led vs lcd display difference made in china

The display of LED video wall technology is colorful, energy-saving and environmental friendly, and the visual angle is high. However, we do not know what led technology is and what is good about it. As the leader of LED display screen industry, Shenzhen Kaipu Technology Co., Ltd. has the obligation to popularize what is led and what is led tv.

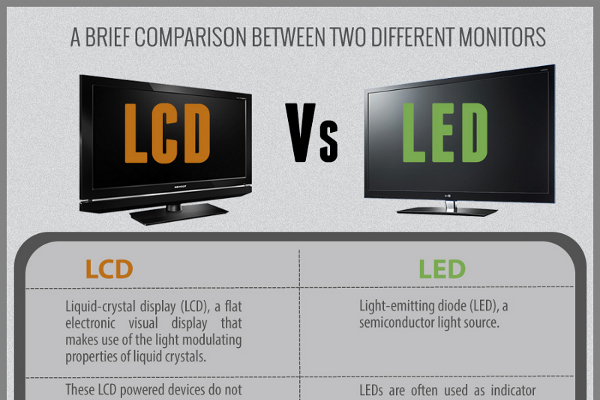

The liquid crystal display we often use is actually an LCD display, which is called liquid crystal display in English. Most of the panels are TFT, TFD, ufb and STN. The working principle of the liquid crystal display is to change the color of the liquid crystal inside the transistor by applying power, and there is a fluorescent lamp CCFL backlight behind the transistor board, which usually consumes a lot of power. The LED screen display we see is usually derived from the LCD display, and generally refers to the liquid crystal display using the LED backlight. The LED technology display is not a real LED display, so Samsung was sued for this matter. Since the LED display on the market only uses LED backlight technology, most of the LED displays on the market have been changed to LED backlight display

Since the display uses LED tubes as the backlight, with the help of LED technology, the display body can be made lighter and thinner; As the LED tube itself is more energy-saving, the energy-saving and environmental protection aspects are certainly better than the normal display; However, there is not as big a gap in imaging as that spread on the Internet, because the essence is the same thing, and it is impossible to have too big differences.

I believe that by now we have basically understood the difference between LCD and LED backlight display. The real LED display does not need backlight, so the process requirements are higher and the price is expensive. At present, it has not been popularized, and the only ones are still limited to commercial use.

It seems as if modern displays have all kinds of different labels: high definition, 3D, smart, 4K, 4K Ultra, the list goes on. The two most common labels are LCD and LED. What’s the difference between the two? Is there a difference? And does this difference make one or the other preferable for certain types of activities like gaming or graphic design?

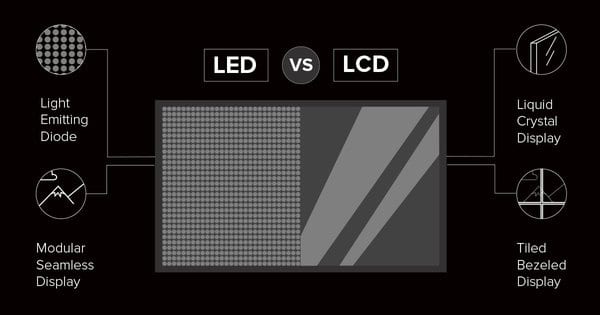

All LED monitors are LCD monitors. But not all LCD monitors are LEDs. Kind of like all eagles are birds, but not all birds are eagles. While the names might be confusing to those wading through specs to find the best monitor, once you break it down it’s easier to understand than you think.

We’ll explain the tech and the naming conventions, and then highlight some HP monitors that might be the perfect fit for your needs. Let’s figure out exactly what LCD and LED monitors are and how to pick the right one for you.

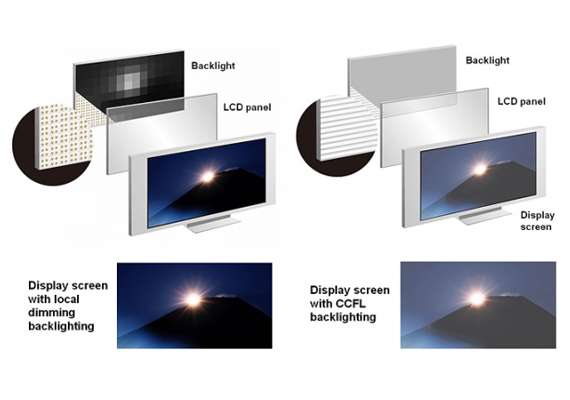

Both types of displays use liquid crystals to help create an image. The difference is in the backlights. While a standard LCD monitor uses fluorescent backlights, an LED monitor uses light-emitting diodes for backlights. LED monitors usually have superior picture quality, but they come in varying backlight configurations. And some backlight configurations create better images than others.

Until 2014, plasma displays were the most commonly manufactured displays. But then the LCD took over. LCD stands for liquid crystal display. We’ll go over what that means in a minute. But first, it’s important to note that an LED also uses liquid crystals, so the name is somewhat misleading. Technically, an “LED monitor” should really go by the name, “LED LCD monitor.”

First, let’s go over how LCD and LED monitors utilize liquid crystals. The science behind this stuff features an incredibly complicated mix of optics, electrical engineering, and chemistry. But we’ll explain it in layman’s terms.

Pixels are the basic building blocks of a digital image. A pixel is a small dot that can emit colored light. Your display is composed of thousands of pixels, and they’re in a variety of different colors to give you your computer interface and the webpage that you’re currently reading. It works like a mosaic, but each individual piece is much less noticeable.

LCD monitors have backlights behind the screen that emit white light, and the light can’t pass through the liquid crystals while they’re in their liquid arrangement. But when the pixel is in use, the monitor applies an electric current to the liquid crystals, which then straighten out and allow light to pass through them[2].

Standard LCD monitors employ “cold cathode fluorescent lamps,” also known as CCFLs as backlights. These fluorescent lights are evenly placed behind the screen so that they deliver consistent lighting across the display. All regions of the picture will have similar brightness levels.

LED monitors don’t use fluorescent lamps. Instead, they use “light-emitting diodes,” which are extremely small lights. There are two methods of LED backlighting: full-array backlighting and edge lighting.

With full-array backlighting, the LEDs are placed evenly across the entire screen, similar to an LCD setup. But what’s different is that the LEDs are arranged in zones. Each zone of LED lights can be dimmed (also known as local dimming).

When there’s an area of the picture that needs to be darker (a night sky, for instance), the LEDs in that region of the picture can be dimmed to create a truer black. This is not possible on standard LCD monitors, where the entire picture is lit evenly throughout.

There are no local dimming capabilities in edge-lighted displays, so they can’t create pictures that are as high-quality as those created by full-array LEDs. However, edge lighting enables manufacturers to create extremely thin displays that don’t cost as much to produce - and which are better for a tight budget.

When it comes to picture quality, full-array LED monitors are almost always superior to LCD monitors. But bear in mind that only full-array LEDs are superior. Edge-lit LEDs may actually be inferior to LCD monitors.

A full-array LED monitor should be your number one choice for gaming. Steer clear if its edge lighting. The problem with edge lighting is that you’ll have fewer optimal viewing angles with which to play games. That’s not an issue if you prefer to sit directly in front of the screen while you’re gaming. But if you like to kick back in your chair or view from different angles, you’ll find that an edge-lit LED loses visibility as you move away from the center viewing angle.

But even if you play while you’re directly in front of the monitor, edge-lit LEDs have more issues with glare than full-array LEDs do. That’s because of the uneven lighting (very bright around the edges, darker as you approach the center of the display). Because the pixels are evenly lit, LCD monitors tend to have better viewing angles and anti-glare than edge-lit LEDs.

Edge-lit LEDs do have two big advantages. If you have a very tight space in which to fit your monitor, you’ll like having an edge-lit LED because they’re usually thinner than the other types. They’re also less expensive to manufacture, which make them easier on the wallet.

When you’re shopping for a new display, don’t forget to review all of its specs. While the backlighting type is important, you should also take the resolution and refresh rate into account.

Resolution refers to how many pixels are displayed on the monitor. Remember, the more pixels you have, the more dynamic your composition of colors can be. The highest-quality monitors have resolutions of at least 1920 x 1080.

Refresh rate refers to how quickly your monitor updates the display with new information from your computer’s GPU. If you’re a gamer, it’s important that you get a monitor with a very fast refresh rate (30 Hz to 60 Hz) so you won’t suffer from screen tearing - a nasty visual effect that happens when your monitor can’t keep up the pace with the GPU.

Because LED monitors create better pictures than LCD monitors, nearly all of HP’s displays are built with LED backlights. When you’re browsing through the HP LED monitors, you might notice that some of them are equipped with either “IPS” or “AHVA” technology. These refer to the types of liquid crystal panels that are used. Both are fantastic, although they have some minor differences:

You’ll also see that some monitors have “TN” LED backlights. This is the oldest form of liquid crystal technology. It’s still very effective, but TN panels are typically used in small, work-oriented monitors that are made to be mounted or used in the field.

HP OMEN gaming monitors are built for the power PC gamer. One of the best gaming monitors for your rig is the HP OMEN 32 32-inch display. This LED monitor has VA-type panels, which help give it a fast refresh rate that’s perfect for high-performance gaming.

If you’re a digital illustrator, video editor, photo editor, or special effects wiz, you should give the HP EliteDisplay S270n 27-inch 4K micro edge monitor a look. When you’re creating digital art, you need the most expansive resolution and highest-quality color production possible, and that’s what you’ll get with this IPS-equipped monitor. The micro edge screen makes it easy to use dual monitors, but the 27-inch screen alone gives you a wide interface to work on.

If you’re a business person, try one our HP EliteDisplay monitors, like the HP EliteDisplay E243 23.8-inch monitor. The IPS LED display is gorgeous and will give you a crisp and clear picture no matter what software you’re using. The micro edges make it perfect for a dual monitor setup, and the 23.8-inch size is wide, but not too large to accommodate a second monitor or to fit into tighter workstations.

There are some up-and-coming technologies that are making LED displays even better. OLED and QLED displays are bound to become more commonplace in the future.

“OLED” stands for “organic light-emitting diode.” What makes an OLED unique is that each pixel has a light source that can be individually shut off. On an LED monitor, the only way to keep a pixel from emitting light is to keep the liquid crystal closed. It’s effective, but not perfect - a small portion of light will always seep through. On an OLED monitor, each pixel’s light can be entirely shut off so no light at all will emanate through the liquid crystal. These means you can get truer blacks, which means deeper contrast ratios and better image quality.

There are two additional advantages. First, OLED monitors can be made even thinner than LED monitors because there’s not a separate layer of LEDs behind the pixels. Second, these monitors are more energy efficient because the pixels will only draw power when their light is turned on. One of the downsides, though, is that pixel burn-in will be more noticeable since some pixels will inevitably be used more than others[4].

“QLED” stands for “quantum light-emitting diode.” In a QLED monitor, each pixel has a “quantum dot.” Quantum dots are tiny phosphor particles that glow when you shine a light upon them[5].

Why would you need a glowing particle over each pixel? Because LEDs aren’t very good at emitting bright light. The brightest color is white. But an LED doesn’t emit white light – it emits blue light. Each LED is given a yellow phosphor coating to make it appear less blue and more white, but it’s still not true white. The “blueness” of LEDs negatively impacts the red, blue, and green colors on LED displays. LED monitors have automatic features that adjust the RGB colors to compensate for the blue light, but it can’t compensate for the weaker light intensity.

That’s where the quantum dots come in. The pixels are overlayed by a sheet of red and green quantum dots (there is no blue because blue light is already being emitted by the LED). When the light shines through the liquid crystals, the quantum dots glow, and you’re given a bright, vivid, and lovely spectrum of RGB colors.

Displays are a complicated science, right? But next time you’re shopping for monitors at the store or on our HP Store site, you’ll be a true expert and will be able to pick out exactly the right display for you.

One of the most common questions we’re asked when assisting businesses establish their digital signage systems is whether an LED or an LCD display is preferred. The answer is always contextual to the clients" needs. It starts by clarifying what the difference between the two actually is.

When we’re talking aboutconsumer products such as computer monitors and televisions the first thing to know is that an LED screenis an LCD screen, but an LCD screen is not always an LED screen. An LED monitor or television is just a specific type of LCD screen, which uses a liquid crystal display (LCD) panel to control where light is displayed on your screen.

For the display to be considered an LED screen, it means it is utilising ‘Light Emitting Diodes’ to generate the light behind the liquid crystals to form an image. A non-LED LCD screen has backlights (called fluorescent lamps) behind the screen that emit white light which cannot pass through the liquid crystals until an electric current is applied to the liquid crystals which then straighten out and allow light to pass through.

This is where it can get easy to divert away from giving clear advice on LED vs LCD for digital displays, because consumer displays differ from commercial displays. We are not trying to give the reader direction on which monitor is best for their gaming set-up, but which screen type is ideal for communicating your business’ messages.

Commercial LED displays are typically referred to as Direct View LED. This is because they use LEDs as the individual pixels that make up the image itself. Using a surface array of LEDs removes any need for a liquid crystal display panel, which carries noticeable benefits for particular uses.

While LCD flat panels are available in resolutions of 1080P and 4K UHD, Direct View LED displays are measured by pixel pitch. Pixel pitch is the distance from the centre of one pixel cluster to the centre of the next pixel cluster in an LED screen. The smaller the pitch, the closer viewers can get to the display before they see the pixels themselves. Outdoor configurations may have a pitch of 10mm to 40mm, as they are viewed at longer distances.

For use indoors, where viewers would be closer to the display, a pitch of 10mm or less would be required, some have even sub-1mm pixel pitch. When considering Direct View LED displays, it is important to know the minimum viewing distance required. Multiplying the pixel pitch by 1,000 gives you a good rule of thumb for the minimum viewing distance.

Direct view LED displays can either use discrete oval LEDs which are basically one single self-contained diode, or Surface Mounted Device (SMD) LEDs. SMD LEDs contain 3 individual light-emitting diodes bunched together. Either way, it’s the light-emitting diodes that create the images you see on screen.

Commercial LCD screens are more closely related to their consumer counterparts like TVs but there are still differences to be aware of. It is not advised to simply purchase an LCD TV from your local electronics retailer and install it in a public setting and expect it to function as desired.

Both have been designed to be used differently. Commercial display manufacturers understand that their displays are going to be exposed to far different conditions than a living room television will be. The componentry in a commercial display is optimised to allow for the display to be on 24 hours a day, all year around. They take into account diverse environments such as hot kitchens, high foot traffic, and bad weather,ensuring the product won’t fail in such exposures. The addition of more durable and resistant technology means commercial LCD displays will typically be priced higher than their consumer cousins.

Benefits of Commercial LED compared to Commercial LCDBrightness: When deployed in areas with strong ambient lighting, even the best LCDs can appear washed out and difficult to view, especially when from an angle. Direct view LEDs for outdoor applications can reach 9,000 nits, making them a brighter and better choice for most outdoor applications.

Contrast: Direct View LEDs can turn off pixels that aren’t being used which allows for a higher contrast and therefore a richer image in varied lighting conditions.

Size and shape: Direct view LED-based walls can be flat, curved, wrapped around pillars and more. With no size limit or set aspect ratio they can be used more flexibly than LCDs. Plus, panels have no bezels which means you can piece together Direct view LEDs to create large and uniquely shaped displays with no visible interruptions between units.

Lifespan and servicing: Most direct view LEDs are rated to last 10 years, compared to a typical 5 years for LCDs. Further, they can be easily replaced on-site, reducing maintenance costs.

Tougher: If you’re using an LCD for any outdoor application or one where the unit has to be protected from extreme temperatures or humidity, you’re going to need to include an enclosure and have an understanding of how to properly seal and vent the unit. Outdoor Direct view LEDs, on the other hand, are purpose-built to withstand harsh environments.

Benefits of Commercial LCD compared to LEDsPrice: The higher upfront cost of Direct LEDs could be the biggest sticking point when it comes to pitching a video wall. While prices have been steadily dropping, Direct view LEDs are still more expensive than LCD alternatives. However, make sure you consider the lifetime cost of the solution and other benefits mentioned above before you discount direct view LEDs.

Functionality: LCD screens can offer a wider range of functionality when it comes to set-up, display settings, and day-to-day control. There is also the addition of touch screen options for LCD displays which are a fairly sought-after feature these days.

Resolution: Whilst the fine pixel pitches available in direct view LEDs today make for impressively resolute images, LCD screens still boast are more uninterrupted image when viewed up close, particularly with the modern 4k displays. This makes them a better option for smaller retail stores, quick service restaurants or office meeting rooms.

As earlier stated, intended use for the display will determine which format you invest in. In outdoor environments or areas with high ambient lighting, brightness is the key concern. For indoor environments, the key concern is image quality and contrast. It’s also imperative to consider the usage environment and what the screen may be exposed to with regards to weather, temperature, humidity, direct contact and other factors. If you have a good understanding of your requirements for content, application, perception and budget then your first move should be to contact a supplier, like Black Lab Design, and we will be able to assist you with designing, building and installing the perfect digital display solution for your business.

What is the difference between LCD display and LED display? LED backlight is power saving, high priced, vibrant and saturated. LCD is power consuming and cheaper compared to LED backlight. On the screen, LED backlighting is more vivid and saturated. LED display"s individual element response speed is 1000 times faster than LCD LCD, which can also look good under strong light and adapt to low temperatures of -40 degrees. Here"s a detailed look at LED and LCD displays with me.

LCD is the full name of Liquid Crystal Display, mainly TFT, UFB, TFD, STN and several other types of LCD can not locate the program input point on the dynamic link library.

TFT (Thin Film Transistor) is a thin film transistor, each LCD pixel point is driven by a thin film transistor integrated behind the pixel point, thus allowing high speed, high brightness, high contrast display screen information, is currently one of the best LCD colour display devices, is now the mainstream display device on laptops and desktops. It is one of the best LCD colour display devices available and is now the dominant display device on notebooks and desktops. Compared to STN, TFT has excellent colour saturation, reproduction ability and higher contrast ratio, and can still be seen very clearly under the sun, but the disadvantage is that it consumes more power and is also more costly.

LED is the abbreviation for Light Emitting Diode. LED applications can be divided into two main categories: one is LED displays; the other is LED single tube applications, including backlight LEDs, infrared LEDs and so on. Now in terms of LED display, China"s design and production technology level is basically synchronized with the international. LED display is a display device composed of an arrangement of light-emitting diodes 5000 yuan computer configuration list. It uses low voltage scanning drive, with: less power consumption, long service life, low cost, high brightness, less failure, large viewing angle, visual distance and other characteristics.

Compared to LCD displays, LED displays have more advantages in terms of brightness, power consumption, viewing angle and refresh rate. Using LED technology, a thinner, brighter and clearer display than LCD can be manufactured.

3, LED provides a wide viewing angle of up to 160 °, can display a variety of text, digital, colour images and animation information, can play TV, video, VCD, DVD and other colour video signals.

4, LED display of the individual elements of the response rate is 1000 times faster than LCD LCD, can also be seen in bright light, and adapt to the low temperature of minus 40 degrees.

Simply put, LCD and LED are two different display technologies, LCD is a display made up of liquid crystals, while LED is a display made up of light emitting diodes.

3, If the viewing distance is far and the area is large, please choose LED display, the spacing can be based on the size of the area, choose more than 2mm spacing LED display.

5, Cost, LED display spacing is probably the watershed in the 2mm spacing, 2mm below the LED display unit area is higher than the LCD splicing display. 2mm spacing above the LED display unit is lower than the LCD splicing display.

An LED stands for light-emitting diodes. It is among the latest in technological innovations related to screening display. It makes use of LEDs behind the screen as the source of light. LEDs are brighter and more energy-efficient than an LCD screen that uses a CCFL backlight. They are also a lot smaller that helps in producing thinner screens like never before. Since LEDs are very bright so the display doesn’t get marred even in broad daylight. That is the reason LEDs are extensively used in signboards and advertising boards throughout the world. Let’s take a deeper look at this technology here and get to know it better.

Outdoor LED displays are used for advertising, promotion, and informative purposes. You can install them easily almost anywhere and they will do their job effectively. You can use them 24/7. They consume less electricity, have a long life, low-maintenance and are eco-friendly. They are available in a variety of sizes and you can also make one according to your custom needs. You can make one giant billboard, signboards, advertising banners, LED boards, LED video walls, perimeter LED boards, with the help of LED screens.

The outdoor LED display market is poised to grow at a robust speed. It is estimated to be worth around US$22.4 billion by the year 2024. That’s a CAGR of over 20% from 2016-2024.

Many factors are fueling this growth. For starters, companies prefer to advertise their brands and products through LED displays, smart billboards with wireless connectivity and easily changeable content are a rage nowadays. Similarly, 3D technology is being employed in LED displays for a more immersive and personal viewing experience. Motion sensor technology and interactive displays are also making their mark. The demand for high resolution displays for showcasing anything like advertising in perimeter boards in a stadium, musical concert, traffic updates on roads, live sporting events, exhibitions will contribute to the growth of the LED display sector. The continuous technological advancements in this sector will mean crisper, clearer, and livelier displays in the future. So, just like the display LEDs, the future is very bright for this sector.

Despite all its success and potential growth, the LED display market is not without its share of challenges. Here, we briefly discuss some of the more important ones.

Unstable supply of raw materials: An LED screen is made of several electronic components. It is difficult to produce all of them in the same country. When you have to import from other countries difficulties arise. From ensuring fair quality to optimum quality to coping with fluctuation in forex rates to import tariffs. All these factors combine to make the procurement of raw materials difficult to manage.

Capital: LED manufacturing involves huge capital. It is not always to raise one on your own. If you go to a bank, it will imply interest payments. This will affect your cash flows and profit margins.

Technological innovation: LED manufacturing is technologically intensive. There is a race going on to beat your competitor at the cutting edge of technology. As a manufacturer, it will be a challenge for you to keep up with all the new changes. It might involve the injection of new funds or training the old staff or hiring a new one.

Logistics: Transporting LEDs from one place to another involves a great deal of caution. They have to be securely packed to withstand shocks and jerks. Even a crack can ruin the entire screen, what to talk of a broken one.

Rules of import: As an importer of LEDs you have to comply with the local import laws. This includes getting an import permit, paying import duties, transportation cost, and custom clearing charges. Sometimes a slight change in rules can throw your estimates out of the window.

Low profits: There is stiff competition going on among the LED manufacturers. While this is good news for the consumer the producer may suffer because of low-profit margins. This precludes entry of new players and leads to grouping.

Expensive labor: You require skilled and competent labor to produce LEDs and they come at a price. This is particularly problematic as the margins of profit continue to squeeze.

Ideal location: Everybody wants the best placement of its LED screens for promotional purposes. The best spots are few and far between. This results in a rising price of prime locations and unhealthy competition among the brands to get the best spot.

Rental screens: The rental LED screens face a lot of wear and tear because they change locations and this consequently reduces their life and performance.

The most important use of LED displays is for advertisement purposes. This includes billboards, banners, perimeter boards, boards, signboards, etc. They can be installed at various locations of choice.

It is the same as outdoor advertising with the only difference that their location is not permanent. They can be installed and uninstalled at various locations as per requirement.

Transparent LED display is an innovation of recent times. It lets viewers see things behind the screen as well. This has become possible due to the material, structure, and design of the display screen. It is not 100% transparent, the transparent rate is around 50-95%. The thickness is around 10mm. It is just like a glass.

LEDs have become quite popular for stage productions. People in the back seats can now see the action on stage thanks to these screens. They are usually large and very bright to produce a visible image. They are used in entertainment events and art exhibitions.

Like entertainment events, LEDs have become very popular to broadcast sporting events too. They are installed inside and out of the sporting arenas to bring spectators closer to the game. Their installation has helped rekindle the interest in live sporting events.

Outdoor digital displays are used for a variety of purposes. They can be installed on roads to provide traffic updates, in airports and railway stations to give information about trains and airplanes’ schedule and in sports to display scorecard. The uses are multiple and varied and you can use it for your advantage.

In such kinds of displays, a video is run on a loop on a large screen. Usually, the video is of an educational or informative nature. You can install it at any event to give information to the visitors, on election day telling people how and where to vote or videos that give useful information on health, social issues, etc. to the general public.

What is life without colors? From the time first black and white image surfaced man had been striving to convert it to colors. Once that was accomplished, the race is on to bring colors as close to real-life as possible. LEDs are no exception. They take pride in reproducing colors on screen as close to nature as possible. They look attractive and capture your attention.

In a quest for excellence, the color display went from better to best and the journey is ongoing. HD display is one such example. HD, of course, stands for high definition. HD has a resolution of 1280×720 pixels. Full HD has a resolution of 1920×1080 pixels. It doesn’t stop here and goes further to UHD, OLED, etc. These are especially helpful where you have to showcase products like jewelry, clothes, etc.

Eye-catching: The first and foremost is that the LED advertising screens are attention-grabbing. Their crisp, colorful and sharp images are very appealing. You are instantly drawn towards them.

Eco-friendly: Unlike flex, paper, or clothing banners there aren’t any harmful chemicals used in producing LEDs. You also save a lot of trees because LEDs don’t require organic elements for production.

Energy-efficient: LEDs consume very low voltage and they produce very striking results. This saves electricity. You get a very bright image at a very cost.

Low-maintenance: LED screens are almost maintenance-free and can withstand weather adversaries too. You will see them displaying their imagery in the rain and intense sunlight.

Changing content: You can change the content of an LED advertising screen quite easily. This means you can run multiple campaigns of the same brand simultaneously. This gives variety to the viewer and he doesn’t feel bored with seeing the same campaign again and again.

Flexibility: It is very easy to change the content of the LED screen as well as to change the location of the screen. You can do so either with very little effort. It allows you great freedom to play with it.

P10 and P6 are both LED screen types. The pixel pitch of P10’s display is 10mm and for P6 it is 6mm. They are both very popular when it comes to outdoor advertising. We list down some of the reasons why;

On a single or double poles: This is a simple installation where LED is installed on single or two columns for displays. A single column is used for a small screen size while the double column is used for a larger screen.

Hanging: You can also hang a LED both inside and outside depending on your need. The panel of the LED should be made for hanging purpose and the LED should itself be lightweight. The wind factor must be taken into consideration before installation.

Embedded type: An LED can also be embedded in a wall. You need to be mindful that you won’t be able to perform any maintenance from behind the LED once it is embedded into the wall.

Mounted type: Another option is that you mount the LED on the wall. In this way, you can do maintenance work on the behind of the LED. It is a very common type of LED installation.

For all your LED requirements from China Shenzhen Dreamway Technology Co. Ltd., should be your top choice. We are a reliable indoor and outdoor LED manufacturer from China. We provide you with all the high-tech and latest LED screens and associated paraphernalia to fulfill your needs and stay ahead in the competition. We provide peerless quality with an unmatched price. Our staff is professional and highly trained to take care of your business requirements. We will customize your LED screen at the most competitive price. We will produce your order in the minimum possible type and you won’t hear of delayed shipments from our side.

China is a manufacturing hub and produces anything from a nail to a ship. You can search for LEDs from China through personally visiting China or browsing through b2b Chinese e-commerce sites. There are trade fairs taking place all over the year in China. Some fairs are general while others are industry-specific. You can choose either and pay a visit. Usually, industry-specific fairs are more beneficial as manufacturers prefer to go there.

As for hunting LED factories online, the most popular resource is Alibaba.com. Then there is made-in-china.com. Globalresources.com is also a good option. They are easy to use and reliable e-commerce sites. You will have to register yourself before contacting any supplier/manufacturer. While some suppliers are verified and the websites vouch for their quality, for others you will have to guard yourself against fraud and wrongdoing.

A: Unless you are technically sound and know the electronic component of the LEDs do not attempt any repair on your own. Hire a technician who will find the cause and repair it. You can try to ascertain the cause of the problem and attempt re-booting. Sometimes the problem is resolved by mere re-booting.

A: No, it won’t. Cold, hot, or harsh climate won’t affect the working of the LED lights. They are manufactured keeping in view the hostilities of weather. This adds to their durability and is one of the reasons for their widespread use and popularity.

The most application of this type of display include; industrial sensors, consumer electronics, home appliances, medical equipment, laboratory instruments, and customization projects.

You will find the LEDs on TV or computer hence they are a subset of LCD.The current technology in LCD manufacture has transformed from using cold cathode fluorescent lamps (CCFLs) and a majority are using LED technology.

Several factors have an influence on how much it would cost you to purchase an LED display;The type of LED display; Monochrome, double primary color, indoor, outdoor or full color LED display would cost you differently.

For instance, an indoor screen display would not consume similar energy as an outdoor screen display which would need to be brighter than the natural lights.

For instance; display brightness of 800~2000cd/m2 is perfect for an indoor display whereas brightness of 5000~7500cd/m2 is expected for an outdoor display.

Therefore, standing in front of a display lit by a high beam of narrow-angle you would see a bright spot but moving further you would see a black spot.

The LED display are better than the traditional advertisement method due to;They easily attract your target due to their brightness hence reaching out to too many people

Ability to produce great color varieties:This is made possible by its display feature of 8-bit panels. Therefore, it is able to produce a full 24-bit color paletteIt has high color accuracy:The IPS has a better backlight capable of producing wide colors. Hence IPS is able to produce close to life colors.

Decades ago, China became the world’s factory. So much so that it has even ceased to be so, since the Asian giant has been relocating its production in regions where labor is cheaper, such as Southeast Asia or sub-Saharan Africa. In any case, more and more companies are considering importing certain items from this country: for example, buying LED screens in China. However, before taking this step, it is worth asking if this is the best option.

Now, to acquire an outdoor or indoor LED display in China, you have to be aware of several aspects that some companies do not value, since many are only focused on the product’s cost. Below, we summarize the most delicate ones, and to which special attention should be paid.

Although it is essential for the sales team to have great knowledge of the product and its characteristics, this figure should not replace the technicians specialized in LED screens in any case. For optimal service, it is necessary that both profiles accompany and support the customer in the purchase process, since post-sale services and maintenance will be in the hands of a technical department. All this without overlooking another problem: if the seller disappears, so does the assistance and the guarantee.

In China, the roles within the company are usually not well defined. And even if this differentiation exists, the language barrier can mean that the interaction may all be through a single person. Moreover, communication is frequently channeled through an intermediary or an agent, who will not be the one who specifically deals with the manufacturing process of the LED display.

In addition to the language differences, the cost of intercontinental phone calls also limits and conditions the communication between the customer and the producer with regard to the manufacturing process of the LED display. Thus, something as simple as a mere clarification of a doubt can be considerably delayed over time. In this sense, the time difference with the Asian giant, which can be between 6 and 7 hours in the case of the United Kingdom, is an added difficulty.

Instead, by purchasing a screen from a nearby distributor, such as Visual Led, you will have the peace of mind that the conversation and attention will be constant and fluid.

Assembling and configuring a giant LED billboards or LED panels does not have to be complicated. What’s more: it can be an extremely simple process. This is precisely one of Visual Led’s aims, since our LED screens are self-supporting and have been designed so that they can be assembled and programmed by the client, either alone or with the help of a second person, without needing prior technical knowledge. We also offer online training so that the buyer can generate their own multimedia content with professional results.

However, this changes – for bad – when the documentation that accompanies the newly acquired LED display is non-existent or insufficient, or it presents translation problems. When this occurs, the buyer can feel very alone during the assembly and configuration process of their LED display.

Chinese producers are exempt from the payment of customs fees, taxes and payments, which are paid by the buyer. Hence, although the base price of LED screens may seem competitive, the truth is that the final amount will be different.

If you want to know approximately how much an LED screen adjusted to the features you want it to have costs, you can use our LED display price calculator, with which you will get an approximate budget instantly.

Another problem of buying LED displays in China has to do with the characteristics of the order. Due to import difficulties, Chinese suppliers often require minimum orders of a considerable volume. A cargo container is usually the minimum order.

In some cases, Chinese manufacturers do not have stocks of replacement parts or the sold material, so they can only repair the items supplied. Therefore, the seller has the obligation to send the parts to China for repair. A forced solution that is synonymous with high costs and long waiting periods, something that can have a negative impact on the client’s commercial activity of screens, posters or LED billboards.

So this is our summary of the things that you have to take into account when purchasing an LED screen in China. If you want to expand this information or clarify your doubts, contact Visual Led: our experts will be happy to guide you and advise you.

When it comes todisplay technologies such asprojectorsand panels, factors such as resolution and refresh rate are often discussed. But the underlying technology is equally, if not more, important. There are tons of different types of screens, from OLED and LED to TN, VA, and IPS. Learn about the various monitor and television types, from operation to pros and cons!

1)Film layer that polarizes light entering2)glass substrate that dictates the dark shapes when the LCD screen is on3)Liquid crystal layer4)glass substrate that lines up with the horizontal filter5)Horizontal film filter letting light through or blocking it6)Reflective surface transmitting an image to the viewer

The most common form of monitor or TV on the market is LCD or Liquid Crystal Display. As the name suggests, LCDs use liquid crystals that alter the light to generate a specific colour. So some form of backlighting is necessary. Often, it’s LED lighting. But there are multiple forms of backlighting.

LCDs have utilized CCFLs or cold cathode fluorescent lamps. An LCD panel lit with CCFL backlighting benefits from extremely uniform illumination for a pretty even level of brightness across the entire screen. However, this comes at the expense of picture quality. Unlike an LED TV, cold cathode fluorescent lamp LCD monitors lack dimming capabilities. Since the brightness level is even throughout the entire array, a darker portion of scenes might look overly lit or washed out. While that might not be as obvious in a room filled with ambient light, under ideal movie-watching conditions, or in a dark room, it’s noticeable. LED TVs have mostly replaced CCFL.

An LCD panel is transmissive rather than emissive. Composition depends on the specific form of LCD being used, but generally, pixels are made up of subpixel layers that comprise the RGB (red-green-blue) colour spectrum and control the light that passes through. A backlight is needed, and it’s usually LED for modern monitors.

While many newer TVs and monitors are marketed as LED TVs, it’s sort of the same as an LCD TV. Whereas LCD refers to a display type, LED points to the backlighting in liquid crystal display instead. As such, LED TV is a subset of LCD. Rather than CCFLs, LEDs are light-emitting diodes or semiconductor light sources which generate light when a current passes through.

LED TVs boast several different benefits. Physically, LED television tends to be slimmer than CCFL-based LCD panels, and viewing angles are generally better than on non-LED LCD monitors. So if you’re at an angle, the picture remains relatively clear nonetheless. LEDs are also extremely long-lasting as well as more energy-efficient. As such, you can expect a lengthy lifespan and low power draw. Chances are you’ll upgrade to a new telly, or an internal part will go out far before any LEDs cease functioning.

Further segmenting LED TVs down, you’ll find TN panels. A TN display or Twisted Nematic display offers a low-cost solution with low response time and low input lag. TN monitors sport high refresh rates, so 100Hz, 144Hz, or higher. Thus, many monitors marketed toward gamers feature TN technology. Unfortunately, while an affordable, fast panel may sound ideal, TN panels suffer from inferior colour reproduction and horrible viewing angles. A TN panel works so that liquid crystal molecules point at the viewer, and light polarizers are oriented at 90-degree angles.

Like TN, IPS or In-plane Switching displays are a subset of LED panels. IPS monitors tend to boast accurate colour reproduction and great viewing angles. Price is higher than on TN monitors, but in-plane switching TVs generally feature a better picture when compared with twisted nematic sets. Latency and response time can be higher on IPS monitors meaning not all are ideal for gaming.

An IPS display aligns liquid crystals in parallel for lush colours. Polarizing filters have transmission axes aligned in the same direction. Because the electrode alignment differs from TN panels, black levels, viewing angles, and colour accuracy is much better. TN liquid crystals are perpendicular.

A VA or vertical alignment monitor features excellent contrast ratios, colour reproduction, and viewing angles. It’s a type of LED monitor with crystals perpendicular to the polarizers at right angles like TN monitors. Pricing varies, but response time isn’t as high as a TN monitor.

A quantum dot LED TV or QLED is yet another form of LED television. But it’s drastically different from other LED variants. Whereas most LED panels use a white backlight, quantum dot televisions opt for blue lights. In front of these blue LEDs sits a thin layer of quantum dots. These quantum dots in a screen glow at specific wavelengths of colour, either red, green, or blue, therefore comprising the entire RGB (red-green-blue) colour spectrum required to create a colour TV image.

QLED TV sets are thus able to achieve many more local dimming zones than other LED TVs. As opposed to uniform backlighting, local dimming zones can vary backlighting into zones for adjustable lighting to show accurate light and dark scenes. Quantum Dot displays maintain an excellent, bright image with precise colour reproduction.

An OLED or organic light-emitting diode display isn’t another variation of LED. OLEDs use negatively and positively charged ions for illuminating individual pixels. By contrast, LCD/LED TVs use a backlight that can make an unwanted glow. In OLED display, there are several layers, including a substrate, anode, hole injection layer, hole transport layer, an emissive layer, blocking layer, electron transport layer, and cathode. The emissive layer comprised of an electroluminescent layer of film is nestled between an electron-injecting cathode and an electron removal layer, the anode. OLEDs benefit from darker blacks and eschew any unwanted screen glow. Because OLED panels are made up of millions of individual subpixels, the pixels themselves emit light, and it’s, therefore, an emissive display as opposed to a transmissive technology like LCD/LED panels where a backlight is required behind the pixels themselves.

Image quality is top-notch. OLED TVs feature superb local dimming capabilities. The contrast ratio is unrivalled, even by the best of QLEDs, since pixels not used may be turned off. There’s no light bleed, black levels are incredible, excellent screen uniformity, and viewing angles don’t degrade the picture. Unfortunately, this comes at a cost. OLEDs are pricey, and the image isn’t as bright overall when compared to LED panels. For viewing in a darkened room, that’s fine, but ambient lighting isn’t ideal for OLED use.

What is an OLED:Organic light-emitting diode display, non-LED. Emissive technology is where negatively and positively charged ions illuminate individual pixels in a display.

As you can see, there are tons of different types of displays, each with their advantages and disadvantages. Although many monitors and TVs are referred to by different names like LED, IPS, VA, TN, or QLED, many are variations of LCD panels. However, specific technology such as the colour of backlighting and alignment of pixels dictates the picture quality. OLED is an entirely different form of display that’s not LED. Now that you understand the various types of monitors and televisions on the market, you can select the best TV to fit your needs!

Chinese companies have gained a competitive edge in the large-screen display industry and the exit of South Korean counterparts such as Samsung Electronics and LG Display from the liquid crystal display market will bring opportunities for China"s panel makers despite the challenges posed by the COVID-19 pandemic.

Market research firm Sigmaintell said BOE Technology Group Co Ltd-a leading Chinese supplier of display products and solutions-became the world"s largest shipper of LCD TV panels for the first time in 2019.

The Beijing-based company shipped 53.3 million units of LCD panels in 2019, with production capacity increasing by more than 20 percent on a yearly basis.

The consultancy said the LCD TV panel production area of Chinese manufacturers will account for more than 50 percent of the global total this year, surpassing South Korean competitors who are accelerating the shutdown of large-sized LCD panel production capacity due to competition from Chinese manufacturers.

It estimated the production capacity of large-sized LCD panels will continue to increase in China over the next three years. In addition, global LCD TV panel shipments stood at 283 million pieces last year, a slight decrease of 0.2 percent year-on-year. Meanwhile, the shipment area was 160 million square meters, an increase of 6.3 percent year-on-year.

"Chinese companies have gained an upper hand in large-screen LCD displays. Samsung and LG"s decision to exit from the LCD sector means Chinese panel makers will take a dominant position in this field," said Li Dongsheng, founder and chairman of Chinese tech giant TCL Technology Group Corp.

Li said South Korean firms will focus on organic LED screens and quantum dot LED displays, while Chinese TV panel makers are catching up at a rapid pace.

The pandemic will accelerate reshuffling in the display industry as supply has surpassed demand in the past few years and competition has become very fierce, he added.

"The outbreak has caused a periodic drop in demand in the global display market and sped up the restructuring of the entire industry. Chinese enterprises are in a favorable position, and I believe that they will further enhance their competitiveness," Li said.

Data consultancy Digitimes Research said it comes as little surprise that Samsung has opted to withdraw from the LCD panel sector as its LCD business was losing money in every quarter of 2019 due to challenges from Chinese competitors.

"China"s semiconductor display industry has made large advances in the past decade, changing the display industry"s global competitive landscape. China has transformed into the world"s largest consumer market and manufacturing base for display terminals, with huge market potential," said BOE Vice-President Zhang Yu.

BOE said its Gen 10.5 TFTLCD production line achieved mass production in Hefei, Anhui province, in March 2018. The plant mainly produces high-definition LCD screens of 65 inches and above. With a total investment of 46 billion yuan ($6.5 billion), the company"s second Gen 10.5 TFT-LCD production line launched operations in Wuhan, Hubei province, in December.

The Gen 11 TFT-LCD and active-matrix OLED production line of Shenzhen China Star Optoelectronics Technology, a subsidiary of TCL, officially entered operations in November 2018, producing 43-inch, 65-inch and 75-inch LCD screens.

Bian said the OLED and QLED will be the next-generation flat-panel display technologies to be in the spotlight. LG Display is currently the world"s only supplier of large-screen OLED TV panels.

OLED is a relatively new technology and part of recent display innovation. It has a fast response rate, wide viewing angles, super high-contrast images and richer colors. It is much thinner and can be made flexible, compared with traditional LCD display panels.

Li Yaqin, general manager of Sigmaintell, said 65-inch TVs will become the mainstream in people"s living rooms in the future, but OLED TVs will not be able to immediately spur customer purchases at this time though the future trend is for higher-tech options.

► When the leading Korean players Samsung Display and LG Display exit LCD production, BOE will be the most significant player in the LCD market. Though OLED can replace the LCD, it will take years for it to be fully replaced.

► As foreign companies control evaporation material and machines, panel manufacturers seek a cheaper way to mass-produce OLED panels – inkjet printing.

When mainstream consumer electronics brands choose their device panels, the top three choices are Samsung Display, LG Display (LGD) and BOE (000725:SZ) – the first two from Korea and the third from China. From liquid-crystal displays (LCD) to active-matrix organic light-emitting diode (AMOLED), display panel technology has been upgrading with bigger screen products.

From the early 1990s, LCDs appeared and replaced cathode-ray tube (CRT) screens, which enabled lighter and thinner display devices. Japanese electronics companies like JDI pioneered the panel technology upgrade while Samsung Display and LGD were nobodies in the field. Every technology upgrade or revolution is a chance for new players to disrupt the old paradigm.

The landscape was changed in 2001 when Korean players firstly made a breakthrough in the Gen 5 panel technology – the later the generation, the bigger the panel size. A large panel size allows display manufacturers to cut more display screens from one panel and create bigger-screen products. "The bigger the better" is a motto for panel makers as the cost can be controlled better and they can offer bigger-size products to satisfy the burgeoning middle-class" needs.

LCD panel makers have been striving to realize bigger-size products in the past four decades. The technology breakthrough of Gen 5 in 2002 made big-screen LCD TV available and it sent Samsung Display and LGD to the front row, squeezing the market share of Japanese panel makers.

The throne chair of LCD passed from Japanese companies to Korean enterprises – and now Chinese players are clinching it, replacing the Koreans. After twenty years of development, Chinese panel makers have mastered LCD panel technology and actively engage in large panel R&D projects. Mass production created a supply surplus that led to drops in LCD price. In May 2020, Samsung Display announced that it would shut down all LCD fabs in China and Korea but concentrate on quantum dot LCD (Samsung calls it QLED) production; LGD stated that it would close LCD TV panel fabs in Korea and focus on organic LED (OLED). Their retreats left BOE and China Stars to digest the LCD market share.

Consumer preference has been changing during the Korean fab"s recession: Bigger-or-not is fine but better image quality ranks first. While LCD needs the backlight to show colors and substrates for the liquid crystal layer, OLED enables lighter and flexible screens (curvy or foldable), higher resolution and improved color display. It itself can emit lights – no backlight or liquid layer is needed. With the above advantages, OLED has been replacing the less-profitable LCD screens.

Samsung Display has been the major screen supplier for high-end consumer electronics, like its own flagship cell phone products and Apple"s iPhone series. LGD dominated the large OLED TV market as it is the one that handles large-size OLED mass production. To further understand Korean panel makers" monopolizing position, it is worth mentioning fine metal mask (FMM), a critical part of the OLED RGB evaporation process – a process in OLED mass production that significantly affects the yield rate.

Prior to 2018, Samsung Display and DNP"s monopolistic supply contract prevented other panel fabs from acquiring quality FMM products as DNP bonded with Hitachi Metal, the "only" FMM material provider choice for OLED makers. After the contract expired, panel makers like BOE could purchase FFM from DNP for their OLED R&D and mass production. Except for FFM materials, vacuum evaporation equipment is dominated by Canon Tokki, a Japanese company. Its role in the OLED industry resembles that of ASML in the integrated circuit space. Canon Tokki"s annual production of vacuum evaporation equipment is fewer than ten and thereby limits the total production of OLED panels that rely on evaporation technology.

The shortage of equipment and scarcity of materials inspired panel fabs to explore substitute technology; they discovered that inkjet printing has the potential to be the thing to replace evaporation. Plus, evaporation could be applied to QLED panels as quantum dots are difficult to be vaporized. Inkjet printing prints materials (liquefied organic gas or quantum dots) to substrates, saving materials and breaking free from FMM"s size restriction. With the new tech, large-size OLED panels can theoretically be recognized with improved yield rate and cost-efficiency. However, the tech is at an early stage when inkjet printing precision could not meet panel manufacturers" requirements.

Display and LGD are using evaporation on their OLED products. To summarize, OLED currently adopts evaporation and QLED must go with inkjet printing, but evaporation is a more mature tech. Technology adoption will determine a different track for the company to pursue. With inkjet printing technology, players are at a similar starting point, which is a chance for all to run to the front – so it is for Chinese panel fabs. Certainly, panel production involves more technologies (like flexible panels) than evaporation or inkjet printing and only mastering all required technologies can help a company to compete at the same level.

Presently, Chinese panel fabs are investing heavily in OLED production while betting on QLED. BOE has four Gen 6 OLED product lines, four Gen 8.5 and one Gen 10.5 LCD lines; China Star, controlled by the major appliance titan TCL, has invested two Gen 6 OLED fabs and four large-size LCD product lines.

Remembering the last "regime change" that occurred in 2005 when Korean fabs overtook Japanese" place in the LCD market, the new phase of panel technology changed the outlook of the industry. Now, OLED or QLED could mark the perfect time for us to expect landscape change.

After Samsung Display and LGD ceding from LCD TV productions, the vacant market share will be digested by BOE, China Star and other LCD makers. Indeed, OLED and QLED have the potential to take over the LCD market in the future, but the process may take more than a decade. Korean companies took ten years from panel fab"s research on OLED to mass production of small- and medium-size OLED electronics. Yet, LCD screen cell phones are still available in the market.

LCD will not disappear until OLED/QLED"s cost control can compete with it. The low- to middle-end panel market still prefers cheap LCD devices and consumers are satisfied with LCD products – thicker but cheaper. BOE has been the largest TV panel maker since 2019. As estimated by Informa, BOE and China Star will hold a duopoly on the flat panel display market.

BOE"s performance seems to have ridden on a roller coaster ride in the past several years. Large-size panel mass production like Gen 8.5 and Gen 10.5 fabs helped BOE recognize the first place in production volume. On the other side, expanded large-size panel factories and expenses of OLED product lines are costly: BOE planned to spend CNY 176.24 billion (USD 25.92 billion) – more than Tibet"s 2019 GDP CNY 169.78 billion – on Chengdu and Mianyang"s Gen 6 AMOLED lines and Hefei and Wuhan"s Gen 10.5 LCD lines.

Except for making large-size TVs, bigger panels can cut out more display screens for smaller devices like laptops and cell phones, which are more profitable than TV products. On its first-half earnings concall, BOE said that it is shifting its production focus to cell phone and laptop products as they are more profitable than TV products. TV, IT and cell phone products counted for 30%, 44% and 33% of its productions respectively and the recent rising TV price may lead to an increased portion of TV products in the short term.

Except for outdoor large screens, TV is another driver that pushes panel makers to research on how to make bigger and bigger screens. A research done by CHEARI showed that Chinese TV sales dropped by 10.6% to CNY 128.2 billion from 2018 to 2019. Large-size TV sales increased as a total but the unit price decreased; high-end products like laser TV and OLED TV saw a strong growth of 131.2% and 34.1%, respectively.

Samsung Display will stop producing LCD panels by the end of the year. The display maker currently runs two LCD production lines in South Korea and two in China, according to Reuters. Samsung tells The Verge that the decision will accelerate the company’s move towards quantum dot displays, while ZDNetreports that its future quantum dot TVs will use OLED rather than LCD panels.

The decision comes as LCD panel prices are said to be falling worldwide. Last year, Nikkei reported that Chinese competitors are ramping up production of LCD screens, even as demand for TVs weakens globally. Samsung Display isn’t the only manufacturer to have closed down LCD production lines. LG Display announced it would be ending LCD production in South Korea by the end of the 2020 as well.

Last October Samsung Display announced a five-year 13.1 trillion won (around $10.7 billion) investment in quantum dot technology for its upcoming TVs, as it shifts production away from LCDs. However, Samsung’s existing quantum dot or QLED TVs still use LCD panels behind their quantum dot layer. Samsung is also working on developing self-emissive quantum-dot diodes, which would remove the need for a separate layer.

Samsung’s investment in OLED TVs has also been reported by The Elec. The company is no stranger to OLED technology for handhelds, but it exited the large OLED panel market half a decade ago, allowing rival LG Display to dominate ever since.

Although Samsung Display says that it will be able to continue supplying its existing LCD orders through the end of the year, there are questions about what Samsung Electronics, the largest TV manufacturer in the world, will use in its LCD TVs going forward. Samsung told The Vergethat it does not expect the shutdown to affect its LCD-based QLED TV lineup. So for the near-term, nothing changes.

One alternative is that Samsung buys its LCD panels from suppliers like TCL-owned CSOT and AUO, which already supply panels for Samsung TVs. Last year The Elec reported that Samsung could close all its South Korean LCD production lines, and make up the difference with panels bought from Chinese manufacturers like CSOT, which Samsung Display has invested in.

Samsung has also been showing off its MicroLED display technology at recent trade shows, which uses self-emissive LED diodes to produce its pixels. However, in 2019 Samsung predicted that the technology was two or three years away from

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey