microcontroller lcd display factory

There are a number of different kinds of displays that can be driven by a microcontroller. This repository contains examples for many of them, along with information about display technologies and some of the more popular libraries for controlling them.

Multi-Segment LED display - There are many models of multi-segment LED displays, including the classic 7-segment LEDs, alphanumeric displays, dot-matrix diplays, bar graph displays, RGB LEDs, and others. What these share in common is that they will have either a common-cathode or common-anode structure. Common cathode LEDs have multiple anodes, one for each LED segment, and one cathode for all. common anode LEDs have a single anode and multiple cathode for all the segments. Driving these displays requires a control pin for each LED segment. They are usually driven by a multiplexer or LED driver, which can provide both a common interface for all the LEDs (such as an SPI or I2C interface), and a controlled current supply for all the LEDs.

Broadcom/Avago’s HCMS-29xx display is multi-segment LED display that has several 5-7 LED matrices with a synchronous serial interface. It has the smallest visibly discrete LEDs in its display that I have encountered.

LCD - Liquid crystal display. LCDs are made up of long-chain molecules in a state between crystal and liquid. When a charge is applied, the molecules align, acting as a polarizer. When paired with a second polarizer, they can either block light or allow it to pass through, appearing either light or dark. A grid of these can form a single-color display. Liquid crystals do not emit light, so a backlight is required to light them up. They come im low-resolution, passive-matrix displays which are usually monochrome or higher-resolution, active-matrix screens which have higher resolution and are usually full color.

OLED - an OLED screen replaces the liquid crystal with a matrix of organic LEDs. This eliminates the need for a backlight, since each pixel generates its own light. For more on OLEDs, see this introduction from ehergy.gov. CNET provides this comparison of LCD vs OLED displays.

ePaper - ePaper displays use a matrix of tiny capsules which are black or colored on one side, and white on the other. Applying a charge to each capsule causes it to turn one way or the other. Unlike LCD or LED displays, ePaper displays maintain their state when powered off. ePaper displays cannot be refreshed as fast as LCD or LED, however. ePaper displays are typically not backlit, and require external lighting. eInk, the primary maker of ePaper displays, has a good FAQ on the technology. Visionect.com has a helpful illustrated explanation as well.

LCD and OLED screens drive their pixels in one of two ways. A passive matrix uses a grid of wires which control each pixel using a row-column scanning method. Voltage is applied to each column in sequence. Then the rows are scanned. If the pixel on that column at a given row should be on, then the row wire voltage is taken low to create a voltage difference, and the pixel turns on. An active matrix uses a grid of thin film transistors (TFT) instead of a row-column scanning apparatus. TFTs allow for greater pixel density and therefore sharper image quality and better response time for each pixel. Jameco offers a good explanation of passive vs. active matrix driver technology.

The oldest form of LCD display, patented in the 1980’s, is known as Twisted Nematic (TN) LCD, and has limits to its viewing angle. Newer LCD technologies such as in-plane switching (IPS) or plane-to-line switching (PLS) afford wider viewing angles and brighter screens.

There are a number of common display driver ICs on the market. Typically a driver IC will be capable of controlling many different sizes and shapes of display, if they are of the same class. For example, you’ll see many TFT displays that use Sitronix’ driver ICs, notably the ST7735 and ST7789. Ilitek’s ILI9225 chip is also common in TFTs. This means that libraries written for one vendor’s display are likely to work for displays from another vendor, if they use the same chipset. This can be convenient, as it means you can sometimes choose the library whose API you find easiest to work with.

Displays for microcontrollers use a variety of control interfaces. The most common are the ones you see for other electronic modules as well: synchronous serial interfaces like I2C and SPI, or asynchronous serial interfaces. also feature parallel interface, requires a large number of I/O pins from your controller.

BUSY - an output pin to indicate that the display controller is busy. connects to whicheve pin the microcontroller has assigned for this function. This pin is less common on TFT displays than on ePaper displays.

Hitachi HD44780 LCD display. See the Arduino LiquidCrystal library. These 2x16 character LCD displays are ubiquitous in the hobbyist market and come in many starter kits for the Uno. They are a passive-matrix LCD with a parallel interface (6 pins) that runs on 5 volts. They will typically not run on 3.3 volts. Each character is a 5x7 pixel matrix, so these are very low-resolution displays. They can usually be foung for $10-$15, which was a bargain in the early Arduino days. Nowadays, if you need an inexpensive 2-line display, some of the OLED displays like the SSD1306 are a better bargain.

There are some display modules which have an asynchronous serial (UART) interfaces. These typically have a microcontroller on the display module itself, which is interfacing with one of the types of interfaces above. These modules typically have a communications protocol that is unique to the vendor. They are convenient, but more expensive than their synchronous serial or parallel counterparts.

Finding the right display library for your Arduino or Arduino-compatible display can be challenging. Vendors who design and sell their own breakout boards tend to publish libraries that are compatible with their own boards. Smaller vendors may not make their own libraries, relying on third-party libraries instead. The Arduino site lists over 300 display-related libraries. The ease-of-use and adaptability of those libraries varies widely. The ones I’ve found most useful are Adafruit’s GFX library and Oli Kraus’ U8g2 library.

Since there is a relatively small number of driver chip manufacturers (Hitachi, Ilitek, Solomon-Systech, and Sitronix among them), different vendors’ boards often use the same driver hardware. This means that the libraries from one vendor can support the hardware from another. When you shop for displays, it’s worthwhile to check what the driver is for each one, and see if there’s a compatible library from your favorite library writer.

Adafruit_GFX is a hardware-independent graphics library written to work with all the Arduino-compatible displays that Adafruit sells. They complement this with display specific libraries like Adafruit_SSD1306 for SSD1306 OLED libraries, Adafruit_EPD for ePaper displays, Adafruit_ST7735 for some TFT libraries, and others. The advantage of the GFX library is that you get a common drawing API regardless of which display you’re using. It uses the Arduino Printable interface too, so commands like print() and println() work with this library just like they do in the serial monitor. There’s a good guide to the GFX library as well. Sparkfun’s got their own complement to the GFX library, Hyperdisplay.

u8g2 is designed as a universal library for many different displays. It supports a wider range of displays than any other I’ve used so far. It has its own graphics API which is more or less similar to Adafruit’s, and a wide font set as well. There’s also U8g2_for_Adafruit_GFX, a library which allows you to add U8g2 fonts to any Adafruit_GFX-based library.

Have you ever asked yourself what LCD is? No worries, we are here for you. Therefore, like in any display gadget, liquid crystal display coordinates with a microprocessor or microcontroller. The MCPU and MCU send the brightness that every pixel should produce. It creates the required color of the pixel for your LCD screen.

However, the mode of communication between the MPU/MCU and an LCD segment is known as the interface. We shall discuss more of the LCD interface in this guide.

The LCD interface is a link between the flat panel display module and the multimedia processor. Therefore, the interface can be separated or incorporated as part of the structure on the chip. Additionally, the application produces an image, and then the screen displays it using an LCD interface for the user.

Besides, the serial peripheral interface has another component known as the slave select (SS) or chip select. The function of the SS is to wake the peripheral to receive or send data. For instance, since the SPI can support several peripherals, the SS can wake particular peripherals instead of all. Finally, you can use the SPI in graphic, character, digit, and small TFT LCDs. It allows simple interfacing, affordable hardware, and faster speeds than in the SCI.

It is another serial interface in LCDs that resembles the SPI with slave, clock functions, and master. The I²C does not integrate the SS line as in SPI. Therefore, a process known as addressing is essential in selecting a slave to communicate. A frame of the signal is sent on the data bus to address a specific slave after the first bit. Nevertheless, the output signal gets to every slave connected with, although only the slave with the corresponding address to the signal will receive the message.

Additionally, in MCU parallel interface for Liquid Crystal Displays, data signals are sent through data lanes on either 18-bit, 16-bit, 9-bit, or 8-bit data channels. Besides, the MCU interface is simple, although it requires a display RAM for its memory functionality. Also, you can use it in graphic LCDs, character LCDs, and small TFT LCDs.

LVDS is an acronym for Low-Voltage Differential Signaling. This type of interface is essential as a complement for large LCDs and peripherals that require high bandwidth, such as HD graphics and fast frame rates. Therefore, it is a good choice due to its fast data transmission while consuming low voltage. One of the LVDS interface wires carries the precise inverse of its companion. Additionally, the electric charge from one wire is correctly masked by the other wire, reducing the interference to the wireless system nearby. Finally, at the recipient end, a circuit checks the variation in voltage between the two wires.

Red Green and Blue (RGB) interface functions are to link with color displays. It transmits 8 bits of data for each of the colors in every clock oscillation. Therefore, this means there are 24 bits of data sent for every clock oscillation.

Currently, you must have seen an improvement in terms of performance as electronic devices become smaller and easy to use. Therefore, this has led to the introduction of an embedded display port. The interface connects a video device to a display device and carries USB, audio, and other data forms. Moreover, this display port offers a high-performance external A/V interface hence high display resolutions of 4K. Additionally, the motive behind the development of this interface is due to several computing requirements. First of all, the main requirement is hardware integration.

This is a new technology development from the MIPI alliance. Mobile Industry Processor Interface has become a preferred option for mobile developers. This interface uses the same signaling as in LVDS. It uses a clock pair and 1-8 data lanes. Mobile Industry Processor Interface supports complex rules that allow low power and high-speed modes. Additionally, it reads data coming from the display at low rates.

When choosing the correct display interface for your device, you need to consider several factors. Therefore, it requires you to know how to connect the display to your electronic system. Nevertheless, it would be best if you choose the correct interface for your display. Additionally, consider the amount of data transferred and the refresh rate your system requires.

Finally, we have made it easier as we have given you all the details on each display interface, including the pros and cons. Therefore, having gone through our guide, you will never have issues when making your choice.

Microcontrollers (MCUs) have a few display options available. A Liquid Crystal Display (LCD) is a common, low-cost option that uses a backlight made of either cold-cathode fluorescent tubes (CCFL) or light emitting Diodes (LEDs). The term “LED display” actually refers to an LCD display with LED backlighting, and thus is the same thing as an “LCD Display.” Another display option is the Organic Light-Emitting Device (OLED), which emits light in a manner similar to LEDs and therefore does not require a separate backlight. An LCD has many more components than OLED displays, and for example might include a light guide panel and a diffuser to evenly disperse the light emitted from the backlight across the whole screen, liquid crystal shutters that switch the light on and off throughout the display, polarizing film and other components to drive the LCD shutters and reflect the backlight (although manufacturing components and techniques may vary).

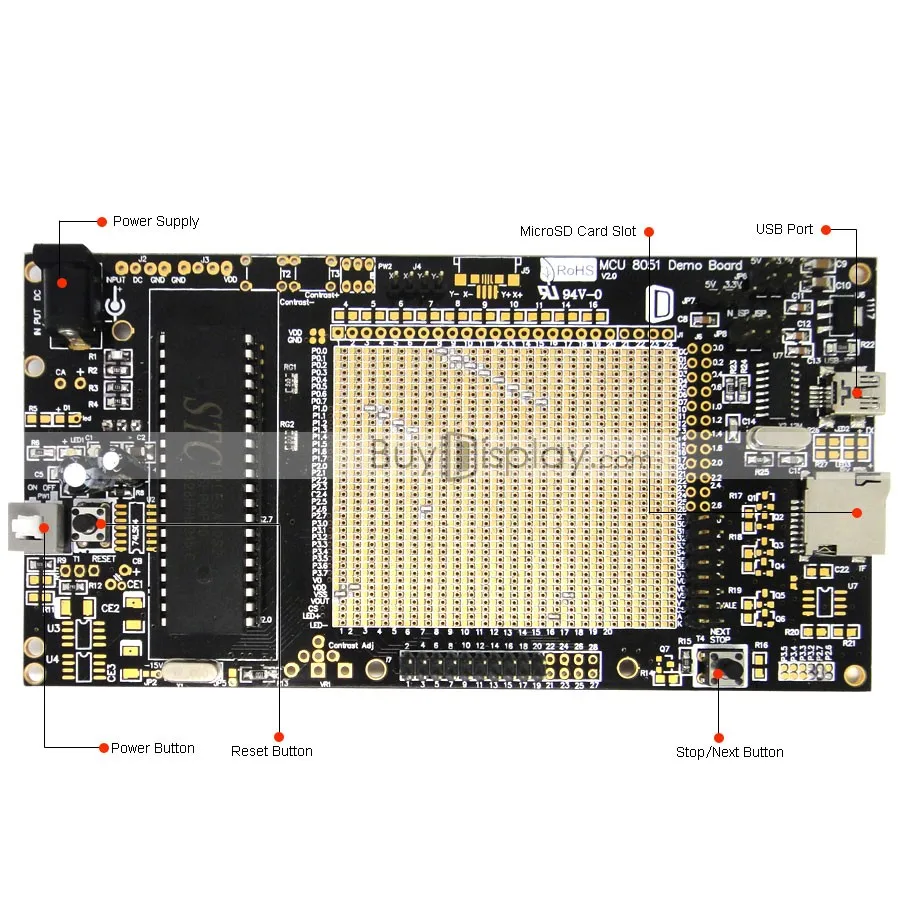

Many microcontrollers have built-in circuitry for display drivers so that the MCU can directly control the display or segments in a display. Controlling a display with an MCU is relatively easy if the display is a simple segment-driven (e.g., text-only), monochrome display. Several MCUs include a software library for operating LCD displays, which will be driver-specific. Find the software library that matches the hardware that drives the LCD display. Sometimes off-brand hardware display drivers will be compatible with other display drivers that are already in wide use so you can still use the software library for the compatible driver. Expect to use several pins for data and power for the backlight that should be included with a segment-driven display. According to the Arduino site, which offers LiquidCrystal software libraries, the Hitachi HD44780 driver has a 16-pin interface. Some MCUs use SPI or I2C to drive an LCD or OLED display. Small OLED displays have become fairly affordable and make sense if you have a strict power budget. See Table 1 for comparison of OLED and LCD to make the best choice for your design.

PROs: LCD displays are thicker and heavier than OLED displays and consume more power than OLEDs, due to the need for a backlight. OLEDs have self-emitting light and do not require backlights. However, OLED displays do not put out as much light as an LCD/LED display. (E.g., all things being equal, an OLEDdisplay as a flashlight is not as effective as your smartphone’s LED display screen in a dark room.) Without a backlight, OLED displays do not leak light when black areas are shown on the OLED display, unlike LCD displays. With OLED displays, each pixel that is set to black is going to be really black. OLEDs, being self-emitting light sources, are also controllable down to the pixel. LCD displays cannot control each pixel, but control in regions. OLED technology is newer than LCD and therefore more expensive, but prices are dropping as OLED technology matures. OLED has a superior viewing angle; the picture does not diminish as you view the screen to 80 degrees or more off center, whereas LCDs lose visibility at around 50 degrees.

CONs: OLED displays can lose their brightness over long-term use, but the technology is improving with time. It is also technically possible for OLEDs to suffer long-term image retention (also known as “burn-in,” an inaccurate term for OLEDs borrowed from CRTs) under extreme conditions. However, OLEDs do not use phosphor coating as CRTs did, so burn-in is not necessarily permanent. The potential for burn-in makes OLED displays used for digital signage a poor candidate, especially if the display image is extremely bright, high-contrast, and never varies (at the pixel level), or if the OLED display is not set up with some screen preservation features. LG claims that OLED TV screens come with built-in features to avoid burn-in, such as pixel-shifting an image, termed “Screen Shift” by LG, which “moves the screen slightly at regular intervals to preserve picture quality.” LG also claims that the quality of an OLED image can be preserved “by resetting the TV so it clears the pixels.”[i] Unlike CRTs, for which long-term image retention is permanent once it’s there (and monochromatic), OLED screens experience an erasable, multi-color long term image retention. Therefore, OLED “burn-in” isn’t the same kind of permanent burn-in that CRTs can experience. Long-term image retention on an OLED screen can be “erased” by playing varying content on the OLED screen for a while.[ii] DIY digital signage with a static image on an OLED display is not recommended, however. Major manufacturers like Samsung and LG offer OLED displays for digital signage but include features to avoid long-term image retention.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey