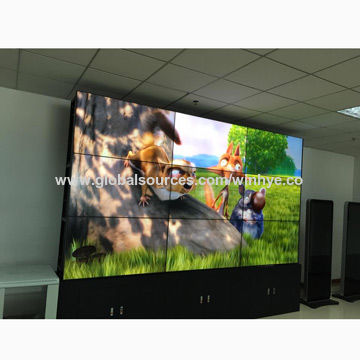

sharp lcd panel factory for sale

sharp lcd panels are easy to install and have the most basic features. When looking for lcd panels at wholesale prices, Alibaba.com offers a wide variety of sharp lcd panels that are easy to install and maintain, and are the perfect option for those looking for a new option.

Small lcd panels for sale are great for those looking for a new option, but be sure to stock a variety of sharp lcd panels for business owners. If you are looking for a sharp lcd panel for your business, consider buying smaller businesses.

sharp lcd panels are versatile and have the same functions as a flexible smartphone. It"s great for first-time buyers to find the lcd panels that are versatile and have the same functions as a flexible smartphone display. lcd panels are versatile and have a wide range of functions, such as displaying Tft displays, and for smart- screen displays.

Alibaba.com offers a wide variety of cheap lcd panels and lcd panel printing. different materials are available, such as wood, laminate, and glass, and metal lcd panels. Although different materials are available, different materials are used, and can be found to satisfy the needs of their customers.

TOKYO, Aug 28 (Reuters) - Japan Display said on Friday it has agreed to sell a smartphone screen plant to Sharp Corp for $390 million, raising funds to repay debt it owes Apple Inc for the plant construction costs.

The company said in a statement it will also sell screen plant equipment at the central Japan factory to “an overseas customer” for $285 million. Sources have said the customer is Apple.

Through improvements in LCD parts and materials, monitor weight has been reduced over earlier models, making it easier to transport and install the display.

TOKYO -- Struggling Apple supplier Japan Display plans to sell a smartphone screen factory and the land it sits on to Sharp for 41.2 billion yen ($386 million), the company has announced.

TOKYO/OSAKA -- Sharp"s decision to purchase a smartphone screen plant from Japan Display came at the behest of Apple, a major client, with hopes of transforming the facility into a key link in its long-term strategy on displays.

Japan Display on Friday said it is selling its halted Hakusan plant and the land under it to Sharp for 41.2 billion yen ($390 million), and part of the related equipment to a "customer" -- meaning Apple -- for 30.1 billion yen. Sharp will take control of the facility by October, and will resume the production of liquid crystal displays for iPhones there.

From time-to-time, we"ve passed along some news on Apple"s long-time LCD supplier Japan Display. The company had the misfortune of sinking a lot of money into new factories just as Apple was making the move to OLED panels for the iPhone. Apple has helped prop up the company this year by investing a reported $100 million into a restructuring of the company and moving some of its LCD production from China to Japan Display"s facilities. Japan Display has lost money for 11 straight quarters, and while it was late to start producing OLED panels, it now produces the AMOLED screens employed by the Apple Watch Series 5. Apple contributes 60% of Japan Display"s annual revenue.

The Nikkei Business Daily reports today that Japan Display is talking to Apple and Sharp about selling its main smartphone display factory for as much as $820 million. Sharp is a unit of Foxconn, a contract manufacturer responsible for assembling the majority of iPhone units sold globally. Sharp also sells displays to Apple and said that it was talking to Japan Display about purchasing the factory after an unnamed client requested that it do so. In a statement it released, Sharp said, "We are carefully considering it, reviewing the impact that any purchase would have on our earnings, and whether and how much risk it would entail." Besides Foxconn, the report suggests that Wistron could be included in the purchase of the factory. Wistron is another company used by Apple to manufacture its products including the iPhone.

The factory, located in Hakusan City, Ishikawa prefecture in western Japan, cost $1.5 billion to build back in 2015, and Apple fronted that money to Japan Display. As part of the deal with the display manufacturer, Apple was to be reimbursed by taking a cut of each LCD panel display sold. But with smartphone manufacturers turning to AMOLED, the plant was running at only 50% capacity. As a result, Japan Display still owes Apple more than $800 million.

Another report says that Sharp will actually purchase the LCD production facilities by next March and will reach a separate agreement with Apple after the deal is closed. The factory has been shut since this past July. Japan Display released a statement today saying that it is looking at all options but isn"t sure what it will do about the factory. The company adds that nothing has been decided and when it does make a decision, it will notify the press. Earlier this month, the company said that it was looking to receive $200 million from a customer, believed to be Apple, for equipment from the plant. But now it appears that Japan Display is taking a different path.

Last year, the panel manufacturer lost $2.3 billion following a $260 million loss in 2017. The firm is one of three companies supplying Apple with the Liquid Retina Display for the iPhone 11 along with LG Display and Sharp. According to reliable TF International analyst Ming-Chi Kuo, Apple could release four new models next year. Forgetting the difference between 4G and 5G models, only one of the four will use an LCD display and that is expected to be the 4.7-inch iPhone9.

Back in 2014-2015, Japan Display (JDI) was considered to be Apple"s major smartphone display supplier. At that time, the iPhone 6 and the iPhone 6 Plus were bringing larger-sized LCD screens to iPhone users. The original 3.5-inch display found on the first iPhone models rose to 4-inches with the iPhone 5 and to 4.7-inches on the iPhone 6. The iPhone 6 Plus carries a screen size of 5.5-inches and those sizes remained the same until 2017"s iPhone X weighed in with a 5.8-inch OLED screen.

Apple to build a new LCD plant. With smartphone manufacturers-including Apple-turning away from LCD, JDI"s new factory was running at only 50% of capacity. According to the Nikkei Asian Review, on Friday Japan Display announced that it will sell a smartphone display factory and the land it sits on to Sharp for 41.2 billion yen (the equivalent of $386 million). The Hakusan LCD factory along with equipment that will be sold to a customer believed to be Apple, will bring Japan Display $668 million while at the same time cutting excess capacity that has negatively impacted its earnings. This specific factory has been idle since 2019.

The facility was supposed to have been sold by the end of this past March but the global pandemic caused the plans to change. When the factory was built, Apple covered most of the 170 billion yen cost ($1.61 billion USD) of the facility. Production started in late 2016 with up to seven million smartphone panels manufactured each month. As time went on, the number of panels churned out by the factory declined on a monthly basis. Japan Display will use the funds it receives from the sale of the plant to pay back Apple for the prepayment it made toward the facility.

Sharp, which is owned by iPhone assembler Foxconn, will rent the necessary equipment from Apple that will allow it to produce LCD displays for older iPhone models. Sharp also expects to use the facility for developing and producing the next generation of displays including microLED screens which use millions of tiny light-emitting-diodes to produce a sharp display (no pun intended). Sharp does plan to spin-off its LCD panel business in October.

Sony said it would take a one-third stake in Sharp"s $3.5 billion LCD panel plant set for completion by March 2010, in an effort to meet fast-growing demand for flat televisions.

The move is the latest in a wave of alliances among Japanese flat TV makers as they try to secure enough panels while keeping initial investments in check to fight steep price declines.

Sharp, which offers Aquos LCD TVs, plans to turn the liquid crystal display factory, which would be the world"s largest, into a joint venture, with the Osaka-based company owning 66 percent and Sony taking the remainder.

Besides LCD panels, the joint venture will also produce LCD modules, which are display panels equipped with components such as a backlight unit and LCD driver chips.

The two Japanese companies plan to hold a joint news conference on Tuesday where Sony President Ryoji Chubachi and Sharp President Mikio Katayama will speak.

"For Sharp, this is a positive step since it means a major buyer that would keep the 10th-generation factory busy," Daiwa Institute of Research analyst Kazuharu Miura said.

Sharp"s new factory would use so-called 10th-generation glass substrates, which can yield more panels than earlier-generation, smaller glass substrates, improving production efficiency and helping both firms offer attractively priced flat TVs.

Global LCD TV sales are likely to more than double to 155 million units by 2012, according to the Japan Electronics and Information Technology Association.

Sony, which aims to sell 10 million units of its Bravia LCD TVs in the current business year to March 31, runs another LCD joint venture, S-LCD, with Samsung.

The announcement follows Toshiba"s decision late last year to buy LCD panels from Sharp, while Panasonic maker Matsushita Electric Industrial said earlier this month it would spend $2.8 billion to build an LCD plant in the face of robust LCD TV demand and tight panel supplies.

"The problem will be 2010 and 2011. Just when TV demand is likely peaking, Sharp"s 10th-generation plant will come onstream, and so will Matsushita"s new factory," Shinko Securities analyst Hideki Watanabe said.

Shares in Sony closed up 1.2 percent at 5,200 yen, while Sharp was flat at 2,100 yen. The Tokyo stock market"s electrical machinery index IELEC.rose 0.3 percent.

Sharp and Sony have reached a basic agreement to form an LCD manufacturing joint venture, in a move that continues a months-long realignment of key players in the LCD panel business.

The two companies aim to conclude a definitive deal by the end of September that will see a new LCD plant already under construction by Sharp taken over by the joint venture. The plant in Sakai in western Japan is being built at a cost of about ¥380 billion (US$3.5 billion), and under the joint venture plan Sony will shoulder 34 percent of the cost of the factory.

The move represents a major shift for Sony, which has previously been investing in LCD panel production with South Korea"s Samsung Electronics. The two companies currently compete with Sharp and produce LCD panels in South Korea through S-LCD, which has a factory at Samsung"s Tangjeong facility.

It will be a so-called "10th-generation" plant. That means it will be able to accept sheets of mother glass -- from which several panels can be made -- of 285 centimeters by 305 centimeters. Sharp said it will be able to produce six LCD panels in the 60-inch class, eight panels in the 50-inch class or 15 panels in the 40-inch class on each sheet.

The area of each sheet is 60 percent larger than the eighth-generation sheets used at Sharp"s current cutting-edge Kameyama factory in Japan. This will translate to a lower per-inch cost for panels produced on the line -- something of great importance in the highly competitive flat-panel TV business.

But in November, Samsung said it would invest 2 trillion Korean won (US$2.1 billion) in a new LCD production line at Tangjeong without participation from Sony. The line is scheduled to begin production in the third quarter of this year and will produce panels 50 inches and larger -- the same types of screens that Sharp is targeting with its new factory in Sakai in western Japan.

In 2016, Apple loaned Japan Display Inc. (JDI) $1.5 billion to enable JDI to construct the Hakusan plant and further ensure Apple a stable supply of LCD panels for its iPhone series. The large production capacity combined with large orders, allowed JDI to become the biggest LCD panel supplier for its iPhone series line-up.

The company saw LCD technology as a big opportunity and decided to invest significantly, ramping up production to cater to the opportunity. However, the company was hit by increasing competition from China display panel vendors which includes BOE, Tianma and TCL CSOT, leading to price wars and unfavorable business deals. During the years, JDI was unable to grab design wins and expand the size of orders to other customers and kept relying on Apple for most of its orders. We estimate more than half of its total revenue was contributed by Apple.

Considering the common adoption of LCD with no unique value proposition, Apple decided to shift its focus on OLED panels and started to increase the utilization of OLED technology, partnering with Samsung Display and LG Display to produce panels for iPhone X, XS, 11 Pro series smartphones.

Over the years, JDI was pushed by Apple to focus on OLED panel technology and mass produce panels for the iPhone series but the panel vendor was unable to do it. However, JDI did manage to produce OLED panels through J-OLED and supplied it to Apple’s Watch series along with LG Display. The company’s OLED arm, J-OLED has created an innovative process to produce large-area TV panels based on inkjet printing and is also collaborating with TCL CSOT to mass-produce these panels.

As per Strategy Analytics estimates, the vendor’s smartphone panel shipments declined annually by 20 percent in CY 2019. The vendor has been losing money for its LCD business and recently recorded its 6th consecutive annual net loss in the fiscal year ended in March 2020.

JDI also implemented structural reforms aimed at cost reduction which includes personnel cost reduction, suspending mobile display plant operation temporarily and asset sales especially the facilities that are currently a burden on JDI’s bottom line. JDI’s Hakusan plant has been underutilized for quite some time as demand for LCD based mobile products has been lower than expected. Hakusan Plant is a significant fixed cost for JDI and a sale is necessary to improve the company’s cash flow, turnaround its business.

Apple is set to announce the iPhone 12 series which will be completely based on OLED panel technology and would exclude an LCD mobile product for the first time in its announcement. JDI’s key customer, Apple has completely shifted to focus on OLED technology for new products which means that the JDI’s mobile LCD business is increasingly jeopardizing its financial position in the near future if it is continuing to rely on Apple"s LCD panel orders.

Japan Display announced today that they had struck a deal with Sharp Corporation to sell its LCD Display plant in Hakusan, Japan for $ 390 million and also agreed to sell plant equipment to Apple for a total of $ 285 million. The proceeds from the sales are expected to be used along with the company’s own funds, for repaying the advances received from Apple (close to $ 700 million).

The LCD plant transfer is expected to be completed by this September and Sharp is expected to start production as soon as Q4 2020 (October) and will rent the plant equipment owned by Apple. Sharp will take over any debt associated with the Hakusan plant.

The Hakusan plant focuses on the production of mobile LCD display panels for Apple iPhones. The transfer of the asset allows Sharp to take over the plant. Sharp is expected to spin off its display business and combine the new plant capabilities to raise the production capacity and meet customer demand. Sharp also negotiated a deal with Apple to use this plant to produce panels to supply other smartphone customers.

The mobile LCD panel production for the company is expected to consolidate at the Mobara plant (G6 LTPS fab) that has twice the production capacity along with an OLED production site. This allows JDI to continue meeting the smartphone LCD demand from its customers.

• Given the strong relationship between Apple and JDI, What does this mean for panel orders from Apple and will the company reduce panel orders to JDI going forward?

Now having taken over the Hakusan plant, Sharp is expected to become a major player in the Apple iPhone supply chain. This allows the display vendor to strengthen its market position in the smartphone display segment. The increased production capacity also ensures a steady supply of LCD panels to Apple’s iPhone series based on LCD technology.

We also cannot ignore the role of Foxconn in this picture, who is being contracted by Apple to produce iPhones. We note that Foxconn being a major shareholder in Sharp Corporation, is looking to integrate the entire supply chain for iPhone production and display is a crucial component where Foxconn wants to control pricing and supply.

Sharp is expected to route all the smartphone panel orders through the Hakusan plant and tap the remaining capacity at the Kameyama plant (G6 LTPS fab) for new opportunities in the automotive and medical sectors.

• Since Sharp has boosted its panel capacity with the acquisition, will the panel vendor replace JDI in the supply chain for supplying LCD panels to Apple iPhone series?

• The plant acquisition also presents a risk of increasing fixed costs and the vendor would need to expand its customers beyond Apple, which all smartphone OEMs can be potential customers for Sharp?

The plant sale is expected to provide Japan Display and Sharp, a unique position to focus on next-generation technologies, especially on OLEDs. Apple has played a crucial role in facilitating this deal as it looks to reduce the reliance on Samsung Display and expand OLED supply to multiple panel vendors.

Japan Display Inc. reached a definitive agreement to sell its liquid crystal display production plant in Hakusan city, Ichikawa Prefecture, Japan, to Sharp Corp. for US$390 million.

The transaction includes the transfer of land, building, ancillary facilities and other assets within the facility to consumer electronics manufacturer Sharp, according to an Aug. 28 statement.

Japan Display will also sell some of its LCD production equipment at its Hakusan plant for US$285 million to a customer, which was not named due to a nondisclosure agreement. The equipment sale was originally only US$200 million, but Japan Display and the customer agreed on the transfer of additional assets worth US$85 million.

Japan Display had suspended production at the Hakusan factory in July 2019 over poor sales, but the plant has been running test operations since the fourth quarter of fiscal 2019.

The display panel maker also decided to scrap plans to convert its in-house mobile company into a subsidiary, after its risk profile changed in line with the sale of the Hakusan plant.

Amidst a recession after the bursting of Japan"s economic bubble, Sharp announced the construction of the world"s largest LCD plant in Taki Town, Mie Prefecture. The news that Sharp, the world leader in LCD, would invest 53 billion yen initially in the facility was the top story in newspapers and on television. Slated to start operation in July of the following year, the plant boasted advanced network CIM (computer integrated manufacturing) and the use of proprietary manufacturing processes and automation, giving it a huge leap in manufacturing efficiency. The facility would mass-produce leading-edge full-color TFT LCDs.

It was 30 years before, on March 18, 1964, that Sharp introduced the CS-10A, the world"s first all-transistor desktop calculator. Although this first model was priced at 500,000 yen, about the same price as a mid-sized car, Sharp went on to manufacture 400 million of the 1.6 billion calculators produced throughout the world as the calculator became the most familiar electronic tool in history. Calculator development spawned a series of technological evolutions that led to advances in semiconductors and LCDs, in the process making a huge contribution to Japan"s electronics industry.

In April, Sharp made waves with the introduction of a reflective-type TFT color LCD that could be viewed clearly in natural or normal room light. Compared to conventional transmissive-type LCD, which required a backlight, this new display used just one-thirtieth the power and boasted a wide viewing angle. The reflective TFT LCD became popular in demand as a display for mobile devices.

In June, Sharp announced the development of a 21-inch TFT color LCD, the world"s largest. This was 1.5 times larger than the 17-inch model Sharp introduced in 1992, showing the world Sharp"s high standard of LCD technology. Sharp had finally broken the 20-inch barrier with this wall-mount TV.

In August, Sharp completed a new plant for the manufacture of air conditioners and microwave ovens. In December, the company added rice cookers to its production repertoire and renamed itself Shanghai Sharp Electronics Co., Ltd. (SSEC).

Less than two years after the LCD ViewCam"s October 1992 introduction, production of the world"s first video camera with LCD screen surpassed the one million mark. The ViewCam was truly a global hit, with 460,000 sold overseas.

It had now been 32 years since Sharp first began mass-producing Japan"s first commercial-use microwave ovens. In 1966, Sharp introduced the first microwave ovens in Japan for home use. In October 1994, worldwide production broke the 40 million mark.

For the second year in a row, Sharp was at the top of the list of companies in Weekly Diamond magazine"s rankings of the best companies and products in Japan. The same year, Sharp received top honors for Company of the Year in the Toyo Keizai Awards, for the Trend Product Awards from Dime magazine, and for the Gold Award from Mono Magazine. All awards praised Sharp for its world-leading LCD technology and its well-balanced business mix of consumer electronics, information products and electronic components.

LEDs, LCDs & Display Modules└ Electronic Components & Semiconductors└ Electrical Equipment & Supplies└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Apple supplier Japan Display is on the hook for more than $800 million it owes to Apple for building a smartphone display manufacturing plant four years ago, and now it could sell the entire factory to the Cupertino firm and Sharp, another Apple supplier that builds LCD panels for some iOS devices.

Japan Display has been bleeding money for the past five years due to sluggish display sales and restructuring costs. It’s only now that it’s starting to build OLED screens for Apple Watch, for example. The company has ignored the superior OLED display technology for far too long so little wonder its LCD business has been shrinking in the past few years.

Making matters worse, the factory cost about $1.5 billion to build but the company still owes Apple more than $800 million for the facility, which is located in Hakusan, Japan.

The cash-strapped company had said this month that financial support of $200 million promised by ‘a customer’, which sources said was Apple, may come in the form of purchasing equipment at the plant. Those discussions appear to have switched to the sale of the entire factory, the Nikkei said.

Sharp has confirmed receiving a client request to join the transaction, saying in a statement it is carefully considering the offer and “reviewing the impact that any purchase would have on our earnings, and whether and how much risk it would entail.”

Back in 2016, to determine if the TV panel lottery makes a significant difference, we bought three different sizes of the Samsung J6300 with panels from different manufacturers: a 50" (version DH02), a 55" (version TH01), and a 60" (version MS01). We then tested them with the same series of tests we use in all of our reviews to see if the differences were notable.

Our Samsung 50" J6300 is a DH02 version, which means the panel is made by AU Optronics. Our 55" has an original TH01 Samsung panel. The panel in our 60" was made by Sharp, and its version is MS01.

Upon testing, we found that each panel has a different contrast ratio. The 50" AUO (DH02) has the best contrast, at 4452:1, followed by the 60" Sharp (MS01) at 4015:1. The Samsung 55" panel had the lowest contrast of the three: 3707:1.

These results aren"t really surprising. All these LCD panels are VA panels, which usually means a contrast between 3000:1 and 5000:1. The Samsung panel was quite low in that range, leaving room for other panels to beat it.

The motion blur results are really interesting. The response time of the 55" TH01 Samsung panel is around double that of the Sharp and AUO panels. This is even consistent across all 12 transitions that we measured.

For our measurements, a difference in response time of 10 ms starts to be noticeable. All three are within this range, so the difference isn"t very noticeable to the naked eye, and the Samsung panel still performs better than most other TVs released around the same time.

We also got different input lag measurements on each panel. This has less to do with software, which is the same across each panel, and more to do with the different response times of the panels (as illustrated in the motion blur section). To measure input lag, we use the Leo Bodnar tool, which flashes a white square on the screen and measures the delay between the signal sent and the light sensor detecting white. Therefore, the tool"s input lag measurement includes the 0% to 100% response time of the pixel transition. If you look at the 0% to 100% transitions that we measured, you will see that the 55" takes about 10 ms longer to transition from black to white.

All three have bad viewing angles, as expected for VA panels. If you watch TV at an angle, most likely none of these TVs will satisfy you. The picture quality degrades at about 20 degrees from the side. The 60" Sharp panel is worse than the other ones though. In the video, you can see the right side degrading sooner than the other panels.

It"s unfortunate that manufacturers sometimes vary the source of their panels and that consumers don"t have a way of knowing which one they"re buying. Overall though, at least in the units we tested, the panel lottery isn"t something to worry about. While there are differences, the differences aren"t big and an original Samsung panel isn"t necessarily better than an outsourced one. It"s also fairly safe to say that the same can be said of other brands. All panels have minute variations, but most should perform within the margin of error for each model.

LCD displays are still going to be around for a long time, at least for smart TVs such as the ones that use Android TV and other operating systems. Today, the massive electronic manufacturing company Foxconn announced a new partnership with Sharp to build and operate a new TV LCD flat-panel factory in China, which will cost $8.8 billion.AMOLED displays set to close in on LCD this year

Reuters reports that the new factory will help with the expected demand of new flat-screen TVs in Asia. Foxconn said that the LCD factory will make 10.5-generation 8K displays, along with screens for smart TVs and electronic whiteboards. Production is expected to begin in 2019.

This news comes even as other companies are embracing OLED displays for both TV as well as smartphones. However, there’s still some life in the LCD market. Panasonic recently announced an LCD IPS display with a 1,000,000:1 contrast ratio. It is supposed to have 600 times more contrast compared to normal LCD panels, and those levels are close to those found in OLED displays.

TOKYO (Reuters) - Japan Display said on Friday it has agreed to sell a smartphone screen plant in central Japan to Sharp Corp for $390 million, raising funds to repay debt it owes Apple Inc for the plant construction costs.

The company said in a statement it will also sell screen plant equipment at the liquid crystal display (LCD) factory to "an overseas customer" for $285 million, or $85 million more than the amount announced in March. Sources said the customer is Apple.

Sharp, a supplier of sensors, camera modules and LCD screens for Apple"s iPhones, is buying the central Japan plant at the request of Apple and plans to consolidate its iPhone panel production there, a source familiar with the matter said.

Sharp, a unit of Taiwan"s Foxconn, has been operating its own smartphone panel plant almost at full capacity, in part due to the popularity of Apple"s new lower cost iPhone SE.

Sharp will use the vacated smartphone panel lines at its existing LCD plant to boost production of panels for autos and medical equipment, said the source, who declined to be identified because the issue is private.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey