lcd touch screen not responding made in china

The touch controller chip is a "Synapdcs" [sic] 5500CB-5 with additional markings FCA6616 (I might have some of the numbers wrong, the silkscreening is very poor quality):

Based on the advice here I reflashed entirely back to a factory 4.2.2 image via fastboot, erasing absolutely everything, and the touchscreen worked. Yay!

I didn"t want to be stuck on 4.2 so I figured I"d try to fix the driver. So I installed CM 10.1.3 (Android 4.2 based), which according to the other forum post didn"t work (but 10.1.2 worked). The touchscreen worked. Installed CM 10.2 (Android 4.3 based) and the touchscreen kept working.

Hard power cycled the phone a few times, including unplugging from USB. Touchscreen still works. Issued a Factory Wipe/Erase User Data from Recovery mode, touchscreen still works.

The touchscreen driver includes firmware upgrade code, and it seems the firmware is stored internally on the driver chip rather than loaded from the kernel each time the phone boots. My theory is that downgrading to 4.2.2 and then upgrading through the various versions somehow created a working firmware upgrade path for the controller!

To test this theory - if anyone else downgraded to 4.2.2 to get a working touchscreen, can you try upgrading and see if it stays working? I don"t know if you can upgrade directly to 5.1 or if the interim steps I went through somehow helped as well - maybe try 5.1 first and if it fails then roll back again and try step-by-step.

Finally, to help debug here"s some debug output from the touchscreen kernel driver via "adb shell". That"s under 5.1 with a working touchscreen. I didn"t get output under any other versions. :(

We"ve all been there. Tapping, swiping or zoom-pinching, there"s often a moment when the touchscreen display on your tablet refuses to respond. How do you overcome this, and achieve tablet-tapping Zen?

As the primary mode of interaction between you and your apps, the tablet touchscreen is vitally important. Any damage inflicted – knocks to the device, scratches or worse – will degrade the touchscreen. Short of paying for a replacement, you will need to make sure the display is kept safe and intact.

The following tips – also suitable for smartphones – will help you resolve your tablet"s touchscreen responsiveness issues. We"ve designed this guide for all touchscreen tablet computers. So, if your Android tablet touchscreen is not working, or your device uses iOS, or Windows, the answers you need are right here.

Perhaps the best place to start in troubleshooting screen responsiveness issues is to make more system RAM available. This may take a moment but should give you an idea of how bad the problem is.

If your Microsoft Surface touchscreen is not working, or you use a different Windows 10 tablet, close as many desktop apps as is practical can before switching to the Start screen. Then:

Restarting a tablet isn"t a case of just tapping the power button to turn the screen off. Instead, the whole device must be switched off and back on again.

After all, how do you fix an unresponsive touchscreen when most of your options are accessible through the screen? The answer is surprisingly simple: connect a mouse.

Knowing which area(s) of the touchscreen are failing to respond correctly can be useful in diagnosing what is wrong. This information would prove useful to any engineer who ends up repairing the tablet.

On Android, free calibration and testing apps are available. Touch Screen Test is a good app that helps you find specific areas where input is not detected.

For devices that are in warranty, this means contacting the manufacturer and arranging a return, or dropping into a store. iPads, for example, can be taken to Apple Stores; Samsung tablets can similarly be taken to Samsung stores. In some cases, doorstep repairs are possible, where the device is repaired in a mobile Samsung-approved workshop parked outside your home. If your Samsung tablet touchscreen is not working, this fast-repair option might be available.

Whether you"re using a Samsung, LG, iPad, or your Lenovo tablet touch screen is not working, check your device manufacturer"s support pages to find the correct steps to arrange repair. Make it clear what steps you have attempted to resolve the touchscreen issues.

As noted above, if your tablet screen is cracked, it can impact touch reliability. Whether big or small, a cracked tablet screen will always fail eventually. Having your tablet looked at by an engineer under warranty is the smart option but isn"t always possible. If your tablet is out of warranty and the screen is cracked, you have two options:

Wondering how to repair a tablet touch screen yourself? For cheaper tablet models repair makes more sense than with premium brands. So, if you have a Vankyo, Onn, Yosatoo, Contixo, or Amazon Fire tablet with a screen that is not working or responding to touch, consider replacing the display yourself. Our guide to replacing a cracked Amazon Fire tablet display will help here.

Most problems can be avoided with care, a screen protector, and a case for your tablet. But where possible, avoid water and don"t get your tablet wet.

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

In Windows, search for and open View pen and touch info. If the Pen and touch section reads No pen or touch input is available for this display, the computer does not have a touch screen.

Right-click the HID-compliant touch screen device, and then click Enable, if possible. If the Enable option is not available, continue to the next step.

To provide you more detailed instruction, you can also click ASUS Youtube video link below to know more about Troubleshooting for No display on LCD Monitor

Check if the signal cable (VGA / DVI / HDMI / DisplayPort) is wellconnected , and confirmed another end of the output cable has been firmly connected to computer input port (graphics card). Unplug and plug 2-terminals again to ensure all pins aren"t bent.

Check if the signal cable (VGA / DVI / HDMI / DisplayPort) is wellconnected and confirmed another end of the output cable has been firmly connected to computer input port (graphics card). Unplug and plug 2-terminals again to ensure all the pins aren"t bent.

If the model had attached with the power supply (AC-adapter), make sure the power supply has connected to the screen. Please check if the light of power supply is ON. If the light is NOT ON, change another power supply to test.

Are there any regional differences inpower specifications thatASUS LCD monitor supported (for example: If monitor was bought in Taiwan, can it be used in China or other countries?)

ASUS LCD monitor can support power specification: AC 100-240V. As long as within this voltage range, the display can work properly. However, please be noted that if you bought a monitor from another region, the power cord is not necessarily compatible to power outlet. Customer should replace the appropriate power cord or plug adapter in order to ensure normal power supply of the display.

Touch panel technologies are a key theme in current digital devices, including smartphones, slate devices like the iPad, the screens on the backs of digital cameras, the Nintendo DS, and Windows 7 devices. The term touch panel encompasses various technologies for sensing the touch of a finger or stylus. In this session, we"ll look at basic touch panel sensing methods and introduce the characteristics and optimal applications of each.

Note: Below is the translation from the Japanese of the ITmedia article "How Can a Screen Sense Touch? A Basic Understanding of Touch Panels"published September 27, 2010. Copyright 2011 ITmedia Inc. All Rights Reserved.

A touch panel is a piece of equipment that lets users interact with a computer by touching the screen directly. Incorporating features into the monitor like sensors that detect touch actions makes it possible to issue instructions to a computer by having it sense the position of a finger or stylus. Essentially, it becomes a device fusing the two functions of display and input.

It"s perhaps not something we think of often, but touch panels have integrated themselves into every aspect of our lives. People who enjoy using digital devices like smartphones interact with touch panels all the time in everyday life—but so do others, at devices like bank ATMs, ticket vending machines in railway stations, electronic kiosks inside convenience stores, digital photo printers at mass merchandisers, library information terminals, photocopiers, and car navigation systems.

A major factor driving the spread of touch panels is the benefits they offer in the way of intuitive operation. Since they can be used for input through direct contact with icons and buttons, they"re easy to understand and easily used, even by people unaccustomed to using computers. Touch panels also contribute to miniaturization and simplification of devices by combining display and input into a single piece of equipment. Since touch panel buttons are software, not hardware, their interfaces are easily changed through software.

While a touch panel requires a wide range of characteristics, including display visibility above all, along with precision in position sensing, rapid response to input, durability, and installation costs, their characteristics differ greatly depending on the methods used to sense touch input. Some typical touch-panel sensing methods are discussed below.

As of 2010, resistive film represented the most widely used sensing method in the touch panel market. Touch panels based on this method are called pressure-sensitive or analog-resistive film touch panels. In addition to standalone LCD monitors, this technology is used in a wide range of small to mid-sized devices, including smartphones, mobile phones, PDAs, car navigation systems, and the Nintendo DS.

With this method, the position on screen contacted by a finger, stylus, or other object is detected using changes in pressure. The monitor features a simple internal structure: a glass screen and a film screen separated by a narrow gap, each with a transparent electrode film (electrode layer) attached. Pressing the surface of the screen presses the electrodes in the film and the glass to come into contact, resulting in the flow of electrical current. The point of contact is identified by detecting this change in voltage.

The advantages of this system include the low-cost manufacture, thanks to its simple structure. The system also uses less electricity than other methods, and the resulting configurations are strongly resistant to dust and water since the surface is covered in film. Since input involves pressure applied to the film, it can be used for input not just with bare fingers, but even when wearing gloves or using a stylus. These screens can also be used to input handwritten text.

Drawbacks include lower light transmittance (reduced display quality) due to the film and two electrode layers; relatively lower durability and shock resistance; and reduced precision of detection with larger screen sizes. (Precision can be maintained in other ways—for example, splitting the screen into multiple areas for detection.)

Capacitive touch panels represent the second most widely used sensing method after resistive film touch panels. Corresponding to the terms used for the above analog resistive touch panels, these also are called analog capacitive touch panels. Aside from standalone LCD monitors, these are often used in the same devices with resistive film touch panels, such as smartphones and mobile phones.

With this method, the point at which the touch occurs is identified using sensors to sense minor changes in electrical current generated by contact with a finger or changes in electrostatic capacity (load). Since the sensors react to the static electrical capacity of the human body when a finger approaches the screen, they also can be operated in a manner similar to moving a pointer within an area touched on screen.

Two types of touch panels use this method: surface capacitive touch panels and projective capacitive touch panels. The internal structures differ between the two types.

Surface capacitive touch panels are often used in relatively large panels. Inside these panels, a transparent electrode film (electrode layer) is placed atop a glass substrate, covered by a protective cover. Electric voltage is applied to electrodes positioned in the four corners of the glass substrate, generating a uniform low-voltage electrical field across the entire panel. The coordinates of the position at which the finger touches the screen are identified by measuring the resulting changes in electrostatic capacity at the four corners of the panel.

While this type of capacitive touch panel has a simpler structure than a projected capacitive touch panel and for this reason offers lower cost, it is structurally difficult to detect contact at two or more points at the same time (multi-touch).

Projected capacitive touch panels are often used for smaller screen sizes than surface capacitive touch panels. They"ve attracted significant attention in mobile devices. The iPhone, iPod Touch, and iPad use this method to achieve high-precision multi-touch functionality and high response speed.

The internal structure of these touch panels consists of a substrate incorporating an IC chip for processing computations, over which is a layer of numerous transparent electrodes is positioned in specific patterns. The surface is covered with an insulating glass or plastic cover. When a finger approaches the surface, electrostatic capacity among multiple electrodes changes simultaneously, and the position were contact occurs can be identified precisely by measuring the ratios between these electrical currents.

A unique characteristic of a projected capacitive touch panel is the fact that the large number of electrodes enables accurate detection of contact at multiple points (multi-touch). However, the projected capacitive touch panels featuring indium-tin-oxide (ITO) found in smartphones and similar devices are poorly suited for use in large screens, since increased screen size results in increased resistance (i.e., slower transmission of electrical current), increasing the amount of error and noise in detecting the points touched.

Larger touch panels use center-wire projected capacitive touch panels in which very thin electrical wires are laid out in a grid as a transparent electrode layer. While lower resistance makes center-wire projected capacitive touch panels highly sensitive, they are less suited to mass production than ITO etching.

Above, we"ve summarized the differences between the two types of capacitive touch panels. The overall characteristics of such panels include the fact that unlike resistive film touch panels, they do not respond to touch by clothing or standard styli. They feature strong resistance to dust and water drops and high durability and scratch resistance. In addition, their light transmittance is higher, as compared to resistive film touch panels.

On the other hand, these touch panels require either a finger or a special stylus. They cannot be operated while wearing gloves, and they are susceptible to the effects of nearby metal structures.

Surface acoustic wave (SAW) touch panels were developed mainly to address the drawbacks of low light transmittance in resistive film touch panels—that is, to achieve bright touch panels with high levels of visibility. These are also called surface wave or acoustic wave touch panels. Aside from standalone LCD monitors, these are widely used in public spaces, in devices like point-of-sale terminals, ATMs, and electronic kiosks.

These panels detect the screen position where contact occurs with a finger or other object using the attenuation in ultrasound elastic waves on the surface. The internal structure of these panels is designed so that multiple piezoelectric transducers arranged in the corners of a glass substrate transmit ultrasound surface elastic waves as vibrations in the panel surface, which are received by transducers installed opposite the transmitting ones. When the screen is touched, ultrasound waves are absorbed and attenuated by the finger or other object. The location is identified by detecting these changes. Naturally, the user does not feel these vibrations when touching the screen. These panels offer high ease of use.

The strengths of this type of touch panel include high light transmittance and superior visibility, since the structure requires no film or transparent electrodes on the screen. Additionally, the surface glass provides better durability and scratch resistance than a capacitive touch panel. Another advantage is that even if the surface does somehow become scratched, the panel remains sensitive to touch. (On a capacitive touch panel, surface scratches can sometimes interrupt signals.) Structurally, this type of panel ensures high stability and long service life, free of changes over time or deviations in position.

All in all, however, these touch panels offer relatively few drawbacks. Recent developments such as improvements in manufacturing technology are also improving their cost-performance.

The category of optical touch panels includes multiple sensing methods. The number of products employing infrared optical imaging touch panels based on infrared image sensors to sense position through triangulation has grown in recent years, chiefly among larger panels.

A touch panel in this category features one infrared LED each at the left and right ends of the top of the panel, along with an image sensor (camera). Retroreflective tape that reflects incident light along the axis of incidence is affixed along the remaining left, right, and bottom sides. When a finger or other object touches the screen, the image sensor captures the shadows formed when the infrared light is blocked. The coordinates of the location of contact are derived by triangulation.

While this type differs somewhat from the above touch panels, let"s touch on the subject of electromagnetic induction touch panels. This method is used in devices like LCD graphics tablets, tablet PCs, and purikura photo sticker booths.

This input method for graphics tablets, which originally did not feature monitors, achieves high-precision touch panels by combining a sensor with the LCD panel. When the user touches the screen with a special-purpose stylus that generates a magnetic field, sensors on the panel receive the electromagnetic energy and use it to sense the position of the pen.

Since a special-purpose stylus is used for input, input using a finger or a general-purpose stylus is not possible, and the method has limited applications. Still, this has both good and bad points. It eliminates input errors due to the surrounding environment or unintended screen manipulation. Since the technology was intended for use in graphics tablets, it offers superior sensor precision—making it possible, for example, to change line width smoothly by precisely sensing the pressure with which the stylus is pressed against the screen (electrostatic capacity). This design approach also gives the screen high light transmittance and durability.

The table below summarizes the characteristics of the touch panels we"ve looked at. Keep in mind that even in devices based on the same sensing method, performance and functions can vary widely in the actual products. Use this information only as an introduction to general product characteristics. Additionally, given daily advances in touch-panel technological innovations and cost reductions, the information below is only a snapshot of current trends as of September 2010.

Each touch-panel type offers its own strengths and weaknesses. No single sensing method currently offers overwhelming superiority in all aspects. Choose a product after considering the intended use and environmental factors.

Among every other component of the phone, the screen is indispensable. Of course, you scroll through Facebook, play games, send texts, etc. Basically, you can"t do anything on your phone without touching the screen if you don"t rely on an external mouse. For this course, it"s very painful when the touch screen is not working. As a professional smartphone repair company, we"ve put up some reasons why this problem persists and how to fix the touch screen not working on the phone, so you can continue enjoying your smartphone.

Applying a screen protector can help protect the device from accidental drops or scratches. However, the same glass acting as a protector can also lead to the “touch screen not working” problem by hindering touches from getting to the sensor.

If your phone screen is unresponsive before, probably before attaching a screen protector, try to remove the screen protector and check if the screen responds to touches.

In this case, restarting the device can guarantee a fix if the phone screen not working problem is caused by software hitches. Of course, restarting your device is what you should do occasionally as it helps refresh the memory and helps fix some software related issues.

But how do you do it when the touch screen is not working? It"s is simple, just hold down the power button for a while - usually 8-10 seconds - to reboot your phone.

Is your screen broken? If yes, that"s probably the root of the problem. Before nailing this problem to a software problem, try looking into the screen if there is a crack somewhere or it"s broken. Though the screen might still be working for a few days, or even months if it"s broken. But it"s open to different sorts of damages upon liquid contact to the surface.

As the name implies, the developer options contain features that are still in development, mainly for app developers and some users who like to test them. This feature is usually hidden until enabled by users. It may also cause the phone screen not to work if you enabled a wrong or incompatible settings from the developer options.

To fix this, kindly disable it from Settings >> System >> Developer options (or Settings >> Developer options on some devices) if your screen still responds to touches. If not so, try connecting a wired mouse to your device with an OTG adapter.

Booting a smartphone in Safe mode starts it without any third-party app. This is worth giving a try and can help fix the problem if the touch screen stopped working due to a third-party app.

Note: If you use a TECNO or INFINIX device, press and hold the HiOS(or XOS) in the power menu until you see the option to reboot to safe mode and click accept.

When you"re in Safe mode, try checking if the touch screen works flawlessly. If it does, that means the problem is caused by a third-party app. Try to uninstall corrupted apps, probably the ones you recently installed before the incident, to fix the problem.

A water accident or even moisture can damage the internal part of the device which leads to mobile touch problem. If you mistakenly drop your device into a pool or just a little water split on it, kindly eject all peripherals and turn off the device to let it dry up. You may also put the phone inside a bowl of rice to let it dry completely. Now turn on the phone to check if the touch screen works perfectly or visit a service center.

Hopefully, the above fixes should get your touch screen working again if it"s just a minor/software problem. If not, the last thing you would want to try is getting a technician to fix it for you.

If your android phone touch is still not working after trying these fixes, you"re already in the right place. Carlcare is the only authorized service provider for TECNO, Infinix, and itel smartphone. We have competent technicians who can help you fix the touch screen not working on the phone. All you have to do is just book an online appointment with us and proceed to the nearest Carlcare service center to get your phone repaired.

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

The third example is a game. Actually it’s a replica of the popular Flappy Bird game for smartphones. We can play the game using the push button or even using the touch screen itself.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Next is the distance sensor button. First we need to set the color and then using the fillRoundRect() function we will draw the rounded rectangle. Then we will set the color back to white and using the drawRoundRect() function we will draw another rounded rectangle on top of the previous one, but this one will be without a fill so the overall appearance of the button looks like it has a frame. On top of the button we will print the text using the big font and the same background color as the fill of the button. The same procedure goes for the two other buttons.

Now we need to make the buttons functional so that when we press them they would send us to the appropriate example. In the setup section we set the character ‘0’ to the currentPage variable, which will indicate that we are at the home screen. So if that’s true, and if we press on the screen this if statement would become true and using these lines here we will get the X and Y coordinates where the screen has been pressed. If that’s the area that covers the first button we will call the drawDistanceSensor() custom function which will activate the distance sensor example. Also we will set the character ‘1’ to the variable currentPage which will indicate that we are at the first example. The drawFrame() custom function is used for highlighting the button when it’s pressed. The same procedure goes for the two other buttons.

So the drawDistanceSensor() custom function needs to be called only once when the button is pressed in order to draw all the graphics of this example in similar way as we described for the home screen. However, the getDistance() custom function needs to be called repeatedly in order to print the latest results of the distance measured by the sensor.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

Have you ever met the iPhone X series aftermarket screen touch issues? These issues include flicking screen, unresponsive screen, ghost touch, etc. Customers complained that the iPhone LCD and OLED screens purchased from China were probably meeting these touching problems. Well, the iPhone aftermarket screen touch issues occur for many reasons, some of which can be solved with simple repair tools. Here Etrade Supply comes up with some normal touching problems and explains why these touching issues happened on iPhone aftermarket screens to you. Also, we will share you tips on how to avoid these issues. Let’s check it below.

Common iPhone aftermarket screen touch issues are flickering screen, full screen unresponsive or partly screen unresponsive, and ghost touch. The flickering screen is the phenomenon that when we turn on the phone after the new screen replaced, the screen keeps flickering with unstable brightness. Flickering screen not only happens on iPhone X series aftermarket screen but also on other iPhone model screens. We will explain why this happens in the next paragraph. The unresponsive screen or partly unresponsive screen is the screen quality problem. It is unrepairable, technically speaking. Any new replaced iPhone screen with these problems will need a second repair. Ghost touch means the irregular automatic response on the screen without touching. This happens on some newly replaced screen occasionally.

These touch issues happen a few days after the new screen replacement. Simple new screen flickering problem occurs because of the bad quality screen or systematic reason, and some of which can be solved on Settings. As to the unresponsive touch issue, the reasons are complex. Some of the new replaced screens cannot touch at all. It may be the problem of the improper screen flex cable connection or the broken screen flex cables. We need to tear down the new screen again and check the flex cables, reconnect the cables or fix the broken flex and reassemble the screen so that it would go back to normal. Partly unresponsive screen is the problem of the screen quality, you need to replace another new screen. Ghost touch issues are complex. Exclude the possibility of the reasons for ESD or improper installation, we may assume the reason for the hardware and software problem of the screen. Most aftermarket iPhone screens from China are manufactured in factories of the mainland, while the touch IC, which is the core part of the iPhone screen is supported by leading companies like Samsung or Taiwan Semiconductor. Most of the aftermarket iPhone X screens and replacement parts from China cannot meet the standard of the touch IC. This will lead to the consequence of the screen touch issue. On the other hand, the software on the aftermarket iPhone X screens is insufficient to computing the larger new iPhone drive IC software volume. That will also cause the problem of screen touch failure.

As we mentioned, the simple touch unresponsiveness issue can be solved by rechecking the screen flex connectors. As to the complex touch issue like ghost touch, these aftermarket iPhone screens are unrepairable. Customers who faced this problem should contact the store or supplier at the first time. Still, there are tips we should keep in mind during the iPhone X teardown and touch screen replacement. Touch a metal object or anti-static wrist strap beforehand to reduce the electric static damage to the iPhone parts. Also, remember to disconnect the battery connector at first when teardown the screen. Moreover, the QC procedure should be improved and strengthened for the third-party manufacturers and suppliers in China. Careless QC may decrease the qualification rate of the products.

At last, we suggest our customers choose the high-quality level iPhone aftermarket screens and parts for repair. A third-party supplier with a good reputation will make sure their best QC on their products. The simple flicking screen issue can be solved by checking the flex and reconnecting the flex cables while the unresponsive screen or ghost touch issue is complex. Etrade Supply recommends our high-quality level iPhone X LCD screen and digitizer for wholesale here. All our LCD screen and other iPhone small parts are 100% tested before packaging. Customers have no worries about after-sale issues or any quality problems. You may leave comments below or contact us if you have any questions about our iPhone parts. We are glad to help you.

Okay, so after almost 2 years with my lovely OPO, I managed to break it"s screen. The creen itself works, it"s just not responding to touch in any part of the screen. Everything else works just fine. I already oredered OnePlus 3, but that"s gonna take some time to arrive in current situation as I live in Europe.

2) I order a new screen from some chinese website which I know doesn"t sell original screens because noone does, risk throwing away 35$ + 20% tax and attempt to repair my broken screen

Learn How to Fix if Mobile Phone Touch Screen Not Working (Unresponsive PDA). You can Fix any Not Working Touch Screen of any Brand – Android and iPhone. These problem and solution apply to all brands and make of mobile phones including Nokia, Samsung, iPhone, China Mobile Phones, Motorola, HTC, Sony, Blackberry, Alcatel, Apple, AudioVox, Benefone, Danger, FIC, Hagenuk, Palm, Kyocera, LG, Panasonic, Huawei, ZTE, Spice, Lava, Sony Ericsson, Micromax etc.

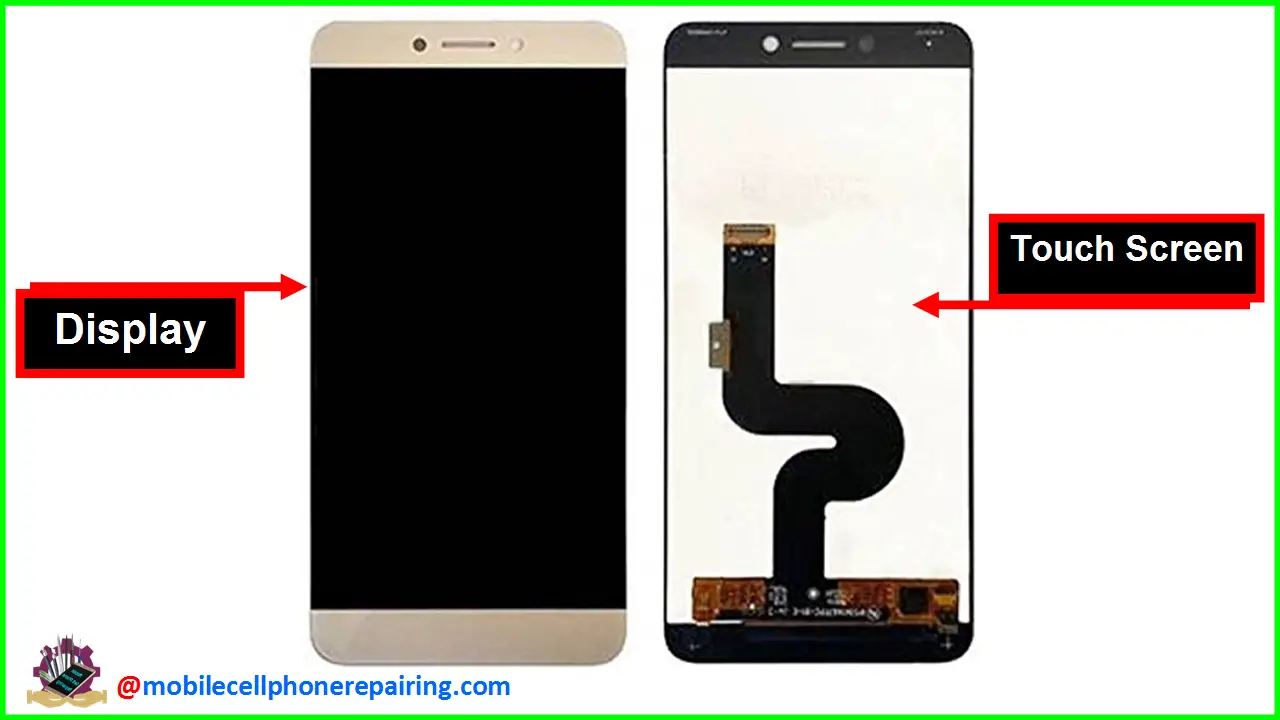

Touch Screen or PDA is a mobile cell phone part that helps to operate a mobile phone by touching the screen. Touch Screen is available in different sizes. It normally has 4 Points namely: – (+), (–), (RX), (TX). Touch Screen is also called PDA. It is controlled by the CPU. In some Mobile Phones there is an Interface IC called PDA IC or Touch Screen IC.

If Yes, then the Main Display is OK and you can just Replace the Touchscreen. Touch Screen can be Separated from the Main Display using a LCD Screen Separator Machine.

If the Display is a Combo Set (Main Display and PDA Combined), then they cannot be separated or their are chances of getting damaged. In such situation it is better to Replace the Whole Combo Set. They are not very Expensive and are Easily Available in Local Markets and even Online.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey