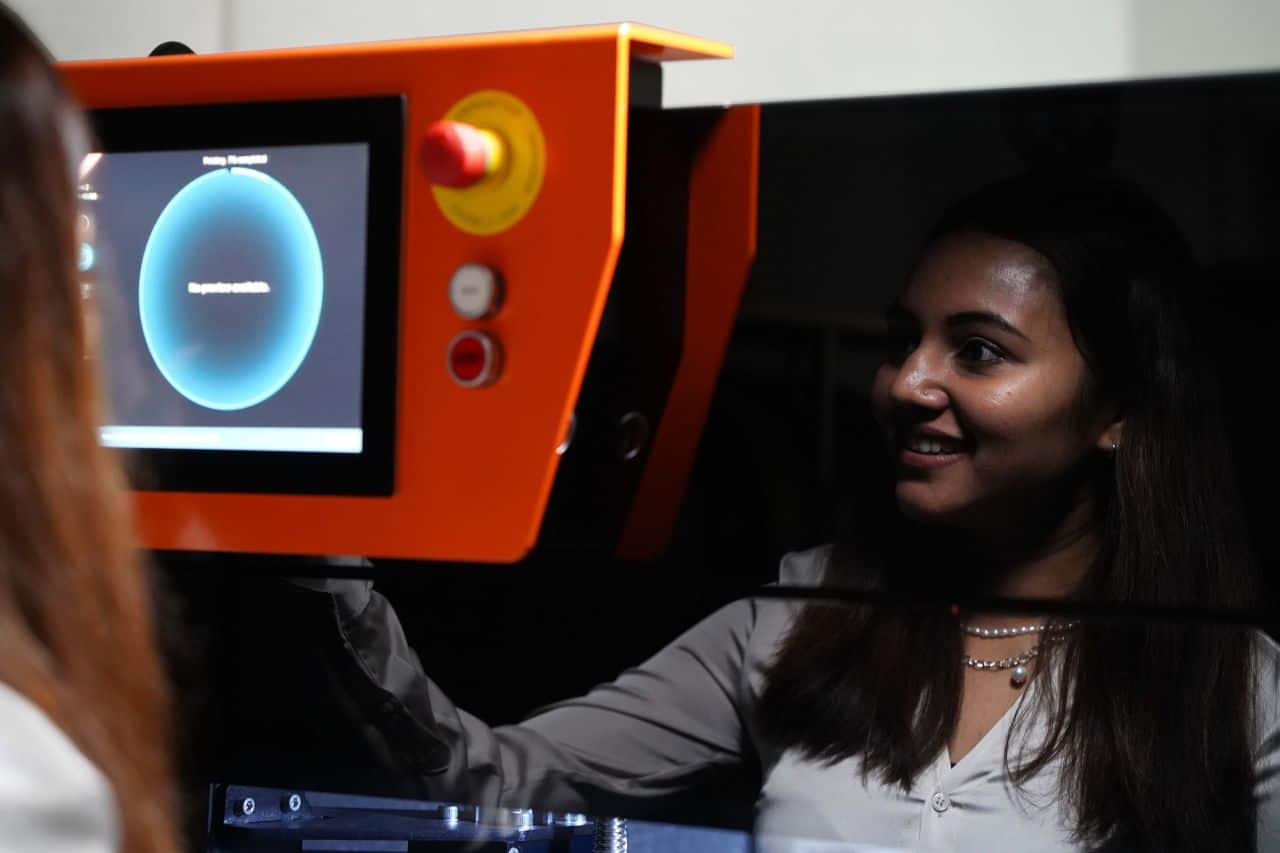

3d printer lcd panel with buttons factory

Ohio-based chemicals and materials company Lubrizol has announced the release of ESTANE 3D TPU M88A thermoplastic polyurethane (TPU) under a selective availability program. This grade was specifically…

3D Printing has had its ups and downs over the years. When it was introduced, the world went crazy with anticipation because the ability to print three-dimensional objects was unheard of, and there was a technology that was providing just that. However, it was very expensive back then due to the cost of setting up the entire machine and the software to run the entire process.

However, that’s no longer a stumbling block. There are a number of new technologies that have been created, bringing down the cost of 3D printing significantly. One of those is the LCD 3D printer.

We are going to explore what anLCD 3D printer machineis, the parts that make it work, the process itself, the benefits it has brought to the industry, and the challenges people who operate them experience. If you have always had a curiosity about how 3D printing is all about, then you are in the right place.

3D Printing has been around since the early 80s where it began as a concept that sought to answer the question of whether the more complicated objects can be reproduced within a three-dimensional structure without compromising the structural integrity. The following is aquick timeline of how 3D printing technology has grown over the years to the present.

1980:An application for the first patent for RP technology was filed by Dr. Kodama in Japan in the month of May 1980. This set of a series of innovations that spurred a race to get 3D printing technology right.

What followed next was a number of companies like Google investing a lot of money in developing 3D printing further. This not only made them smaller but brought their access closer to the people. Although the technology still has a long way to go, the many contributions that have been added over the years have made it possible for 3D printing to gain so much in a short period of time. It"s only a matter of time before they become the norm in the daily lives of people. Now for less than $300, you can get yourself an LCD 3D printer.

An LCD printer is a type of printer that uses an array of UV LCDs as the source of light. The light emanates from the flat LCD panels and is shined directly in a parallel manner against the surface of the building area. The light is very focused without any expansion, a feature that reduces pixel distortion that is common in many other 3D printing techniques in the market right now.

Due to this, LCD 3D printers are in high demand around the world as their print quality is higher. The higher the LCD density, the more pixels the final output has and the sharper and more realistic it gets.

As earlier mentioned, the technology behind 3D Printing has become cheaper by the day, and now you can have your own 3D printer in your house. But to safely operate the machine, you have to understand how it works in the first place. The following are the steps that an LCD 3D Printer uses to create an object from scratch.

Step 1:You begin by pouring theliquid polymer, also called resin, into the crucible. This is then spread by the printer’s roller into arazor-thin layeracross the entire platform to make sure that there’s uniformity in terms of thickness. Consistency is key in this situation.

Step 2:The UV-sensitiveliquid polymeris then hit with a computer-controlled UV laser to change the resin into a solid-state from the aqueous solution. In layman’s terms, this is the point where the laser draws the outlines of whatever you are trying to print onto the resin layer, hardening the needed parts only with every touch. The parts that are not needed will not be touched by the laser, and they maintain their liquid state.

Step 4:Once the printing is done, the object is raised out of the resin tank, with the excess fluid flowing back into the tank for further use. The final product is then finished off outside for the final touches. This includes removing the support structures, smoothing surfaces, or spray painting them.

Caution should be excised whenhandling resin. You should always ensure you are wearing protective gloves and masks because coming into contact with resin is harmful to your health. When washing off the excess resin, make sure you use the correct liquids and don’ drain that water into the sink. Once you have cleaned the excess resin off, don’t touch the final product with bare hands until it undergoes a UV light treatment. You can either let it stand in the sun for a few minutes or if you have a working UV light machine, use it for a few minutes. Once you have covered all that, you are now free to handle the final product.

3D printing technology has transformed human lives in ways that cannot be described, and the more advanced and cheaper they become, the more their applications and benefits they bring. The following are some of the notable benefits of using an LCD 3D printer.

There is nothing that cannot be made using a 3D printer, and this has made things very convenient. You can make all kinds of additions and omissions in real-time however you want. This has allowed people to create a lot of shapes and objects that would otherwise have been impossible by any other means. You can even see the same printing chamber to create a number of objects at the same time at no added cost at all. The cheaper these machines become the more customization capabilities.

It would cost a lot of money to create objects of great complexity by other normal means like manufacturing. However, 3D printing has made that work faster, cheaper and accessible. You can create objects of such a high level of complexity that could even blow your mind. You are only limited by your imagination. The complexity offered by 3D printers has transformed the lives of designers and artists as they are now able to turn their art into realistic 3D objects without compromising on the detailing and sophistication aspects.

3D printing is slated to bring down the cost of manufacturing once it goes into mass production. There are no tools involved in 3D printing, all you require is a computer, a modeling program, and the printer itself, and you are set. This will reduce lead times, the costs of getting tools, and the labor costs of having to operate those tools. The ability to make complex objects without any use of other tools is going to transform the manufacturing industry in a very significant way in the near future. You only need someaccessories and add-onsto make the process easier.

With fewer tools, less energy, and less raw materials, 3D printing is the mosteco-friendly manufacturing processso far. The utilization rate of raw materials is over 90%, with most of the residue recyclable, which means nothing really goes to waste. The finished products are also very hardy and durable, which gives them a decent longevity period of use before they are discarded; this reduces the number of plastics in the environment.

The best part of 3D printing is that finally, manufacturing can be controlled based on need and demand rather than manufacturing in anticipation of demand which leads to surplus and waster of energy. This will eliminate huge inventories, the need to hire storage as well as cut down on the costs of transportation.

3D printing is becoming faster by the day, and when you consider that it involves creating something from scratch using rudimentary raw materials, the sheer brilliance behind the technology starts making sense. One of the manufacturing processes that has benefited greatly from these increased speeds is theprototyping segment, where different parts of the same items can be made at the same time in concurrent processes and later joined up, cutting down the time needed to create products. Once this goes full scale, we will experience manufacturing speeds never seen before.

A goodLCD 3D printerwill save you a lot of money and headache. There are currently a good number of models and brands in the market, each claiming to be better than the next. Making the selection can therefore be a little confusing if you don"t know what it is you are looking for exactly. The following are some of the factors you have to keep in mind when choosing a quality LCD 3D printer.

Size of the print bed:The bigger the bed, the bigger the prints you can make and vice versa. A bigger bed also means you can print several products at the same time concurrently without interfering with the quality of each. This could come in handy considering how time-consuming and complicated setting up the inter for a single operation can be.

Calibration:Some machines require the user to calibrate them before use, and this can be a little time-consuming. It involves adjusting the nozzle until it assumes the right position. You would be served better going for a primer that comes with automated calibration, but that will cost you extra.

Cost of resin:Resin is the material used to make the products, and it is not cheap. There are many types in the market, and each has its own unique properties. Most are sold per pound, and they can vary from $35-$70. As 3D printing picks up, the resin is expected to become cheaper, but at the moment, these are the prices that are in the market.

The Software:There are two types of software you have to deal with. The first one is the modeling software that you use to design the products you want to print. It has to have all the tools, and it must be compatible with the printer. The second software is the one that runs the printer. It should be ‘open source,’ meaning it has to be customizable, allowing the user to set it in line with their needs.

LCD display:A primer that allows you to operate without the need for a computer nearby is more convenient. Having an LCD display withcontroller boardsmakes your work easier as you have fewer buttons to deal with. It also reduces the complications associated with setting up a computer nearby.

Durability and ease of maintenance:As much as their prices have come down considerably, there’s no reason why you should have to be subjected to breakdowns and the need for maintenance after every use. Go for a 3D printer that is durable and can run for long without any maintenance. Having totroubleshoot problemsevery few days will disrupt the quality and speed of your work.

Current trends and the space of development point to a future where 3D printers will be so widespread that people will own them in their houses the same way they own electronics. This will change consumption patterns for people as they will have the power to create most of what they need, and that is a good thing. If you are interested in knowing more about LCD 3D printers, feel free tocheck out the websiteat your own time, and if you have any questions, our team of experts will be there to address every single one of them.

When turning on your Ultimaker 2+ or Ultimaker 2 Extended+, you will always see the Ultimaker logo first. When the printer has finished booting up, you will see the main menu. The main menu offers three options: Print, Material, and Maintenance.

Tip: When you power on the printer for the first time, or after a factory reset, you will first go through the welcome setup. After this is completed, you will see the main menu when you power on the printer.

Rotate the controller button to scroll through the menu items, and press the button to select. When pushing the button, a beeping sound can be heard. A blinking button means the printer is waiting for user input.

You can change the spool of material that is installed on the printer. If you want to switch to a different material or a different color, select this option. The printer will guide you through the process. More information about changing material spools is found here: Change material on the Ultimaker 2+

We guarantee your satisfaction on every product we sell with a full refund - and you won"t even need a receipt.* We want you to be satisfied with your Micro Center purchase. However, if you need help or need to return an item, we"re here for you!

*If you are a Micro Center Insider or if you have provided us with validated contact information (name, address, email address), you won"t even need your receipt.

Desktop / notebook computers, tablets, processors, motherboards, digital cameras, camcorders and projectors, 3D printers, 3D scanners, and CD/DVD duplicators may be returned within 15 days of purchase. All other products may be returned within 30 days of purchase. Merchandise must be in new condition, with original carton/UPC, and all packaging/accessories/materials. If you need to return software, a game or a movie, remember that you may not retain any copies - it"s not legal, and it"s not nice.

The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third-party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray.

Navigating the LCD menu is done by a single control element: a rotational knob that you press to confirm a selection. In addition, you have a Reset button which will reset the printer if pushed. The main LCD screen also displays some other information about your printer"s current state.

Easy to use 3D Printing Pen with LCD screen, temperature adjustment, and sliding feed adjustment. This 3D Pen is great for users of all levels and is the exact same Pen you find on Amazon and Matterhackers for $60+. We get our Pens directly from the factory in China, and they come with a 1 year warranty (so far we"ve only had 1 fail out of over 100 sold).

Toybox is designed from the ground up for entertainment and ease-of-use. We enable kids to 3D print their own toys by providing an intuitive interface and a rich selection of high quality toys and content. By giving children the ability to create their own toys on the fly, we enable them to create richer adventures and stories with their toys.

No. You can import models from other platforms, and you can also use other 1.75mm PLA filament. However, our Printer Food Rolls are Toybox"s favorite, and we cannot guarantee that Toybox won"t get sick from other rolls.

No. The Creator Space is a suite of apps and tools that allow you to easily create your own inventions. You can also import models from the internet or even import models that you have created with a computer-aided design tool (CAD).

Yes. You can print directly from our website www.make.toys/toys. Just make sure you log in to the same account your printer is connected to, or connect the printer to the account that you log into from the website.

This really depends on what you are printing. You can printer around 500 cat rings, or 8 full size action figures per roll. We recommend printing things in different colors to make it more fun.

Nexa3D is a leading provider of ultrafast 3D printing solutions. Our photopolymer and thermoplastic range of industrial 3D printers offer unrivaled speed and throughput, superb surface finish, all on an open material platform. Our patented Lubricant Sublayer Photo-curing (LSPc) 3D printing process unlocks productivity gains by as much as 20x greater than those of conventional SLA or DLP processes. We offer a range of polymer solutions, spanning from a desktop resin 3D printer, industrial 3D printers, and a thermoplastic laser sintering solution for serial production.

New 3D printing methods and applications are being discovered daily, with industries adopting 3D printing for everything from human tissue to film props.

Originally designed to drastically reduce product development cycles, the earliest 3D printers weren’t overly concerned about cycle times. But today’s 3D printers are highly capable machines in terms of throughput, build volume, repeatability, and precision. They help accelerate product development, create better-quality prototypes, reduce operational costs – and fit right on your desk.

3D printing, also known as Additive Manufacturing (AM), refers to various processes of creating three-dimensional objects layer by layer using computer-aided designs (CAD).

In contrast to traditional subtractive manufacturing methods, 3D printing is an additive process. In subtractive manufacturing, parts are created by cutting away materials from a block until the desired shape is achieved. Additive manufacturing builds objects layer-by-layer, resulting in very little material waste.

Since its inception in the 1980s, 3D printing technology has rapidly evolved, transforming prototype creation and product manufacturing by shortening the design process and time to market.

After a design process, the 3D printing process begins with the loading of materials into the printer. Depending on the technology, some 3D printers use a laser to cure liquid resin into hardened plastic, while others fuse small particles of polymer powder at high temperatures to build parts. The most common 3D printing materials used are plastics, but metals, ceramics, and composites are all gaining popularity enabled by evolving technologies.

After the material is loaded, the 3D printer starts building the object layer-by-layer from the bottom up according to the instructions provided by the software. When all the layers have been printed, the object is complete.

After printing, the product must go through a post-processing stage before it can be used. It might require rinsing with solvents, removal of support structures, or sanding and painting. The 3D printing post-process may stabilize the mechanical properties of the object or improve its surface quality.

3D printing materials are as diverse as the applications of 3D printing technology. As such, the technology allows manufacturers to create products from various materials, including metals, plastics, ceramics, and resins.

The most popular 3D printing materials are thermoplastics. Thermoplastics are a type of material that becomes soft and moldable when heated and then returns to its solid form when cooled.

The most common types of thermoplastics used in 3D printing are acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and polylactic acid (PLA). PLA is by far the most common material used because of its ease of use; it undergoes minimal expansion and contraction when heated and cooled.

Photopolymers are more versatile than other materials and can create objects that adhere to different specifications. Builders use them for various 3D printing processes, especially since the advent of Stereolithography (SLA) 3D technology. Acrylic and epoxy resins are common examples of photopolymer materials used in SLA 3D printing.

Metals are used in various industries because of their durability and strength. The process of 3D printing metal is quite different from other materials. It involves using a high-powered laser to melt the metal powder into the desired shape (a process called DMLS).

The most common metals used for 3D printing are aluminum, stainless steel, bronze, and titanium. These materials are often used for creating prototypes and functional parts for end-use applications. The biggest hurdles for metal 3D printing are very high costs and low dimensional accuracy of metal 3D printing – often requiring secondary machining to achieve the required tolerances.

Composite materials are often made up of two or more different materials, which, when combined, have properties different from their original materials. In 3D printing, composite materials are usually a combination of a thermoplastic base material and other reinforcing elements like nylon, carbon fiber, fiberglass, kevlar, or graphene.

Composites are very common in the FDM 3D printing space as base thermoplastics. They often range from commodity materials like Acrylonitrile Butadiene Styrene (ABS) and PolyLactic Acid (PLA) to other high-performance polymers like PEEK. In SLS 3D printing, builders use nylon as a common material for composite SLS powders.

Powders are somewhat of a 3D printing material subcategory since they are typically made up of either metals or thermoplastics. This 3D printing material can be used to create products from various materials, including metals, plastics, and ceramics. The 3D printer melts the powder by melting or spraying a liquid binder evenly across the build platform until the desired thickness is achieved.

The most common powder materials used for 3D printing are Polyamide and Alumide. Polyamide allows a high level of detail and is often used for joints and interlocking parts. For example, the PA11 and PA12 nylons have strong chemical resistance, excellent resolution, and can recycle more than 50% of unfused powder after a build.

Alumide, on the other hand, is a mixture of polyamide and gray aluminum powder. It’s often used for creating functional parts and products with a metallic finish.

Material extrusion is a 3D printing technology that uses a continuous material filament to create objects. The process begins with the material, typically plastic filament, being fed through a heated nozzle. The nozzle melts the material and deposits it onto the build platform.

Material extrusion is commonly known as fused deposition modeling (FDM) or fused filament fabrication (FFF). FDM technology is best for creating large parts with simple geometries from various materials.

Vat photopolymerization is an additive manufacturing technique that produces 3D objects by selectively curing photopolymer liquid resin through light-activated polymerization. The build platform is lowered into, or raised out of, a vat of liquid photopolymer resin during this process.

Resin 3D printers are now available in three generations. The first generation, Stereolithography (SLA) uses a laser to draw out each layer, the second, Digital Light Processing (DLP) uses a projector chip to project a full layer of curing light, and the third, Masked Stereolithography (mSLA), uses an LCD panel to project a full layer of curing light.

Stereolithography (SLA) is an additive manufacturing technology that uses a laser to cure photosensitive materials, layer by layer, to create 3D objects. This is a popular resin 3D printing process that has become widely accepted because of its ability to use various materials to produce accurate, isotropic prototypes and end-use parts with fine features and smooth surface finish.

SLA machines work with the principle of using a light source (UV laser or projector) to cure liquid resin into hardened plastic. SLA machines can be physically identified through their core components, like the light source, the build platform, and the resin tank.

Digital Light Processing (DLP) uses a liquid resin and an LCD screen or projector to display the images of each layer which then cures when exposed to ultraviolet light. The projector flashes an image of an entire cross-section, thereby printing a whole layer at once. This ensures faster printing speeds and represents a major upgrade from the traditional SLA 3D printers.

However, Digital Light Processing does not accurately solve the classic speed vs quality issues that existed in the predecessor SLA 3D printers. Ordinarily, the print speed is not affected by the number of parts on a build plate, but it may affect the quality of the parts because the limited number of pixels gets distributed within the number of parts.

Another potential challenge with DLP is that its single projection source means that the image can become distorted, which can lead to uneven build quality.

The mSLA uses an LED array light source rather than a laser or a single projection point. This LED array projects light through an LCD panel, which masks the necessary pixels while printing and allows only the necessary pixels to pass light. As a result, curing occurs only in the unmasked section.

Nexa3D’s resin 3D printers use a proprietary version of mSLA technology called Lubricant Sublayer Photo-curing (LSPc). While mSLA itself is one of the fastest technologies – using an LCD light engine to project UV light across the build platform to cure a full layer of the print at once – LSPc goes a step further. This technology combines a UV light array and LSPc Optical lens layer to ensure light uniformity in this process, which is essential for optimal use of LSPc High Contrast Mask.

The LSPc HC Mask is in charge of projecting 3D image slices onto the vat where the photopolymerization process takes place layer by layer. This provides the fastest printer on the market with the largest build area in its class without sacrificing image quality: you get high edge-to-edge performance with no distortion, as in the case of DLP 3D printers.

mSLA 3D printers have a high resolution, resulting in parts with a smooth surface finish. This allows them to work in a broader range of industries including dentistry, automotive, jewelry, and manufacturing. Stereolithography in general is best for creating smooth surfaces with high accuracy and detail.

In powder bed fusion, a laser or an electron beam selectively melts the powder material layer by layer. The process begins with a layer of powder spread evenly over the build platform and then the laser or electron beam fuses the powder to form the desired shape. The build platform is lowered, and another layer of powder is spread over it.

Selective Laser Sintering (SLS) is an additive manufacturing technology that uses a laser to fuse small particles of plastic, metal, ceramic, or glass powders into a solid object. In sintering, the powder is heated below its melting point which causes the particles to bond without changing the object’s overall shape. In melting, the powder is heated above its melting point, which allows it to flow and take on the desired shape.

Powered by Quantum Laser Sintering technology, Nexa3D’s QLS 820 delivers premium production capabilities with incredible speed, end-to-end traceability, centralized printer management, real-time data monitoring, and the highest throughput in its class.

Binder jetting deposits a liquid binder onto a powder bed to join the particles and create the desired shape. The process begins with a layer of powder spread evenly over the build platform. The print head moves over the powder bed and selectively deposits the binder onto the powder. The binder binds the particles together and creates the desired shape.

After the binder is deposited, the build platform is lowered, and another layer of powder is spread over it. The process is then repeated until the object is complete. Depending on the material, the part may then go into a debind/sintering oven as is the case with metal before the part reaches its final performance specs. The most common type of binder jetting is selective deposition modeling (SDM).

Material Jetting (MJ) 3D printing works in the same way as a 2D printer. A printhead (similar to the printheads used in regular inkjet printing) dispenses droplets of a photosensitive polymer material that solidifies under ultraviolet (UV) light. This technology dispenses viscous liquids to create wax-like parts which have applications in investment casting.

Material jetting parts have high dimensional accuracy and a smooth surface finish. Multi-material printing is possible, and it’s compatible with a wide range of materials, including ABS-like, rubber-like, and fully transparent materials.

Sheet lamination technology builds objects by bonding together layers of flat sheets. The process begins with a stack of flat sheets placed on the build platform. The print head then selectively applies adhesive to the sheets and bonds them together. The build platform is then lowered, and another layer of sheets is placed on top.

Sheet lamination 3D printing often uses Laminated Object Manufacturing (LOM) and Ultrasonic Additive Manufacturing (UAM). The former involves using alternate layers of material and adhesive to produce items with visual and aesthetic appeal, while UAM employs ultrasonic vibrations to weld layers of material together.

3D printing technology is constantly evolving and the 3D printing process varies according to the exact technology and software used. But, most 3D printing follows these steps:

The CAD model is imported into a slicing software that specifies print settings, and “slices” the digital model into layers representing the part’s horizontal cross-sections. Adjustable printing settings on the 3D printer include orientation, layer height, support structures, and more.

While there are a number of open-source software platforms that enable the masses of hobbyist resin 3D printers, they tend to require in-depth knowledge to dial in parameters for your specific 3D printer. Fortunately, most OEMs will supply homegrown software, such as NexaX.

The next stage after deciding to 3D print your parts is selecting the most appropriate materials and machines for the job. The combination of material and printer depends on various factors, including the final product’s desired strength, flexibility, durability, and heat tolerance.

Printing preparation involves packing the build plate, orienting and stacking parts, slicing thousands of layers, generating supports, simulating and validating the build process, and then creating the file for the 3D printer.

The best 3D printing software automates as much of the build process as possible, from material recommendations to part orientation and support generation. The NexaX print preparation software quickly auto-generates supports and helps users validate their build processes before committing to print.

The 3D printing process depends on what AM technology is being used. Whether it’s sheet lamination, DLP, or SLS, the 3D printer gets to work creating three-dimensional objects layer by layer using CAD files.

Like the actual printing, post-processing varies based on the 3D technology used. For example, in SLA post-processing, curing is done by exposing the product to either heat, UV light, or a combination in a controlled chamber. For extrusion and powder-based 3D printing, post-processing can include manual sanding and finishing, depending on the quality of the print.

Great post-processing systems should ensure consistent process controls and workflows – no matter the size or complexity of parts. An advanced 3D printer should have an automatic self-contained device that accepts the build plate from the printer and cleans the printed parts.

For instance, Nexa3D printers come with the xWash and xCure tools which allows operators to move an entire job from the 3D printer to the wash station in seconds.

Additive manufacturing is making a mark on the medical industry by 3D printing custom prosthetics, implants, and body parts. 3D technology is used to create personalized medical devices such as hearing aids, braces, and even dentures that fit perfectly.

For example, the company WeMed designs telemedicine devices. After discovering the need for remote diagnostic medical devices, WeMed partnered with Nexa3D to manufacture the SKOP™ 3D printed stethoscope. Using 3D printing to create the cardiopulmonary auscultation medical device allowed it to be both accessible and affordable.

3D printers are also ideal for dental models, splints, impression trays, occlusal night guards, and more. For example, Nexa3D’s NXD 200Pro was designed specifically for the dental industry and offers world-class dental model manufacturing capabilities at ultrafast speeds, with a large build plate to create up to 20 flat 3D-printed dental models in less than 30 minutes.

3D printing technology is used to create prototype parts and improve production cycles in industrial manufacturing. The additive process reduces waste and the need for large spare part inventories. Shorter production times also mean that industrial manufacturers can quickly respond to customer demands and produce customized products.

Organizations can also conduct hybrid manufacturing: the use of 3D printing as well as traditional manufacturing technologies to create a part. Traditional processes can be made more agile and flexible by using 3D printing, offering the potential to reduce costs and improve an organization’s economies of scale.

The auto, rail, and aviation industries use 3D printing technology to create lightweight parts and develop prototypes for new designs, helping save time and money during the development process.

The rail industry uses 3D printing technology to address spare part obsolescence issues by producing on-demand tools. Railway companies are adopting toolless production backed by 3D printing to significantly cut the manufacturing time for obsolete spare parts, in some cases by as much as 95%.

Williams Racing F1 is another great example of 3D innovation in the auto industry. The company uses Nexa3D’s NXE400 3D printer for its cutting-edge innovation and testing operations.

3D printing technology allows designers to visualize their designs and create photo-realistic renditions of products before they are manufactured. Even better, with 3D visualization technology, product designers can go beyond the limitation of photos and create full-color, moving images of their products.

In addition, engineers are using 3D printing technology to create prototypes for testing and experimentation. The ability to quickly produce prototypes helps engineers save time and money during the product development process.

3D construction is an exciting new application of 3D printing technology that is being used to build homes, office buildings, and other structures. The technology offers several advantages over traditional construction methods, including printing custom designs, using recycled materials, and constructing buildings in remote locations.

3D printers can now print entire homes, including walls, floors, and roofs. The technology also creates concrete molds that can be used to construct buildings quickly and efficiently. Also, 3D construction is less labor-intensive than traditional construction methods, reducing construction project costs.

A perfect example is the world’s first 3D-printed commercial building, the Dubai Future Foundation (DFF). The 250 sqm office building was printed using a 20m x 40m concrete printer in just 17 days, costing less than $100,000.

Furniture, eyewear, home decor, jewelry, and more are all being created by 3D printing. The technology offers several advantages for manufacturers, including the ability to create intricate designs, material recycling, and time-saving.

As other industries continue to explore the potential of 3D printing technology, the applications of the technology are expected to grow exponentially.

The 3D printing industry has gone from huge machines taking days to make a single product to professional-grade 3D printers that take you from CADs to parts in less than 30 minutes. From medical devices to airplane parts, 3D printing is changing the capabilities of different industries every day.

Nexa3D’s 3D printers, which use its patented Lubricant Sublayer Photo-curing (LSPc) technology, achieve the fastest printing speeds and highest throughput in their class. From the XiP to the NXE series, the Nexa3D 3D printers are known for their groundbreaking combination of speed and quality.

Introducing the SLA 750 stereolithography solution, anchored by the SLA 750 and SLA 750 Dual – the world’s first synchronous, dual-laser stereolithography printer – delivering cost-efficient, high quality production manufacturing at up to 2X speed and 3X throughput. This solution includes our new Accura AMX Durable Natural material, the industry’s toughest production-grade SLA material, and our new PostCure 1050 system for high-volume post-processing, as well as factory-level integration through the Oqton Manufacturing Operating System (MOS).

SUNLU launched a natural green LCD-3D photocuring material that uses soybean oil as raw material in order to reduce the impact of chemicals on the environment and the human health.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey