lcd display monochrome factory

As we said the original panels come from professional manufacturers such as BOE; Sharp; JDI; Tianma; LGDisplay etc, they start making screens for 3d printing now.

LCDs, along with OLED displays, are manufactured in cleanrooms using large sheets of glass whose size has increased over time. You can check Wiki here

Several displays are manufactured at the same time and then cut from the sheet of glass, also known as the mother glass. The increase in size allows more displays or larger displays to be made. The glass sizes are as follows:

Most 5.5inch and 6inch screens are from GEN 4/4.5 include current Sharp04 and the 6inch monochrome screen. You can also find most LCD screens over the world from this website:https://www.panelook.com/

These manufacturers are focus on the bigger generation with OLED, You can find high-resolution screen use on VR/AR products, which is not used on our printer now, our screen is TFT-LCD.

Below is BOE’s generation with the screen type, the large size LCD mainly uses on TVs, Monitors, Laptops, and mobiles. But I do believe there will be more option for 3d printers in the soon future.

Aperture ratio is the ratio of the area of the light transmission part of the pixel (or sub-pixel) (the area available for display) to the total area of the pixel (or sub-pixel).

As shown in below. The aperture ratio of TFT-LCD is about 50 ∼ 80%. Generally, the larger the aperture ratio, the higher the optical utilization rate of the liquid crystal display, and the higher the brightness of the display.

Optical performance includes three main indicators: polarization, transmittance, and hue. The higher the degree of polarization and transmittance, the higher the display efficiency of the LCD display device and the lower the energy consumption.

This actually talks about decrease exposure time, because the UV transmission can reach 6% on a monochrome screen, and RGB LCD is about 1%. Below you can see ELEGOO Saturn is much faster than Mars.

The UV light source also needs an upgrade to work with monochrome LCD. It requests more vertical & parallel light to make sure the quality.There will come out the new UV LED for the mono screen soon and CBD-Tech will keep an update.

Many companies are preparing their 2K mono printers this year, the customer who owns Phrozen sonic mini has already experienced a Monochrome LCD printer.

If you are interested in upgrade your RGB screen to monochrome LCD, Take a look at ChiTu systems online store, and we also the original RGB color screens for mars and photon.

Viewing direction (or bias angle) is the direction from which the display will look the best. It is set during the manufacturing process, and cannot be changed later by rotating the polarizers. Viewing direction is specified as positions of a clock face. A twelve o"clock viewing direction means that the optimum direction is above the normal to the display, while a part with a six o"clock viewing direction is best viewed from below the normal.

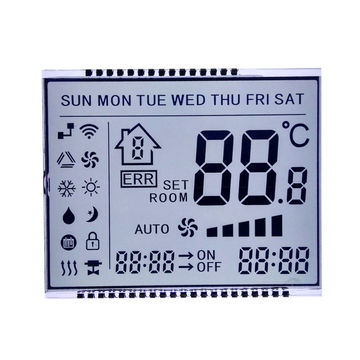

When specifying the viewing direction, one needs to think about how the device is going to be used. For example, a calculator is usually sitting on a desktop or held in the palm of your hand and viewed from the six o"clock direction . Some instrumentation, like a wall thermostat, may be mounted below the viewer and needs to be viewed from the twelve o"clock direction. Other viewing directions are possible but not common. A car clock display, which is usually to the drivers right, may have a nine o"clock viewing direction, or possibly a ten-thirty one if the clock is low on the dashboard.

In a direct drive display, viewing direction is not critical because the display will look good from almost any direction. It becomes critical when the display is multiplexed. The higher the multiplex rate, the greater the problem becomes. In displays with extremely high multiplex rates, great care must be taken when designing the drive circuitry. Special films can also be applied to the front of the display glass to enhance the overall viewability. However they tend to be expensive.

The viewing angle is the angle formed on either side of the viewing direction (or bias angle), where the contrast of the display is still considered acceptable. The term "viewing angle" is often used erroneously with the term "viewing direction" or "bias angle".

Liquid Crystal Displays have a limited viewing angle. They lose contrast and become hard to read at some viewing angles and they have more contrast and are easier to read at others. The size of the viewing angle is determined by several factors, primarily the type of Liquid Crystal Display fluid and the duty cycle. Because the viewing angle tends to be smaller than most people would like, certain viewing direction (or bias angle) is designed into the module at the time it is manufactured. This means the nominal viewing angle is offset from the perpendicular by some amount. Several versions of the LCD module are then offered with this bias set to different angles or positions to accommodate as many applications as possible.

An STN character display running at a duty cycle of 1/16 has a viewing angle of ±20 degrees, and a bias angle of 25 degrees. For this example, assume the display is a 12:00 (top viewing) type. When the display is viewed from 25 degrees above the vertical, it will have its maximum contrast and best “look”. If the viewer moves his eye further above the display by an additional 30 degrees, he will see the display reduce in contrast (but still be easily readable). Moving the viewing position any further above the display will reduce its contrast to an unacceptable degree.

Adjusting the contrast voltage, VO, will effect the viewing direction (bias angle) to some extent, but not the viewing angle. 12:00 display can be optimized for a 6:00 viewing position by adjusting the contrast voltage. A 12:00 display set for 6:00 viewing position will not have as great a contrast as a 6:00 display set for 6:00 viewing position, and vice versa. Designers often want a display to be optimized for straight-on viewing. Either a 12:00 or a 6:00 module can be used; and the contrast voltage can be adjusted slightly to optimize the display for that viewing position. In the example used above, the viewing angles of both the 6:00 and 12:00 modules actually overlap the perpendicular (or straight on) viewing position.

Elastomers are silicon strips of alternating conductors and insulators. These materials are generally soft and compliant and can be easily compressed between the Liquid Crystal Display and circuit board. Elastomers require a bezel to squeeze the display and circuit board together. This method will yield a higher conductor interconnection than pins, potentially less costly than pins, but requires a specialized compression bezel.

Pins are attached to the display to allow the user to either mount the display in a socket or solder it directly into a circuit board. From an end user standpoint, pins are the easiest to use since there is no requirement for a compression bezel or expensive heat seal bonding equipment.

Heat seals are similar to flexible circuit boards with the difference being that the interface tabs are made of a conductive hot melt adhesive. Generally, particles such as carbon, gold, or silver are added to the adhesive to make it conductive. The pads of the heat seal are aligned with the pads of the display and a hot bar is brought down under pressure and the conductive adhesive is melted and bonded to the display. The adhesive is allowed to cool and an electrical bond is made with the display. This method is the most cost effective for the higher volume applications, but due to the expensive setup and equipment required in this process, Heat Seals are typically not used for lower volume / low interconnection density requirements.

Light Emitting Diode, or LED, backlight is the most popular backlighting for small and medium LCDs. The advantages of LED backlighting are its low cost, long life, immunity to vibration, low operational voltage, and precise control over its intensity. The main drawback is it does require more power than most of the other methods, and this is a major drawback if the LCD size is large enough. LED backlights come in a variety of colors, with yellow-green being the most common, and now white is becoming cost effective and very popular. LED backlights offer a longer operating life - 50,000 hours minimum - and are brighter than ELPs. Being a solid state device, they are configured to operate with typically a +5VDC power (and optionally 12VDC power), so they do not require an inverter.

The LED backlight has two basic configurations; Array and edge lit. In both types the LEDs are the light source that are focused into a diffuser that distributes the light evenly behind the viewing area. In Array lit configuration there are many LEDs mounted uniformly behind the display, it offers more uniform and brighter lighting and consumes more power. In Edge lit configuration, the LEDs are mounted to on side (typically the top) focused edge on into the diffuser, it offers a thinner package and consumes less power.

Electroluminescence Panel, or ELP, is a solid state phenomenon which uses colored phosphors, not heat, to generate light. EL backlights are very thin, lightweight and provide an even light. They are available in a variety of colors, with white being the most popular for use with LCDs. While their power consumption is fairly low, they require voltages of 100 VAC @ 400Hz. This is supplied by an inverter that converts a 5, 12 or 24 VDC input to the AC output. Information about these inverters can be found in the Power Supply section of our website. ELPs also have a limited life of 3,000 to 5,000 hours to half brightness. The biggest drawbacks to an EL panel is that it requires an inverter to generate the 100VAC, consistent brightness, and limited life.

Cold Cathode Fluorescent Lamp, or CCFL, backlights offer low power consumption and a very bright white light. The primary CCFL configuration used in LCD backlighting is edge lighting. A cold cathode fluorescent lamp is the light source with a diffuser distributing the light evenly across the viewing area. CCFLs require an inverter to supply the 270 to 300 VAC @ 35KHz used by the CCFL tube. Information about these inverters can be found in the Power Supply section of our website. They are used primarily in graphic LCDs and have a longer life - 10,000 to 20,000 hours - than ELPs do. Their biggest drawbacks are: cold weather will reduce the light output by as much as 60% (see graph below), they require an inverter to generate the 350VAC (please note that the inverters do not function well at low temperatures), the light intensity cannot be varied (it is either on or off), and vibration can reduce the life expectancy of up to 50%.

With only alphanumeric symbols or graphics in a single color, users are able to read these displays easily. This means better efficiency for industrial applications and better usability in others.

Because monochrome displays are basic in their functionality they are also very power efficient. This allows your device to be more usable by lasting longer on set of batteries or a single charge.

If you need to display a concise set of information in a small area, a monoschrome display is what you need. With most being no bigger than a deck of cards, these displays can give you the right information at just the right size.

With only alphanumeric symbols or graphics in a single color, users are able to read these displays easily. This means better efficiency for industrial applications and better usability in others.

Because monochrome displays are basic in their functionality they are also very power efficient. This allows your device to be more usable by lasting longer on set of batteries or a single charge.

If you need to display a concise set of information in a small area, a monoschrome display is what you need. With most being no bigger than a deck of cards, these displays can give you the right information at just the right size.

[Wenting Zhang] is clearly a fan of old school STN LCD displays, and was wondering how various older portable devices managed to drive monochrome LCDs panels with multiple grey levels. If the display controller supports multiple bits per pixel, it can use various techniques, such as PWM, in order to produce a pseudo-grayscale image. But, what if you have a monochrome-only display controller? With a sufficiently high pixel clock, can you use software on the application side of things to flip those pixels in such a manner as to give a reasonable looking grayscale image?

[Wenting] goes through multiple techniques, showing the resulting image quality in a clear, systematic manner. The first idea is to use a traditional dithering technique. For each pixel, it is set to black if the grey value is below some threshold. The resulting error value, is then propagated to neighbouring pixels. This error diffusion process smears the error out over the whole display, so spatially speaking, on average the pixel values correspond roughly to the original gray values. But, the pixels themselves are still either on or off. This isn’t quite enough. The next idea is to PWM the individual pixels over multiple frames, to approximate different grey levels. But, that gives a worst case effective refresh rate of 8 Hz with a PWM period of 15 frames, at 120 fps, and that flickers. Badly. One way to mitigate that is to switch to PDM (pulse density modulation) which selects different length sequences to give the same duty cycle but at higher frequency, at least for some grey values. Slightly better, but there’s more that can be done.

The thing is, our brains do weird things with the visual signals we perceive. Regions with the same gray value, will be pulsating at the same time, and the eye will be drawn to it and perceive flickering. So, the next trick was to try to decouple nearby pixels in such regions using a LFSR sequence, which did give an noticeable improvement. The real aim was to try to play video through the LCD, so after investigating spatial dithering, [Wenting] moved over to wondering if he could also dither in time, i.e. can the error in the time sequence be smoothed out in a similar manner, to make the video look better? By using a simple noise-shaper, the video looked noticeably smoother, and practically flicker free. Great results! All in all, this is a long video to watch, but so crammed with useful tricks that it is in our opinion definitely worthy of your time.

We’re no strangers to driving retro displays with modern hardware, for example CRTs, and whilst we’re thinking about retro displays, how about this retro (and quite disturbing) touch-enabled CRT from the early ’80s?

This study did not show any significant difference in image quality between a standard 2-MP color LCD display and a medical-grade 2-MP monochrome LCD display, neither using the contrast-detail phantom nor in the visual grading study. Our findings are in accordance with several studies that have shown similar performances for color and monochrome displays in a variety of clinical tasks such as brain CT,,2 was acceptable provided that the ambient illuminance was low.

The main purpose of calibrating a monitor according to DICOM part 14 is to obtain similar image presentation on all displays. A calibration distributes the total contrast of the display equally across the entire grayscale and objects will thus be presented with the same contrast regardless of whether they are present in bright or dark parts of the image. When the task is to find known objects in an image, such as targets in a contrast-detail phantom, the window/level controls can be used to optimize image contrast. The display’s contrast characteristics becomes less important and the noise properties become more important—noise from the image detector and noise from the image display. However, this does not mean that calibrating a display is meaningless. Clinical images have little resemblance to images of a contrast-detail phantom in that pathology might be present also in the bright or dark parts of the image. A consistent display of images is even more important when, for example, a current image is compared to a previous image on another display. Any differences between the images should be caused by the imaged object and not by the displays.

The main advantage of medical-grade monochrome displays is their high luminance, which makes it easier to see the entire grayscale from black to white in an image. In a recent report,

The major drawback of color displays is their lower maximum luminance—143 cd/m2 in our study compared to 295 cd/m2 for the monochrome display. A low luminance has been stated to increase the time for diagnosis.

The tests with the contrast-detail phantom showed very small differences in image quality between the two types of displays. There was in fact a larger difference in image quality between the flat-panel detector and the storage phosphor plates (Fig. 2). It might thus be more appropriate to choose a better (more expensive) imaging system such as a flat-panel detector and use (cheaper) color displays than the opposite. Irrespective of the detector being used, there was a large interobserver variability, similar to what has been reported previously.2.

The higher ambient illuminance setting resulted in slightly poorer lesion detection on the 2-MP color display, but resulted in no difference with the 2-MP monochrome display. It is known that ambient illuminance should be low as ambient light elevates the black level of the display,

The visual grading study using clinical images showed significantly higher image quality for the 2-MP monochrome display for reproduction of pedicles and intervertebral joints; and lower for reproduction of spinous and transverse processes. Overall, there was no significant difference between the displays in the visual grading part of the study.

Free adjustment of window width and level was allowed in our study, as that is the way radiologists work in everyday practice. Windowing is easily performed by moving the computer mouse. If this type of image processing is not done, the full potential of digital imaging is not used. We consider image adjustment and manipulation to be a natural part in reading a digital image, and indeed a necessity to view all information in the image, and consequently a comparison between monochrome and color displays without the use of free adjustment of window and level was not included in this study. This is probably one reason why the 2-MP color display performed so well. All information in the image could be placed in the middle (gray) area of the contrast span where the two display types were almost equal. A drawback is that the user’s performance efficiency might be reduced.

To let all PACS stations in a radiology department have the capability to display all types of images, it is necessary to equip them with display units that are able to display also images with color information such as Doppler ultrasound, 3D volume rendered CT images, PET images, and SPECT images. It is costly to furnish an entire radiology department with the more expensive monochrome displays, and color displays might also, for economic reasons, be a better alternative. The new users of digital radiological image information, the clinicians, usually opt for color displays, which may be a conscious cost-saving decision or simply the effect of old habits.

The spatial resolution of the displays was not evaluated specifically in this study because the two displays used in the majority of tests had the same resolution. When used without magnification, the 3-MP monochrome display showed a trend toward higher image quality compared to the 2-MP color display. This is not surprising because the images were scaled to fit the display in that particular test. None of the displays managed to show all of the five megapixels that the test image consisted of, but the 3-MP display did show a larger proportion of the image information than the 2-MP displays.

Monochrome LCD display manufacturer, support full series of monochrome LCD screen customization, one-stop service, support various series of sample testing, support small batch trial production, fastest same-day delivery.

In this new age of technological advancements, the monochrome LCD display still plays a very important role in the computer business. Monochrome is a computer display system that only shows one color or two colors with several shades, to display information. Monochrome displays are usually found in terminals, and instruments using CRT or LCD technology. LCD displays are popular due to their low cost LCD technology, low power consumption, and ease of customization with minimal tooling costs. Vatronix is one of the companies that manufactures and produces Monochrome LCD displays.

The monochrome displays that they produce are made from high-quality materials, which ensures that they are durable and last a long time without defects. They also offer customization services of these Monochrome LCD displays to suit your preferences. All you have to do is place your order and clearly state your specifications and they will do it. Keeping these displays at optimum working conditions without servicing them increases the risk of having unscheduled downtime, hence the need for a one-stop service. This is guaranteed by Vatronix when you purchase these displays from them. It also prevents expensive repair work on equipment.

Vatronix offers a variety of sample testing programs for these displays to ensure they are working properly. This sample testing also ensures all displays are meeting the required standards before being used. They also support small batch trial production for displays offered by clients. This small batch production allows flexible production and gives room for the client to make necessary adjustments before they decide on large scale manufacturing. With Vatronix, you get fast-same day delivery for products ordered which ideally saves you a lot of time.

They currently have over 400 standard LCD modules that support customization, and below are some of the display modules they produce; PCB-TC2004A-SDBTSW. This is a dot matrix display LCD screen module, which is a standard screen displaying 4 lines and 20 letters per line. The TC1602C2-SDYFSG monochrome LCD panel is sized at 84.0mm by 44.0mm and it displays 2 lines of letters, 16 letters per line. It is available in black letters on emerald green background, white letters on blue background, blue letters on gay background and other colors. The KNY1602G-FUTFNF is a 1602 custom monochrome display screen. It displays 2 lines of letters and 16 words per line on a gray film and blue letters. The TS2023-ic2 is a Font LCD with an operating temperature range of -30 to +80 degrees Celsius. The storage temperature ranges from -40 to +85 degrees Celsius. It is usually used in automotive electronics, instrumentation, intelligent terminals, and open mold custom

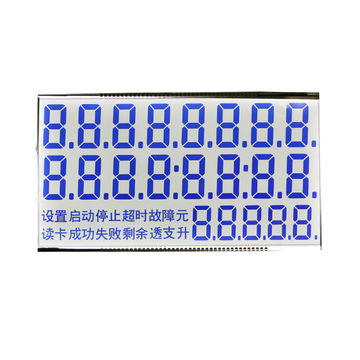

LCD displays. Of course, there is only one color for the backlight and one color for the characters, but as you can see here on the picture above, there could be many colors of backlights. We can have a white backlight, orange, green, blue or any backlight color.

It does not fit every display technology, positive and negative, but as you can see on the picture above, there is a vast number of combinations of different technologies, positive, negative, STN, FSTN or VA technology (Vertical Alignment), a little bit different technology, allowing us to have wide viewing angles, and different backlight colors. So, we can have a lot of different variations that can be used to build every application.

The last part of this article covers graphic displays and character displays, the difference between them and how it influences the cost of an LCD display. The most basic LCD displays are the segmented monochrome LCD displays or icon displays. In this kind of LCD displays we have only some icons and characters, but they are defined when the display is being produced. What we see on the display is defined and we cannot have anything else, the other area is completely off. You can only switch on and off the display segments. This is the cheapest technology to produce, and it is made by mask during the production, so it is usually reserved for high volume applications, that are very well defined during the production phase. For example, this can a be kind of watch, or calculator, or temperature controller. The advantage is the cost, but the disadvantage is that later we cannot change anything, we cannot change the software and add another icon.

Another type of a display is a graphic display. So, we have character displays and a fully graphic display. The character display is also a very popular technology, and it is a combination between a segment display and the graphic display because we have the fields, that are defined, and they can show only the characters, letters, numbers, symbols and some added characters defined by the controller of a display. On this kind of screen, we cannot put the full graphic, because every character is physically separated from the other.

Next, we have the fully graphic display. In this kind of LCD display we have a matrix of pixels. It could be 64 by 256, or 64 by 128 pixels, so on this kind of screen we can show almost every image, because we can switch every pixel on and off. We can show letters, characters, images, small, big, anything we want. The disadvantage is the vast number of pixels that we need to connect. The controller and the glass are complicated, because we need to route the wires from every pixel out from the glass and connect it to the controller. So, in the monochrome LCD display family, this kind of display is the most expensive. Other kinds of displays are cheaper, not only because the glass is simple, but because the controllers are simple too.

Whether you want one for nostalgia sake or because you need a monitor that"s compatible with your classic computer, a monochrome monitor could be what you"re looking for. Take a look on eBay for a wide variety of monochrome monitors.Which brands made monochrome monitors?

The first thing you will need to consider is your intended purposes. Some screens are intended for medical use while other screens are intended for use with a personal computer. Deciding if you want an LCD or CRT screen will be another factor. LCD screens create sharper images, but you can find used CRT screens at a lesser price. You will also want to consider what kind of computer you intend to hook it up to if you are buying for a personal computer. Also, check to see if it is refurbished, new, or used. Refurbished means that the monitor has been checked and anything that is broken has been fixed. If a monitor is labeled as "used," then it hasn"t been tested, so you"re taking more of a chance on how well it will work.What is the difference between LCD and CRT monitors?

LCD stands for "Liquid Crystal Display." It"s often used in laptops and flat-panel computer screens, and it produces clearer images than CRT screens. In an LCD screen, liquid crystals rotate polarized light to create the image. CRT stands for "Cathode Ray Tube." It was often used in computer monitors and televisions screens until the LCD and plasma screens replaced them. This type of screen creates images by sending electrons from the back of the tube to the phosphors at the front of the tube.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey