LCD TVs used Cold-Cathode Fluorescent Lamp (CCFL) as their backlight. These are long tubes that are placed horizontally across the screen behind the LCD panel. When the light is turned on, it applies a voltage to the pixels, which makes them rotate a certain way to allow light through and produce an image. When it wants to display black, the pixels are rotated to create an opaque screen so that light doesn"t get through. This is what makes them different from plasma TVs because each pixel isn"t self-emitting.

Light-Emitting Diode (LED) TVs are the same as traditional LCD TVs, but instead of using CCFL backlights, they use many smaller LED lights. It produces an image the same way as a regular LCD TV because it still uses an LCD panel, but it has more control over the backlighting. The LEDs can be placed along the edges, which is called edge-lit LED, or all over the back panel, which is either called direct LED or full-array backlighting. You can see the differences between LCD and LED TVs below.

It"s also important to note LED is simply a marketing term used by manufacturers to describe their backlight. They"re still technically LCD TVs, but since calling them LED is so common now, we even label them as LED, and we"ll continue to do so throughout this article.

Plasma and LED TVs each present their own advantages and disadvantages in terms of picture quality, price, build, and availability. It"s generally thought that plasma produces a better picture quality due to their superior contrast ratio, but LED TVs became more popular because of other factors, like a lower cost and greater availability.

Below you can see the differences in picture quality between two older TVs from 2013. It"s clear the plasma was better at the time, but LED TVs have also gotten better since then, so picture quality has greatly improved.

Contrast ratio was one of the main advantages and selling points of plasma TVs. Since each pixel emitted its own light, it simply turned itself off when it wanted to display a black image. This allowed the TV to display very deep blacks, but because there was always a bit of charge left in the plasma, it still wasn"t a perfect black level.

On the other hand, LED TVs can"t achieve a perfect black level because the backlight is always on. However, technology has evolved to greatly improved the contrast of LED TVs, even to the point where it"s also as good as what plasma once was. There are two main types of LCD panels in TVs: Vertical Alignment (VA) and In-Plane Switching (IPS). VA panels produce a better contrast than IPS, and high-end TVs also have local dimming features that turn off certain zones of the LED backlights. Still, you won"t get a perfect black level, but most modern LED TVs produce such deep blacks that even in a dark environment it looks like perfect black levels. For reference, plasma TVs had a max contrast of about 4,000:1, according to DisplayMate.com, but some recent LED TVs can reach a contrast of over 20,000:1 with local dimming enabled, like the Samsung QN90A QLED.

LED TVs are a clear winner here, and it"s one of the reasons why they surpassed plasmas in terms of popularity. LED TVs get significantly brighter, so they can fight glare from light sources easier. Additionally, plasma TVs had to use glass on their front panel, which caused intense glare if you had any lamps or windows around the TV. LED TVs can use a coating on their glass panel to help reflect and diffuse light, making it a better choice for well-lit rooms.

Plasmas were designed for dark-room viewing, but since most people don"t have dedicated home theater setups and often watch with a few light sources around, they weren"t that useful. As you can see below, the plasma TV had pronounced reflections, to the point where it"s even hard to see the image, and instead you"re watching yourself watch TV. Reflections are still noticeable on an LED TV, but at least you can see the image.

Pixels on plasma TVs emitted light in all directions, creating extremely wide viewing angles, much better than most LED TVs. This means that the image remained accurate when viewing from the side, which was great for watching sports or a show with a few people. Out of the two main panel types for LED TVs, IPS has wider viewing angles than VA panels, but it"s still not as good as plasma.

Below you can see the differences in viewing angles between a plasma and a VA panel. These TVs were tested on different test benches, so you shouldn"t directly compare the videos, but we included them to give you an idea of how each technology affects the viewing angle.

Plasma TVs were great for motion handling, like with sports and video games due to their quick response time. Since each pixel had to retain a certain charge at any given moment, it was ready to display an image almost instantly. This meant fast-moving scenes looked crisp and smooth, with no motion blur behind them. However, for LED TVs, it can be a toss-up; some lower-end models have a slow response time that causes motion blur, while other high-end TVs have a really fast response time.

Some LED TVs also use Pulse Width Modulation to dim their backlight, and this causes the backlight to flicker, which may create image duplication in fast-moving scenes. This can be particularly annoying, especially if you"re watching sports with fast-moving content.

In terms of refresh rate, plasma TVs had a higher internal refresh rate, up to 600Hz, while LED TVs tend to be 60 or 120Hz. However, the refresh rate depends on the content, and since most content doesn"t go past 120 frames per second, having a higher refresh rate TV isn"t very useful.

Screen uniformity is another area where plasma TVs win. Since they didn"t have a backlight, they could evenly control each pixel. LED TVs can suffer from uniformity issues, like darker edges or Dirty Screen Effect in the center, because the backlight output may not be even across the panel. However, this is only really noticeable when watching content with large areas of uniform color, like a hockey or basketball broadcast, or if you"re going to use the TV as a PC monitor. It shouldn"t be noticeable with other types of content, and since uniformity can vary between units, you shouldn"t worry about it too much.

One of the reasons plasma TVs didn"t last too long at the top of the TV world is because of their risk of temporary image retention and permanent burn-in. Plasmas lose their brightness over the years, and in the worst case, would have permanent burn-in with certain colors staying on the screen, as you can see here. Even after watching content with static elements, like the news, for an extended period, the outline of the static elements would stay on the screen for a few minutes after changing the channel.

These problems are particularly annoying, especially if you watch a lot of TV. There was no way to help reduce this issue, and after a few years, depending on how much you used the TV, your plasma would need replacing. LEDs don"t suffer from this same permanent burn-in, so you won"t have to worry about replacing your LED TV down the line because of burn-in.

Due to their different technologies, LED and plasma TVs are built differently. Plasma TVs tended to be heavier and thicker because the panel itself was larger. Although plasmas were the first flat-screen TVs available at a consumer level at the end of the 20th century, LCD TVs quickly became even thinner, easier to package, and lighter to carry from the store to your house. These days, LED TVs are as thin as 1", like the Samsung QN85A QLED.

Plasma TVs also required a lot of power to work and tended to get very hot. With the growth of environment-friendly consumer practices, it became clear LED TVs would win out since they required a lot less electricity, and in a way were better for the environment.

Both plasma and LED TVs were made with larger sizes, but LED had a slight advantage because they were also made in displays smaller than 32 inches, like with monitors. Although small TVs are rare now, you can still find a basic 28 or 32 inch TV for a kitchen or bedroom with an LED panel. Plasma TVs weren"t made that small. LED TVs also cost less to produce and are cheaper on the market, so at the end of the day, the lower cost drove LED sales.

When 4k TVs started to become the norm over 1080p and 720p TVs in the mid-2010s, manufacturers started to produce 4k LED TVs, while plasma TVs were stuck at 1080p. This presented a major advantage for LED TVs, as a higher resolution helps create a crisper image, and this essentially was the nail in the coffin for plasma TVs. Since manufacturers were focused on making 4k LED TVs, plasma TVs became less available, and by 2014, Panasonic, LG, and Samsung all stopped their plasma production. LED TVs surpassed plasma sales in 2007, and they haven"t looked back since.

There were a few other problems that contributed to the decline of plasma TVs. First of all, plasma TVs didn"t work at high altitudes because of the change in air pressure with the gasses inside. They would create a buzzing noise, and the image wouldn"t look the same, so this could have been problematic if you lived at a high altitude. LED TVs can be used at any altitude; you shouldn"t use them in extreme cold or extreme heat, but this is standard practice for any electronic, and temperature is easier to control than your altitude. Also, plasma TVs emitted a radio frequency that could have interfered with other devices around, like if you had a radio in the same room. Each of these issues are simply inconvenient for most people.

There could be other advantages if you upgrade your TV, like technological advancements and a higher 4k resolution. Modern TVs come with a built-in smart system, which isn"t something that most plasmas had, and this allows you to directly stream your favorite content without the need for an external streaming device. As mentioned, LED TVs aren"t very costly, and you can easily find the best 4k TVs for under $500.

At the same time that plasma TVs met their end, OLEDs grew from the ashes of their predecessor. After LG released the first commercially available 55 inch OLED in 2012, it soon competed with LED TVs. OLED, which stands for Organic Light-Emitting Diode, is different from plasma, but shares many of the same characteristics, while also avoiding some of plasma"s downfalls.

OLEDs use self-emissive pixels, but what sets them apart is how the pixels completely shut off, creating an infinite contrast ratio and perfect black uniformity. This is an improvement from plasma because it was never able to reach those perfect blacks. OLEDs also have wide viewing angles and a near-instant response time like plasmas. Sadly, they don"t get extremely bright, but they"re still better for well-lit rooms than plasma because they get a bit brighter and have much better reflection handling. Also, OLEDs have the same burn-in risk as plasma, but this only happens with constant exposure to the same static elements, and we don"t expect it to be a problem for people who watch varied content.

Another advantage for OLED is how thin they are, especially compared to plasma, and they aren"t as heavy. For example, the LG GX OLED is a TV designed to sit flush against the wall and it"s only 0.94" thick!

Compared to LED competitors, OLEDs are much more costly, and even though they offer superior picture quality, LEDs are still the favorite. Also, LED TVs are available in smaller sizes, while the smallest OLED TV we"ve tested is 48 inches. LEDs are generally the better choice for well-lit rooms since they still get much brighter, but OLEDs are a fantastic choice for dark room viewing.

Although plasma TVs once dominated the TV market for a short time at the turn of the 21st century, their disadvantages outweighed their advantages, and LED-backlit LCD TVs soon held the market share of sales. There were a few reasons for this, like burn-in issues, low peak brightness, and a thick and heavy design compared to LED TVs. Despite plasma TVs" superior overall picture quality, improved contrast, and very quick response time, it wasn"t enough to convince consumers to keep buying them once 4k LED TVs became readily available. If you still have a plasma, it"s likely you"ll need to replace it within the next few years, and you"ll probably buy a new LED TV.

Plasma screens contain tiny pockets of gas that get excited when voltage is applied to them, turning them into a state of plasma. In that state, the voltage then strikes electrons of mercury, turning them into ultraviolet (UV) light, which isn"t visible to the human eye. The UV light then passes through phosphor cells; each pixel contains red, green, and blue phosphor cells. Thanks to these phosphor cells, the TV can turn the UV light into colors that are visible on the light spectrum. Essentially, plasma TVs don"t require a light, and each pixel is self-emissive, so how one pixel displays itself is independent of the next pixel.

Since each pixel emits its own light, blacks are really deep. When the television wants to display black, it simply emits no light at all for the selected pixels. However, these aren"t perfect blacks because each pixel retains a bit of voltage, leaving a bit of light to pass through. Each pixel emits light in all directions, creating wide viewing angles, so the image remains accurate when viewing from the side.

The pixels aren"t excited continuously, but in short pulses, and some plasma TVs can pulse up to 600 times every second. The naked eye perceives this as flickering, and some people are very sensitive to this. There can also be some advantages to this; since each pixel holds a certain charge, it"s ready to turn on and off as needed, resulting in minimal motion blur. This means that fast-moving content, like in sports or video games, appears smooth.

One of the downsides of plasmas was how they suffered from occasional image retention if they displayed the same image for a long period. So if you watched the news for about an hour, with all of its static displays, then switch channels, you"d still see the outline of the static elements. Eventually, they disappeared, but it could have been particularly annoying. Also, after several years in use, plasmas suffered from permanent burn-in. This happened when the phosphor cells simply stayed stuck in one color and couldn"t display any colors. Unfortunately, there was no way to avoid eventual burn-in, and almost every plasma TV suffered from it.

OLED TVs have similar characteristics to plasmas with their infinite contrast ratio, wide viewing angles, near-instant response time, and to a lesser extent, the risk of permanent burn-in. Since 2012, they"ve replaced plasma as a competitor to LCD TVs, and to learn more about OLEDs and how they differ from LCD TVs, see here.

An LCD screen is composed of two parts: the actual liquid crystal display and a light source at the back of the screen (called backlight). A light diffuser is placed between the backlight and the LCD screen to make the source of light uniform across the screen.

The LCD panel doesn"t emit light by itself, and this is why it needs a backlight; it only acts as a filter to block the light on a per-pixel basis. The backlight is always on, and the pixels in the display rotate to allow light through, creating the colors needed for the image. If the screen wants to display black, the LCD pixels rotate to try to block the light completely. If it wants to display white, it lets all light through. Since the display is only a filter, the blacks will not be as deep as with a plasma screen because an LCD panel will always let a small portion of light through.

There are different types of LCD panels, each with its unique characteristics. Vertical Alignment (VA) panels generally have a high contrast ratio and narrow viewing angles, while In-Plane Switching (IPS) panels have a low contrast ratio with wide viewing angles. You can read about their differences here.

By using a backlight, LCD TVs use much less power than plasmas, which you can read about here. Also, LCD TVs tend to get much brighter than plasmas, making them more suitable for well-lit rooms. There are two main types of backlights used in LCD screens: CCFL and LEDs.

When someone refers to an LCD TV, they usually mean a Cold-Cathode Fluorescent Lamp (CCFL) backlit LCD screen. The first LCD TVs were lit by CCFLs, but they"re extremely rare as of the start of the 2020s. The backlight is a series of light tubes placed behind the screen. These tubes are very similar to fluorescent lamps used in buildings but smaller.

CCFL-backlit LCD TVs were eventually replaced by LED TVs because they cost less, were made thinner, and required less power. Also, LED TVs have more control over their backlight, resulting in vivid colors and better picture quality.

An LED (Light-Emitting Diode) screen is an LCD screen, but instead of having a normal CCFL backlight, it uses LEDs as the source of light behind the screen. Companies label their TVs as LED, even though they"re technically LCD; it can be confusing at times, but if you see an LED TV, you know it has an LCD panel. These TVs are more energy-efficient and a lot smaller than CCFLs, enabling a thinner television screen.

In a full-array LED screen, the LEDs are distributed evenly behind the entire screen. This produces a more uniform backlight and provides more effective use of local dimming, where it can turn off and dim complete zones of LEDs.

With an edge-lit LED screen, the LEDs are placed at the edges of the screen. Depending on the display, it can be all around the screen, on the left and right sides, or at the top and bottom. This allows the screen to be very thin.

However, it can cause some spots on the screen to be brighter than others, like the edges. This problem is called flashlighting or clouding. It can be seen when watching a dark scene in a dark environment. Also, edge-lit screens usually don"t result in good local dimming as they don"t have control over the dimming zones.

Like the full-array method, the LEDs are directly behind the screen. However, there are very few of them, and they can"t be controlled separately to match the luminosity of the picture.

As TV companies attempt to improve their technology, a new type of LED backlighting has emerged: Mini LED. It uses the same traditional LED backlighting behind an LCD panel, except the LED lights are even smaller. This allows for more lights, creating a brighter image and more control over local dimming. Only a handful of Mini LED TVs were produced before 2021, but it now seems that manufacturers are starting to use the technology more often. The Samsung QN90A QLED is an example of a Mini LED TV.

Another technology, Micro LED, is only in its initial phases of development. This doesn"t even have an LCD panel as each LED pixel is self-emissive, similar to OLEDs, but without the burn-in risk. Currently, there aren"t any Micro LED TVs available at the consumer level; Samsung has produced large Micro LED TVs (over 100 inches), and they"re very expensive. However, we may begin to see Micro LED technology in the consumer TV market soon.

Plasma and LCD each present advantages and disadvantages when it comes to picture quality. Plasma TVs generally offer better contrast, wider viewing angles, and improved response times, while LCD TVs get much brighter and have better reflection handling. LCDs also cost less and can be much thinner, which are two of the main reasons why they took over the market share from plasmas in the mid-2000s. Plasma TVs are now extinct, and although OLEDs share many of the same characteristics, LED-backlight LCD TVs are now the norm, and it"s likely your next TV purchase will have an LCD panel.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey