lcd panel banding supplier

Try using lcd banding machine for iphone found on Alibaba.com to make many types of production jobs faster and easier. Each model can be filled with different types of liquid and quickly dispensed into containers. Use lcd banding machine for iphone to fill paint cans with speed and precision. Other compatible fluids include resin or glue, making such devices suitable for manufacturing all kinds of helpful products.

All lcd banding machine for iphone are built to be easy to operate, reducing labor and training times needed. Some versions can pour food-grade liquids such as beer or milk into bottles for future sealing. Most units work automatically so workers can program them and stay back as they work on their own. When installed on a factory floor, they offer greater efficiency to help save time and costs.

Shop for lcd banding machine for iphone at Alibaba.com to find many helpful suppliers with a wide range of options that can be ordered. Choose just the right size to fit the intended workspace. Pick a wattage level that promises good speed and power without using too much electricity and driving up costs. Certain designs can dispense products in the form of powder or granules into nearby containers. Use these to package particular powdered food and pharmaceutical ingredients.

Search for lcd banding machine for iphone on Alibaba.com and enjoy lower costs when working with various liquids or powders. Whether for use in food manufacturing or building materials, there are plenty of options to browse. Find a satisfactory brand that will improve efficiency for better overall quality in each final product.

The Digital LCD Display Veneer Edge Banding Sealing Iron for applying heat-activated, pre-glued edge banding to veneer-ply case pieces. The Digital LCD Display Veneer Edge Banding Iron quickly covers the raw edges of veneered sheet stock.It takes a finish in the same way as your veneered sheet stock does. Its many uses include covering edges of shelves, doors and frameless cabinet components.

Apply pre-glued edge banding with ease and accuracy. The Digital LCD Display Veneer Edge Banding Iron has non-stick surface of the iron allows smooth and easy application. The thermostatically controlled short preheat time gets you working quicker.

The WoodRiver® Digital LCD Display Veneer Edge Banding Iron is the right tool for applying heat-activated, pre-glued edge banding to veneer-ply case pieces. Precise digital temperature control from 100°C - 220°C (212°F - 428°F) provides the perfect temperature for the task at hand – all displayed on the LCD screen to allow easy temperature setting changes. Display can easily be changed from °C to °F with just the touch of a button. Other features include a rounded edge and bevel up nonstick toe for easy access to tight corners. An ergonomically designed handle is constructed from a special TPR material to provide a comfortable but secure gripping surface for hours of use. A built-in safety feature ensures automatic shutoff after six hours, regardless of use, unless manually turned off. Unit comes equipped with a 4" 9", 110V power cord, metal stand, and cotton sock for more delicate fabrics and films.

In this quick guide we’ll cover what Dirty Screen Effect looks like, what’s happening on a technical level, and what, if anything, you can do to get rid of it. We’ll also touch on the notion of the so-called “panel lottery” and how that plays into how clean — or dirty — your new TV screen might look.

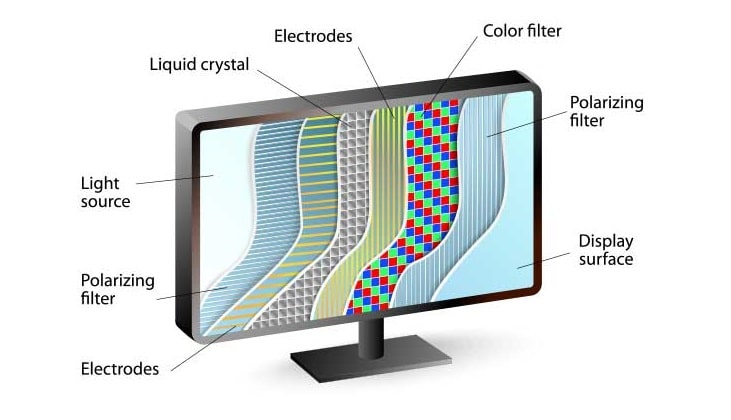

Dirty Screen Effect (DSE) is a term that’s used to describe an LCD panel that has inconsistent luminance performance across its surface area. It can appear as random splotches, uniform lines, wide bars, and, in some cases, vignetting (a slight darkening toward the corners). DSE once plagued plasma TV panels as well. But since those are no longer in production, we’ll keep this explainer focused on LCD-based TVs.

As a reminder, any TV that uses an LED backlight also uses an LCD panel, so TVs marketed as LED, QLED, and mini-LED are all susceptible. Due to what causes DSE on a technical level, some may argue it can only apply to LCD-based TVs. However, similar effects can be seen in OLED-based displays — thus the term is often applied — so we’ll include those types of TVs as well, but address them separately.

There are a number of factors stemming from the manufacturing of an LCD panel that can cause Dirty Screen Effect, from variance in backlight distribution to variance in TFT switching for sub-pixels, to variance in conductivity and/or capacitance of transparent electrodes. That’s super-nerdy, though, and the actual cause is less important than the common theme here: inconsistency.

In panel manufacturing, there are numerous variables that can be introduced that would cause an LCD panel to have groups of pixels that shine less bright than others. This variance is, unfortunately, part of the tech that makes our TVs. And the manner in which different manufacturers handle that variance is also … you guessed it: Varied.

Dirty Screen Effect also can be caused by damage to the panel in shipping or mishandling of the TV during the setup or installation process. Generally speaking, it’s recommended one avoids “pinching” or otherwise exerting pressure on the front of the TV screen.

From what I’ve seen, DSE — ranging from insignificant to severe — seems fairly common among newly manufactured LCD-based televisions, due primarily to the nature of LCD panel manufacturing. Very broadly, the less expensive a TV is, the more likely it is to exhibit some level of DSE. More expensive TVs are not immune to the issue, but some manufacturers have tighter quality assurance tolerances for their high-end products so — again, very broadly speaking — DSE tends to be less prevalent among those models.

DSE as a symptom of age is virtually impossible to track, however — again, anecdotally — I have witnessed DSE creep into a TV’s display panel slowly over time and worsen with age. I’ve seen it happen in TVs I own, TVs friends and family have owned, and TVs installed in commercial environments such as hotels and bars.

Unfortunately, there’s no way to eliminate DSE. Some websites suggest loosening the screws on the back of a TV to lessen the strain on the panel. We do not recommend this tactic as it could stand to void an active warranty. Also, it’s not very likely to work.

Most TVs offer a “game mode” which, due to its tendency to brighten everything on-screen, can help to obscure DSE. But this is really just a Band-Aid measure. The DSE is still there, but it may be less obvious. Another somewhat helpful tip to reduce the appearance of DSE in LCD panels is to view the TV from as direct an angle as possible. As you move off-axis (view a TV from an angle) DSE tends to become more obvious.

The so-called “panel lottery” refers to the game TV buyers unwittingly play when purchasing a TV. Sometimes you “win the panel lottery,” which is a way of saying that the TV you got was in especially pristine shape and shows no signs of DSE. It’s also a term used to easily express that there’s such a variance in panel quality that it’s virtually impossible you’ll win a perfect panel. In other words, it’s all up to chance.

Banding could be minimized through changes in firmware/software and other manufacturing, engineering and QC program changes. Adding Several "dither options", that are noise filter algorithms, would allow the user to attempt to adjust the banding to a minimal nuisance level. Hence, the addition of the “Soft Dither” option that now appears in the 2407 A03 factory menu. Whether Dell or BenQ will diligently peruse this option for these panels or for future products is up to them. This could help compensate for the minimal banding in Desktop and heavy banding in Multimedia and Gaming modes caused by the faulty Faroudja video processing ACC chip feature.

l_e_e , “would it be safe to say that the problem (banding) lies with Faroudja video processing ACC and that it’s a by-product of this so the problem is never going to be fixed.”

LCD vertical banding is a flaw that can occur in the manufacturing process of the LCD panels themselves, and some LCD panels will tend to manifest it more noticeably than others. The panels that cause the most visible problems are usually weeded out in the vendor"s quality control process.

However, those that create just a hint of banding often pass through QC, since it is prohibitively expensive to discard all parts that exhibit flaws, which may have no practical impact on picture quality.

So, we end up with a situation in which some LCD panels, even within a given production run on one model, will have no banding at all, some may have a hint of it that does not rise to the level of a significant issue, and some may have a more visible problem that really does impair the enjoyment of the viewing experience. In the latter case, sometimes the problem can be mitigated with internal adjustments made by the dealer or vendor service departments, and sometimes the LCD panels or the entire unit need to be replaced.

1. Dell and suppliers should work towards providing consumer friendly adjustable LCD"s so they can adjust these LCD"s to eliminate or minimize the banding issues.

Thanks to RadxGe, for the definitive proof (picture) of the hidden menu obvious firmware update in the A03"s. A "Soft Dither" option has been added to A03’s. This is an option that most likely has an impact on banding and noise.

Some LCD panels offer several options, "Dither Options", to eliminate banding or noise by utilizing various algorithmic noise filters for use in different LCD applications.

Features, jack panel (connectivity), price and an Advanced Exchange Warranty that can’t be beat. Some of the competitor’s panels I’ve seen have major hitches in games and flaws that are very disturbing and some panels on the market would be considered unusable.

In LCD and LED TVs, DSE is typically a bigger issue, one that"s due to the way these units are illuminated. Before we proceed, it"s worth mentioning that although marketing-speak often treats LED and LCD TVs as completely different technologies, they"re not different beasts.

LED units could be more accurately described as "LED-backlit LCD televisions," but salespeople and consumers alike are too lazy to utter that tongue-wearying phrase while haggling in a big-box store. What"s important to realize is that both categories rely on LCDs (liquid crystal displays), which act as shutters that either block light or allow it to pass, depending on the image that"s being rendered on the screen.

There are a variety of factors that affect LCD quality, notably illumination source. Older LCD TVs, for example, used multiple cold cathode fluorescent lamps (CCFL) to light LCDs from the rear. They provide generally smooth and even illumination, but they make the final product rather bulky.

If you"ve ever pressed a little too hard on your smartphone or computer screen, you"ve likely witnessed a bit of discoloration, clear evidence of how sensitive LCDs are to physical pressure. Now, picture a huge manufacturing facility that cranks out thousands of these units per week. It"s easy to see how a bit of mishandling could alter the screen"s consistency.

The same goes for shipping. Some units travel long distances in cargo boxes, and then take bouncy rides in your car to their final resting place on your living room wall. That"s a lot of opportunities for tiny mishaps to affect LCD uniformity.

With LED-backlit LCD TVs, gray uniformity issues are caused by a couple of factors. LCD panels are pretty sensitive to pressure, so extra pressure caused by misalignment of the TV"s components or by mishandling of the panel during manufacturing or shipping could lead to defects appearing. Also, too much pressure can affect the backlight and how much light it diffuses, which causes some areas to be darker. Size may also have an effect because it"s harder to keep a larger screen uniform, but since we only test one size of each TV, we can"t draw any conclusions about this.

Gray uniformity is unique to each individual panel. This means that no two TVs, even of the same model, will have matching uniformity. Generally, though, higher-end TVs should have better gray uniformity, as the manufacturers will have stricter standards for the panels used. Higher-end LED-backlit TVs tend to use either Mini LED or direct LED backlighting, generally better for uniformity than edge-lit TVs.

LED and OLED TVs use different technologies to display an image. While LED TVs are really LCD TVs backlit by LED backlights, OLEDs don"t have any backlighting and instead turn each pixel on and off. As such, they perform differently when it comes to uniformity. For the most part, OLEDs tend to have better uniformity, and there are rarely any issues. LED TVs can suffer more from uniformity issues, especially if their backlight is edge-lit and not direct LED. However, we can"t confidently say one TV will have better uniformity than another just because of the backlight or panel type.

Unfortunately, gray uniformity is entirely down to the panel you get. There isn"t much you can do to improve gray uniformity as it"s down to panel lottery. You can try massaging the screen with a soft cloth to relieve the pressure, but this is a delicate technique, so it may be best to not do it if you"re unsure of yourself.

Unfortunately, there aren"t many steps that you can take to improve gray uniformity – it’s entirely down to the panel you get. You can try massaging the screen, but that"s hard to do. If you find yourself with uniformity that you can"t live with, you should exchange your TV for a different unit, or even a different model.

The Samsung QN90B QLED is the best TV with an LED panel we"ve tested. It"s an impressive TV with amazing picture quality and a great selection of gaming features. It uses a Mini LED backlight, with way more dimming zones than most LED TVs, which allows for greater control over the local dimming feature for better dark room performance, with less distracting blooming around bright objects. It also gets exceptionally bright, meaning it can handle lots of glare in a bright room.

Posterization, also called solarization or color banding, is characterized by a loss of image quality on color gradients. Instead of being smooth and progressive, they appear in the form of successive patches or bands with clearly defined shades. This unwanted effect is usually due to the television or projector’s insufficient color depth compared to the source, or sometimes to poor management of the color space by the distributor (TV or projector) which fails to properly sample the colors.

If you have adjusted these settings accordingly and still see bands instead of color gradients, try disabling any video processing features that are enabled. Options such as “dynamic contrast” can generate color banding in the image.

The reproduction of color gradients reveals a television’s ability to display detailed colors. This is very important with HDR images, so if you want to make the most of content with a wide dynamic range (HDR10, Dolby Vision, etc.), you must make sure you have a TV capable of displaying color gradients without posterization. This is generally the case with HDR compatible televisions, as long as they support at least the HDR10 format. However, if your TV meets these requirements but you still see bands of color in the gradients, try disabling the various video processing features one by one to see which ones generate banding.

Your film, 1994 Computer Lab, is in post-production. While reviewing the dailies, you’ve noticed a big problem. The CRT monitors in every shot have fat, dark lines scrolling vertically on their screens. No worries: You have a billion-dollar budget to work with, so you’ll simply rename the film 2014 Computer Lab and reshoot all those scenes with LCD monitors.

But what’s this? There are no lines on the screens anymore, but the LCD monitors look like they’re flickering in your footage. Will you need to rename the movie 2034 Computer Lab and develop futuristic monitor technology to use in the film? And why don’t any of these monitors look right when you point a camera at them?

Although the technologies inside CRT and LCD monitors are quite different, what’s happening in each scenario has a similar underlying cause: Your camera’s frame rate doesn’t match up with the monitor’s refresh rate. What adds to the problem is that human beings process moving images in a very different way than video cameras do.

LCDs (including LED-backlit LCD monitors) don’t have the same banding problems as CRTs, because they create images in an entirely different way. There’s a constant source of backlight behind the screen, and the entire image doesn’t have to be “redrawn,” line by line, at a cyclical rate.

However, you may still see a bit of flicker when an LCD monitor is recorded on video. Much of this has to do with the pulse width modulation used to regulate the brightness of many LED-backlit displays. Pulse width modulation is essentially like flicking a power switch on and off at a very fast rate: It pulses the amount of power supplied to the backlight system based on the selected brightness level. Even though it’s rarely visible to the naked eye, some people report getting headaches from it.

Sixty frames per second for a 60Hz monitor is ideal, and 30fps for a 60Hz monitor should also work. If you’re shooting any monitor at 24fps, you may see some weirdness—it’ll just be far more subtle with an LCD display. If you’ve already synced up the frame rate and the refresh rate but you’re still seeing flickering on an LED-backlit monitor, try turning its brightness all the way up. That should mitigate any pulse width modulation madness.

This is normal, your next screen will probably be the same. In fact all TVs, OLED or LCD suffer from this sort of thing to a certain degree, google "dirty screen effect". The problem is on large screens it"s very hard for the chemical processes etc to be completely uniform across the entire screen, so when certain pans happen, this uniformity variation can be seen as a dirtly screen effect. The more you notice it and look for it, the clearer it stands out. You may find you see it, but other people can"t see it.

Also as a TV ages over the years, with LCD their tends to be air currents due to heat inside the TV from the backlight, and light guides can get dusty behind the LCD panel with dust building up in a pattern caused by the air currents, this then also gives a dirty screen effect. If you smoke, or have open fires where the TV is, it can happen a lot sooner.

With edge lit LCDs like this model, the backlight is also in vertical bands so that it can vary in brightness using local dimming to improve contrast. Because the back light is split like this, you will always get some element of vertical banding.

If it"s only visible during camera pans on sports, which is where most people first notice it, then it sounds a normal limitation of the technology, and your replacement TV will likely be the same, or luck of the draw a bit better, or could be even worse. It is possible to just follow the action and ignore the banding, but if you fixate on the banding, your brain learns to see it very clearly, so once seen it"s hard to unsee.

When the LG V30 hit shelves earlier this month, we were excited to see how LG"s all-new POLED panels would stack up against Samsung"s class-leading AMOLED displays. It didn"t take long to realize there was no comparing the two.

We took our LG V30 out of the box, powered it on anxiously ... and were immediately disappointed. The blacks looked almost gray — as if this weren"t an OLED panel after all, and instead, was suffering from the type of light bleed you"d normally only see on a backlit LCD display. To quote our writer Kevin at the time, "I don"t even know how to describe it. It"s so strange."

Over the next few days, reports of the V30"s POLED screen suffering from banding, light bleed, uneven colors, and various other defects began to pour in. These were the type of quality control issues that plagued early OLED panels when the technology was in its infancy — the problems we all thought had been solved over the years.

It was around this time that prospective Pixel 2 XL buyers were starting to worry. You see, Google invested nearly a billion dollars in LG Display hoping the infusion of capital would speed up their development of a smartphone-sized OLED panel, and the Google Pixel 2 XL was set to use the same 6-inch, 18:9 screen found in the V30.

Banding and uneven colors aside, the Pixel 2 XL"s POLED screen was not without its faults. Most notably, whites shift to the cool end of the spectrum when the phone is viewed from an angle, and according to several users, colors are fairly drab.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey