thin-film transistor tft display manufacturer

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

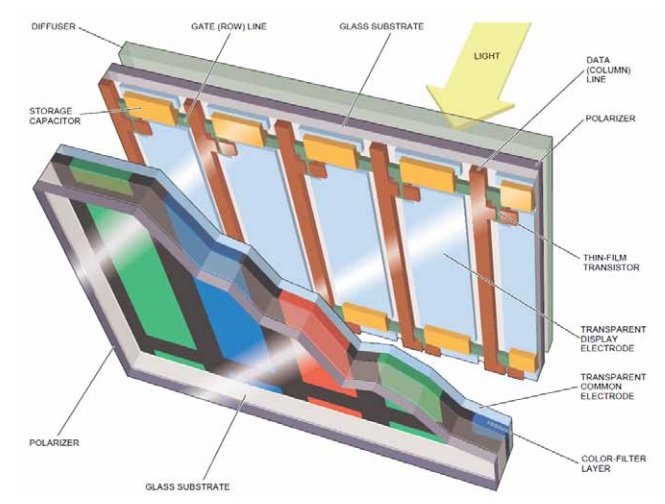

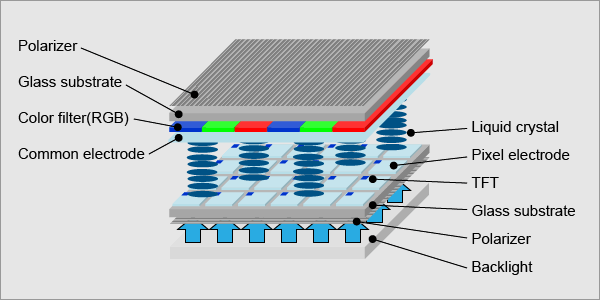

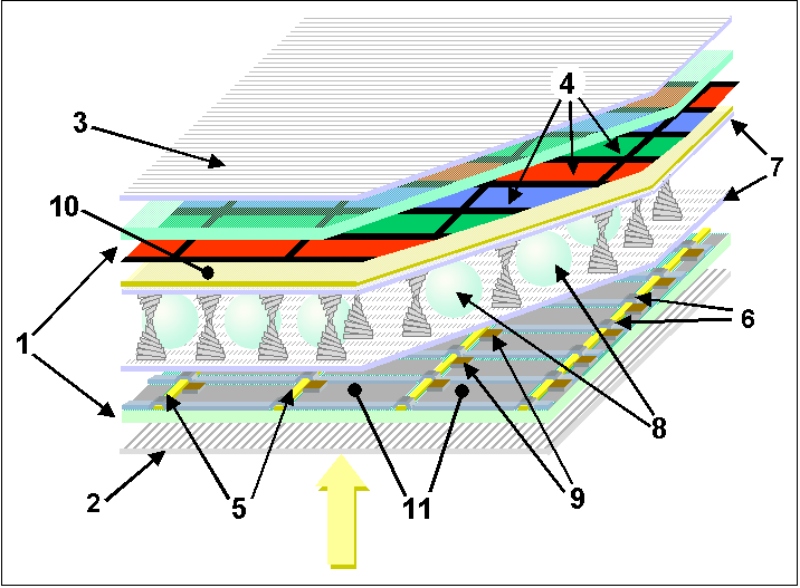

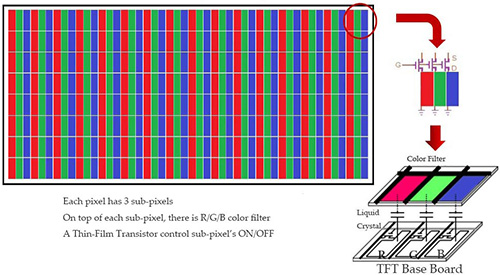

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

1971 – Lechner, F. J. Marlowe, E. O. Nester, and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs

2020 – TFT LCD display technology dominants the display market now. Within the last 20 years, it has wiped out the market of CRT (cathode-ray tube) and Plasma. The only challenges are OLED (organic light-emitting diode)and Micro LED (Maybe, still in lab).

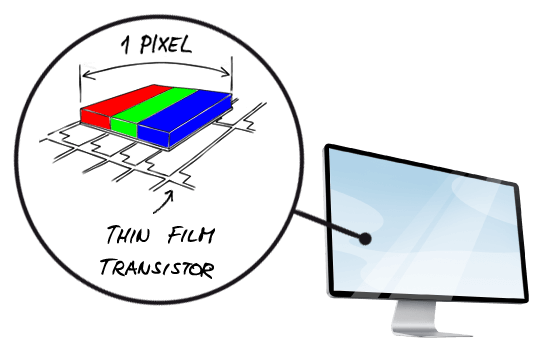

TFT LCD Display (Thin-Film-Transistor Liquid Crystal Display) technology has a sandwich-like structure with liquid crystal material filled between two glass plates. Two polarizer filters, color filters (RGB, red/green/blue) and two alignment layers determine exactly the amount of light is allowed to pass and which colors are created.

Each pixel in an active matrix is paired with a transistor that includes a capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. The TFT layer controls light flow a color filter displays the color and a top layer houses your visible screen.

Utilizing an electrical charge that causes the liquid crystal material to change their molecular structure allowing various wavelengths of backlight to “pass-through”. The active matrix of the TFT display is in constant flux and changes or refreshes rapidly depending upon the incoming signal from the control device.

The pixels of TFT displays are determined by the underlying density (resolution) of the color matrix and TFT layout. The more pixels the higher detail is available.Available screen size, power consumption, resolution, interface (how to connect) define the TFT displays.

The pixels of TFT displays are determined by the underlying density (resolution) of the color matrix and TFT layout. The more pixels the higher detail is available. Available screen size, power consumption, resolution, interface (how to connect) define the TFT displays.

The TFT screen itself can’t emit light like OLED display, it has to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light emitting diodes) to generate their light and therefore utilize less power and require less depth by design.

Orient Display sunlight readable TFT displays can be categorized into high brightness TFT displays, high contrast IPS displays, transflective TFT displays, Blanview TFT displays etc.

The brightness of our standard high brightness TFT displays can be from 700 to 1000 nits. With proper adding brightness enhancement film (BEF) and double brightness enhancement film (DBEF) and adjustment of the LED chips, Orient Display high brightness TFT products can achieve 1,500 to 2,000 nits or even higher luminance. Orient Display have special thermal management design to reduce the heat release and largely extend LED life time and reduce energy consumption.

Our high contrast and wide viewing angle IPS displays can achieve contrast ratio higher than 1000:1 which can make readability under strong sunlight with lower backlight luminance. High brightness IPS displays have been widely accepted by our customers with its superb display quality and it has become one of the best sellers in all our display category.Transflective display is an old monochrome display technology but it has been utilized in our color TFT line for sunlight readable application. Orient Display has 2.4” and 3.5” to choose from.

Blanview TFT displays are the new technology developed by Ortustech in Japan. It can provide around 40% of energy consumption for TFT panels which can use smaller rechargeable or disposable batteries and generate less heat. The price is also lower than traditional transflective TFT displays. Orient Display is partnering with the technology inventor to provide 4.3” and 5.0”.

Orient Display can also provide full customized or part customized solutions for our customers to enhance the viewing experience. Orient Display can provide all the different kinds of surface treatments, such as AR (Anti-reflection); AG (Anti-glare), AF (Anti-finger print or Anti-smudge); AS (Anti-smashing); AM (Anti-microbial) etc. Orient Display can also provide both dry bonding (OCA, Optical Clear Adhesive), or wet bonding (OCR, Optical Clear Resin and OCG, Optical Clear Glue) to get rid of light reflective in air bonding products to make the products much more readable under sunlight and be more robust.

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch.

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

Engineers are always looking for lower cost, faster, more convenient interfaces to transmit signals and to accept data and commands. The numbers of available interfaces available in the market can be dazzling. Orient Display follows market trends to produce various kind of interfaces for our customers to choose.

Genetic Interfaces: Those are the interfaces which display or touch controller manufacturers provide, including parallel, MCU, SPI(,Serial Peripheral Interface), I2C, RGB (Red Green Blue), MIPI (Mobile Industry Processor Interface), LVDS (Low-Voltage Differential Signaling), eDP ( Embedded DisplayPort) etc. Orient Display has technologies to make the above interface exchangeable.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

Manufacturer of standard & custom touch screen displays & thin film transistor touchscreen monitors. Features include 17 in. to 23 in. LCD, rugged steel & aluminum construction, optional resistive or capacitive touch-screens, light textured powder coated black color, contrast filters, transmissive daylight modification, hard coated vandal shields, 16.7 million display colors, anti-glare hard coating, analog RGB input, weight ranging 13 lbs to 24 lbs & 1280 x 1024 SXGA or 1600 x 1200 UXGA resolution. Applications include use for rack, wall, panel or kiosk installations in commercial, military & broadcast industries. One year limited warranty. RoHS compliant. Meet NEMA & Military Spec.

Winstar Display offers a series of medium size O-Film TFT (Thin Film Transistor) displays featuring with wider viewing angle Technology. Most industrial application of TFT-LCD glasses that are available in the market are TN-LCD type. However, TN technology suffers from phenomenon called gray scale inversion. This means the display have one viewing side in which color of the image change suddenly after exceeding specified view angle. Therefore, the normal TFT models we offer which the viewing angle are limited. Winstar offers an O-Film TFT solution to enhance TN glass viewing angle and can overcome gray scale inversion.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

A TFT display is a form of Liquid Crystal Display with thin film transistors for controlling the image formation. The technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen.The liquid-crystal behaviour is similar to that of a TN display, relying on 90-degree twisted stacks acting as a waveguide to control the passage of light through the display.

ITO electrodes are deposited on the upper and lower glass substrates, and red, green and blue colour filters are deposited on the inner surface of the upper substrate. A thin-film transistor is embedded in every sub-pixel, and connected to the data bus line.

This enables the display drive system to address every sub-pixel individually. By controlling the intensity of light transmitted through each colour filter, the TFT-LCD can display millions of colours. A storage capacitor is also embedded in each pixel to maintain an applied voltage across the cell during pixel updating.

When a signal is applied to the pixel, the liquid crystal changes from its twisted state to align with the electric field and prevent light passing through – much the same as in a TN display. The TFT-LCD is able to switch rapidly between ON and OFF states, allowing response times fast enough to support rapid display-update rates suitable for presenting video content or smooth animation.

Global Thin Film Transistor (TFT) Display Market, By Technology (Plasma Display (PDP), Organic Light Emitting Diode (OLED), Other), Type (Twisted Nematic, In-Plane Switching, Advanced Fringe Field Switching, Multi-Domain Vertical Alignment, Advanced Super View, Cell Technology), Panel Type (A_MVA, ASV, MVA, S_PVA, P-IPS), End Use (Domestic Use, Industrial Use) – Industry Trends and Forecast to 2029

Liquid crystal are considered highly light valves or electo-optic transducers. These thin film transistors are known to be simple electronic control devices widely fabricated on a large transparent substrates. They enable fabrication of electronic display.

Global Thin Film Transistor (TFT) Display Market was valued at USD 270.26 million in 2021 and is expected to reach USD 968.64 million by 2029, registering a CAGR of 17.30% during the forecast period of 2022-2029. Twisted Nematic accounts for the largest type segment in the respective market owing to its low cost. The market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis.

A thin-film-transistor display refers to a form of LCD that uses TFT technology for enhancing image quality including addressability and contrast. These displays are commonly utilized in mobile phones, handheld video game systems, projectors, computer monitors, television screens, navigation systems and personal digital assistants.

Technology (Plasma Display (PDP), Organic Light Emitting Diode (OLED), Other), Type (Twisted Nematic, In-Plane Switching, Advanced Fringe Field Switching, Multi-Domain Vertical Alignment, Advanced Super View, Cell Technology), Panel Type (A_MVA, ASV, MVA, S_PVA, P-IPS), End Use (Domestic Use, Industrial Use)

Panasonic Corporation (Japan), LG Display Co., Ltd (South Korea), HannStar Display Corporation (Taiwan), AU Optronics Corp. (Taiwan), Chi Mei Corporation. (Taiwan), SAMSUNG (South Korea), SHARP CORPORATION (Japan), Schneider Electric (France), Siemens (Germany), Mitsubishi Electric Corporation (Japan), SONY INDIA. (India), FUJITSU (Japan), Chunghwa Picture Tubes, LTD. (Taiwan), Barco.(Belgium), BOE Technology Group Co., Ltd. (China), Innolux Corporation (Taiwan), Advantech Co., Ltd (Taiwan), among others.

The increase in the smartphone and tablet proliferation acts as one of the major factors driving the growth of thin film transistor (TFT) display market. Technological advancements are leading a radical shift from traditional slow, bulky and imprecise resistive mono touch to highly sensitive multi-touch capacitive screen have a positive impact on the industry.

The rise in number of electronic readers and growing demand for on-the-move information accelerate the market growth. The development of easy-to-use display devices drives the growth of the market.

The increase in application areas of large e thin film transistor (TFT) display due to the advantages offered by these paper displays in terms of user experience, manufacturing cost, readability, and energy consumption further influence the market.

Additionally, rapid urbanization, change in lifestyle, surge in investments and increased consumer spending positively impact the thin film transistor (TFT) display market.

On the other hand, high cost associated with the manufacturing is expected to obstruct market growth. Also, lack of awareness and low refresh rate are projected to challenge the thin film transistor (TFT) display market in the forecast period of 2022-2029.

This thin film transistor (TFT) display market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on thin film transistor (TFT) display market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

The COVID-19 has impacted thin film transistor (TFT) display market. The limited investment costs and lack of employees hampered sales and production of electronic paper (e-paper) display technology. However, government and market key players adopted new safety measures for developing the practices. The advancements in the technology escalated the sales rate of the thin film transistor (TFT) display as it targeted the right audience. The increase in sales of devices such as smart phones and tablets across the globe is expected to further drive the market growth in the post-pandemic scenario.

The thin film transistor (TFT) display market is segmented on the basis of technology, type, panel type and end-use. The growth amongst these segments will help you analyze meager growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

The thin film transistor (TFT) display market is analysed and market size insights and trends are provided by country, technology, type, panel type and end-use as referenced above.

The countries covered in the thin film transistor (TFT) display market report are U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA).

North America dominates the thin film transistor (TFT) display market because of the introduction of advanced technology along with rising disposable income of the people within the region.

The thin film transistor (TFT) display market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies" focus related to thin film transistor (TFT) display market.

The thin film transistor-liquid crystal display (TFT-LCD) has been used all over the world. Although the manufacture process of TFT-LCD was highly automated, employees are hired to do manual job in module assembly process. The operators may have high risk of musculoskeletal disorders because of the long work hours and the repetitive activities in an unfitted work station. The tools of this study were questionnaire, checklist and to evaluate the work place design. The result shows that the participants reported high musculoskeletal disorder symptoms in shoulder (59.8%), neck (49.5%), wrist (39.5%), and upper back (30.6%). And, to reduce the ergonomic risk factors, revising the height of the work benches, chairs and redesigning the truck to decrease the chance of unsuitable positions were recommended and to reduce other ergonomics hazards and seta good human machine interface and appropriate job design.

The present invention relates to an active matrix organic light emitting diode (AMOLED) display, more particularly, to a method for manufacturing various thin film transistors (TFTs) used in AMOLED displays and an AMOLED display having such TFTs.

Organic light emitting diodes (OLEDs) have been widely utilized in displays. An AMOLED display uses a driving circuit to drive a light emitting element, i.e. an OLED. The AMOLED driving circuit uses TFTs, including a switch TFT and a driving TFT. The switch TFT, which is implemented by an N-type TFT (NTFT), is used for switching the ON/OFF state of a sub-pixel of the display. The driving TFT, which is implemented by a P-type TFT (PTFT), is used for driving the light emitting element (e.g. an OLED). In addition, a peripheral circuit of the AMOLED display also needs to use NTFT and PTFT. Conventionally, polycrystalline silicon (also referred to as poly-silicon) used in the TFTs of the AMOLED driving circuit and peripheral circuit is made by using a standard laser crystallization method to lead amorphous silicon growing on a glass substrate to crystallize into poly-silicon. Not like a silicon wafer used for manufacturing general transistors, the glass substrate suitable for a flat display cannot endure high temperatures, and therefore it is required to use a crystallization technique in which the temperature is lower than the melting temperature of glass substrate. Accordingly, the standard laser crystallization method is used. However, the standard laser crystallization technique has a problem. During triggering crystallization, output laser energy errors will result in a luminance non-uniform phenomenon called “mura” in the resultant display.

Further, the AMOLED driving TFT drives the OLED by an output current. The light emitting result is very sensitive to the variation in the driving current. A display area has a driving TFT matrix for a plurality of sub-pixels. If there are differences among the electrical properties of the respective driving TFTs, then light intensities of OLEDs in this area will have corresponding differences, resulting in visible distinction for human"s vision.

After being made into a display, standard laser technique, current driving and the like factors regarding the driving TFT may result in stripe mura, thereby causing the yield of AMOLED products to be low. The present invention is to solve such a problem.

An objective of the present invention is to provide an OLED display TFT manufacturing method for manufacturing N-type and P-type peripheral circuit TFTs for an OLED display peripheral circuit as well as a switch TFT and driving TFT used in a driving circuit of a display area. By using the method of the present invention, the manufactured peripheral TFT, switch TFT and driving TFT are respectively provided with different properties to meet the use requirements thereof. The peripheral circuit TFT and switch TFT have excellent electrical performance such as high carrier mobility. The driving TFT has good stability so that the resultant display can operate with good luminance uniformity.

Another objective of the present invention is to provide an OLED display, which comprises a peripheral circuit portion and a display area portion. The peripheral circuit portion uses peripheral circuit TFTs. The display area portion has a plurality of sub-pixels, each sub-pixel contains a light emitting element, a driving TFT for driving the light emitting element and a switch TFT for switching a state of the sub-pixel. The peripheral circuit TFTs, switch TFT and driving TFT are respectively provided with properties meeting the use requirements thereof. The peripheral circuit TFT and switch TFT have excellent electrical performance such as high carrier mobility. The driving TFT has good stability so that the resultant display can operate with good luminance uniformity.

In accordance with an aspect of the present invention, an OLED display TFT manufacturing method comprises steps of providing a substrate, the substrate having a first region and a second region; forming a buffer layer on the substrate; forming a first poly-silicon layer on the buffer layer by a first crystallization process; patterning the first poly-silicon layer to form active areas of first TFTs; forming a first insulating layer; forming a second poly-silicon layer on the first insulating layer by a second crystallization process different from the first second crystallization process; patterning the second poly-silicon layer to form an active area of a second TFT; forming a second insulating layer; and respectively forming gates of the first TFTs and second TFT on the second insulating layer.

In accordance with another aspect of the present invention, an OLED display includes a peripheral circuit portion and a display area portion. The display area portion has a plurality of sub-pixels. Each sub-pixel has a light emitting element, a driving TFT for driving the light emitting element and a switch TFT. The OLED display comprises a substrate, first TFTs formed on the substrate. Each first TFT has a first buffer layer formed on the substrate, an active area made by a first poly-silicon layer provided on the buffer layer, a first gate insulation layer covering the active area and a first gate provided on the first gate insulation layer. The OLED display further comprises a second TFT formed on the substrate. The second TFT has a second buffer layer formed on the substrate, an active area made by a second poly-silicon layer provided on the buffer layer, a second gate insulation layer covering the active area and a second gate provided on the second gate insulation layer. The first poly-silicon layer and the second poly-silicon layer have different grain properties. In addition, the first gate insulation layer and the second gate insulation layer have different thicknesses.

FIG. 3 to FIG. 12 are sectional schematic illustrations showing respective steps of an OLED display TFT manufacturing method in accordance with an embodiment of the present invention;

FIG. 15 is a schematic block diagram showing an electronic device including the OLED display in accordance with an embodiment of the present invention.

FIG. 1 is a schematic diagram showing a basic circuit structure of an AMOLED display 110. The OLED display 110 includes a control circuit 140, a data line driving circuit 160, a scan line driving circuit 180 and a display panel 200. The display panel 200 has a plurality of sub-pixels 210. Each sub-pixel 210 is connected with a data line (D1-Dn) 165 and a scan line (S1-Sn) 187 so as to form a matrix. The sub-pixel 210 receives an image data signal from the data line driving circuit 160 via the data line 165 and receives a switch/address signal from the scan line driving circuit 180 via the scan line 187. The data line driving circuit 160 and the scan line driving line circuit 180 are controlled by the control circuit 140.

The sub-pixel can be designed to contain several TFTs. Generally, each sub-pixel comprises at least a driving TFT for driving a light emitting element and a switch TFT for switching the state of the sub-pixel, as shown in FIG. 2. FIG. 2 schematically shows a basic circuit structure of the sub-pixel 210 in FIG. 1. The sub-pixel 210 has a light emitting element 212 such as an OLED, and a driving TFT 214, which is generally implemented by a PTFT, for driving the light emitting element 212. The sub-pixel 210 further has a switch TFT 216, which is generally implemented by an NTFT, and a capacitor 218. The switch TFT 216 has a gate thereof electrically coupled to the corresponding scan line 187, a drain thereof electrically coupled to the corresponding data line 165, and a source thereof connected with a terminal of the capacitor 218 and a gate of the driving TFT 214. The capacitor 218 has the other terminal thereof connected to a source of the driving TFT 214 and a voltage source Vdd. The driving TFT 214 is connected with the light emitting element 212. The operation of such a circuit is widely known in this field and is not the key point of the present invention, and therefore the description thereof is omitted herein.

According to the discussion above, the requirement of uniformity for the driving TFT of each sub-pixel in the display panel is very strict so as to avoid luminance mura occurring in the display area. The requirement of electrical performance is very high for the switch TFT for switching the sub-pixel state and the peripheral circuit TFTs. In other words, for an AMOLED display, the requirements for the driving TFT and switch TFT, peripheral circuit TFT are different. The present invention provides a technique so that TFTs meeting different requirements can be manufactured in the same process.

In an embodiment of the present invention, the N-type TFT and P-type TFT used in the OLED display peripheral circuit, the switch TFT, which is usually implemented by an NTFT and is used in the display area, and the driving TFT, which is usually implemented by a PTFT for driving the light emitting element in the display area are simultaneously manufactured in different regions of the same glass substrate. For the sake of description convenience, the NTFT, PTFT used in the peripheral circuit and the switch TFT used in the display area are generally called “non-driving TFTs”. According to the embodiment of the present invention, the non-driving TFT and the driving TFT are manufactured to have different properties which meet the different requirements. The non-driving TFT has excellent electrical performance, while the driving TFT is able to cause the resultant flat display to have good luminance uniformity.

The process of the AMOLED display TFT manufacturing method of the present invention is shown in FIG. 3 to FIG. 12. In each drawing, the left portion of a first region shows a process for an N-type non-driving TFT, and the right portion shows a process for a P-type non-driving TFT. A second region shows a process for the driving TFT.

With reference to FIG. 4, the first poly-silicon layer 30 is patterned and subject to n-doping and channel doping. In the NTFT portion, the remaining poly-silicon layer is used as an active area 36, which is further formed to have a drain 36 a, a channel 36 band a source 36 c. In the PTFT portion, the remaining poly-silicon layer is used as an active area 34. At this time, the active area 34 of the PTFT has not been doped. It is noted that the poly-silicon layer 30 in the second region is entirely removed by any suitable technique such as dry etching. Successively, a first insulating layer 40 is formed over the whole structure. According to various embodiments, the thickness of the first insulating layer 40 is as thin as possible. In practice, the thickness of the first insulation layer 40 is about 200 to 300 angstrom. In the present embodiment, the material of the first insulating layer 40 is oxide such as silicon oxide. According to various embodiments, the material of the first insulating layer 40 can be the same as that of the oxide layer 23 of the buffer layer.

The poly-silicon layer of the active area 52 in the second region is used in the driving TFT for driving the light emitting element, while the poly-silicon layers of the active areas 34, 36 in the first region are used in the non-driving NTFT and PTFT (e.g. peripheral circuit TFT and switch TFT). The former and latter are induced to crystallize by using different crystallization methods, that is, the first crystallization process and the second crystallization process. The first crystallization process can be the standard laser crystallization method such as ELA. The second crystallization process can be the non-laser crystallization method such as SPC or the low power (low temperature) laser crystallization method such as low power excimer laser crystallization method. The poly-silicon layers generated by using these two different crystallization processes appear significant difference in grain properties.

By using the poly-silicon layers made by the standard crystallization method to form the active areas of the peripheral circuit TFTs, excellent electric performance can be obtained. For example, the poly-silicon formed by the standard laser crystallization method has high carrier mobility such as 100 cm2/V·s or larger than 100 cm2/V·s. However, variation of carrier mobility for such poly-silicon is greater. That is, standard deviation of carrier mobility for such poly-silicon is high. The poly-silicon used in the driving TFT, for which the requirement of electric performance is not so critical, is formed by the non-laser crystallization method or low power laser crystallization method rather than the standard laser crystallization method so that the strip mura can be avoided after the display using the driving TFT is fabricated. The poly-silicon formed by the non-laser crystallization method or low power laser crystallization method has a lower carrier mobility, which is about 10-40 cm2/V·s. Accordingly, such poly-silicon is not suitable for being used to manufacture the peripheral circuit TFT and switch TFT. However, such carrier mobility is sufficient for the driving TFT for driving the OLED. The driving TFT using the latter poly-silicon has a low carrier mobility standard deviation, that is, the variation is less, the stability is higher. Therefore, the strip mura can be effectively reduced after the display using the driving TFT is fabricated.

FIG. 15 is a schematic block diagram showing an electronic device 600 including the OLED display 110 in accordance with an embodiment of the present invention. The OLED display 110, which has the driving TFT, switch TFT and peripheral circuit TFT as shown in FIG. 12, can be a part of the electronic device 600. The electric device 600 comprises the OLED display 110 and a power supply 700. The power supply 700 is coupled to the OLED display 110 to power the OLED display 110, so that the OLED display can generate images. The electronic device 600 can be a mobile phone, digital camera, PDA, notebook, desk-top computer, television set, satellite navigation device, vehicle display or portable DVD player.

Get rich colors, detailed images, and bright graphics from an LCD with a TFT screen. Our standard Displaytech TFT screens start at 1” through 7” in diagonal size and have a variety of display resolutions to select from. Displaytech TFT displays meet the needs for products within industrial, medical, and consumer applications.

TFT displays are LCD modules with thin-film transistor technology. The TFT display technology offers full color RGB showcasing a range of colors and hues. These liquid crystal display panels are available with touchscreen capabilities, wide viewing angles, and bright luminance for high contrast.

Our TFT displays have LVDS, RGB, SPI, and MCU interfaces. All Displaytech TFT LCD modules include an LED backlight, FPC, driver ICs, and the LCD panel.

We offer resistive and capacitive touch screens for our 2.8” and larger TFT modules. Our TFT panels have a wide operating temperature range to suit a variety of environments. All Displaytech LCDs are RoHS compliant.

We also offer semi-customization to our standard TFT screens. This is a cost-optimized solution to make a standard product better suit your application’s needs compared to selecting a fully custom TFT LCD. Customizations can focus on cover glass, mounting / enclosures, and more - contact us to discuss your semi-custom TFT solution.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey