arduino tft lcd menu library factory

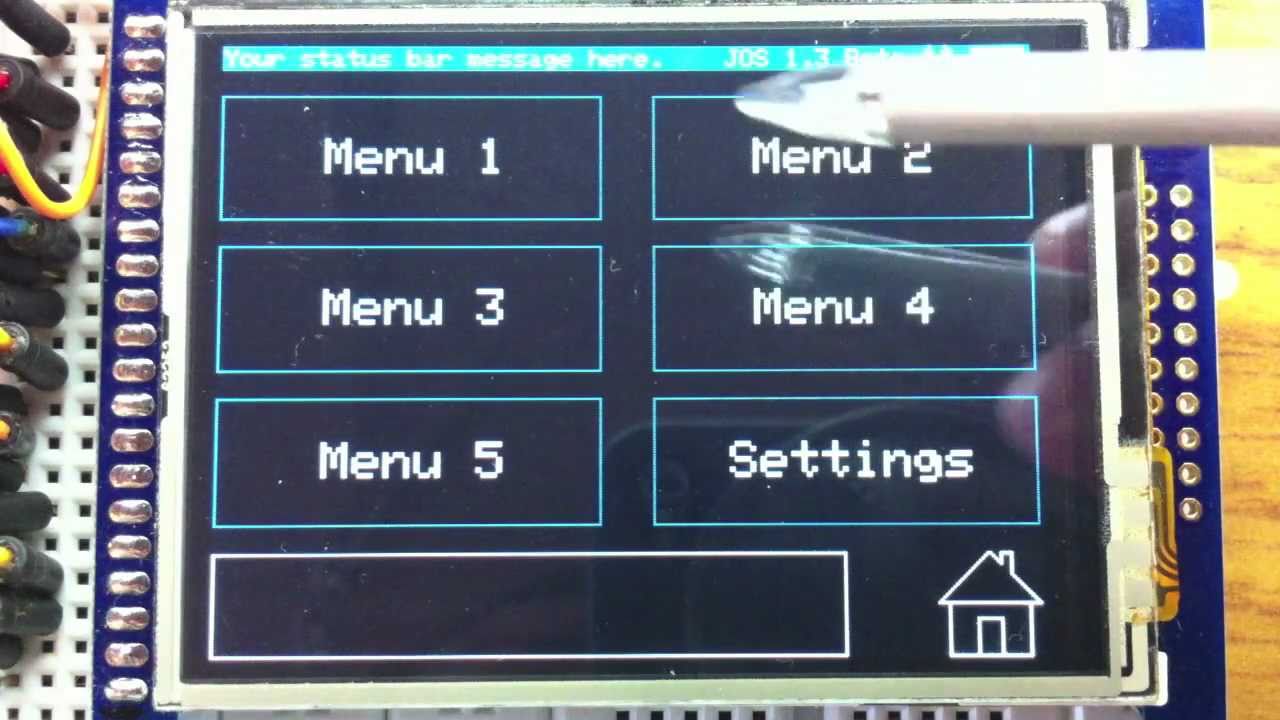

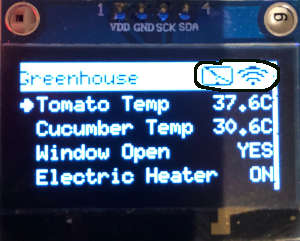

TcMenu supports a wide range of rendering devices, from HD44780 based units using our LiquidCrystal fork through to mono OLEDs and full colour TFT displays using Adafruit_GFX and TFT_eSPI library. Over to the left you see an example of rendering to OLED device with title widgets.

How a menu will look on the device will largely depend on which display is used. However, there are a few common features of all displays. They can generally all have a title, and the title can nearly always contain title widgets. Title widgets provide a way to present the graphical state of something within the system in a small icon, the most common would be the signal strength indicator, or a connection status icon. An example showing this is presented below:

From the above diagram we can see that most graphical and LCD displays (except Uno cases) extend from at least the BaseGraphicalRenderer. And in fact all the true graphical displays extend from GraphicsDeviceRenderer and then have a custom drawable. The benefit of GraphicsDeviceRenderer is that does all the complex logic, and the drawable just has to implement the drawing glue code that calls into the library.

Type: BaseMenuRenderer in BaseRenderers.h - this just provides a few functions to help formatting items, taking over the display and handling dialogs.

In all cases the display plugins will create a global variable called renderer in your sketch. It will be at least of type MenuRenderer meaning that you can rely on an absolute base set of functionality. In most cases it will be of BaseGraphicalRenderer or GraphicsDeviceRenderer so you will be able to rely on nearly all functions being available.

Usually, the renderer is initialised during menu setup and this starts a task manager timer task that calls the display back frequently to check if anything needs drawing. It is this task that keeps the screen up-to-date.

Controllers allow you far more control over a dialog, you can not only add additional menu items and buttons to the dialog, but you can also be informed when dialog buttons are pressed before the dialog ends, and be informed when it is initialising.

You can add additional menu items of any type to the dialog, you can even add more buttons, additional buttons should be of this type [https://www.thecoderscorner.com/ref-docs/tcmenu/html/class_local_dialog_button_menu_item.html].

The easiest way to use touch support, is from tcMenuDesigner where it can be automatically added to appropriate display devices, this just explains how designer adds touch support for those who want more information, or wish to do it manually.

Some displays are buffered by default, these include nearly all monochrome displays and the LTDC frame buffer support. However, TFT displays are typically not buffered into local memory as the memory requirements would be too high. However, if instead of buffering all 16-bit (or 32-bit) color information, we only buffer a palette then only 2 or 4 bits are needed per pixel. This reduces the memory requirement by about 4-8 times.

Further, we only tend to draw one thing at once, so if we also reduce the height of the buffer, for example, to handle the largest menu item height memory is reduced further. In the case of a 320x40 4 color palette buffer for Adafruit_GFX memory requirement is about 3200 bytes. For TFT_eSPI, the requirement would be about 6400 bytes as the buffers are 4 bit (16 color).

CAUTION: It will return nullptr if the dimensions are beyond the size that is supported. These dimensions are normally set in the code generator plugin as the line buffer size. If you’re using tcMenu code generator, then the lines to buffer are set up

The purpose of this guide is to get your 0.96″ color LCD display successfully operating with your Arduino, so you can move forward and experiment and explore further types of operation with the display. This includes installing the Arduino library, making a succesful board connection and running a demonstration sketch.

Although you can use the display with an Arduino Uno or other boad with an ATmega328-series microcontroller – this isn’t recommended for especially large projects. The library eats up a fair amount of flash memory – around 60% in most cases.

So if you’re running larger projects we recommend using an Arduino Mega or Due-compatible board due to the increased amount of flash memory in their host microcontrollers.

(As the display uses the ST7735S controller IC, you may be tempted to use the default TFT library included with the Arduino IDE – however it isn’t that reliable. Instead, please follow the instructions below).

Please check that the library has been installed – to do this, select the Sketch > Include Libraryoption in the IDE and scroll down the long menu until you see “ER-TFTM0.96-1” as shown below:

The display uses the SPI data bus for communication, and is a 3.3V board. You can use it with an Arduino or other 5V board as the logic is tolerant of higher voltages.

The library used is based on the uTFT library by Henning Karlsen. You can find all the drawing and other commands in the user manual – so download the pdf and enjoy creating interesting displays.

We covered the basics of accelerometer previously inUsing Arduino with Parts and Sensors – Accelerometer Part 1andUsing Arduino with Parts and Sensors – Accelerometer Part 2. Today we’ll be testing KX022-1020 accelerometer using TFT liquid crystal panel. We’ll discuss how to control the TFT LCD in more detail in the next article. In addition, we’ll further exploreArduino Create. For more information about Arduino Create, please refer back tothisarticle.

Now, let’s test the accelerometer. Download the library from the “Software” section at the bottom of theaccelerometer page from theRohm Sensor Evaluation Kit website.

We’ll continue using Arduino Create Web Editor as we did in our lasttutorial. To add the library, you can upload the zip file by selecting it from “Libraries” on the left menu and clicking on “ADD ZIP LIBRARY.”

After adding the library, attach the accelerometer to the Sensor Shield (I2C I/F) and try running the sample program. The accelerometer should be set to 1.8V or 3.0V.

Now the sample program is working fine, let’s try to display the values on a 1.8 inch TFT LCD monitor. Although this TFT liquid crystal monitor has a resolution slightly smaller than 126 x 160 px, it’ll be quite useful when displaying numbers or letters with Arduino etc.

When using the TFT monitor, the connection method and the library used in the program may be different depending on the specification of each TFT monitor. The TFT monitor used in this tutorial is a monitorSainSmart ST7735R. In addition to Arduino, the monitor is also compatible with Raspberry.

In order to use the monitor to run the program in Arduino, we’ll have to modify the downloaded library a little bit.We’ll go over how to control the TFT LCD in more detail in the next article. Once everything is set, you will be able to output numerical values in the monitor as shown in the video below:

In the next part, we’ll create a simple device using the same accelerometer and TFT monitor. We’ll show how to create graphs and display the values obtained from the accelerometer on the TFT monitor.

The component TFT supports a 2.8 inch TFT display with a resolution of 240*320 pixels.The display is not soldered on the board, but there is a 14 pin connector for a TFT display. The ILI9341 has been tested.

There are four sample projects for the Arduino IDE which could be downloaded: TFT-Box3D (download here), TFT-Graphic-Test (download here), TFT-HelloWorld (download here) and TFT-HowToUseFonts (download here). And there are two examples for the Arduino IDE for using the touch functionality which could be downloaded: TFT-TouchBtn (download here) and TFT-TouchDraw (download here).

There are two dip switches for the component: SW311 and SW314. If you want to use the TFT display all switches on SW311 have to be on on. If you additonally want to use the touchpad of the display all switch of SW314 have to be on. The following two tables shows the functions and the potential conflicts with other components

After the download it"s necessary to add both libraries to your Arduino IDE. Open Sketch > Include Library > Add .ZIP Library ... and select the downloaded archive. Do it for both libraries.

There are four sample projects for the Arduino IDE which could be downloaded: TFT-Box3D (download here), TFT-Graphic-Test (download here), TFT-HelloWorld (download here) and TFT-HowToUseFonts (download here).

And there are two examples for the Arduino IDE for using the touch functionality which could be downloaded: TFT-TouchBtn (download here) and TFT-TouchDraw (download here).

Voltage type: 5v or 3v voltage input voltage,input is selectable. Because TFT can only work under 3.3 V voltage, so when the input voltage VIN is 5V, need through the 3.3 V voltage regulator IC step down to 3.3V , when the input voltage of 3.3 V, you need to use the zero resistance make J2 short , is equivalent to not through the voltage regulator IC for module and power supply directly.

In addition to a serial/usb/host interface, Marlin also includes a menu-based user interface for inexpensive character and graphical LCD controllers. Rotate a knob or use buttons to navigate menu items, edit values, and make other adjustments. Click the knob or press a button to choose menu items, exit adjustment screens, and perform other actions.

Note: In low-level contexts we refer to the first extruder as E0, the second as E1, etc. However, at “user level” in the LCD menus, we refer to the first extruder as E1, the second as E2, etc. (Marlin 2.0 includes an option to show the first extruder as E0.)

The Tune menu is only available during active printing. Most items in this menu are editable values. Item Description Requirements Speed: -–- Feed Rate Multiplier

The move axis sub-menu was reorganized for Marlin 1.1. To use the move commands, first select the axis to move, then select the move distance. Use the controller wheel (or arrow buttons) to adjust the axis position. For larger move sizes, Marlin waits until you stop moving the controller for 1/2 second before it starts the move, giving you an opportunity to catch overshoot. Item Description Requirements Free XY Move Z down to safe-zone DELTA (above safe zone)

The Bed Leveling menu groups together commands for calibrating the nozzle-to-bed distance. Different options will appear depending on your setup and the type of leveling you’ve enabled. Level Bed runs the default G29 procedure. For auto bed leveling this will deploy the probe, measure all points, and stop. For manual leveling (PROBE_MANUALLY or MESH_BED_LEVELING) you’ll be taken through a step-by-step process. Item Description Requirements Free XY Move Z down to safe-zone DELTA (above safe zone)

The Unified Bed Leveling menu groups together commands for leveling and mesh editing. Since this menu is very large and complex, it will be described in a separate document - coming soon.

Set the fan speed plus bed and/or nozzle temperature to the preset “PLA” settings. Use M145 S0 ... to change the temperatures and fan speed used for this menu. Item Description Requirements Preheat PLA Active Extruder, fan, bed HOTENDS == 1

Set the fan speed plus bed and/or nozzle temperature to the preset “ABS” settings. Use M145 S1 ... to change the temperatures and fan speed used for this menu. Item Description Requirements Preheat ABS Active Extruder, fan, bed HOTENDS == 1

The Control sub-menu includes the Temperature, Motion, and Filament sub-menus and Settings/EEPROM commands, plus a few other miscellanous hardware control commands. Item Description Requirements LCD Contrast » HAS_LCD_CONTRAST

Use this sub-menu to set the target temperature for nozzles and the bed, fan speed, AUTOTEMP, PID factors, and material preheat settings. Item Description Requirements Nozzle: -–- Current E Target Temperature HOTENDS == 1

When the ANTCLABS BLTouch probe acts up you can use the items in this sub-menu to reset and test the probe. Item Description Requirements Reset BLTouch Revive after an error

This 2.0”LCD display adopts T7789V driver chip and has 320*240 color pixels (RGB565). It uses IPS TFT display and can display 18-bit color(16-bit is basically used). The module performs excellently in displaying color bitmap. Besides, there is an onboard MicroSD card slot for displaying more pictures. There are two connection ways for this module: pin headers and GDI. Only one fpc cable is needed when working with main-cotnrollers with GDI, which greatly reduces the complexity of wiring.

• (2.4", 2.8", 3.2", 3.5", 4.3", 5.0", 7.0")• TFT 65K RGB Resistive Touchscreen• Onboard Processor and Memory• Simple ASCII Text Based Instruction Set• The Cost-effective HMI Solution with Decreased

Nextion is available in various TFT LCD touchscreen sizes including 2.4”, 2.8”, 3.2”, 3.5”, 4.3”, 5.0”, 7.0”, 10.1” . With a large selection to choose from, one will likely fit your needs. Go Nextion Series and Product Datasheets.

First of all, a happy new 2023! I"ll use this occasion to introduce a new type of Sunday blog post: From now on, every now and then, I"ll publish a collection of FAQ around a specific topic, to compile support requests, forum posts, and questions asked in social media or by email...Whatever you are currently celebrating, Christmas, Hanukkah, Jul, Samhain, Festivus, or any other end-of-the-civil-year festivities, I wish you a good time! This December 25th edition of the Nextion Sunday Blog won"t be loaded with complex mathematical theory or hyper-efficient but difficult to understand code snippets. It"s about news and information. Please read below...After two theory-loaded blog posts about handling data array-like in strings (Strings, arrays, and the less known sp(lit)str(ing) function and Strings & arrays - continued) which you are highly recommended to read before continuing here, if you haven"t already, it"s big time to see how things work in practice! We"ll use a string variable as a lookup lookup table containing data of one single wave period and add this repeatedly to a waveform component until it"s full.A few weeks ago, I wrote this article about using a text variable as an array, either an array of strings or an array of numbers, using the covx conversion function in addition for the latter, to extract single elements with the help of the spstr function. It"s a convenient and almost a "one fits all" solution for most use cases and many of the demo projects or the sample code attached to the Nextion Sunday Blog articles made use of it, sometimes even without mentioning it explicitly since it"s almost self-explaining. Then, I got a message from a reader, writing: "... Why then didn"t you use it for the combined sine / cosine lookup table in the flicker free turbo gauge project?"105 editions of the Nextion Sunday blog in a little over two years - time to look back and forth at the same time. Was all the stuff I wrote about interesting for my readers? Is it possible at all to satisfy everybody - hobbyists, makers, and professionals - at the same time? Are people (re-)using the many many HMI demo projects and code snippets? Is anybody interested in the explanation of all the underlying basics like the algorithms for calculating square roots and trigonometric functions with Nextion"s purely integer based language? Are optimized code snippets which allow to save a few milliseconds here and there helpful to other developers?Looking through the different Nextion user groups on social networks, the Nextion user forum and a few not so official but Nextion related forums can be surprising. Sometimes, Nextion newbies ask questions or have issues although the required function is well (in a condensed manner for the experienced developer, I admit) documented on the Nextion Instruction Set page, accessible through the menu of this website. On top of that, there is for sure one of my more than 100 Sunday blog articles which deals not only with that function, but goes often even beyond the usual usage of it. Apparently, I should sometimes move away from always trying to push the limits and listen to the "back to the roots!" calls by my potential readers...

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey