psoc 6 tft display quotation

Those who have read our previous posts will note that we have only had good things to say about the PSoC product line, be it a BLDC Motor kit or re-designing punched tape readerelectronics, we’ve thoroughly enjoyed using PSoC ICs in the past.

Being the hottest topic around it shouldn’t be a surprise that IoT is the focus for the new PSoC range. That is not to say the PSoC6 would not suit other roles, but there are a few key adaptations that will differentiate it from previous incarnations that are aimed at IoT endpoint applications. Due to the flexibility of the PSoC family, these specialisations will almost certainly find other uses.

The new PSoC 6 architecture aims to provide a third option — the equivalent of having your cake and eating it. The PSoC 62 has an ARM Cortex M4 with floating point and a second “low power” M0+. A point to note is the low power is in quotes for a reason: the M0+ is no slouch; this is the CPU in the PSoC 4 range which is more than enough for some applications on its own. Unlike the big.little, architecture both cores are available in parallel so can share workload, but just like the big.little, the system can turn off the high power CPU and run on the smaller lower power system when processing requirements are not required. By implementing the architecture in this way the PSoC 6 becomes a true multi-core CPU, all be it asymmetric.

The PSoC 61, 62 and 63 architecture incorporates a cryptographic module to allow code to be secured so that it cannot be read (or booted) without the correct key. The CPU has one-time fuses so that this function can be “burned” into the chip, forcing a secure boot. This prevents any hacking of the device and malicious code being run. The quad SPI expansion port allows execute-in-place operation, which without a security cryptographic engine would fully circumvent any built-in security. For the PSoC 62 and 63 this has been thought of and there are cryptographic accelerators to make sure execute-in-place does not impact the trusted environment or performance.

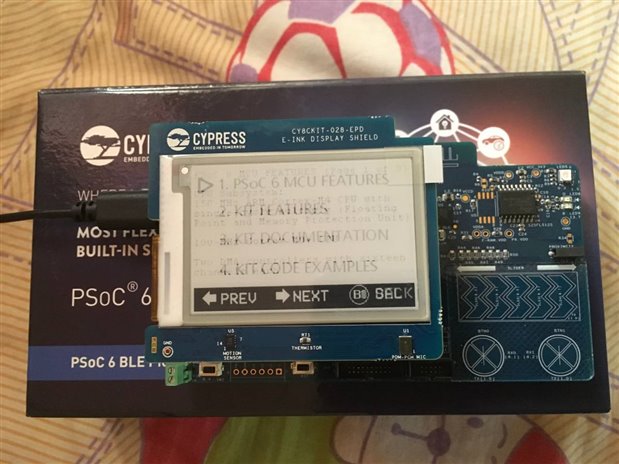

The PSoC BLE kit has both PMOD and Arduino shield connections to allow rapid prototyping and taking your Arduino project to the next level. If this is not enough just like the PSoC 4 kit (CY8CKIT-042-BLE), it comes with everything required to get started, including the equivalent of the kitchen sink — a Bluetooth dongle to ensure you can debug your device correctly. Your laptop may have Bluetooth, but it’s highly likely that it is not BLE capable and for this reason, Cypress provide a known working BLE device.

We have to be honest at this point and admit that our PSOC 4 kit has had less use than the supplied CY5677 CySmart BLE dongle, as it has proved to be a very handy debugging tool for any BLE device and not just Cypress devices!

All of this boils down to requiring a rock solid PD controller and the Cypress kit comes with a CYPD3126, part of the CCG3 family of Power Delivery ICs, which are fully featured (PD3 and even billboard support (AUX mode)). If it performs like the CCG2 we expect only good things.

If you read either the BLDC or recent tape punch article, you will know PSoC is not just any micro — it’s a FPGA/CPLD and analogue front-end to boot. PSoC6 has variants will all of the goodies PSoC 4 and 5 support, and the high-end devices, and as such are seriously powerful. For digital designs the UDB (internal FPGA) allowing significant component reduction. Need another timer or shift register, no problem!

Unlike previous PSoC examples, there are two “main” files: a main_cm4 and main_cm0p. These are the two cores the M4 and M0+. For the example we opened, all code was executing in the cm0p file, so the M4 was inactive. Another example of the power of the M0+ in its own right, the PSoC6 products are aimed at serious high demand applications where typical CPUs would struggle.

As usual, the example files are a great start for any project. With the dual processor architecture of PSoC 6 it’s quite possibly the only chip required for a full IoT solution: security, BLE, analogue or digital, it has it all. The CY8CKIT-62-BLE is one of the more fully featured kits to date and will be very useful in the future.

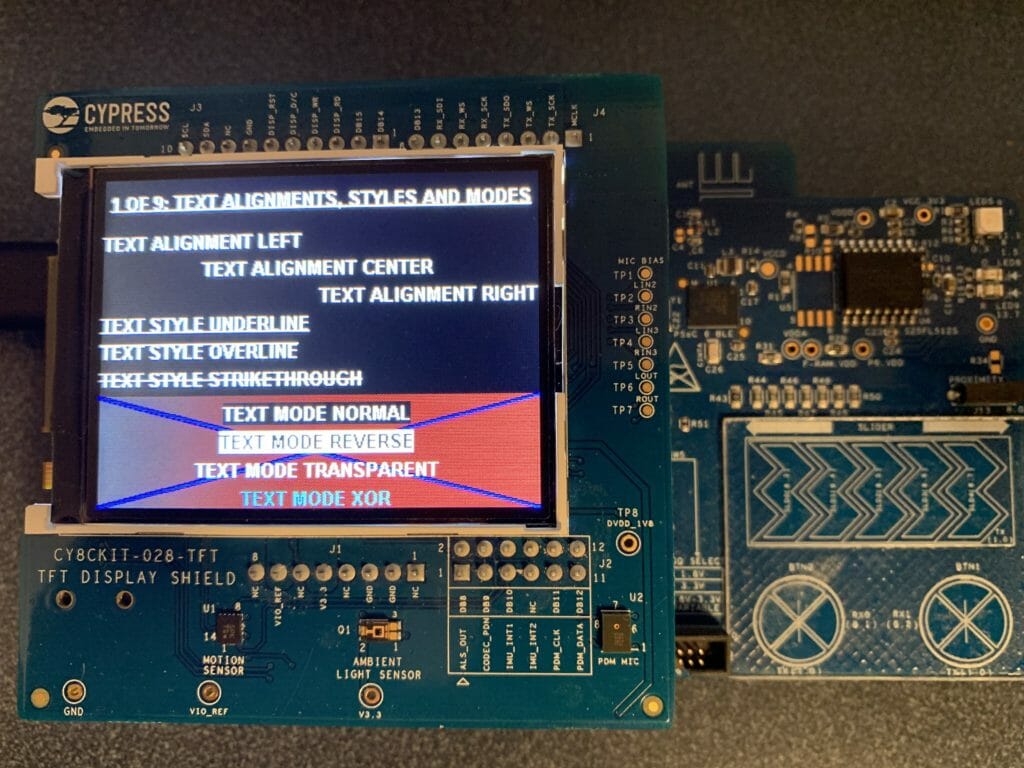

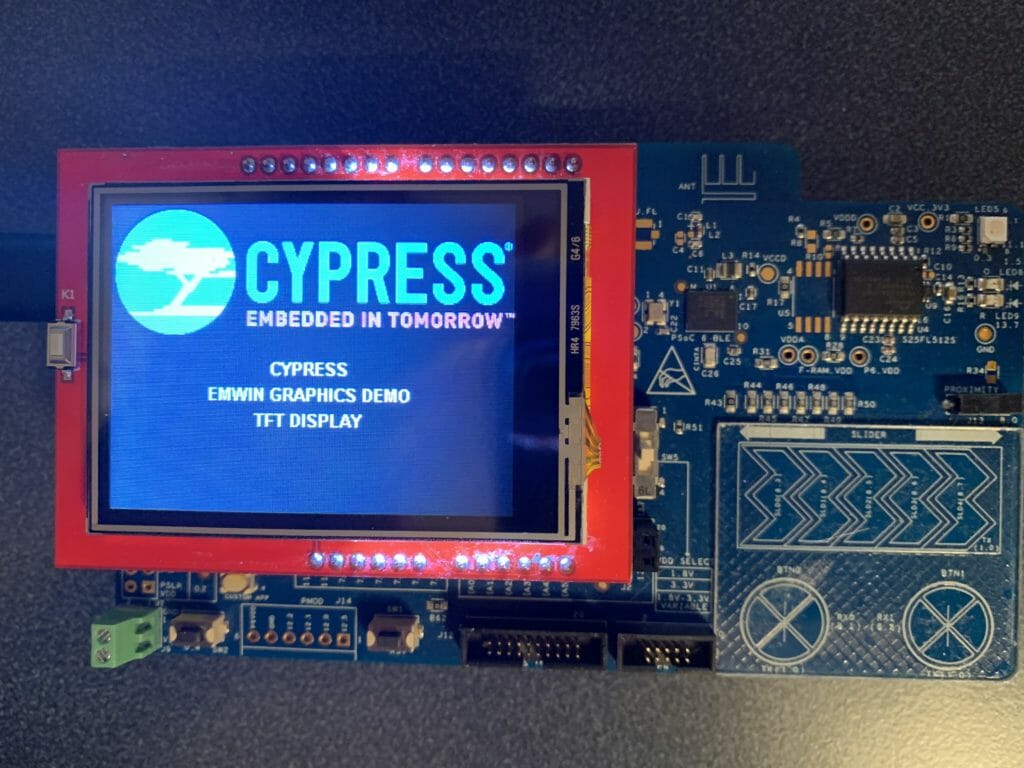

This example demonstrates displaying 2D graphics on a TFT display using the emWin graphics library and the AppWizard GUI design tool in FreeRTOS. The application initializes the system peripherals and creates a task that cycles through demo images in response to button presses.

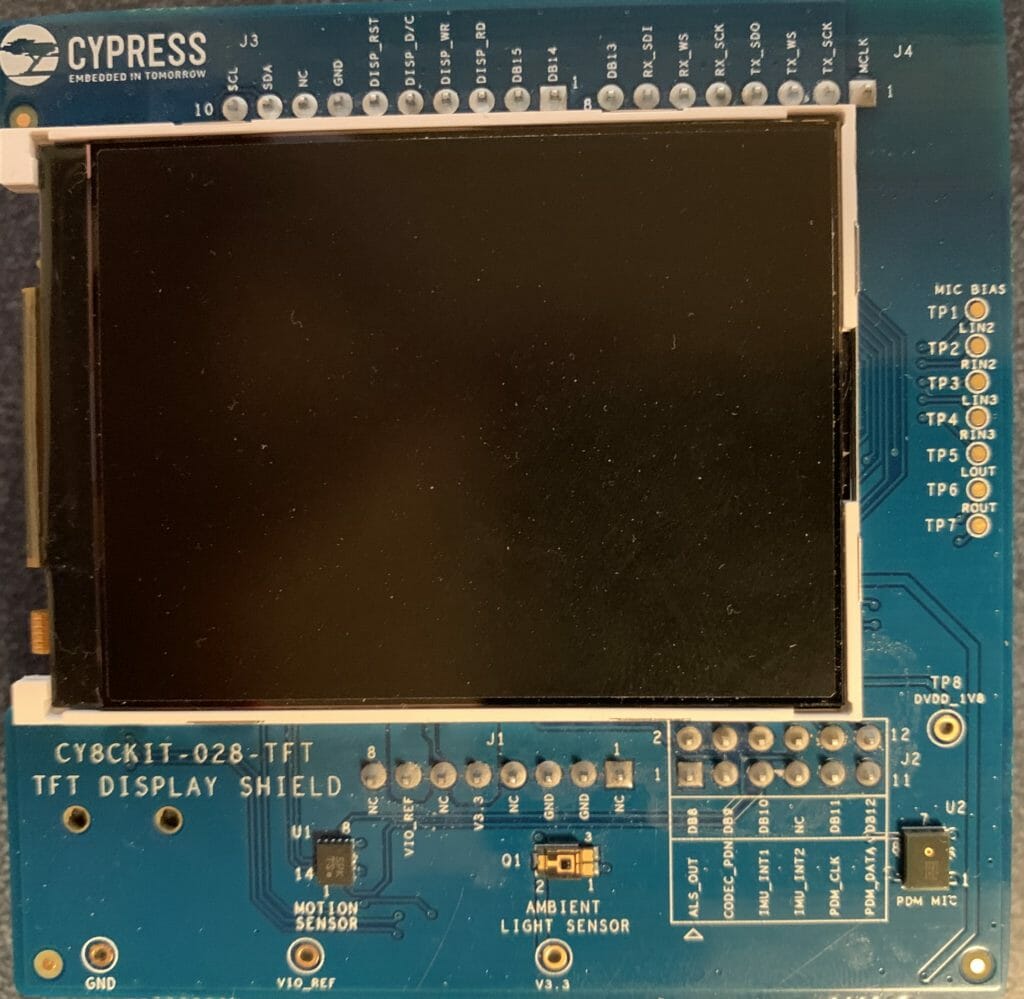

This code example requires CY8CKIT-028-TFT; TFT display shield board. This shield comes with PSoC™ 6 Wi-Fi Bluetooth® pioneer kit. It can also be purchased standalone and used with other supported kits.

Note: The PSoC™ 6 Bluetooth® LE pioneer kit (CY8CKIT-062-BLE) and the PSoC™ 6 Wi-Fi Bluetooth® pioneer kit (CY8CKIT-062-WIFI-BT) ship with KitProg2 installed. The ModusToolbox™ software requires KitProg3. Before using this code example, make sure that the board is upgraded to KitProg3. The tool and instructions are available in the Firmware Loader GitHub repository. If you do not upgrade, you will see an error like "unable to find CMSIS-DAP device" or "KitProg firmware is out of date".

The following example clones the "mtb-example-psoc6-emwin-tft-freertos" application with the desired name "EmwinTftFreeRtos" configured for the CY8CKIT-062-WIFI-BT BSP into the specified working directory, C:/mtb_projects:

project-creator-cli --board-id CY8CKIT-062-WIFI-BT --app-id mtb-example-psoc6-emwin-tft-freertos --user-app-name EmwinTftFreeRtos --target-dir "C:/mtb_projects"

If using a PSoC™ 64 "Secure" MCU kit (for example, CY8CKIT-064B0S2-4343W, CY8CKIT-064S0S2-4343W), the PSoC™ 64 device must be provisioned with keys and policies before being programmed. Follow the instructions in the "Secure Boot" SDK user guide to provision the device. If the kit is already provisioned, copy-paste the keys and policy folder to the application folder.

Observe the startup screen with the Infineon logo on the display. Follow the instructions that come on the screen after two seconds. Press the user switch to move between pages when the user LED is OFF.

This project uses a CY8CKIT-028-TFT; TFT display shield together with a pioneer board. The TFT shield has a Newhaven 2.4″ 320×240 TFT display with a Sitronix ST7789 display controller and uses the 8080-series parallel interface.

emWin middleware documentation on GitHub for understanding the structure of the emWin package, supported drivers, and a quick start guide to create and run your first emWin project from scratch. The documentation page also contains configuration details on a wide variety of display drivers provided by emWin.

AppWizard project: The GUI that is displayed on the screen is designed using the AppWizard software. The code example includes the corresponding AppWizard project.

Major update to support ModusToolbox™ v3.0. This version is not backward compatible with previous versions of ModusToolbox. Migrated the CE to use the latest emWin version V1.30_6.26d

Cypress, the Cypress logo, and combinations thereof, WICED, ModusToolbox, PSoC, CapSense, EZ-USB, F-RAM, and Traveo are trademarks or registered trademarks of Cypress or a subsidiary of Cypress in the United States or in other countries. For a more complete list of Cypress trademarks, visit cypress.com. Other names and brands may be claimed as property of their respective owners.

This is a quick video showing our new 1.3 inch TFT LCD. This is a small, full-color TFT. It"s controlled via 4-wire SPI. It has a ST7789H2 controller. This display runs off a single 3.3v supply which controls the logic and backlight.

Additional datasheets, footprints and schematics for CY8CKIT-028-TFT are listed on our Part Details page. You can also find images and similar parts to CY8CKIT-028-TFT on this page.

Distributor pricing and stock information is available for CY8CKIT-028-TFT on our Product Comparison page. Access via the "View Pricing & Stock" button to view CY8CKIT-028-TFT price breaks, MOQs, lead times, inventory and SKUs from distributors.

Submit any questions directly to the customer support team of the distributor listing the product. For the CY8CKIT-028-TFT you can contact the distributor directly for product support, shipping queries etc.

Authorised distributors including Chip One Stop, Farnell, element14, Newark Electronics and Avnet America have stock available or on a lead time for CY8CKIT-028-TFT.

You can fill out our help required form which you can use to request a quote for CY8CKIT-028-TFT from some of our verified obsolescence suppliers. Alternatively, contact us via our web chat in the bottom left of your screen and one of our team will try to help.

Along 3 years I have been trying several leg mechanism, at first I decided to do a simple desing with tibial motor where placed on femur joint.This design had several problems, like it wasn"t very robust and the most importat is that having the motor (with big mass) that far from the rotating axis, caused that in some movements it generate unwanted dynamics to the robot body, making controlability worse.New version have both motors of femur/tibial limb at coxa frame, this ends with a very simple setup and at the same time, the heaviest masses of the mechanism are centered to the rotating axis of coxa limb, so even though the leg do fast movements, inertias won"t be strong enough to affect the hole robot mass, achieving more agility.Inverse Kinematics of the mechanismAfter building it I notice that this mechanism was very special for another reason, at the domain the leg normally moves, it acts as a diferential mecanism, this means that torque is almost all the time shared between both motor of the longer limbs. That was an improvent since with the old mechanism tibial motor had to hold most of the weight and it was more forced than the one for femur.To visualize this, for the same movement, we can see how tibial motor must travel more arc of angel that the one on the new version.In order to solve this mechanism, just some trigonometry is needed. Combining both cosine and sine laws, we can obtain desired angle (the one between femur and tibia) with respect to the angle the motor must achieve.Observing these equations, with can notice that this angle (the one between femur and tibia) depends on both servos angles, which means both motors are contributing to the movement of the tibia.Calibration of servosAnother useful thing to do if we want to control servo precisely is to print a calibration tool for our set up. As shown in the image below, in order to know where real angles are located, angle protactor is placer just in the origin of the rotating joint, and choosing 2 know angles we can match PWM signal to the real angles we want to manipulate simply doing a lineal relation between angles and PWM pulse length.Then a simple program in the serial console can be wrtten to let the user move the motor to the desired angle. This way the calibration process is only about placing motor at certain position and everything is done and we won"t need to manually introduce random values that can be a very tedious task.With this I have achieved very good calibrations on motors, which cause the robot to be very simetrial making the hole system more predictable. Also the calibration procedure now is very easy to do, as all calculations are done automatically. Check Section 1 for the example code for calibration.More about this can be seen in the video below, where all the building process is shown as well as the new leg in action.SECTION 1:In the example code below, you can see how calibration protocol works, it is just a function called calibrationSecuence() which do all the work until calibration is finished. So you only need to call it one time to enter calibration loop, for example by sending a "c" character thought the serial console.Also some useful function are used, like moving motor directly with analogWrite functions which all the calculations involved, this is a good point since no interrupts are used.This code also have the feature to calibrate the potentiometer coming from each motor.#define MAX_PULSE 2500 #define MIN_PULSE 560 /*---------------SERVO PIN DEFINITION------------------------*/ int m1 = 6;//FR int m2 = 5; int m3 = 4; int m4 = 28;//FL int m5 = 29; int m6 = 36; int m7 = 3;//BR int m8 = 2; int m9 = 1; int m10 = 7;//BL int m11 = 24; int m12 = 25; int m13 = 0;//BODY /*----------------- CALIBRATION PARAMETERS OF EACH SERVO -----------------*/ double lowLim[13] = {50, 30, 30, 50, 30, 30, 50, 30, 30, 50, 30, 30, 70}; double highLim[13] = {130, 150, 150, 130, 150, 150, 130, 150, 150, 130, 150, 150, 110}; double a[13] = { -1.08333, -1.06667, -1.07778, //FR -1.03333, 0.97778, 1.01111, //FL 1.03333, 1.05556, 1.07778, //BR 1.07500, -1.07778, -1.00000, //BL 1.06250 }; double b[13] = {179.0, 192.0, 194.5, //FR 193.0, 5.5, -7.5, //FL 7.0, -17.0, -16.0, //BR -13.5, 191.5, 157.0, //BL -0.875 }; double ae[13] = {0.20292, 0.20317, 0.19904 , 0.21256, -0.22492, -0.21321, -0.21047, -0.20355, -0.20095, -0.20265, 0.19904, 0.20337, -0.20226 }; double be[13] = { -18.59717, -5.70512, -2.51697, -5.75856, 197.29411, 202.72169, 185.96931, 204.11902, 199.38663, 197.89534, -5.33768, -32.23424, 187.48058 }; /*--------Corresponding angles you want to meassure at in your system-----------*/ double x1[13] = {120, 135, 90, 60, 135 , 90, 120, 135, 90, 60, 135, 90, 110}; //this will be the first angle you will meassure double x2[13] = {60, 90, 135, 120, 90, 135, 60, 90, 135, 120, 90, 135, 70};//this will be the second angle you will meassure for calibration /*--------You can define a motor tag for each servo--------*/ String motorTag[13] = {"FR coxa", "FR femur", "FR tibia", "FL coxa", "FL femur", "FL tibia", "BR coxa", "BR femur", "BR tibia", "BL coxa", "BL femur", "BL tibia", "Body angle" }; double ang1[13] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; double ang2[13] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; float xi[500]; float yi[500]; float fineAngle; float fineL; float fineH; int motorPin; int motor = 0; float calibrationAngle; float res = 1.0; float ares = 0.5; float bres = 1.0; float cres = 4.0; float rawAngle; float orawAngle; char cm; char answer; bool interp = false; bool question = true; bool swing = false; int i; double eang; int freq = 100; // PWM frecuency can be choosen here. void connectServos() { analogWriteFrequency(m1, freq); //FR coxa digitalWrite(m1, LOW); pinMode(m1, OUTPUT); analogWriteFrequency(m2, freq); //femur digitalWrite(m2, LOW); pinMode(m2, OUTPUT); analogWriteFrequency(m3, freq); //tibia digitalWrite(m3, LOW); pinMode(m3, OUTPUT); analogWriteFrequency(m4, freq); //FL coxa digitalWrite(m4, LOW); pinMode(m4, OUTPUT); analogWriteFrequency(m5, freq); //femur digitalWrite(m5, LOW); pinMode(m5, OUTPUT); analogWriteFrequency(m6, freq); //tibia digitalWrite(m6, LOW); pinMode(m6, OUTPUT); analogWriteFrequency(m7, freq); //FR coxa digitalWrite(m7, LOW); pinMode(m7, OUTPUT); analogWriteFrequency(m8, freq); //femur digitalWrite(m8, LOW); pinMode(m8, OUTPUT); analogWriteFrequency(m9, freq); //tibia digitalWrite(m9, LOW); pinMode(m9, OUTPUT); analogWriteFrequency(m10, freq); //FR coxa digitalWrite(m10, LOW); pinMode(m10, OUTPUT); analogWriteFrequency(m11, freq); //femur digitalWrite(m11, LOW); pinMode(m11, OUTPUT); analogWriteFrequency(m12, freq); //tibia digitalWrite(m12, LOW); pinMode(m12, OUTPUT); analogWriteFrequency(m13, freq); //body digitalWrite(m13, LOW); pinMode(m13, OUTPUT); } void servoWrite(int pin , double angle) { float T = 1000000.0f / freq; float usec = float(MAX_PULSE - MIN_PULSE) * (angle / 180.0) + (float)MIN_PULSE; uint32_t duty = int(usec / T * 4096.0f); analogWrite(pin , duty); } double checkLimits(double angle , double lowLim , double highLim) { if ( angle >= highLim ) { angle = highLim; } if ( angle <= lowLim ) { angle = lowLim; } return angle; } int motorInfo(int i) { enc1 , enc2 , enc3 , enc4 , enc5 , enc6 , enc7 , enc8 , enc9 , enc10 , enc11 , enc12 , enc13 = readEncoders(); if (i == 0) { rawAngle = enc1; motorPin = m1; } else if (i == 1) { rawAngle = enc2; motorPin = m2; } else if (i == 2) { rawAngle = enc3; motorPin = m3; } else if (i == 3) { rawAngle = enc4; motorPin = m4; } else if (i == 4) { rawAngle = enc5; motorPin = m5; } else if (i == 5) { rawAngle = enc6; motorPin = m6; } else if (i == 6) { rawAngle = enc7; motorPin = m7; } else if (i == 7) { rawAngle = enc8; motorPin = m8; } else if (i == 8) { rawAngle = enc9; motorPin = m9; } else if (i == 9) { rawAngle = enc10; motorPin = m10; } else if (i == 10) { rawAngle = enc11; motorPin = m11; } else if (i == 11) { rawAngle = enc12; motorPin = m12; } else if (i == 12) { rawAngle = enc13; motorPin = m13; } return rawAngle , motorPin; } void moveServos(double angleBody , struct vector anglesServoFR , struct vector anglesServoFL , struct vector anglesServoBR , struct vector anglesServoBL) { //FR anglesServoFR.tetta = checkLimits(anglesServoFR.tetta , lowLim[0] , highLim[0]); fineAngle = a[0] * anglesServoFR.tetta + b[0]; servoWrite(m1 , fineAngle); anglesServoFR.alpha = checkLimits(anglesServoFR.alpha , lowLim[1] , highLim[1]); fineAngle = a[1] * anglesServoFR.alpha + b[1]; servoWrite(m2 , fineAngle); anglesServoFR.gamma = checkLimits(anglesServoFR.gamma , lowLim[2] , highLim[2]); fineAngle = a[2] * anglesServoFR.gamma + b[2]; servoWrite(m3 , fineAngle); //FL anglesServoFL.tetta = checkLimits(anglesServoFL.tetta , lowLim[3] , highLim[3]); fineAngle = a[3] * anglesServoFL.tetta + b[3]; servoWrite(m4 , fineAngle); anglesServoFL.alpha = checkLimits(anglesServoFL.alpha , lowLim[4] , highLim[4]); fineAngle = a[4] * anglesServoFL.alpha + b[4]; servoWrite(m5 , fineAngle); anglesServoFL.gamma = checkLimits(anglesServoFL.gamma , lowLim[5] , highLim[5]); fineAngle = a[5] * anglesServoFL.gamma + b[5]; servoWrite(m6 , fineAngle); //BR anglesServoBR.tetta = checkLimits(anglesServoBR.tetta , lowLim[6] , highLim[6]); fineAngle = a[6] * anglesServoBR.tetta + b[6]; servoWrite(m7 , fineAngle); anglesServoBR.alpha = checkLimits(anglesServoBR.alpha , lowLim[7] , highLim[7]); fineAngle = a[7] * anglesServoBR.alpha + b[7]; servoWrite(m8 , fineAngle); anglesServoBR.gamma = checkLimits(anglesServoBR.gamma , lowLim[8] , highLim[8]); fineAngle = a[8] * anglesServoBR.gamma + b[8]; servoWrite(m9 , fineAngle); //BL anglesServoBL.tetta = checkLimits(anglesServoBL.tetta , lowLim[9] , highLim[9]); fineAngle = a[9] * anglesServoBL.tetta + b[9]; servoWrite(m10 , fineAngle); anglesServoBL.alpha = checkLimits(anglesServoBL.alpha , lowLim[10] , highLim[10]); fineAngle = a[10] * anglesServoBL.alpha + b[10]; servoWrite(m11 , fineAngle); anglesServoBL.gamma = checkLimits(anglesServoBL.gamma , lowLim[11] , highLim[11]); fineAngle = a[11] * anglesServoBL.gamma + b[11]; servoWrite(m12 , fineAngle); //BODY angleBody = checkLimits(angleBody , lowLim[12] , highLim[12]); fineAngle = a[12] * angleBody + b[12]; servoWrite(m13 , fineAngle); } double readEncoderAngles() { enc1 , enc2 , enc3 , enc4 , enc5 , enc6 , enc7 , enc8 , enc9 , enc10 , enc11 , enc12 , enc13 = readEncoders(); eang1 = ae[0] * enc1 + be[0]; eang2 = ae[1] * enc2 + be[1]; eang3 = ae[2] * enc3 + be[2]; eang4 = ae[3] * enc4 + be[3]; eang5 = ae[4] * enc5 + be[4]; eang6 = ae[5] * enc6 + be[5]; eang7 = ae[6] * enc7 + be[6]; eang8 = ae[7] * enc8 + be[7]; eang9 = ae[8] * enc9 + be[8]; eang10 = ae[9] * enc10 + be[9]; eang11 = ae[10] * enc11 + be[10]; eang12 = ae[11] * enc12 + be[11]; eang13 = ae[12] * enc13 + be[12]; return eang1 , eang2 , eang3 , eang4 , eang5 , eang6 , eang7 , eang8 , eang9 , eang10 , eang11 , eang12 , eang13; } void calibrationSecuence( ) { //set servos at their middle position at firstt for (int i = 0; i <= 12; i++) { rawAngle , motorPin = motorInfo(i); servoWrite(motorPin , 90); } // sensorOffset0 = calibrateContacts(); Serial.println(" "); Serial.println("_________________________________SERVO CALIBRATION ROUTINE_________________________________"); Serial.println("___________________________________________________________________________________________"); Serial.println("(*) Don"t send several caracter at the same time."); delay(500); Serial.println(" "); Serial.println("Keyboard: "x"-> EXIT CALIBRATION. "c"-> ENTER CALIBRATION."); Serial.println(" "i"-> PRINT INFORMATION. "); Serial.println(" "); Serial.println(" "n"-> CHANGE MOTOR (+). "b" -> CHANGE MOTOR (-)."); Serial.println(" "m"-> START CALIBRATION."); Serial.println(" "q"-> STOP CALIBRATION."); Serial.println(" "); Serial.println(" "r"-> CHANGE RESOLUTION."); Serial.println(" "p"-> ADD ANGLE. "o"-> SUBTRACT ANGLE. "); Serial.println(" "s"-> SAVE ANGLE."); delay(500); Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); while (CAL == true) { if (Serial.available() > 0) { cm = Serial.read(); if (cm == "x") { Serial.println("Closing CALIBRATION program..."); CAL = false; secuence = false; startDisplay(PAGE); angleBody = 90; anglesIKFR.tetta = 0.0; anglesIKFR.alpha = -45.0; anglesIKFR.gamma = 90.0; anglesIKFL.tetta = 0.0; anglesIKFL.alpha = -45.0; anglesIKFL.gamma = 90.0; anglesIKBR.tetta = 0.0; anglesIKBR.alpha = 45.0; anglesIKBR.gamma = -90.0; anglesIKBL.tetta = 0.0; anglesIKBL.alpha = 45.0; anglesIKBL.gamma = -90.0; } else if (cm == "i") { // + Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println("(*) Don"t send several caracter at the same time."); delay(500); Serial.println(" "); Serial.println("Keyboard: "x"-> EXIT CALIBRATION. "c"-> ENTER CALIBRATION."); Serial.println(" "i"-> PRINT INFORMATION. "); Serial.println(" "); Serial.println(" "n"-> CHANGE MOTOR (+). "b" -> CHANGE MOTOR (-)."); Serial.println(" "m"-> START CALIBRATION."); Serial.println(" "q"-> STOP CALIBRATION."); Serial.println(" "); Serial.println(" "r"-> CHANGE RESOLUTION."); Serial.println(" "p"-> ADD ANGLE. "o"-> SUBTRACT ANGLE. "s"-> SAVE ANGLE."); Serial.println(" "); delay(500); Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println(" "); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); Serial.println("Actual parameters of the motor: "); Serial.print("High limit: "); Serial.print(highLim[motor]); Serial.print(" Low limit: "); Serial.print(lowLim[motor]); Serial.print(" Angle 1: "); Serial.print(ang1[motor]); Serial.print(" Angle 2: "); Serial.println(ang2[motor]); Serial.println("---------------------------------------------------------------------------------------------------"); } else if (cm == "m") { // + secuence = true; } else if (cm == "s") { // + } else if (cm == "n") { // + motor++; if (motor >= 13) { motor = 0; } Serial.print("SELECTED MOTOR: "); Serial.println(motorTag[motor]); } else if (cm == "b") { // + motor--; if (motor < 0) { motor = 13 - 1; } Serial.print("SELECTED MOTOR: "); Serial.println(motorTag[motor]); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } } if (secuence == true) { Serial.print("Starting secuence for motor: "); Serial.println(motorTag[motor]); for (int i = 0; i <= 30; i++) { delay(20); Serial.print("."); } Serial.println("."); while (question == true) { unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 100000) { previousMicros = currentMicros; if (Serial.available() > 0) { answer = Serial.read(); if (answer == "y") { question = false; interp = true; secuence = true; } else if (answer == "n") { question = false; interp = false; secuence = true; } else { Serial.println("Please, select Yes(y) or No(n)."); } } } } answer = "t"; question = true; if (interp == false) { Serial.println("___"); Serial.println(" | Place motor at 1ts position and save angle"); Serial.println(" | This position can be the higher one"); rawAngle , motorPin = motorInfo(motor); calibrationAngle = 90; //start calibration at aproximate middle position of the servo. while (secuence == true) { /* find first calibration angle */ if (Serial.available() > 0) { cm = Serial.read(); if (cm == "p") { // + Serial.print(" | +"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle + res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "o") { // - Serial.print(" | -"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle - res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } else if (cm == "q") { // quit secuence secuence = false; Serial.println(" | Calibration interrupted!!"); } else if (cm == "s") { // save angle ang1[motor] = calibrationAngle; secuence = false; Serial.print(" | Angle saved at "); Serial.println(calibrationAngle); } } } if (cm == "q") { Serial.println(" |"); } else { secuence = true; Serial.println("___"); Serial.println(" | Place motor at 2nd position and save angle"); Serial.println(" | This position can be the lower one"); } while (secuence == true) { /* find second calibration angle */ if (Serial.available() > 0) { cm = Serial.read(); if (cm == "p") { // + Serial.print(" | +"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle + res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "o") { // - Serial.print(" | -"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle - res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } else if (cm == "q") { // quit secuence secuence = false; Serial.println(" | Calibration interrupted!!"); } else if (cm == "s") { // save angle ang2[motor] = calibrationAngle; secuence = false; Serial.print(" | Angle saved at "); Serial.println(calibrationAngle); } } } /*--------------------start calibration calculations------------------*/ if (cm == "q") { Serial.println("___|"); Serial.println("Calibration finished unespected."); Serial.println(" Select another motor."); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); } else { Serial.println("___"); Serial.println(" |___"); Serial.print( " | | Interpolating for motor: "); Serial.println(motorTag[motor]); secuence = true; //real angle is calculated interpolating both angles to a linear relation. a[motor] = (ang2[motor] - ang1[motor]) / (x2[motor] - x1[motor]); b[motor] = ang1[motor] - x1[motor] * (ang2[motor] - ang1[motor]) / (x2[motor] - x1[motor]); Serial.println(" | |"); } interp = true; } /*---------------------------make swing movement to interpolate motor encoder-----*/ if (interp == true and secuence == true) { delay(200); double x; int k = 0; int stp = 180; swing = true; i = 0; orawAngle , motorPin = motorInfo(motor); previousMicros = 0; while (swing == true) { // FIRST unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor] + float(i) * (x1[motor] - x2[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // SECOND unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor] + float(i) * (x2[motor] - x1[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // FIRST unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor] + float(i) * (x1[motor] - x2[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // SECOND unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } Serial.println(" | | Interpolation finished!"); /*-------Calculate linear interpolation of the encoder from 60 meassures done in swing------*/ double sx = 0; double sy = 0; double sx2 = 0; double sy2 = 0; double sxy = 0; double xmean = 0; double ymean = 0; int n = 300; for (int i = 0 ; i < n ; i++) { sx += xi[i+10]; sy += yi[i+10]; sx2 += xi[i+10] * xi[i+10]; sy2 += yi[i+10] * yi[i+10]; sxy += xi[i+10] * yi[i+10]; } ae[motor] = (n * sxy - sx * sy) / (n * sx2 - sx * sx); //sxy / sx2; // be[motor] = (sy - ae[motor] * sx) / n; //ymean - ae[motor] * xmean; Serial.println(" | | Moving back to ZERO position."); // turn the motor back to middle position swing = true; i = 0; while (swing == true) { unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor] + float(i) * (90 - x1[motor]) / 60; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); eang = ae[motor] * rawAngle + be[motor]; if ((i % 4) == 0) { Serial.print(" | | Servo ang: "); Serial.print(calibrationAngle); Serial.print(" -> Real ang: "); Serial.print(x); Serial.print(" -> Encoder ang: "); Serial.println(eang); } if (i >= 60) { swing = false; } i++; } } Serial.println("___|___|"); Serial.println(" | "); Serial.println("___"); Serial.println(" | Calibration finished satisfactory. Results data:"); Serial.print(" | HIGH lim: "); Serial.print(highLim[motor]); Serial.print(" LOW lim: "); Serial.println(lowLim[motor]); Serial.print(" | angle 1: "); Serial.print(ang1[motor]); Serial.print(" angle 2 "); Serial.println(ang2[motor]); Serial.print(" | Regression Motor a: "); Serial.print(a[motor], 5); Serial.print(" b: "); Serial.println(b[motor], 5); Serial.print(" | Regression Encoder a: "); Serial.print(ae[motor], 5); Serial.print(" b: "); Serial.println(be[motor], 5); Serial.println(" |"); Serial.println(" | ______________________________________________________________"); Serial.println(" | | |"); Serial.println(" | | This code won"t be able to save the updated parameters |"); Serial.println(" | | once the robot is shutted down. |"); Serial.println(" | | |"); Serial.println(" | | Please, write down the results |"); Serial.println(" | | and save them in the definition of each variable. |"); Serial.println(" | |_____________________________________________________________|"); Serial.println(" |"); Serial.println("___|"); Serial.println(" Select another motor."); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); } interp = false; secuence = false; } } SAFE = false; Serial.println("Calibration killed"); } // END OF CALIBRATION

Pay once and never worry about it again. Once you buy Visual TFT you are entitled to a lifetime of free upgrades. Upgrading the software takes only a few minutes and a few clicks. We are constantly adding new features, and you can keep track of what is happening on the Software Roadmap page.

The Visual TFT currently supports 17 graphics controllers from leading manufacturers. You can be a part of the process by letting us know what graphics controllers you wish to see supported next, by using our helpdesk and submitting a ticket.

Visual TFT supports a total of 17 TFT controllers and many different display sizes, from 131x131 to 800x600 pixels. The most popular ones are the 320x240 TFT displays running on ILI9341controller. This display is found in many embedded devices worldwide. All MikroElektronika multimedia boards have this display integrated, so you’ll have all the hardware you need to get started. You can also order TFT displays separately from MikroElektronika’s online store.

Visual TFT also supports FTDI chip™ - the latest EVE GUI Platform and FT8x and FT81x families of graphics controllers. These powerful devices allow for sophisticated forms of human-machine interaction and more satisfying user experiences, including video playback. EVE integrates display, audio and touch onto a low cost, easy-to-use, single-chip solution. The EVE family has an object-based structure (where objects can be images, fonts, etc). This offers you an easy way to design more effective GUIs for TFTs, with all the display, audio and touch functionality included. Visual TFT is the first software in the world to provide full support for many of EVE’s powerful features like sound, transparency and anti-aliasing fonts. There are many new components available for GUI design, which are natively supported in the controller itself.

Visual TFT supports all our development and multimedia boards, so you will find all the hardware you could possibly need in one place. Each board has a hardware pattern, a configuration template with hardware connections for TFT and touch screen, and you can do all necessary settings with a single click.

Three major compiler groups are currently supported: mikroC, mikroBasic and mikroPascal for PIC, dsPIC, PIC32, AVR, ARM and FT90x. This means that no matter what compiler you will write your project in, source code generated by Visual TFT Tool will be integrated smoothly.

The Visual TFT Interface is really easy to use, and implements standard intuitive behavior, so you will feel like using any other vector graphic editors. But we have mixed functionalities from both worlds: world of design and world of programming. There are several palettes of most useful components that you can use in your application. Just drag a component onto a pixel grid display screen and it will be drawn instantly. Use Object Inspector to edit component properties and to assign desired events.

Do you need more space for your images and fonts? Do you want to create image slideshows, or to even play a video from MMC/SD Card? With new Resource file feature, Visual TFT software brings you all this and much more. If this option is selected, after code generation, Visual TFT will store all of your images and fonts in the resource file and will optimize them as much as possible for faster utilization. You just have to copy that file onto your MMC/SD card and you are ready to go.

The help file is the best place to start if you want to get to know the Visual TFT software. The easy-to-read format and detailed explanations of every functionality and feature will make you an expert in no time.

This is a Development Board, Display Shield for PSoC6 Development Kits, 2.4" TFT product from CYPRESS SEMICONDUCTOR with the model number CY8CKIT-028-TFT

Wir arbeiten mit Google im Rahmen des Programms „Google Kundenrezensionen“ zusammen. Dieses Programm gibt uns die Möglichkeit, Kundenrezensionen von Nutzern unserer Website einzuholen. Hierbei werden Sie nach einem Einkauf auf unserer Website gefragt, ob Sie an einer E-Mail-Umfrage von Google teilnehmen möchten. Wenn Sie Ihre Einwilligung gemäß Art. 6 Abs. 1 lit. a DSGVO erteilen, übermitteln wir Ihre E-Mail-Adresse an Google. Sie erhalten eine E-Mail von Google Kundenrezensionen, in der Sie gebeten werden, die Kauferfahrung auf unserer Website zu bewerten. Die von Ihnen abgegebene Bewertung wird anschließend mit unseren anderen Bewertungen zusammengefasst und in unserem Logo Google Kundenrezensionen sowie in unserem Merchant Center-Dashboard angezeigt. Außerdem wird Ihre Bewertung für Google Verkäuferbewertungen genutzt. Im Rahmen der Nutzung von Google Kundenrezensionen kann es auch zu einer Übermittlung von personenbezogenen Daten an die Server der Google LLC. in den USA kommen. Sie können Ihre Einwilligung jederzeit durch eine Nachricht an den für die Datenverarbeitung Verantwortlichen oder gegenüber Google widerrufen. Für den Fall der Übermittlung von personenbezogenen Daten an die Google LLC. mit Sitz in den USA, hat sich Google LLC. für das us-europäische Datenschutzübereinkommen „Privacy Shield“ zertifiziert, welches die Einhaltung des in der EU geltenden Datenschutzniveaus gewährleistet. Ein aktuelles Zertifikat kann hier eingesehen werden: https://www.privacyshield.gov/list

"DPI" (Display Pixel Interface) meaning that you need to continuously refresh the display, and provide synch signals and clock; the advantage is the complete control on the image and fast updates, the disadvantage is the memory occupied by a frame buffer and the need for refresh

"DBI" (Display Bus Interface) an MCU bus interface, one writes command and data and the refresh is taken care of by the controller, no frame buffer needed, simpler handling (no strict timings) but slower updates

A display driver supports a particular family of display controllers. The drivers can be configured by modifying their configuration files whereas the driver itself does not need to be modified. The configuration files contain all required information for the driver including how the hardware is accessed and how the controller(s) are connected to the display.

Direct accessible frame buffer means the frame buffer is accessible directly via data- and address bus. For that case the driver GUIDRV_Lin could be used. This driver supports all display controllers with linear video memory accessible via direct interface. The driver does only manage the content of the video memory. It is independent of the register interface of the display controller and can be used for managing each linear mapped video memory.

Whereas the direct interface accesses the video memory directly by the address bus of the CPU, the indirect interface requires a more complex communication with the display controller to get access to the video memory. On LCD controller side that interface is often called "MPU" interface. It normally consists of a set of control- and data lines. on emWin side this requires a few simple communication routines. These are getting called for writing and reading operations to/from the LCD controller.

The following table lists the currently available run-time configurable drivers developed for the current interface of emWin:Display driverSupported display controllers / PurposeSupported bits/pixelGUIDRV_BitPlainsThis driver can be used for solutions without display controller. It manages separate bitplains for each color bit. Initially it has been developed to support a solution for an R32C/111 which drives a TFT display without display controller. It can be used for each solution which requires the color bits in separate plains.1 - 8

GUIDRV_LinThis driver supports every display controller with linear addressable video memory with a direct (full bus) interface. This means that the video RAM is directly addressable by the address lines of the CPU. The driver contains no controller specific code. So it can also be used for solutions without display controller which require a driver which only manages the video RAM.1, 2, 4, 8, 16, 24, 32

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey