psoc 6 tft display factory

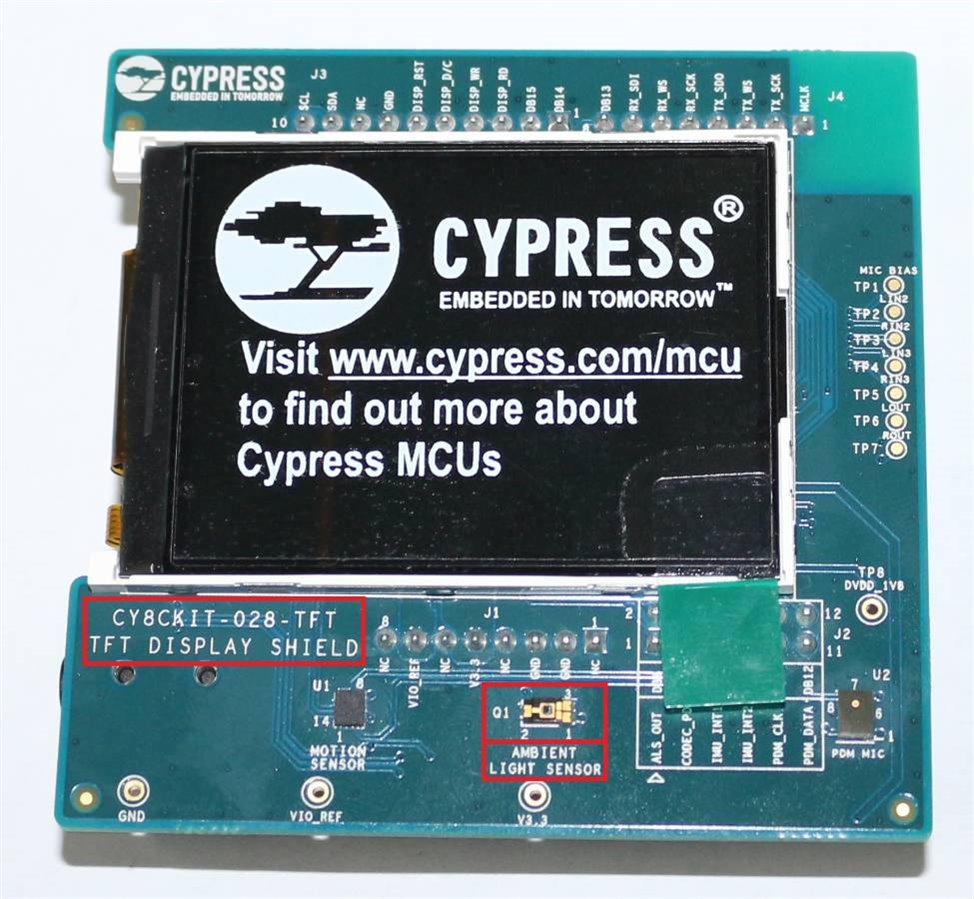

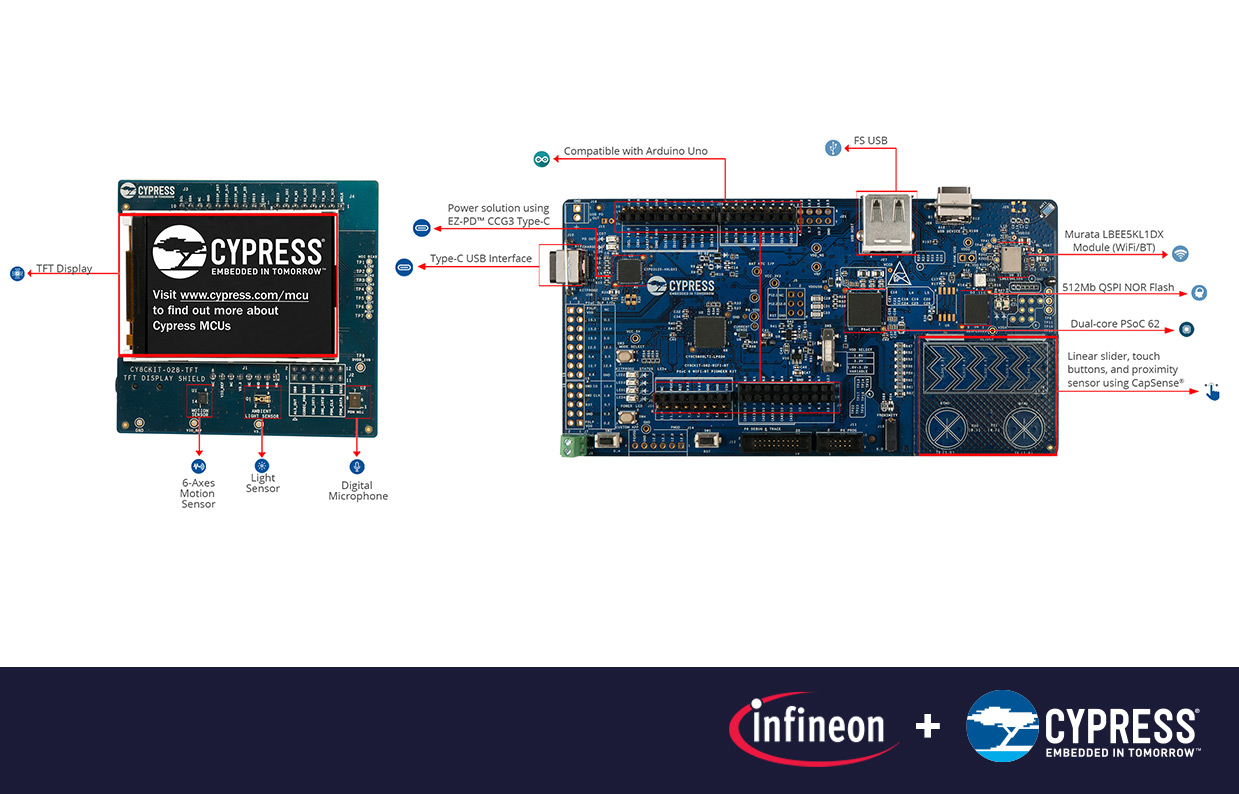

The TFT Display Shield Board (CY8CKIT-028-TFT) has been designed such that a TFT display, audio devices, and sensors can interface with Infineon"s PSoC 6™ MCUs.

The TFT Display Shield Board is compatible with the PSoC 6™ WiFi-BT Pioneer Kit CY8CKIT-062-WiFi-BT and the PSoC 6™ BLE Pioneer Kit CY8CKIT-062-BLE. Refer to the respective kit guides for more details.

This article will take you through a high level overview of all of the parts of a TFT LCD display. The vast majority of what I have read on the internet makes this whole issue massively complex. I’m quite sure that this complexity problem is a real reflection of the serious design and manufacturing complexity in these displays and drivers. That being said, to get a conceptual understanding is much simpler, and is the point of this article.

A significant amount of my learning about this subject came from a 195 page powerpoint presentation by Dr. Fang-Hsing Wang entitled “Flat Panel Display : Principle and Driving Circuit Design“. He has graciously allowed me to reproduce a few of his images. This dude knows way way more about these circuits than I do and I would encourage you to read his work.

The fundamental element in a TFT display is the liquid crystal. These elements have the property that the crystals will align from horizontal (which blocks the light) to vertical (which lets most of the light through) based on the electric field applied to them. Basically, you shine light through the liquid crystal, which blocks some or all of the light, the remainder of the white light then goes through a color filter to make red, green, or blue. It works like this:

This architecture means that every pixel in the display will require a red, green and blue element. And, you will need to control the voltage on all of the elements (which will be quite a lot on a screen of any size)

What does the schematic for one element in a pixel look like? And where is the T(transistor) in the TFT? The three letter acronym TFT stands for a thin film transistor that is physically on the top of the LCD matrix right next to each liquid crystal element. Here is a schematic model for one element in the array. C-LC represents the capacitance of the liquid crystal. CS is a storage capacitor that is used to hold the electric field across the liquid crystal when the transistor is OFF. To apply a voltage across the LC you just turn on the gate and apply the correct voltage to the column commonly known as the source.

You should notice that the “back” terminal of the two capacitors is called “VCOM” and is physically on the other side of the liquid crystal matrix from the TFT. All of the liquid crystal backsides in the display are connected to the same VCOM. A bit of painfulness in this system is that the CS capacitor leaks, which means that the LCD changes state which means that each pixel must be updated, properly called refreshed, on a regular basis.

If you have been thinking about this system you might have done a little bit of math and figured out that you are going to need an absolute boatload of source and gate driver signals. And you would be right! For example, a 4.3″ screen with 480×272 will require 480x272x3 elements which are probably organized into 480 rows by 816 columns. This would require a chip with at least 480+816=1296 pins, that is a lot. It turns out that for small screens <=3.5″ there are chips with enough pins to do the job. But, for larger screens, it requires multiple chips to do the job. The “…” in the picture above shows the driver chips being cascaded. The next thing to know is that “TFT Glass” usually has the driver chip(s) embedded into the screen at the edge (you can see that in the picture from Innolux above).

In its most basic form, the TFT source driver is responsible for taking an 8-bit digital input value representing the value of an individual LCD element and turning it into a voltage, the driving the voltage. Like this:

What appears to happen in real life on bigger screens is some combination of column and row multiplexing. In one display that I found there were 2x the number of rows which allows the columns to be multiplexed 2-1. The display is 1024×600. That requires 1024*3 RGBs in the column = 1536 pins. This means that you need to double the number of gate drivers, resulting in 1200 pins in the row direction. Here is a picture from their datasheet.

The last issue that I will address in TFT LCD drivers is called Gamma Correction or more simply Gamma. Gamma is an intensity adjustment factor. For any given digital intensity input, you will need a non-linear translation to a voltage output on the source. For example a doubling of digital input (so that a pixel appears twice as bright) you will not double but instead will have some non-linear translation of the output voltage.

The good news is that this gamma correction is built into the display drivers. From my reading, this is sometimes done with digital processing, and sometimes done with an analog circuit. But in general, it appears to be tuned and programmed into the driver by the panel vendor for these smaller display.

Clicker 2 for PSoC® 6 is a compact development kit with two mikroBUS™ sockets for click board connectivity, an ideal solution for rapid development of custom applications. It is equipped with the PSoC® 6, a dual-core 32-bit CY8C6347BZI-BLD53 Microcontroller Unit (MCU). This powerful device is a combination of ARM® Cortex™ based dual-core MCU with low-power flash technology and digital programmable logic, programmable analog resources, industry-leading CapSense® technology, and other standard communication and timing peripherals. One of the key features of this MCU is the support for the BLE 5 compliant wireless connectivity. Supported by the PSoC® Creator and equipped with the KitProg2 compatible onboard programmer, this board is the ultimate development platform for building portable and IoT applicationsin the entire range of Clicker 2 products.

Power Management. Clicker 2 for PSoC® 6 is equipped with the LTC3586, a high-efficiency USB power manager, and battery charger, featuring the proprietary PowerPath™ and Bat-Track™ technologies, from Linear Technology. The LTC3586 power manager takes care of all the power options of the Clicker 2 for PSoC® 6, providing stable and low ripple voltage outputs for all parts of the board while ensuring proper Li-Po battery charging conditions. The power manager IC allows charging of the Li-Po battery while the Clicker 2 for PSoC® 6 board is connected to the USB port of the computer.

Programming. The programming can be done using the PSoC Creator IDE or stand-alone PSoC Programmer software application. The onboard KitProg2 compatible programmer is automatically detected by the software when Clicker 2 for PSoC board is connected, with no additional configuration steps required. PSoC Creator IDE and PSoC Programmer software applications are available for download from the Infineon official download page, as well as from the download links, below

Since the PSoC 6 MCU launch in 2017, multiple PSoC 6 MCU Dev Kits have been developed to enable innovative ideas for a range of developers. There are smaller form factor "Prototyping Kits" as well as more full-featured "Pioneer Kits" all coming with wireless connectivity, CapSense, sensors, and the ability to expand to off-the-shelf shields for added functionality (the Pioneer Kits even come with Arduino® display shields).

The software environment you should use for this design contest is: ModusToolbox™. The ModusToolbox Software Environment is the ideal software platform to create IoT MCU and Wireless designs. Think about ModusToolbox as a collection of firmware libraries (BSPs, middleware, examples, and more) and tools that you can easily arrange to suit the needs of your PSoC 6 project. ModusToolbox allows you to bring your PSoC 6 idea to life. Take advantage of our intuitive configurators that allow you to easily setup system functions, configure and tune CapSense hardware applications, setup and write to displays, and configure connectivity settings for Wi-Fi, Bluetooth, and USB. ModusToolbox also provides a world-class integration of 3rd party ecosystems such as Mbed OS and FreeRTOS for AWS IoT cloud services. There are a plethora of easy-to-use code examples on the Cypress GitHub Repository that show you how to take advantage of all these features and development flows.

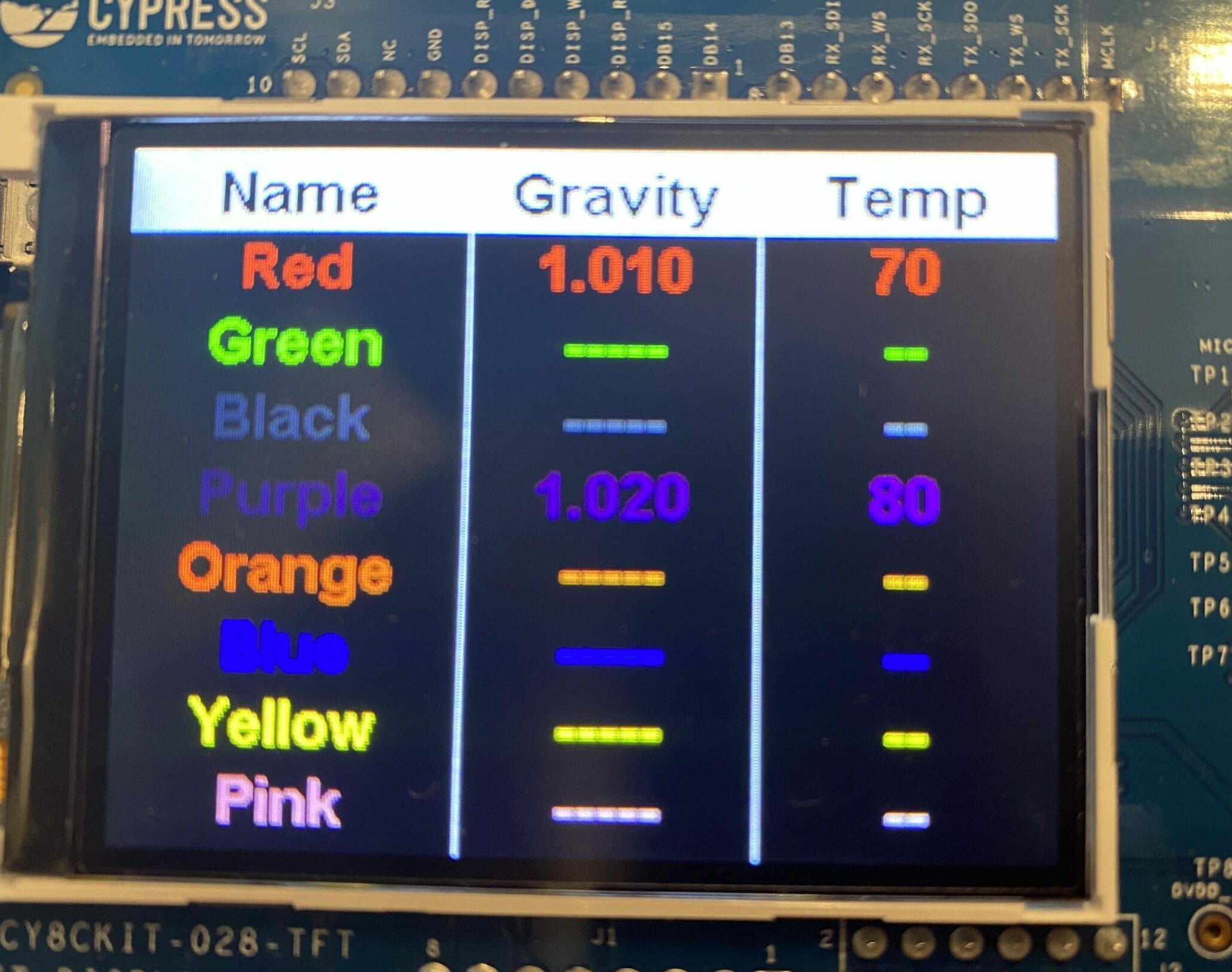

This example demonstrates displaying 2D graphics on a TFT display using the emWin graphics library and the AppWizard GUI design tool in FreeRTOS. The application initializes the system peripherals and creates a task that cycles through demo images in response to button presses.

This code example requires CY8CKIT-028-TFT; TFT display shield board. This shield comes with PSoC™ 6 Wi-Fi Bluetooth® pioneer kit. It can also be purchased standalone and used with other supported kits.

Note: The PSoC™ 6 Bluetooth® LE pioneer kit (CY8CKIT-062-BLE) and the PSoC™ 6 Wi-Fi Bluetooth® pioneer kit (CY8CKIT-062-WIFI-BT) ship with KitProg2 installed. The ModusToolbox™ software requires KitProg3. Before using this code example, make sure that the board is upgraded to KitProg3. The tool and instructions are available in the Firmware Loader GitHub repository. If you do not upgrade, you will see an error like "unable to find CMSIS-DAP device" or "KitProg firmware is out of date".

The following example clones the "mtb-example-psoc6-emwin-tft-freertos" application with the desired name "EmwinTftFreeRtos" configured for the CY8CKIT-062-WIFI-BT BSP into the specified working directory, C:/mtb_projects:

project-creator-cli --board-id CY8CKIT-062-WIFI-BT --app-id mtb-example-psoc6-emwin-tft-freertos --user-app-name EmwinTftFreeRtos --target-dir "C:/mtb_projects"

If using a PSoC™ 64 "Secure" MCU kit (for example, CY8CKIT-064B0S2-4343W, CY8CKIT-064S0S2-4343W), the PSoC™ 64 device must be provisioned with keys and policies before being programmed. Follow the instructions in the "Secure Boot" SDK user guide to provision the device. If the kit is already provisioned, copy-paste the keys and policy folder to the application folder.

Observe the startup screen with the Infineon logo on the display. Follow the instructions that come on the screen after two seconds. Press the user switch to move between pages when the user LED is OFF.

This project uses a CY8CKIT-028-TFT; TFT display shield together with a pioneer board. The TFT shield has a Newhaven 2.4″ 320×240 TFT display with a Sitronix ST7789 display controller and uses the 8080-series parallel interface.

emWin middleware documentation on GitHub for understanding the structure of the emWin package, supported drivers, and a quick start guide to create and run your first emWin project from scratch. The documentation page also contains configuration details on a wide variety of display drivers provided by emWin.

AppWizard project: The GUI that is displayed on the screen is designed using the AppWizard software. The code example includes the corresponding AppWizard project.

Major update to support ModusToolbox™ v3.0. This version is not backward compatible with previous versions of ModusToolbox. Migrated the CE to use the latest emWin version V1.30_6.26d

Cypress, the Cypress logo, and combinations thereof, WICED, ModusToolbox, PSoC, CapSense, EZ-USB, F-RAM, and Traveo are trademarks or registered trademarks of Cypress or a subsidiary of Cypress in the United States or in other countries. For a more complete list of Cypress trademarks, visit cypress.com. Other names and brands may be claimed as property of their respective owners.

Mouser Electronics, Inc., the industry"s leading New Product Introduction (NPI) distributor with the widest selection of semiconductors and electronic components, is now stocking the CY8CKIT-062-WiFi-BT PSoC® 6 Pioneer Kit from Cypress Semiconductor. Ideal for Internet of Things (IoT) applications and wearable devices, the PSoC 6 WiFi-BT Pioneer Kit enables the development of Wi-Fi applications using a high-performance Cypress PSoC 6 microcontroller.

The Cypress PSoC 6 Wi-Fi-BT Pioneer Kit, available from Mouser Electronics, includes a PSoC 6 WiFi-BT Pioneer Board, TFT display shield, necessary jumper wires, and a USB cable. The Pioneer Board offers header footprints for compatibility with Arduino UNO shields and Digilent® Pmod™ modules with operating voltages from 1.8V to 3.3V. The board also includes an onboard programmer and debugger with mass storage programming and custom applications support as well as 512 Mbits of NOR flash for expandable memory. The board’s five-segment slider, two buttons, and one proximity sensing header allow engineers to evaluate the latest generation of Cypress’ CapSense® capacitive-sensing technology. The Pioneer Kit’s TFT display shield includes a 2.4-inch module, six-axis motion sensor, ambient light sensor IC, and PDM microphone for voice input.

The Pioneer Board is based on a PSoC 62 microcontroller, coming soon to Mouser Electronics. The device delivers ultra-low-power performance with the critical security features required for IoT applications, integrating an Arm® Cortex®-M4 core and Arm Cortex-M0+ core, 1 MByte of flash, 288 Kbytes of SRAM, and 104 general-purpose inputs and outputs (GPIO). Additionally, the board features a USB Type-C power delivery system, plus a Murata LBEE5KL1DX module — based on a Cypress CYW4343W Wi-Fi and Bluetooth®combo chip — for 2.4-GHz WLAN and Bluetooth functionalities.

The PSoC 6 microcontroller capitalizes on Cypress’ proprietary ultra-low-power 40-nm SONOS process technology, which enables industry-leading power consumption with 22 µA/MHz and 15 µA/MHz of active power on the Arm Cortex-M4 and Cortex-M0+ cores, respectively. The powerful microcontroller also features software-defined analog and digital peripherals, multiple connectivity options and programmable analog-front-end (AFE) functions.

For more information about the PSoC 6 WiFi-BT Pioneer Kit, visit www.mouser.com/cypress-psoc6-wifi-bt-pioneer-kit. To learn more about the Cypress Semiconductor PSoC 6 microcontroller, go to www.mouser.com/cypress-psoc-6-soc.

We are happy to announceacollaboration with Cypress, one of the world’s leading designers and manufacturers of MCUs, Connectivity, and Memory for IoT and Automotive applications – on enabling Python onPSoC6MCUs.

We are starting off the enablement of Python onPSoCMCUs by adding Cypress’PSoC6WiFi-BT Pioneer Kit(CY8CKIT-062-WIFI-BT)to our list of supported devices.

This kit provides a rich hardware platform that enables designing and debugging of the PSoC 62 MCU and the Murata LBEE5KL1DX802.11n Wi-Fi and Dual-Mode Bluetooth ComboModule. The baseboard comes with 2 buttons, a 5-segment slider, and a proximity sensor. Using the 4th generation CapSense provided in the PSoC 62 Line, self- and mutual-capacitive-sensing systems can be evaluated with this kit. In addition, this kit comes with a TFT Display shield board thatfeaturesa 2.4 inch TFT display, motion and light sensors, anddigitalmicrophone.

November 13, 2018 - Mouser Electronics, Inc., the authorized global distributor with the newest semiconductors and electronic components, is now stocking the PSoC® 6 microcontroller from Cypress Semiconductor. Bridging the gap between power-hungry application processors and low‑performance microcontrollers, the ultra‑low‑power PSoC 6 microcontroller delivers all-in-one high-performance processing and critical security features that are purpose-built for Internet of Things (IoT) applications.

The Cypress PSoC 6 microcontroller, available from Mouser Electronics, utilizes a dual-core architecture, with an Arm® Cortex®‑M4 for high‑performance tasks and an Arm Cortex‑M0+ for low-power tasks. Active power consumption is as low as 22 μA/MHz for the M4 core, and 15 μA/MHz for the M0+ core. The highly flexible PSoC 6 architecture enables the addition of features, such as USB, Bluetooth® low energy, and other software‑defined peripherals to create custom analog front ends (AFEs) and digital interface circuits that address the needs of those IoT designs requiring multiple connectivity options.

For IoT security, PSoC 6 integrates a hardware-based Trusted Execution Environment with secure boot capability and integrated secure data storage to protect firmware, applications and secure assets such as cryptographic keys. The device also implements industry-standard symmetric and asymmetric cryptographic algorithms which include elliptical-curve cryptography, Advanced Encryption Standard (AES), and secure hash algorithms (SHA 1,2,3).

Mouser is also stocking the PSoC® 6 WiFi-BT Pioneer Kit, which provides a PSoC 6 WiFi-BT Pioneer Board, TFT display shield, necessary jumper wires, and a USB cable for evaluation and development. The Pioneer Board offers header footprints for compatibility with Arduino Uno shields and Digilent® Pmod™ modules, plus a five-segment slider, two buttons, and one proximity-sensing header that allow engineers to evaluate Cypress" CapSense® capacitive touch-sensing technology. The TFT display shield board includes a 2.4-inch display, six-axis motion sensor, ambient light sensor IC, and PDM microphone for voice input.

Mouser Electronics, a Berkshire Hathaway company, is an award-winning, authorized semiconductor and electronic component distributor focused on rapid New Product Introductions from its manufacturing partners for electronic design engineers and buyers. The global distributor"s website, Mouser.com, is available in multiple languages and currencies and features more than 5 million products from over 750 manufacturers. Mouser offers 23 support locations around the world to provide best-in-class customer service and ships globally to over 600,000 customers in more than 220 countries/territories from its 750,000 sq. ft. state-of-the-art facility south of Dallas, Texas. For more information, visit www.mouser.com.

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

Mouser Electronics, Inc., the industry’s leading New Product Introduction (NPI) distributor with the widest selection of semiconductors and electronic components,is now stocking the CY8CKIT-062-WiFi-BT PSoC 6 Pioneer Kit from Cypress Semiconductor. Ideal for Internet of Things (IoT) applications and wearable devices, the PSoC 6 WiFi-BT Pioneer Kit enables the development of Wi-Fi applications using a high-performance Cypress PSoC 6 microcontroller.

The Pioneer Board is based on a PSoC 62 microcontroller, coming soon to Mouser Electronics. The device delivers ultra-low-power performance with the critical security features required for IoT applications, integrating an Arm Cortex-M4 core and Arm Cortex-M0+ core, 1 MByte of flash, 288 Kbytes of SRAM, and 104 general-purpose inputs and outputs (GPIO). Additionally, the board features a USB Type-C power delivery system, plus a Murata LBEE5KL1DX module — based on a Cypress CYW4343W Wi-Fi and Bluetoothcombo chip — for 2.4-GHz WLAN and Bluetooth functionalities.

The PSoC 6 microcontroller capitalises on Cypress’ proprietary ultra-low-power 40-nm SONOS process technology, which enables industry-leading power consumption with 22 µA/MHz and 15 µA/MHz of active power on the Arm Cortex-M4 and Cortex-M0+ cores, respectively. The powerful microcontroller also features software-defined analog and digital peripherals, multiple connectivity options and programmable analog-front-end (AFE) functions.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

Richard Ahrons (2012). "Industrial Research in Microcircuitry at RCA: The Early Years, 1953–1963". 12 (1). IEEE Annals of the History of Computing: 60–73. Cite journal requires |journal= (help)

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

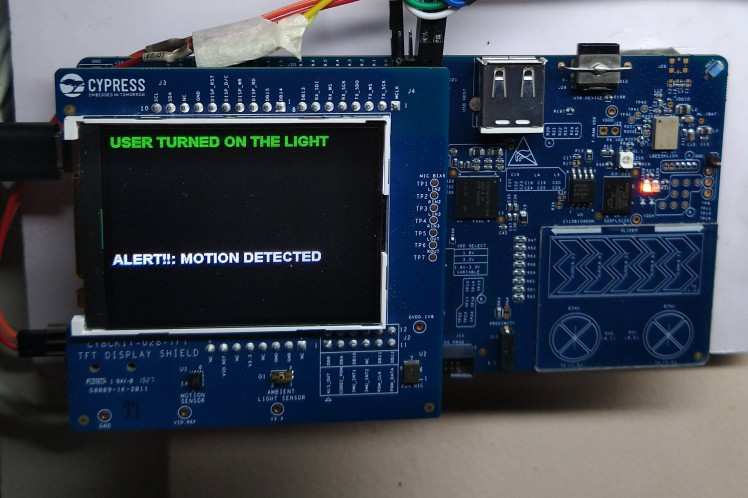

This code example demonstrates how to use TFT Display available with CY8CKIT-062-WiFi-BT to print text messages. It also demonstrates how to use CapSense slider to control the intensity of a LED.

This example uses the TFT display driver available withCE222494 -PSoC 6 WICED WiFi Demoand the µGUI framework available in WICED Studio to control the TFT Display.

CapSense library available for CY8CKIT_062 platform (PSoC 6 MCU+LBEE5KL1DXmodule) in the WICED Studio is used for detecting the CapSense buttons touch and slider position.

2. Copy the extracted "PSoC_6_MCU" folder to WICED Studio installation directory under following path:

2. Slide your finger on the CapSense slider to change the intensity of the on-board LED. Also observe that the current finger position is shown on the display.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey