sharp lcd panel factory supplier

The most advanced facility for the integrated production of LCD TVs from the manufacturing of LCD panels to assembly of final products was completed in Kameyama, Mie Perfecture, Japan, and started operation. The plant also provides rationalization in the process of production, inspection and delivery, as well as technology development, resulting in high production efficiency and high value-added performance.

Plant No. 2 will adopt large-size 8th generation glass substrates of 2,160 x 2,400 mm, which are optimum for the production of 40-inch-class and 50-inch-class models. Eight 40-inch-class panels or six 50-inch-class panels can be obtained from this single 8th generation substrate. Compared with the substrates of Plant No. 1 (1,500 x 1,800 mm for eight 32-inch-class panels) the size will be roughly double.

With the expansion of the supply of large LCD panels from the Kameyama factories, Sharp is greatly advancing LCD TV production to meet increasing market needs.

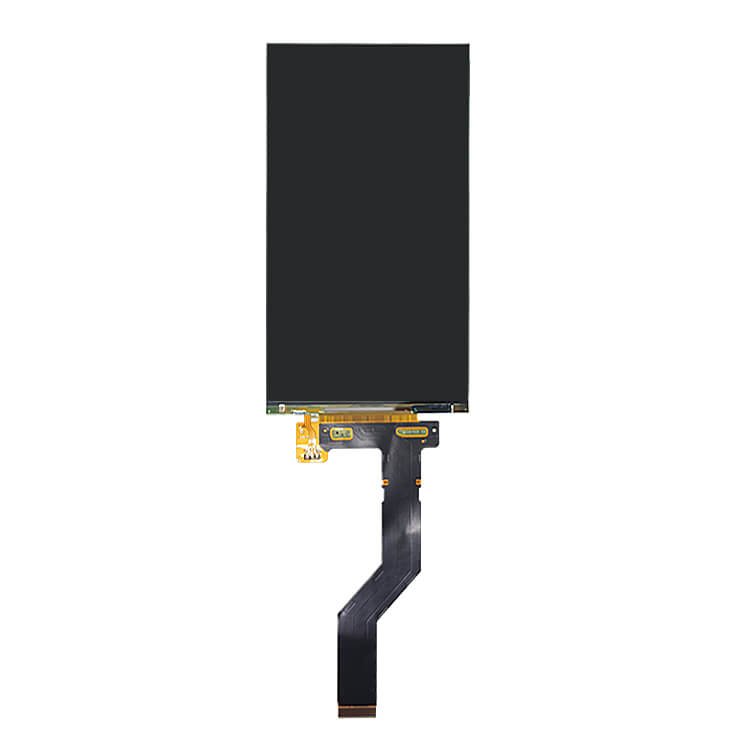

A wide variety of sharp lcd panel manufacturers options are available to you, You can also choose from original manufacturer, odm and agency sharp lcd panel manufacturers,As well as from tft, ips, and standard.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

As CBN reports, after Sharp acquired the Hakusan factory of Japan Display Corporation (JDI) at the end of last month, yesterday Apple asked Sharp to increase the production of iPhone panels. So the Hakusan factory will restart within this year.

Chen Jun, chief analyst of Qunzhi Consulting, said today that Sharp will become the largest supplier of LCD (liquid crystal) screens for iPhones in the future and continue to increase its B2B business.

Apple’s latest iPhone 11 series currently uses LCD and OLED screens. The 5.8-inch iPhone 11 Pro and the 6.5-inch iPhone 11 Pro Max use OLED screens, while the 6.1-inch iPhone 11 use LCD panels.

Currently LGD, JDI and Sharp are the main LCD screen suppliers for Apple iPhones. However, LGD will supply OLED screens to Apple next year, thus exiting the list of LCD screen suppliers.

Prior to this, we also reported that the LCD screen required by Apple’s new SE series iPhone is currently exclusively supplied by its previous major LCD screen supplier, Japan Display Company (JDI). However, Sharp, which was acquired by Hon Hai Precision in 2016, subsequently also will supply LCD screens to Apple’s new iPhone SE.

Before the iPhone adopted the OLED screen, JDI was a major supplier of LCD panels for Apple smartphones. And Apple was also the main source of income for JDI. However, after Apple turned to OLED screens, JDI, which was not in time for transition, also fell into trouble. Apple has also rescued from multiple levels. In 2019, JDI still has 61% of revenue from Apple.

Japan"s Sharp said Thursday it will team with a large Chinese manufacturer to build a factory in Nanjing and mass-produce LCD screens for TVs, computers and tablets.

Sharp said it will form a joint venture with China Electronics Corp. (CEC) to manage the project, and aims to begin production in June 2015. The plant will eventually handle 60,000 LCD panels per month, each measuring 2.2 x 2.5 meters, which can then be divided into smaller sizes for consumer products.

Although Sharp is struggling with massive losses and going through a major restructuring to rebuild its finances, the company is still one of the largest LCD display makers in the world and possesses cutting-edge technology. Japan"s Nikkei newspaper reported that as part of the deal, Sharp will transfer its technology for producing IGZO (Indium Gallium Zinc Oxide) screens to the venture and will receive payment in the "tens of billions of yen" in return, part of which it will use to fund the new investment.

IGZO allows for higher resolutions and lower power drain than traditional LCD screens, and devices that use the technology are beginning to appear on the market. Sharp has launched smartphones and tablets with IGZO screens, and Samsung Electronics, Asustek Computer and Fujitsu are all releasing laptops that use the technology.

Rumors have long circulated that Samsung and Apple are looking to build smartphones using IGZO screens. A second factory that can produce the technology would help allay fears of being dependent on a single supplier.

The new venture will be called Nanjing CEC-Panda LCD Technology and will be funded by a 17.5 billion yuan (US$2.8 billion) investment, 92 percent from CEC Group and 8 percent from Sharp. It will be officially established in March of next year.

Sharp said the Chinese plant will allow production at lower costs than its current factories, and it will retain the right to buy the panels produced at the new facility.

Sharp has been aggressively pursuing deals with foreign partners to shore up its finances as it looks to recover from deep losses. Since last year it has signed deals with Samsung, Foxconn and Qualcomm for joint production and research.

As a result of a deal announced in August 2009, Sharp and CEC already operate a Chinese joint venture producing smaller LCD panels, to which Sharp transferred some of its older technology. They said at the time they would negotiate a deal to build larger panels in the future.

Sharp booked a ¥545 billion loss last fiscal year but forecasts it can rebound to a ¥5 billion profit during the current period. It said Thursday that the finances of the new deal are already factored into its current forecast.

There has been a significant shift in the global display industry lately. Apart from new display technologies, the display world is now dominated by players in Asian countries such as China, Korea, and Japan. And rightly so, the world’s best famous LCD module manufacturers come from all these countries.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a Cortex A8 1GHz Standard 256MB. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

In this post, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the reputable LCD module manufacturers in the world.

Samsung is the world’s largest semiconductor and consumer electronics manufacturer by revenue. The electronics giant is well-known for its smartphones and home appliances, but the company also manufactures LCD, LED, and OLED panels.

Probably the most in-demand and popular display panel product for Samsung is their OLED technology. Most of its current smartphones use their trademark Super AMOLED displays. The technology allowed Samsung’s smartphones to be ultra-thin, with better image brightness, and less energy consumption.

Samsung now produces panels for smart TVs. With their ever-evolving technological expertise and high-quality products, the company shows no signs of slowing down as one of the world’s best famous LCD module manufacturers.

Stone provides a professional product line that includes intelligent TFT-LCD modules for civil, advanced, and industrial use. Furthermore, Stone also creates embedded-type industrial PCs. The company’s products are all highly-reliable and stable even when used with humidity, vibration, and high temperatures.

Stone Technologies caters to a wide range of clients and industries, being among the world’s best famous LCD module manufacturers. The company’s products are used in the following industries:

Originally, LG Display was a joint venture of mother company LG Electronics and the Dutch company Phillips. They dedicated the company to creating active-matrix LCD panels. Another joint venture called LG. Phillips Displays was created to manufacture deflection yokes and cathode ray tubes.

LG Display has risen above the rest because of its world-class module products. Because of this, the company caters to a massive range of famous clients including Hewlett Packard, Apple, Sony, Dell, Acer, and Lenovo. LG Display also creates LCD modules and similar display panels for the company’s television product range.

Innolux Corporation is another famous LCD module manufacturer. This company was established in 2003 and is currently based in Zhunan, Miaoli County, Taiwan.

The company is a well-known manufacturer of display panels in Taiwan. Innolux supplies TFT-LCD and LED panels, open cells, and touch modules for the following products:

What makes Innolux stand out from other LCD module manufacturers is the company’s commitment to its humanistic qualities. Innolux believes that they are in the business to contribute to the well-being and prosperity of their customers. This is then achieved by creating world-class products that satisfy its clients.

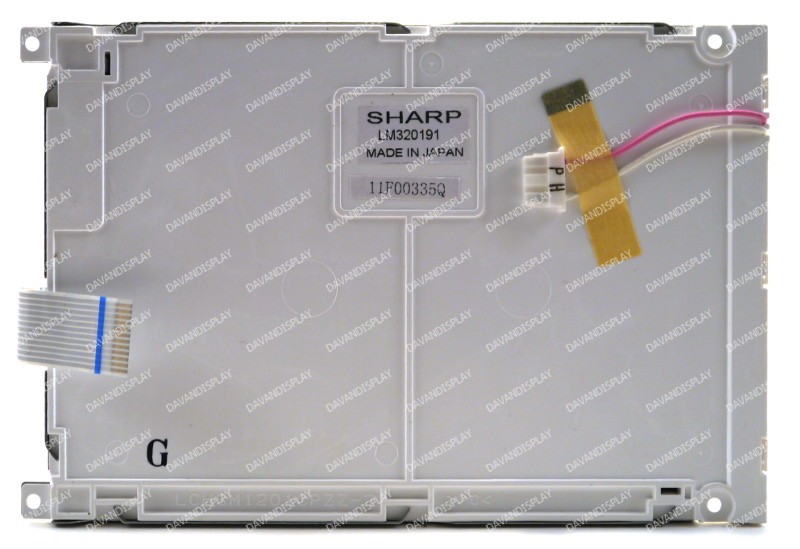

Sharp is a Japanese company founded in 1912. It is now based in Sakai, Osaka Prefecture. The company produces various kinds of electronic products including mobile phones, LCD panels, calculators, PV solar cells, and consumer electronics. Sharp has produced TFT-LCD products as early as the 1980s.

For the regular public consumers, Sharp produces a variety of smart TVs and LCD TVs marketed under the Aquos brand. The company’s television line-up boasts of impressively high-quality technology. The TVs are equipped with technologies that support 4K and 8K UHD display, allowing for a great high-resolution viewing experience.

Meanwhile, Sharp operates several factories worldwide. Apart from plants in its native Japan, Sharp also has manufacturing plants in Malaysia, Indonesia, and Poland.

Sharp credits its success to the company’s commitment to sincerity and creativity. Sharp believes that sincere work and a creative mindset will bring fruitful progress for its clients, dealers, shareholders, and the entire company worldwide.

BOE Display is among the leading display manufacturers in the world. The company started in 1993 and is currently based in Beijing, China. Apart from display panels, BOE also manufactures smart systems using IoT technology.

The company proudly utilizes high-end technologies to create world-class display solutions. For instance, AU’s production lines can manufacture a variety of display applications in a full panel size range. The manufacturing lines also support:

Sustainability is among the ultimate goals of AU Optronics. The company takes steps to integrate green solutions into their products for more sustainable development. This commitment to sustainability, among other strong qualities, makes AU Optronics one of the best LCD manufacturers in the world.

Most of these products use TFT-LCD panels alongside other technologies to create ultra-high-definition images. Also, modern Toshiba display products incorporate IoT and artificial intelligence for a smarter product experience.

Kyocera is a Japanese LCD manufacturer. The company started in 1959 as a fine technical ceramics manufacturer but gradually added consumer electronics products to its offerings.

The Japanese company acquired Optrex Corporation in 2012. The acquisition paved the way for creating an R&D center and more production, sales, and marketing bases. Hence, Kyocera’s global LCD business boomed even more.

The company also operates factories, R&D centers, and marketing facilities in Asia, the Middle East, Europe, Africa, North and South America, and Oceania continents. Kyocera has a vast worldwide reach that makes it one of the world’s best famous LCD module manufacturers.

To wrap all this up, we listed 10 of the world’s best famous LCD module manufacturers. These are all highly-respected companies that built their reputations and climbed up the ladder of LCD module manufacturing. Their quality products, dedication to their craft, and excellent customer service truly make them among the world’s best display solutions providers.

TOKYO -- Struggling Apple supplier Japan Display plans to sell a smartphone screen factory and the land it sits on to Sharp for 41.2 billion yen ($386 million), the company has announced.

Japan Display, who supplies screens for the iPhone and has been struggling of late, is planning to sell a smartphone screen factory to Sharp for around $377 million.

The company had been planning to sell the idle factory by the end of March, but the pandemic slowed down its negotiations with Sharp as well as another buyer of the equipment inside the plant (most likely Apple).

Japan Display, also known as JDI, had intended to sell the factory by the end of March as part of its turnaround plan, but the coronavirus pandemic slowed down negotiations. The company announced a deal late that month with an unnamed customer for some equipment at the factory, while continuing to hold talks with Sharp to unload the remaining assets.

According to the report, Japan Display will use the money from the sale to pay Apple back for covering most of the costs associated with the building of the factory.

When the facility was built, Apple covered most of the 170 billion yen cost with a "prepayment." The plant, which began operating in late 2016, can produce the equivalent of up to 7 million smartphone panels per month. But production later slumped. JDI will use funds from the sale to repay Apple for the prepayment, lightening the burden on its finances.

Osaka-based Sharp, part of top iPhone assembler Hon Hai Precision Industry, is expected to consolidate production of LCD panels for Apple"s iPhone at the Hakusan plant, renting the equipment from Apple. Sharp"s Kameyama factory, currently used for that purpose, will likely switch to making panels for new customers in such areas as automotive and medical equipment.

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

LG Display was, until 2021, the No. 1 display panel manufacturer in the world. Owned by LG Group and headquartered in Seoul, South Korea, it has R&D, production, and trade institutions in China, Japan, South Korea, the United States, and Europe.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Since its establishment, Truly Semiconductors has focused on researching, developing, and manufacturing liquid crystal flat panel displays. Now, after twenty years of development, it is the biggest small- and medium-sized flat panel display manufacturer in China.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

Founded in June 1998, Hannstar specializes in producing thin-film transistor liquid crystal display panels, mainly for use in monitors, notebook displays and televisions. It was the first company in Taiwan to adopt the world’s top ultra-wide perspective technology (AS-IPS).

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

TCL CSOT – short for TCL China Star Optoelectronics Technology (TCL CSOT) – was founded in 2009 and is an innovative technology enterprise that focuses on the production of semiconductor displays. As one of the global leaders in semiconductor display market, it has bases in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou, and India, with nine panel production lines and five large modules bases.

TCL CSOT actively produces Mini LED, Micro LED, flexible OLED, printing OLED, and other new display technologies. Its product range is vast – including large, medium, and small panels and touch modules, electronic whiteboards, splicing walls, automotive displays, gaming monitors, and other high-end display application fields – which has enabled it to become a leading player in the global panel industry.

In the first quarter of 2022, TCL CSOT’s TV panels ranked second in the market, 55 inches, 65 " and 75 inches second, 8K, 120Hz first, the first, interactive whiteboard and digital sign plate; LTPS flat panel, the second, LTPS and flexible OLED fourth.

EDO (also known as EverDisplay Optonics) was founded in October 2012 and focuses on the production of small- and medium-sized high-resolution AMOLED semiconductor display panels.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Although Sony’s TVs use display panels from TCL CSOT (VA panel), Samsung. Sony still produces the world’s best micro-OLED display panels. Sony has many micro OLED model such as 0.23 inch, 0.39 inch, 0.5 inch, 0.64 inch, 0.68 inch, 0.71 inch. Panox Display used to test and sell many of them, compare to other micro OLED manufacuturers, Sony`s micro OLEDs are with the best image quality and highest brightness (3000 nits max).

Sharp Corporation (Sharp) will participate in CES 2023 in Las Vegas, Nevada, United States, to be held from January 5 to 8, 2023. CES is one of the largest and most influential tech events in the world.

Sharp will exhibit advanced technologies and products that embody the company’s ESG-focused management under the four themes of New Energy, Automotive, AR/VR, and TV.

On October 8, Sharp announced that it has signed a cross-license agreement with OPPO, which covers global patent licenses for communications standards involved in the two parties’ end product sales. Meanwhile, the two companies agreed to withdraw lawsuits against each other, ultimately ending patent litigations and disputes between the two in various countries since 2020.

To protect its intellectual property, Sharp filed a patent infringement lawsuit against OPPO in March 2020 in the German Regional Court of Munich and District Court of Mannheim. The Japan...

Sharp is going to spin off its display business, setting up a new subsidiary named “Sharp Display Technology” (SDTC) on October 1, 2020, reported The Sankei News. The new spinoff will focus on novel display technology particularly Micro LED.

By establishing SDTC, Sharp plan to collect more external funds for Micro LED development, which will support the company to join the competition of next-gen display technology that currently ruled by Sony, Samsung and other competitors. It was revealed in August that Sharp has buil...

Samsung Display has sold its LCD factory in China to Chinese display maker CSOT, a company under TCL group, to further cut down its LCD capacity, which goes in line with Samsung’s plan to quit LCD business. By ending its LCD panel production, Samsung aims to expand its development in QD displays and OLED displays. The Korean giant has also reportedly t...

Japan Display (JDI) is going to sell its LCD plant in Hakusan, Japan, to Sharp and Apple, so that the Japanese display maker can pay off its debt to Apple. The total transfer price is estimated to be JPY 71 billion (US$ 672 million).

The plant will be transferred to Sharp, who is also a display supplier of Apple, by the end of September. With the transaction, Sharp will take over most of the debt of JDI which JDI borrowed from Apple when building the plant. The plant was originally built for supplying LCD panels for iPhone. But S...

Sharp’s mass production plan for Micro LED displays marked a progress of the Foxconn Group in next-gen display technology development. Incorporates LED chip production, packaging technology, panel manufacture and TV brands, the Foxconn Group is known for its ambition to set up an internal Micro LED supply chain.

The Micro LED displays developed by Sharp, a 0.38-inch full color panel featuring 1053 PPI and a 0.13-inch blue display with 3000 PPI, were designed by the semiconductor group under Foxconn and manufactured by Sharp Fukuyama Semiconductor.

Sharp, one of the panel providers of Apple, is reportedly developing small size Micro LED displays and will mass produce the products by 2023 for eye-wear smart devices, reported Nikkan Kogyo Shimbun.

According to the report, Sharp Fukuyama Semiconductor, a subsidiary of Sharp, has developed Micro LED prototypes including a 0.38-inch full color panel featuring 1053 PPI and a 0.13-inch blue display with 3000 PPI. The company deploys its proprietary color conversion technology to achieve full color display and aims to mass produce the products in 2023 to 2024 for A...

NEC and Sharp announced that they will combine NEC Display Solutions (NDS) with Sharp to create a joint venture to leverage their strengths to advance display technology development.

Sharp will obtain over 66% share of NDS with JPY 9.24 billion (US$ 82.96 million). The transfer is scheduled to be concluded on July 1st, 2020 and the joint venture will continue to provide NEC branded products.

Hisatsugu Nakatani, President, NEC Display Solutions, said, "This joint venture between Sharp and NEC Display Solutions will bring even greater valu...

Universal Display Corporation announced that the Company and display manufacturer Sharp have entered into an extended and updated evaluation agreement.

The Japanese digital panel giant Japan Display Inc. (JDI) had a struggle revamping its liquid crystal display (LCD) panel business. To make the recovery happen, JDI planned to accept fundings from outside investors. Not only that, JDI will restructure LCD panel production sites, and lay off employees at a large scale, slashing about 4,000 jobs, according to Nikkei"s report on August 8.

It has been spreading like crazy that in 2H17 three iPhone models- the high-end iPhone 8 featuring an OLED display, iPhone 7s and iPhone 7s Plus that continue to use LCD displays- will hit the shelves. Latest sources leaked Apple might increase OLED display use in its products and all the three new iPhones to roll out in 2018 are likely to sport OLED displays. That possibly implies orders Apple places with LCD display providers Sharp and Japan Display Inc. (JDI) would plummet. It will be much of a shock to JDI which earns over 50% of its revenue from Apple’s phone screen demand.

Sharp, the Foxconn-controlled company, is possibly to partner with ASTRODESIGN, a Japanese video and signal processing tech company, to jointly develop video processing systems able to support displays with 8K ultra-high definition, as Nikkei Asian Review carried in its report on 26 June. With Sharp’s strengths in the development of sensor technology for LCD screens and cameras, and ASTRODESIGN’s capability to upgrade digital broadcasting, the system can be used in cameras, displays and other image processing devices.

While the public thought Sharp might focus fully on the manufacture of 8K resolution television screens after the first one was made public two years ago, according to the Japan Times, the LCD TV maker now seems determined to step into the market of OLED display by establishing new product lines- one in the city of Sakai, Osaka, and the other in Taki, a town in Mie Prefecture.

Google"s VR vice president, Clay Bavor, recently revealed at the Society for Information Display’s (SID) week that Google has teamed up with Sharp to develop VR LCD displays. If the plan goes well, Google is expected to adopt these displays in its VR devices.

Following in the footsteps of Apple and Samsung, Taiwan’s contract manufacturer Hon Hai Precision Industry, better known as Foxconn, announced that Sharp and other Foxconn group companies will acquire an U.S. startup to develop Micro LED display technology.

WitsView, a division of TrendForce, reports shipments of LCD TV sets for the first quarter of 2017 came to 44.05 million units, a decrease of 31% from the prior quarter and a year-on-year decline of 8.4%. Poor sales results in China during the Chinese New Year holiday period was a major factor behind the year-on-year shipment drop.

Apple’s plan to adopt OLED panels for its next iPhone series has apparently led to a fierce competition between OLED makers. According to The Wall Street Journal, sources close to the matter confirmed that Japan’s Sharp will invest around 100 billion yen (USD 878 million) to expand OLED production to compete with its rival Samsung Electronics Co,.

Foxconn subsidiary Sharp will no longer be supplying LCD panels to Samsung Electronics starting in 2017, a report from The Japan Times cited industry sources saying.

Sharp President Tai Jeng-wu confirmed last Saturday market rumors that Cupertino-based Apple will be adapting OLED screens in its next generation iPhones, reported Nikkei Asian review.

Sharp might be shutting down its LED display plant in Hiroshima Prefecture in Japan in 2017, as part of its restructuring efforts implemented by parent company Foxconn, sources familiar with the matter told Japan Times recently.

Sharp President Tai Jeng-wu told The Nikkei and other reporters that it intended to collaborate with Japan Display Inc. (JDI) in the development of OLED displays to catch up with Korean competitors Samsung.

Sharp might be adjusting its OLED panel production plan, and move the production plant in Taiwan to a joint venture factory with Foxconn in Japan, reported Nikkei Asian Review.

Major iPhone assembler Hon Hai Precision Industry, or also kn0own as Foxconn Technology Group announced the Chinese government finally gave it the green light to approve Japanese conglomerate Sharp for US $3.5 billion, reported Nikkei Asian Review.

Following Foxconn’s takeover of Sharp, the company will start shipping panels using advanced OLED materials next year, said Foxconn Chairman Terry Guo on Wednesday.

From time-to-time, we"ve passed along some news on Apple"s long-time LCD supplier Japan Display. The company had the misfortune of sinking a lot of money into new factories just as Apple was making the move to OLED panels for the iPhone. Apple has helped prop up the company this year by investing a reported $100 million into a restructuring of the company and moving some of its LCD production from China to Japan Display"s facilities. Japan Display has lost money for 11 straight quarters, and while it was late to start producing OLED panels, it now produces the AMOLED screens employed by the Apple Watch Series 5. Apple contributes 60% of Japan Display"s annual revenue.

The Nikkei Business Daily reports today that Japan Display is talking to Apple and Sharp about selling its main smartphone display factory for as much as $820 million. Sharp is a unit of Foxconn, a contract manufacturer responsible for assembling the majority of iPhone units sold globally. Sharp also sells displays to Apple and said that it was talking to Japan Display about purchasing the factory after an unnamed client requested that it do so. In a statement it released, Sharp said, "We are carefully considering it, reviewing the impact that any purchase would have on our earnings, and whether and how much risk it would entail." Besides Foxconn, the report suggests that Wistron could be included in the purchase of the factory. Wistron is another company used by Apple to manufacture its products including the iPhone.

The factory, located in Hakusan City, Ishikawa prefecture in western Japan, cost $1.5 billion to build back in 2015, and Apple fronted that money to Japan Display. As part of the deal with the display manufacturer, Apple was to be reimbursed by taking a cut of each LCD panel display sold. But with smartphone manufacturers turning to AMOLED, the plant was running at only 50% capacity. As a result, Japan Display still owes Apple more than $800 million.

Another report says that Sharp will actually purchase the LCD production facilities by next March and will reach a separate agreement with Apple after the deal is closed. The factory has been shut since this past July. Japan Display released a statement today saying that it is looking at all options but isn"t sure what it will do about the factory. The company adds that nothing has been decided and when it does make a decision, it will notify the press. Earlier this month, the company said that it was looking to receive $200 million from a customer, believed to be Apple, for equipment from the plant. But now it appears that Japan Display is taking a different path.

Last year, the panel manufacturer lost $2.3 billion following a $260 million loss in 2017. The firm is one of three companies supplying Apple with the Liquid Retina Display for the iPhone 11 along with LG Display and Sharp. According to reliable TF International analyst Ming-Chi Kuo, Apple could release four new models next year. Forgetting the difference between 4G and 5G models, only one of the four will use an LCD display and that is expected to be the 4.7-inch iPhone9.

LCD displays are still going to be around for a long time, at least for smart TVs such as the ones that use Android TV and other operating systems. Today, the massive electronic manufacturing company Foxconn announced a new partnership with Sharp to build and operate a new TV LCD flat-panel factory in China, which will cost $8.8 billion.AMOLED displays set to close in on LCD this year

Reuters reports that the new factory will help with the expected demand of new flat-screen TVs in Asia. Foxconn said that the LCD factory will make 10.5-generation 8K displays, along with screens for smart TVs and electronic whiteboards. Production is expected to begin in 2019.

This news comes even as other companies are embracing OLED displays for both TV as well as smartphones. However, there’s still some life in the LCD market. Panasonic recently announced an LCD IPS display with a 1,000,000:1 contrast ratio. It is supposed to have 600 times more contrast compared to normal LCD panels, and those levels are close to those found in OLED displays.

Just last week, we learned about the surprising news, reported on by almost all of the media in Japan, that Sharp had notified Samsung it would no longer supply it with LCD panels starting in 2017. In that situation, much like this one, word was that price negotiations had broken down between the parties working on a new supply agreement. In effect, Sharp had terminated Samsung…their largest LCD panel customer.

Now reports are that Sharp is taking the same position with China’s Hisense, another large TV manufacturer. Certainly, like other media, we have been reporting on Sharp’s many problems, including their struggle with generating substantial annual financial losses. In fact, it was their deteriorating financial condition that drove them into the arms of Terry Gou, chairman of Hon Hai Precision Industry Co., the large Taiwanese OEM manufacturer that is better known as Apple, Inc. supplier Foxconn Technology Group.

Foxconn has vowed to right the Sharp ship and to drive the company back to profitability again. As such, with Foxconn now calling the shots, Sharp executives are said to be adopting tough tactics in negotiating for more profitable panel pricing with TV manufacturers. But customers like Samsung and Hisense are pushing back.

Some in the industry told us that they thought that Sharp’s strategy was crazy. Samsung, they suggested, would simply go to another supplier to get the panels they need…and Sharp would be the ultimate loser. But the calculation of who wins and who loses is not quite that easy.

Market reports showed clearly that Samsung was absolutely scrambling to find alternative suppliers of quality LCD panels at this late date. Sharp, one report indicated, had supplied Samsung with 5 million panels in 2015 (the last full year for which data was available). This number was likely even higher in 2016.

So can’t Samsung simply increase their orders with their other panel suppliers? Most OEM manufacturers need to hit a certain capacity level in order to efficiently – and hopefully profitably – manufacture their panels. Too little capacity and they won’t get the supply contract. Too much capacity and then they have factories, lines, and machines sitting idle – a very expensive proposition that takes a bite directly out of their bottom line.

Hence, as we reported last week, Samsung was scrambling to find enough supply to meet their projected unit needs. How hard was this going to be? Apparently, so hard that Samsung was forced to go, hat in hand, to archrival LG to ask them to supply LCD panels. These companies are not friends. In fact, they are brutal competitors, locked in a battle to dominate the business both in their local South Korean market…and around the world.

The Nikkei is reporting that there may be another strategy behind Sharp’s new, tougher negotiating stance. Foxconn is said to be planning on a resurgence of sales of Sharp’s Aquos premium line of LCD TVs. In fact, Foxconn is projecting that they will double sales to 10 million units in fiscal 2018, their next fiscal year.

One way they will do that is by exanding their global market presence. But this plan has some challenges. As Sharp sought to cut the losses of their TV division, they decided to pull out of the North American market and license their brand to a third-party TV manufacturer. Now they want the market back.

If Foxconn is planning a major Sharp comeback, then terminating panel supply agreements with other manufacturers could be an effort to build panel supply for a new wave of Sharp branded and manufactured TVs…including those targeted for North America.

But it also could be a squeeze play on Hisense…cutting their supply so that they are unable to take advantage of holding the license for the North American market. If they have no TVs to sell in North America, Hisense would be more likely to sell the license back to Sharp.

In China. The biggest LCD panel manufacturer in the world now. BOE has G4 (Chengdu), G5 (Beijing), G5.5 (Ordos), G6 (Hefei, Chengdu, Mianyang, Dalian), G8 (Beijing, Hefei, Chongqing), Fuqing, Dalian, Chongqing) and 10.5 (Hefei) production lines.

In Taiwan. One of the daughter company of Foxconn/Hon Hai. In 2010, it bought the then famous LCD manufacturer, ChiMei, then changed its name to Innolux. It has G7.5 production lines.

In Korea and China. It is used to be the 2nd biggest TFT LCD manufacturers. LG also planned to stop the production but delayed the plan after the price increased. LG has G7.5 and G8.5 (Guangzhou) production lines.

In Korea. It used to be the biggest TFT LCD manufacturers before it was dethroned by BOE in 2019. Because of tough competition, Samsung planned to stop the production in 2021 but delayed because the price increase during the pandemic. Samsung has G7 and G8.5 production lines.

In Japan and China. The pioneer and queen of LCD industry. Because of high cost and tough competitor, Sharp was acquired by Foxconn/Hon Hai in 2016. Sharp has G8, G8.5(Suzhou), G10, G10.5 (Guangzhou) production lines.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey