optically bonded lcd monitors quotation

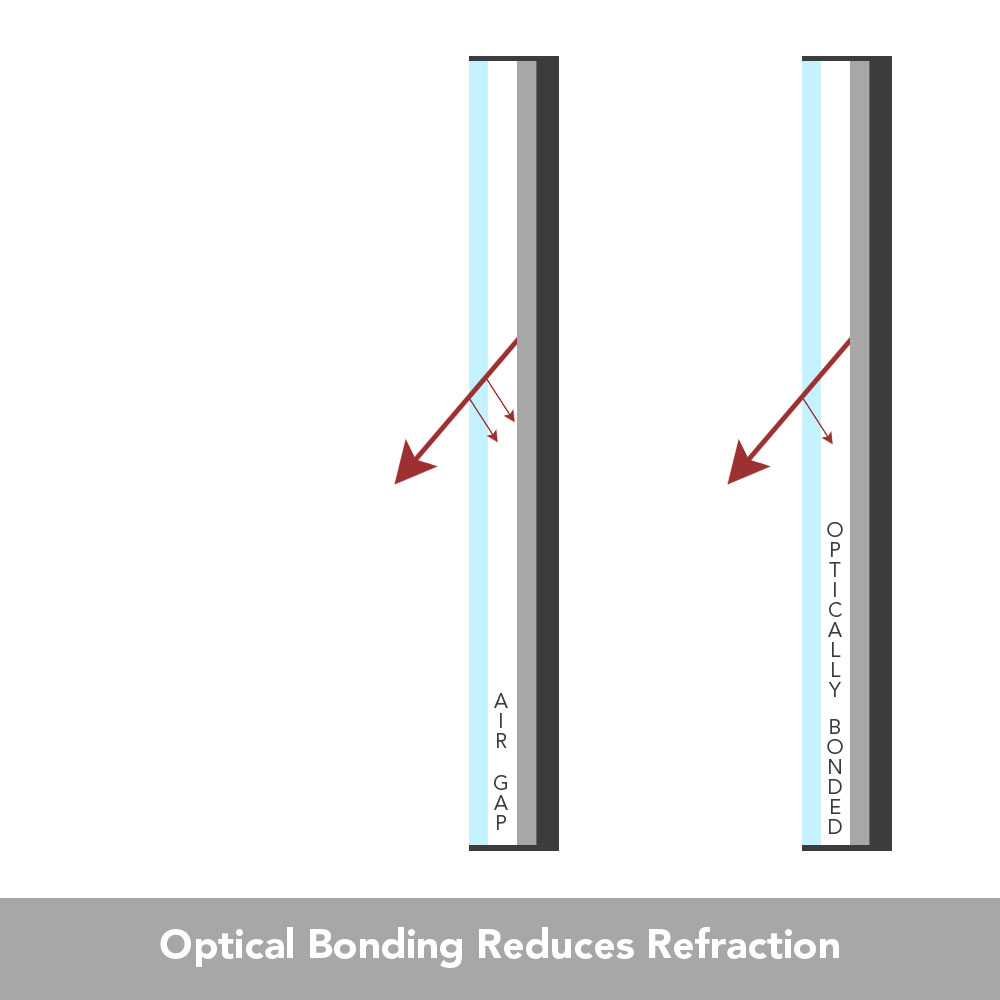

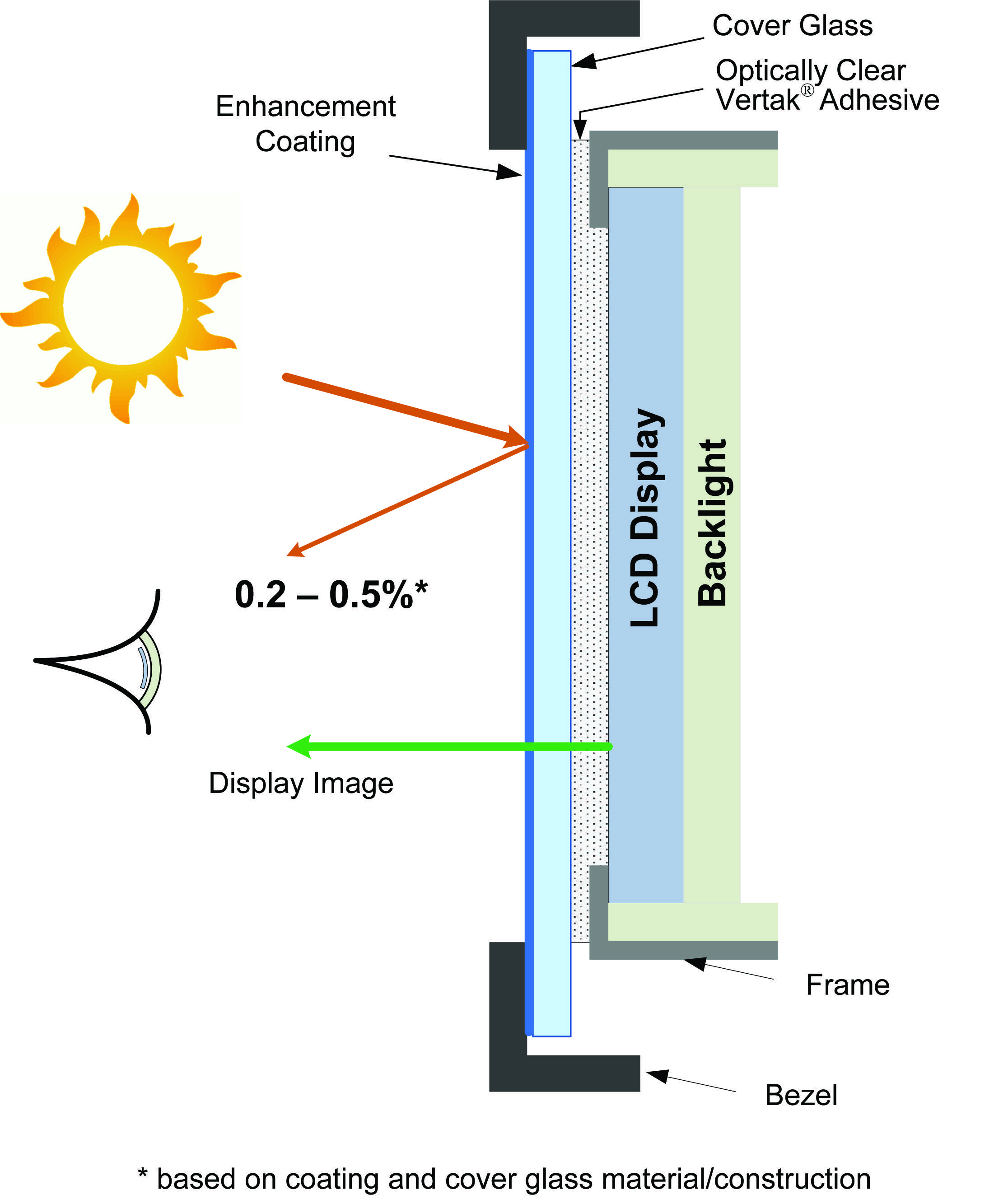

Optically bonding an LCD, OLED or Plasma display improves both optical performance and durability. By selecting an appropriate adhesive that matches the index of refraction of the flat panel and the overlay, General Digital is able to remove all of the air gaps, thus reducing the number of internal reflecting surfaces that can lead to degradation of optical performance. Providing a durable adhesion between the flat panel and the overlay improves the displays’ ability to resist shock, vibration and moisture.

On the practical side, the adhesive must also provide adequate bond strength, have a reasonable pot life after preparing, not present any health or safety issues, be available at reasonable cost from reliable sources, and cure to the proper finished bond condition using temperatures and times that are friendly to optical bonding facilities. Fortunately, there exist a relatively large number of choices. Typical bonded overlays include contrast enhancement filters, EMI/RFI filters, vandal shields, touch screens, and thermal heaters.

Bonded display assemblies mimic shatterproof glass. Although the bonded overlay can fracture from impact, the adhesive prevents/minimizes broken pieces from becoming airborne and endangering the operator and other nearby personnel.

The in-the-frame design is currently in limited production, primarily for avionic applications. The adhesive is epoxy, which was selected so that the bezel could be affixed to the display’s metal frame, with the bonded antireflective glass extending into the opening, reducing any issues of viewing angle and parallax to the display.

One drawback to the under-the-frame and in-the-frame bonds is that they are not suitable for making a liquid-proof seal to the bezel of the monitor. To accomplish this, monitor builders usually prefer to form a seal to the antireflective glass. In this case, an over-the-frame bond is necessary. This bond design is also required in the case of an optically bonded touch sensor. The details of the bond may vary slightly, depending on the nature of the overlay. However, in general, an appropriate gasket is placed onto the face of the OEM frame, forming a well-defined bond thickness and protecting the edge of the seal from abrasion.

It is, of course, possible to bond more than one overlay to the display. A specific example is the use of a conductive glass to control EMI, which is bonded to a touch sensor. As of this writing, General Digital Optical Bonding Laboratories has produced over 475 displays of this design for an aerospace application.

This bond design is the preferred over-the-frame bond. A gasket is applied between the LCD, OLED or Plasma display and the overlay and the space between them is then filled with adhesive.

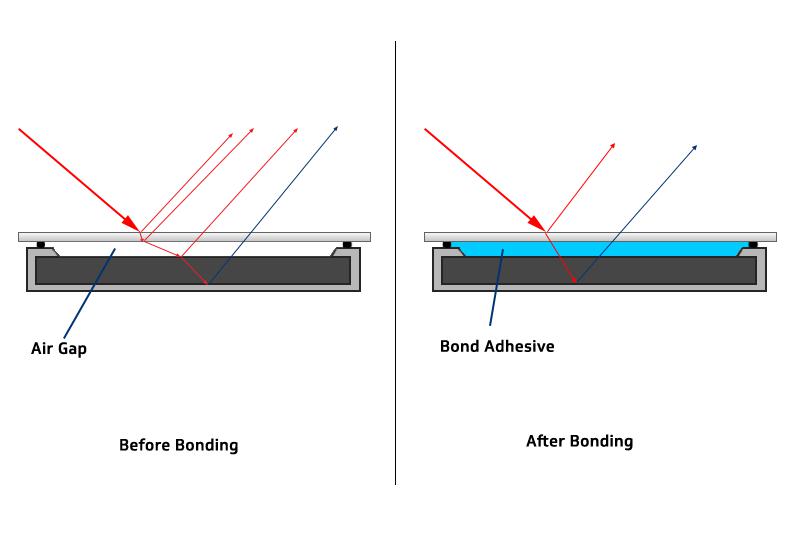

TFT LCD monitors are susceptible to glare and reflection from direct sunlight or high-bright applications. In almost all TFT LCDs there is an air gap between the TFT panel and the cover lens. Having an air gap causes repeat refraction between each component level of the display when in high-brightness installations. Reducing the reflection inside these components with optical bonding gives greater contrast and makes the screen more viewable in outdoor or high bright conditions without the need to increase the brightness of the screen itself.

Optical bonding is a process where a layer of resin is applied between the glass or touchscreen and TFT LCD TFT panel of a monitor, bonding them to make a solid laminate with no gaps or pockets of air. When choosing a screen for any project, you should evaluate the environment and operating conditions the screen will have to endure. Industrial grade screens and panel PCs are made rugged with all types of features available to withstand any type of application. One such feature available to consider is optical bonding.

When LCD displays are manufactured, including touchscreens, the front glass of the screen is layered onto the LCD module. This doesn’t present a problem in standard viewing environments, however in certain conditions, like with outdoor placement, the tiny gap between the 2 layers can impair viewing performance.

The display from an non-optically bonded monitor is created by the light of the LCD reflecting through the gap and then the outer glass of the screen. The light is interrupted and bends when it passes through the gap and glass of the screen and some of the light is actually reflected back to the LCD module, this is called refraction. This refraction through the layers impairs the intensity and clarity of the end image and thus lowers brightness and readability. By bonding the LCD module and glass together you remove the interruptions and chances for the light to be reflected back. More light gets through to the surface of the screen and therefore the image is brighter.

The same principle is applied when an external source of light hits the screen. With an non-bonded screen, the gap between the glass and LCD module creates opportunities for refraction which bounces external light back off the screen to the viewer as glare. When bonded together the light passes through the bonded layers and is absorbed somewhat into the screen. Optical bonding is therefore important in making screens sunlight readable.

The most obvious benefit to adding a resin bonding layer between the glass and LCD module is that it physically prevents dust and liquid ingress from getting between the two. The quality of manufacturing means that dust and water isn’t a big problem for screens in standard environments. What can be a problem however is condensation getting between the glass and LCD panel in environments with wide temperature ranges or fluctuating humidity. Condensation can cause screens to become foggy from moisture that penetrates the air gap. Again, the physical filling of the gap prevents this problem from arising. Optical bonding should therefore be considered for any outdoor application as well as indoor applications where consistent temperatures aren’t maintained.

Assured Systems are partnered with design and manufacturers industrial displays with optically bonded touch screens request, their displays or touchscreen displays can be optically bonded to remove the air gap inside the screen. If you require an optically bonded display or optically bonded panel PC please get in touch with Assured Systems.

The main advantage of optical bonding is the improved readability and contrast of the display, even under intense lighting conditions and wide viewing angles. This is accomplished by eliminating changes in index of refraction between the LCD, the front surface and air gap. The yellow arrows represent negative reflections that shrink your pulis and reduce perceived brightness and reduce actual contrast.

Since there is no gap between the LCD and front surface no foreign particles or condensation can occur in that gap. This is critical in outdoor environments where temperature can vary greatly causing condensation.

Most optical bonding adhesives are shock absorbing materials. Having a shock absorbing material between the LCD and front surface instead of air helps the front glass handle shock without breaking.

SRMOB-19U are 19″ sunlight readable LCD displays with the addition of Optical Bonding. They feature at least 1000 nits brightness! They are 4:3 aspect ratio. We design the SRMOB-19U 19″ 1000 nits displays for use in direct sunlight. Consequently, they are also perfect for other high ambient-light conditions. They utilize state-of-the-art LED backlights. The SRMOB-19B produce at least 1,000 nits brightness. In contrast, this is over 3 to 5 times brighter than standard monitors. For example, standard monitors are only 200-300 nits brightness. Therefore, the result is an amazingly bright screen. This will provide you with crystal-clear images, even with bright, direct sunlight on the face of the screen.

The SRMOB-19U 19″ sunlight readable LCD feature Anti-Reflective glass to protect the LCD panel. The glass also reduces unwanted surface reflections. However, the glass also introduces internal reflections. Therefore, TRU-Vu daylight readable monitors include Optical Bonding. This process injects an optical-grade resin into the air gap between the LCD panel and the glass, and completely fills the gap. The Optical Bonding eliminates the internal reflections and increases the contrast ratio, thereby greatly improving image quality. Optical Bonding also eliminates moisture and condensation beneath the glass.

These 19″ sunlight readable LCD are extremely rugged. For instance, we build them with true industrial-grade components. Furthermore, they receive our exclusive TRU-Tuff treatment. The TRU-Tuff process includes RTV silicone on all connections and critical components. Additionally, all wires are dressed, tie-wrapped and secured. Lastly, we apply ThreadLock to all screws. The rugged ABS enclosure ensures maximum shock and vibration resistance for this rugged 1000 nit monitor.

We design the SRMOB-19-U High Brightness Display Series to operate in nearly any environmental conditions. Whether in frigid conditions or blazing heat, these sunlight displays will survive and thrive. To clarify, these monitors will operate in temperatures down to -22°F (-30°C). They will also withstand brutal heat. Moreover, operating temperatures go up to 185°F (85°C). The rugged ABS enclosures assures these 19″high brightness displays will provide years of reliable imaging performance. Specifically, typical MTBF for these monitors is 50,000 hours.

Our 19″ sunlight readable LCD 1000 nit monitors have been deployed in a wide range of demanding industries. For example, military, law enforcement, aviation and entertainment benefit. They are also deployed in inspection, marine cranes, and transportation. TRU-Vu monitors are backed by our full 3-Year Warranty. This ensures you of many years of reliable service.

See our full line-up of industrial-grade Sunlight Readable and Daylight Readable. This highlights all of our high brightness monitors. Additionally, you’ll find the sunlight readable touch screens in all the sizes and configurations available. We offer over 540 models of touch screens and monitors. Use our Advanced Search Tool to help you hone down the choices. You may filter by features important to you. See all mid-sized monitors, or view only those monitors that operate on 24VDC.TRU-Vu can provide modified or Custom OEM LCD Displays. Private Label Monitors are also an option if you have very specific requirements.

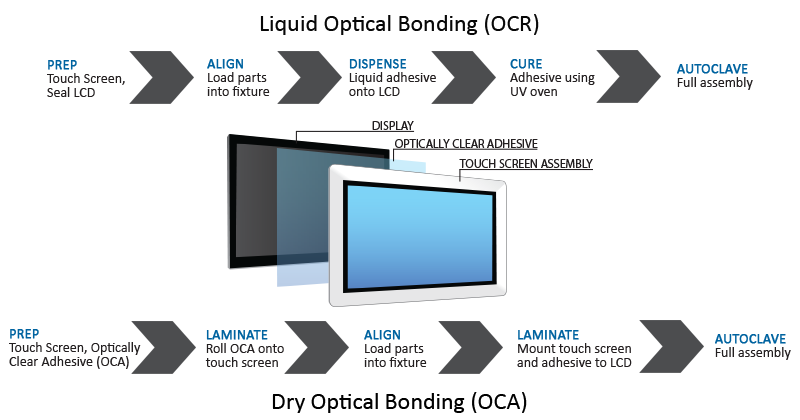

Displays and touch panels are at their best when they perform with highly transparent, low-haze, and UV-resistant features. Adding an optically clear adhesive to your LCD’s stack up promotes these features. Liquid optical bond can prove to be expensive. OCA bonding is considered a safe and effective alternative to the liquid optical bond method. Like liquid clear adhesives, OCA reduces the reflection layers in a panel. There are various advantages to choosing OCA bonding as your preferred integration method. OCA bonding is clean, which eliminates the need to clean up residuals after the bonding process is complete. The process produces high yield and is repairable.

OCA bonding is thin, making it an ideal choice for rigid bonding and small LCD frames. Our OCA adhesives are precisely adjusted to fit LCD panels 12” or smaller. The material is considered a dry film, its pressure-sensitive application allows for precise and unique processing in which it fits into your industrial LCD. Although thin, bonding protects the LCD against environmental factors as well as foreign contaminants and abrasive material. Applications include laminating films to rigid or flexible substrates; laminating together two rigid substrates; bonding touch panels and cover lenses; bonding displays to cover lenses or touch panels.

Our experienced team services each industrial panel model individually to diagnose cover glass irregularities. After ensuring repairability, our professional team uses an advanced optically clear adhesive to fuse the LCD and new cover glass, creating a blemish and scratch-free surface. Our advanced OCA prevents and protects end-user’s industrial panels from further damage due to natural wear and tear.

Lowered optical clarity due to increase in glare layers: the addition of a single piece of glass will create two additional reflective surfaces which trap glare, not only from ambient light but can even produce glare from the actual LCD. Adding an AR film does not match the level of clarity and visibility achieved with OCA bond.

Optical bonding is the process of adjoining the LCD and touchscreen or cover glass together to create a single optical index. Put simply, the air gap between the LCD and the cover glass is eliminated, therefore benefiting the LCD’s optical functionality and reducing the number of reflection points. Creating this singular optical index adds clarity and viewability to the display’s screen. Our bonding is performed with a proprietary adhesive, which is solidified with a quick but reliable curing method.

Why add an optical bond to your display? Besides creating a single optical index, there are other benefits to adding an optical bond to your LCD. Most LCDs have plastic surfaces that are not vandal or weatherproof. This component is called a cover lens. The material does not hold up well against scratches or damages, leaving your LCD with large vulnerabilities. To protect your LCD display, you will need to install a cover glass or other strengthened polycarbonate material to the LCD for protection. Adding this hardened substrate will require a bond. Adding an optical bond improves resistance against shock and vibration, which benefits those using their display in a volatile or rugged environment. Lastly, eliminating the gap prevents dust, moisture and condensation ingression, keeping your LCD readability and clarity at superior levels.

Our optical bonding service is the most robust ruggedized bonding service AGDisplays has to offer. Augmented optical performance including increased luminance, increased contrast, and reduced internal reflections. Optical bonding creates superior LCD strength and prevents a shattering screen and less vulnerable to contamination and moisture. Increase the quality and lifespan of your LCD while keeping replacement costs low with this service. AGDisplays is capable of low and high volume production. Full lamination may include outer substrates consisting of adhesive and elements such as mesh and other optical films.

Our optical bonding method is performed in-house by a skilled technician on any sized LCD. Each LCD is carefully handled throughout the technical process. Quality assurance measures and testing are performed on each LCD to guarantee your specifications are met. We strive to meet the needs of medical, military and other specialty markets and ensure that each product maintains high quality standards.

When optical bonding is not practical for your LCD, AGDisplays offers tape, or perimeter, bonding. Perimeter bonding helps your company save on costs while still ruggedizing your panels sufficiently. Our tape bond services provide a secure bond that increases productivity, long-term durability and improved appearance. The adhesive offers a wide temperature specification, allowing durable placement of the touch screen to the LCD in various environments.

Our technical experts use a class 1000 clean room to manually perform each bond with precision. Manufacturing yield for perimeter bond is high and is a cost-effective & common solution. AGDisplays offers tape perimeter touch screen and shield front perimeter bonding. Consult AGDisplays today to speak with a representative about which option is best for your project. AGDisplays supports virtually any manufacturer of LCD and touchscreen. For cover glass shield protection, AGDisplays can work with your requirements to offer products and glass materials to achieve your exact requirement.

Alibaba.com offers 233 optical bonding monitors products. such as return and replacement, call center and on-line technical support, and repair. You can also choose from led, lcd. As well as from new, stock, and open-box. And whether optical bonding monitors is for home and student, or industrial.

Optical bonding is a process where a layer of optical-grade resin is applied between the protective glass or touchscreen and LCD panel of the monitor. By bonding them together to make a solid laminate with no gaps or air pockets eliminates the internal reflections as well as internal moisture and/or condensation. A touch screen with optical bonding maintains a more accurate touch response because the pressure is maintained through the substrate, rather than being delayed by a gap.Optical bonding will strengthen the LCD display and make the monitor more rugged and durable. It will enhance the viewability of sunlight readable applications.

Our displays are available in small to very large quantities, bringing you high-quality LCDs with quick shipping at extremely competitive prices and low MOQs (minimum order quantities).

Now imagine we"re spraying high temperature water onto one of our industrial panel PCs. Thanks to the IP69K rating, the water will not penetrate the space between the screen and the bezel. However, without an optically bonded screen, air will be able to breach that space. If the surrounding air temperature is similarly high or even moderate, this moisture will eventually evaporate out the way it came in as water vapor. However, if the surrounding temperature is low enough, that water vapor will reconstitute as a liquid on the inside of the screen, which is also known as condensation. This same phenomenon can be observed in your car when it"s hot and humid outside, but cool in your car, which then causes your windshield to fog up on the inside.

The CPX1 -27 square rackmount LCD displays offer all the features you need for your harsh environment application. This extremely rugged, military-grade display is engineered to meet MIL-S-901E and MIL-STD-810G. The LCD is best in class offering revision controlled long product availability. It can be driven from multiple video sources including DVI-D, HDMI, DisplayPort or optionally 3G HD-SDI. It supports Picture-In-Picture or Picture-By-Picture to allow multiple video streams to be viewed at once. It is designed for the harshest of environments constructed off aircraft grade aluminum, optically bonded LCD cover glass and locking stainless steel hardware.

Display26.5″ Square LCD1920×1920 Resolution5mm Bonded Cover Glass StandardAnti-Reflective Coating on Cover GlassContrast Ratio: 1000: 1Brightness: 300 cd/m2Picture-in-Picture and Split Screen

Optical bonding refers to a protective adhesive layer, sandwiched in between the gap between the touchscreen and LCD to enhance its readability when installed in outdoor environments subject to drastic changes in temperature and humidity. When a normal display is used in an outdoor environment, in certain conditions, there are factors that affect its readability. The most common is condensation, which forms on the outer surface of the display, in the layer of air between the LCD and touchscreen. Another factor is the reflection of sunlight, which can cause a distorted image on the display – the air between the two causing repeated internal reflection of the light. Both phenomenon can be solved by using optical bonding.

Solisbond, Densitron"s optical bonding service, offers optically bonded engineered solutions created in our new class 10,000 clean room bonding facility. Solisbond optical bonding can be tailored to each specific display, cover lens and touchscreen combination. We will advise our customers on the design of the cover lens, helping with the selection of the right material, treatment and printing process. We can also manufacture the cover lenses to request and provide a suitable display and touchscreen combinations. Solisbond bonded displays can be customized to meet automotive, high humidity and marine standards (-30C to 85C). Environmental testing and tolerance analysis are for us an obvious standard. Documentation for the tests and calculations are of course also available.MechanismReflection loss is about 8% due to air gap

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey