what does an lcd screen look like made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Everdisplay Optronics (Shanghai) Co.,Ltd.(EDO) is a company dedicated to production of small-to-medium AMOLED display and research of next generation technology. The company currently has generation 4.5 OLED line.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

Founded in 2006, K&D Technology makes TFT-LCM, touch screen, finger print recognition and backlight. Its products are used in smart phone, tablet computer, laptop computer and so on.

Established in 2013, Eternal Material Technology is committed to the research, development and manufacturing of electronic materials and providing technical services. EMT is leading the industry with its products of OLED and color photoresist materials.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Founded in 2008,Yunnan OLiGHTEK Opto-Electronic Technology Co.,Ltd. dedicated themselves to developing high definition AMOLED (Active Matrix-Organic Light Emitting Diode) technology and micro-displays.

In Topway, we work side by side to help you overcome any technical and none technical challenges that may arise during product design, manufacture or installation. We can even take care of component sourcing and manufacturing for you.

LCD manufacturers are mainly located in China, Taiwan, Korea, Japan. Almost all the lcd or TFT manufacturers have built or moved their lcd plants to China on the past decades. Top TFT lcd and oled display manufactuers including BOE, COST, Tianma, IVO from China mainland, and Innolux, AUO from Tianwan, but they have established factories in China mainland as well, and other small-middium sizes lcd manufacturers in China.

China flat display revenue has reached to Sixty billion US Dollars from 2020. there are 35 tft lcd lines (higher than 6 generation lines) in China,China is the best place for seeking the lcd manufacturers.

The first half of 2021, BOE revenue has been reached to twenty billion US dollars, increased more than 90% than thesame time of 2020, the main revenue is from TFT LCD, AMoled. BOE flexible amoled screens" output have been reach to 25KK pcs at the first half of 2021.the new display group Micro LED revenue has been increased to 0.25% of the total revenue as well.

Established in 1993 BOE Technology Group Co. Ltd. is the top1 tft lcd manufacturers in China, headquarter in Beijing, China, BOE has 4 lines of G6 AMOLED production lines that can make flexible OLED, BOE is the authorized screen supplier of Apple, Huawei, Xiaomi, etc,the first G10.5 TFT line is made in BOE.BOE main products is in large sizes of tft lcd panel,the maximum lcd sizes what BOE made is up to 110 inch tft panel, 8k resolution. BOE is the bigger supplier for flexible AM OLED in China.

As the market forecast of 2022, iPhone OLED purchasing quantity would reach 223 million pcs, more 40 million than 2021, the main suppliers of iPhone OLED screen are from Samsung display (61%), LG display (25%), BOE (14%). Samsung also plan to purchase 3.5 million pcs AMOLED screen from BOE for their Galaxy"s screen in 2022.

Technology Co., Ltd), established in 2009. CSOT is the company from TCL, CSOT has eight tft LCD panel plants, four tft lcd modules plants in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou and in India. CSOTproviding panels and modules for TV and mobile

three decades.Tianma is the leader of small to medium size displays in technologyin China. Tianma have the tft panel factories in Shenzhen, Shanhai, Chendu, Xiamen city, Tianma"s Shenzhen factory could make the monochrome lcd panel and LCD module, TFT LCD module, TFT touch screen module. Tianma is top 1 manufactures in Automotive display screen and LTPS TFT panel.

Tianma and BOE are the top grade lcd manufacturers in China, because they are big lcd manufacturers, their minimum order quantity would be reached 30k pcs MOQ for small sizes lcd panel. price is also top grade, it might be more expensive 50%~80% than the market price.

Panda electronics is established in 1936, located in Nanjing, Jiangshu, China. Panda has a G6 and G8.6 TFT panel lines (bought from Sharp). The TFT panel technologies are mainly from Sharp, but its technology is not compliance to the other tft panels from other tft manufactures, it lead to the capacity efficiency is lower than other tft panel manufacturers. the latest news in 2022, Panda might be bougt to BOE in this year.

Established in 2005, IVO is located in Kunsan,Jiangshu province, China, IVO have more than 3000 employee, 400 R&D employee, IVO have a G-5 tft panel production line, IVO products are including tft panel for notebook, automotive display, smart phone screen. 60% of IVO tft panel is for notebook application (TOP 6 in the worldwide), 23% for smart phone, 11% for automotive.

Besides the lcd manufacturers from China mainland,inGreater China region,there are other lcd manufacturers in Taiwan,even they started from Taiwan, they all have built the lcd plants in China mainland as well,let"s see the lcd manufacturers in Taiwan:

Chimei Innolux Corporation was the successor company, and it initially preserved the Chimei name. In order to differentiate itself from the ChiMei brand, the company was renamed "Innolux Corporation" in December 2012.

Innolux"s 14 plants in Taiwan possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line in Taiwan and China mainland, offering a full range of large/medium/small LCD panels and touch-control screens.including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions,full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels.

AUO is the tft lcd panel manufacturers in Taiwan,AUO has the lcd factories in Tianma and China mainland,AUOOffer the full range of display products with industry-leading display technology,such as 8K4K resolution TFT lcd panel, wide color gamut, high dynamic range, mini LED backlight, ultra high refresh rate, ultra high brightness and low power consumption. AUO is also actively developing curved, super slim, bezel-less, extreme narrow bezel and free-form technologies that boast aesthetic beauty in terms of design.Micro LED, flexible and foldable AMOLED, and fingerprint sensing technologies were also developed for people to enjoy a new smart living experience.

Hannstar was found in 1998 in Taiwan, Hannstar display hasG5.3 TFT-LCD factory in Tainan and the Nanjing LCM/Touch factories, providing various products and focus on the vertical integration of industrial resources, creating new products for future applications and business models.

driver, backlight etc ,then make it to tft lcd module. so its price is also more expensive than many other lcd module manufacturers in China mainland.

Maclight is a China based display company, located in Shenzhen, China. ISO9001 certified, as a company that more than 10 years working experiences in display, Maclight has the good relationship with top tft panel manufacturers, it guarantee that we could provide a long term stable supply in our products, we commit our products with reliable quality and competitive prices.

Maclight products included monochrome lcd, TFT lcd module and OLED display, touch screen module, Maclight is special in custom lcd display, Sunlight readable tft lcd module, tft lcd with capacitive touch screen. Maclight is the leader of round lcd display. Maclight is also the long term supplier for many lcd companies in USA and Europe.

If you want tobuy lcd moduleorbuy tft screenfrom China with good quality and competitive price, Maclight would be a best choice for your glowing business.

One of today’s modern technological wonders is the flat-panel liquid crystal display (LCD) screen, which is the key component we find inside televisions, computer monitors, smartphones, and an ever-proliferating range of gadgets that display information electronically.What most people don’t realize is how complex and sophisticated the manufacturing process is. The entire world’s supply is made within two time zones in East Asia. Unless, of course, the factory proposed by Foxconn for Wisconsin actually gets built.

Last week I had the opportunity to tour BOE Technology Group’s Gen 10.5 factory in Hefei, the capital of China’s Anhui Province.This was the third factory, or “fab” that Beijing-based BOE built in Hefei alone, and in terms of capability, it is now the most advanced in the world.BOE has a total of 12 fabs in Beijing, Chongqing, and several other major cities across China; this particular factory was named Fab 9.

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass.On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through.That’s how you can get electrical signals to the middle of a screen.Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts.This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen.Each step has to be precisely aligned to the previous one within a few microns.Remember, the average human hair is 40 microns in diameter.

On the other sheet of glass, you make an array of millions of red, green, and blue dots in a black matrix, called a color filter array (CFA).This is how you produce the colors when you shine light through it.Then you drop tiny amounts of liquid crystal material into the cells on the first sheet and glue the two sheets together.You have to align the two sheets so the colored dots sit right on top of the cells, and you can’t be off by more than a few microns in each direction anywhere on the sheet.The sandwich is next covered with special sheets of polarizing film, and the sheets are cut into individual “panels” – a term that is used to describe the subassembly that actually goes into a TV.

For the sake of efficiency, you would like to make as many panels on a sheet as possible, within the practical limitations of how big a sheet you can handle at a time.The first modern LCD Fabs built in the early 1990s made sheets the size of a single notebook computer screen, and the size grew over time. A Gen 5 sheet, from around 2003, is 1100 x 1300 mm, while a Gen 10.5 sheet is 2940 x 3370 mm (9.6 x 11 ft).The sheets of glass are only 0.5 - 0.7 mm thick or sometimes even thinner, so as you can imagine they are extremely fragile and can really only be handled by robots.The Hefei Gen 10.5 fab is designed to produce the panels for either eight 65 inch or six 75 inch TVs on a single mother glass.If you wanted to make 110 inch TVs, you could make two of them at a time.

The fab is enormous, 1.3 km from one end to the other, divided into three large buildings connected by bridges.LCD fabs are multi-story affairs.The main equipment floor is sandwiched between a ground floor that is filled with chemical pipelines, power distribution, and air handling equipment, and a third floor that also has a lot of air handling and other mechanical equipment.The main equipment floor has to provide a very stable environment with no vibrations, so an LCD fab typically uses far more structural steel in its construction than a typical skyscraper.I visited a Gen 5 fab in Taiwan in 2003, and the plant manager there told me they used three times as much structural steel as Taipei 101, which was the world’s tallest building from 2004- 2010.Since the equipment floor is usually one or two stories up, there are large loading docks on the outside of the building.When they bring the manufacturing equipment in, they load it onto a platform and hoist it with a crane on the outside of the building.That’s one way to recognize an LCD fab from the outside – loading docks on high floors that just open to the outdoors.

LCD fabs have to maintain strict standards of cleanliness inside.Any dust particles in the air could cause defects in the finished displays – tiny dark spots or uneven intensities on your screen.That means the air is passed through elaborate filtration systems and pushed downwards from the ceiling constantly.Workers have to wear special clean room protective clothing and scrub before entering to minimize dust particles or other contamination.People are the largest source of particles, from shedding dead skin cells, dust from cosmetic powders, or smoke particles exhaled from the lungs of workers who smoke.Clean rooms are rated by the number of particles per cubic meter of air.A class 100 cleanroom has less than 100 particles less than 0.3 microns in diameter per cubic meter of air, Class 10 has less than 10 particles, and so on. Fab 9 has hundeds of thousands of square meters of Class 100 cleanroom, and many critical areas like photolithography are Class 10.In comparison, the air in Harvard Square in Cambridge, MA is roughly Class 8,000,000, and probably gets substantially worse when an MBTA bus passes through.

Since most display manufacturing has to be done in a cleanroom and handling the glass requires such precision, the factory is heavily automated.As you watch the glass come in, it is placed into giant cassettes by robot handlers, and the cassettes are moved around throughout the factory.At each step, robots lift a piece of glass out of the cassette, and position it for the processing machines.Some of the machines, like the ones that deposit silicon or ITO, orient the glass vertically, and put them inside an enormous vacuum chamber where all the air is first pumped out before they can go to work.And then they somehow manage to deposit micrometer thin layers that are extremely uniform.It is a miracle that any of this stuff actually works.

It obviously costs a lot to equip and run such a fab.Including all of the specialized production tools, press reports say BOE spent RMB 46 billion (US$6.95 billion). Even though you don’t see a lot of people on the floor, it takes thousands of engineers to keep the place running.

The Hefei Gen 10.5 is one of the most sophisticated manufacturing plants in the world.On opening day for the fab, BOE shipped panels to Sony, Samsung Electronics, LG Electronics, Vizio, and Haier.So if you have a new 65 or 75-inch TV, there is some chance the LCD panel came from here.

Over the years, with the wider and wider application of LCD screens, more and more brand products have been favored by the people. Together, more and more LCD manufacturers have emerged. Of course, the most popular brands in China are BOE, INNOLUX, CHIMEI, AUO, CSOT, etc. So, Which is the best brand of

It is better to say who is more professional than good or bad. In fact, the above mentioned LCD screen manufacturers are very professional, and the quality is guaranteed. But the most popular must be BOE and INNOLUX, these two panel manufacturers are also obvious to all. They all have multiple distributors, but not every distributor has the best size and price.

SZ XIANHENG TECHNOLOGY CO., LTD. is the agent of AUO, BOE, INNOLUX, SHARP, IVO and Mitsubishi, and other domestic and foreign well-known brands of small and medium-sized LCD display; specializing in customized production of touch screen display, LCD and industrial touch display and other high-tech products. According to the needs of customers, we can provide various LCD products: high-brightness LCD screen, LCD driver board, touch screen, booster board, all kinds of LCD special wires, etc. to produce industrial displays.

What brand of LCD screen is good? If you choose BOE, INNOLUX, CHIMEI, AUO or CSOT, you can buy them from us. 18.5 inch LCD screen, 21.5 inch LCD screen and other small and medium size, our price is the lowest in the industry.

-Select-AfghanistanAlbaniaAlgeriaAndorraAngolaAnguillaAntigua and BarbudaArgentinaArmeniaArubaAustriaAzerbaijan RepublicBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia and HerzegovinaBotswanaBrazilBritish Virgin IslandsBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape Verde IslandsCayman IslandsCentral African RepublicChadChileChinaColombiaComorosCongo, Democratic Republic of theCongo, Republic of theCosta RicaCroatia, Republic ofCyprusCzech RepublicCôte d"Ivoire (Ivory Coast)DenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Islas Malvinas)FinlandFranceFrench GuianaGabon RepublicGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHondurasHong KongHungaryIcelandIndiaIndonesiaIraqIrelandIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKorea, SouthKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMartiniqueMauritaniaMauritiusMayotteMexicoMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueNamibiaNepalNetherlandsNetherlands AntillesNicaraguaNigerNigeriaNorwayOmanPakistanPanamaParaguayPeruPhilippinesPolandPortugalPuerto RicoQatarReunionRomaniaRwandaSaint HelenaSaint Kitts-NevisSaint LuciaSaint Pierre and MiquelonSaint Vincent and the GrenadinesSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSomaliaSouth AfricaSpainSri LankaSurinameSwazilandSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTogoTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsUgandaUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVatican City StateVenezuelaVietnamVirgin Islands (U.S.)Western SaharaYemenZambiaZimbabwe

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

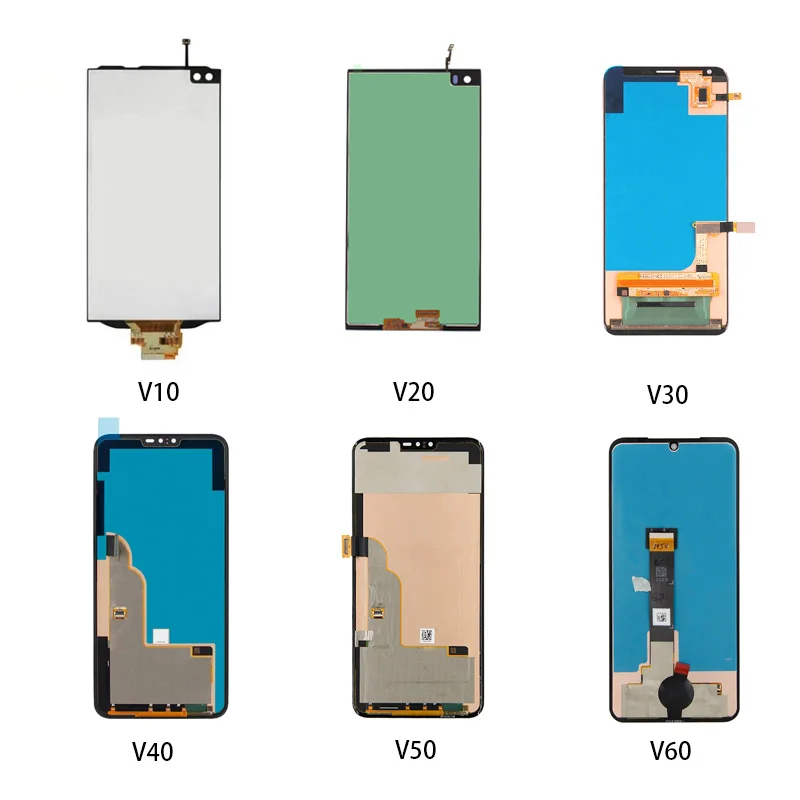

Not too long ago, we’ve just got some samples of the new China Made iPhone 6 LCD Display. No doubt that this will be another option for all who are suffering from the high price of the iPhone screens. Let’s take a deep look of these screens.

At the moment, there are two companies producing the iPhone 6 LCD screens, one is LT, the other one is JDF (no iPhone 6 screens made by TM are available now). Below are some detailed comparisons after our tests.

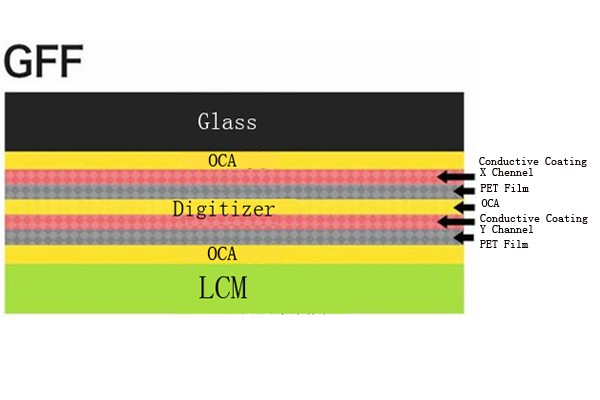

When taking a closer look at both of the LT and JDF iPhone 6 screens under direct light, you’ll see the digitizer textures. While for the original screen, the textures had been hidden by a special painted layer.

The glass lens of LT made iPhone 6 screen is far too thin compared with the original one, which can’t secure the display well. At the same time, thinner glass lens will make the home button stick up above the screen. While for the JDF made the screen, a plastic layer has been added to make it thicker.

It’s hard to be realized through eyes, but it’s easily to be touched. When you grab the iPhone 6 with LT made screen, it’s hard to ignore that annoying uncomfortable feeling. At this point, the JDF made screen is much better.

High and low temperature tests have been applied to both the LT and JDF iPhone 6 screens. Both of them have survived and worked well after been putted in a 55 centi degrees room for 2 hours and -5 centi degrees room for 2 hours.

Through our tests, the first version of both the LT and JDF displays are not good choices for the repair industry. The obvious color differences, thickness differences still need to be improved. If you have any questions regarding the LT/JDF iPhone 6 screens, please leave your comment below, we’ll try our best to answer it.

China is the leader in producing LCD display panels, with a forecast capacity share of 56 percent in 2020. China"s share is expected to increase in the coming years, stabilizing at 69 percent from 2023 onwards.Read moreLCD panel production capacity share from 2016 to 2025, by countryCharacteristicChinaJapanSouth KoreaTaiwan-----

DSCC. (June 8, 2020). LCD panel production capacity share from 2016 to 2025, by country [Graph]. In Statista. Retrieved November 17, 2022, from https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "LCD panel production capacity share from 2016 to 2025, by country." Chart. June 8, 2020. Statista. Accessed November 17, 2022. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. (2020). LCD panel production capacity share from 2016 to 2025, by country. Statista. Statista Inc.. Accessed: November 17, 2022. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "Lcd Panel Production Capacity Share from 2016 to 2025, by Country." Statista, Statista Inc., 8 Jun 2020, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC, LCD panel production capacity share from 2016 to 2025, by country Statista, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/ (last visited November 17, 2022)

You can check the logistics status by the tracking number we informed you in the email or in your account on the above website of express company to see where the parcel is, or you can contact us.

Apple is considered a sign of luxury and due to that its products have a huge demand. To meet this demand, Apple started to open factories in other countries. China is so far the largest producer of Apple products in the world.

Why is Apple using China as its source for iPhones and iPads? Well, in this chapter, we will try to explain in detail why Apple is doing so. These facts and figures will help in understanding what is going on.

See, the thing is that about 46 percent of Apple suppliers are Chinese manufacturers and firms. That means that over 360 suppliers from China are working for apple, creating every component required for building the iPhone/iPad.

Take a look at this that two cities nearby Chinese Delta rivers (Pearl River Delta and the Yangtze River Delta) have the most Apple suppliers that make components such as LCD screens, mics, sensors, cameras, RF readers, and every other component.

This makes China a perfect place for Apple to develop its products. There is another advantage to that and we will discuss that later in the upcoming chapters.

Whenever you get your new iPhone, you think that it is made in California. Well, if you look closely, it is written as “Designed by Apple in California, Assembled in China”.

Apple is considered as the symbol of luxury and that is why it has a huge demand all over the world. To meet the demand, Apple needs a workforce that can create thousands of iPhones in a matter of days.

And that is where Apple China comes in. Other than that, China has the skill set that is required to make complex components of the iPhone and other Apple products.

Why Apple is manufacturing products in China? Apple has the option to select countries such as India or Bangladesh. But why China is the only one that has this advantage? Well, here is why.

China has the power to meet the demand for Apple products and that can be defined in a number of ways. For instance, firstly, China has the skillset to develop new products for Apple.

As an example, last year, Apple iPhone 12 sales went beyond expectations. That was all because China helped Apple in making the iPhone 12 models at a very large scale. And that is how Apple China is meeting the demand.

The first one is that in China, the average working wage is relatively lower than in USA. Due to this, the Chinese firms are able to produce Apple products in lower cost and give more profit margins to Apple.

So, the making of components and assembling those components is straightway done in China (That is why you see “Assembled in China” at the back of the phone).

Another reason why Apple is manufacturing in China is the targeted audience. See, Apple is popular all over the world that includes regions such as UAE and Asia.

It is expensive to ship iPhones from the USA to these areas. So, with the help of China, Apple can lower that cost and can deliver phones to the vendors working in Asia and gulf countries.

The reason China is going with Apple products is that it has the resources that help Apple in meeting the demand. And by resources, we mean the workforce.

Actually, the thing is Chinese are considered hardworking people and that is true. Apple is taking the advantage of that because China has the capability of producing almost 100,000 iPhones every year.

Yes, mainly China handles the production of iPhones and new Airpods, people can also get their hands on items such as iMacs, iPods, iPads, and other related products at an optimum price.

However, there is a misconception that Apple products in China are cheap, compared to the rest of the world. Well, these prices are similar or differ a little bit to those you get in countries like the USA, UK, and Europe.

Now, let’s move towards the section that contains some of the key vendors of Apple that provide the components required for making the Apple products such as iPhones and iPads. This information is only provided to give you an idea of how Apple is working in China.

Foxconn is a contract manufacturer of Apple based in Taiwan. The company is famous for producing Iphones for the US-technology giant Apple. It is headquartered in Taipei, Taiwan.

They are have a giant Foxconn factory in Shenzhen, China. Foxconn brought revenues of around $175bn in 2018 and it was ranked 24t among the fortune 500 companies.

Foxconn manufacturers around 60-70% of the Iphones sold each year and Apple is by far Foxconn’s largest customer. Foxconn also developed some equipment for Iphone in order to increase their profit margins.

The first official vendor that is working for Apple is Bosch Sensortec. Bosch is a worldwide operating company based in Germany that provides components such as barometer, pressure, and humidity sensors.

The company’s Chinese firm is related to Apple and makes accelerometer sensors for Apple iPhones. Similarly, it also makes accelerometer modules for Apple iPad devices.

Cirrus Logic is a US-based technology company that makes audio components for various companies. They have factories in China that are producing audio chips for Apple.

Qualcomm China uses its resources to make camera modules for iPhones. These modules include the camera algorithm, chassis, lens, and focus sensor for the iPhone.

These devices include communication ICs, audio chips, current sensors, and compass modules. AKM, China makes compass sensors for all iPhones and it is doing that since the launch of the iPhone 6

Like Qualcomm, TSMC is another important partner of Apple that is working from China. TSMC is a Taiwan-based company that makes LCD/AMOLED screens for Apple as well as Samsung.

The Chinese branch of the company provides screens for Apple iPhones and iPads. Moreover, the company also makes the glass that is required for screens for Apple.

There are two terms that are required to be understood- Assembling and manufacturing. In this chapter, we are going to discuss and whether China is a manufacturer of Apple products or an assembler. Let move forward.

Before talking about assembling, let’s talk about the manufacturing term. Manufacturing means that a company makes the product from scratch using raw materials.

In this process, the company designs the product, gathers the raw material, and then produces the item. Manufacturing is an expensive process when compared to assembling. And it takes a lot of time in the manufacturing process.

Talking about assembling, let’s take an example, suppose you are the assembler of a shoe company. You take the laces from another company, sole from another one; hire a firm that designs the logo and design of the shoe.

Then, you take all these parts and then join them together. Assembling is a cheap process when compared to manufacturing because there is no need to buy machines and spend money on designing the product.

In simple words, you can say that China is a manufacturer and the assembler of Apple. Some companies are just the manufacturer and some are just the assembler. Some may even do both like Foxconn.

Foxconn is a Taiwanese-based company that designs and produces electronic components such as PCBs, computer chips. It is headquartered in New Taipei City, Taiwan, China. Foxconn also has its assembling facility in China.

Apple is linked with Foxconn China and for Apple, Foxconn is assembling the Apple products. Foxconn holds the assembly of the majority of Apple products because it is the first partner of Apple in China.

Pegatron is another Taiwan (China) based company that makes computing and consumer electronics for vendors. It also designs and manufactures computer peripherals.

The mainland China facility of Pegatron uses its resources for making Apple products. The company has new ties with Apple. However, it is playing an important role in assembling Apple products.

There are currently 4 Taiwan (China) based companies that are assembling products for Apple. All of these companies have an assembling facility in China and are using that to minimize the assembling costs and delays.

The company currently assembles the majority of iPhones, Ipads and MacBooks in its Shenzhen assembly plant. Foxconn also operates in countries like Thailand, South Korea, Czech Republic.

Similarly, Foxconn also assembles iPads for Apple. It has worked on iPads series such as iPad generation 3, 4, 5, and 6. Currently, it is also assembling the latest iPad.

Pegatron is the second assembler of Apple that uses its resources to assemble iPhones. Pegatron has a new partnership with Apple. At the launch of the iPhone 6, Pegatron assembled almost 30% of the phones to meet the demand.

Goertek uses its HQ (Head Quarter) facility to assemble Apple Air pods. The newest Apple headphones (Air Pods Max) are assembled with the resources and knowledge of Goertek.

Like Goertek, Luxshare is another Chinese company that assembles consumer electronics, telecom equipment, and audio parts for automobiles. Luxshare is a key assembler of Apple Air Pods and it has assembled both Air Pods 1 and 2 for Apple.

Apple does not have own factory and make products in China. It has given a contract to multiple Chinese companies that make and produce Apple products.

Apple entered China in 2001 and due to the high demand, Apple partnered with Foxconn and China to assemble the iPhones and iPads in the production facility of Foxconn in Zhengzhou. Later the production and assembling shifted to Shenzhen facility of Foxconn.

There is a misconception that China is the center of Apple so the products here are cheaper than the rest of the world. Well, that is not true. In fact, Apple products in China are a little bit expensive when compared to the rest of the world.

There are no Apple-owned factories in China. However, we can say that Foxconn and Pegatron and others are the companies in China that is making the product and assembling it as well. Plus, Apple is using the help of various Chinese companies to make its components.

Till now, Apple has not stopped the manufacturing of its products in China. However, it is planning to move its assembling factories to India and Vietnam because of low assembling costs. This is also due to the trade war during Donald Trump presidency between China and USA.

Apple has gained a lot of attention due to the fact that it is considered a sign of luxury. Apple products have a huge demand and there is no way to meet this demand unless there is a huge workforce present with Apple. That is where China comes in.

We hope that this blog has provided you all the information of what kind of products are being made in China for Apple company and which companies and Manufacturing it and which are Assembling it.

As is known to all, in the past 40 years, China has made remarkable achievements in its industry. With the establishment and improvement of a modern industrial system with complete categories, China has long been the world’s largest manufacturing country.

This is mainly because China has a large population, about the same as the rest of the developed world put together, but it has not yet developed to the point where services account for a large proportion. Because China has a large population and a large number of employed people, labor is cheaper than in other countries. Foreign enterprises can take advantage of China’s labor force by putting their products into production in China, which not only increases the employment rate of Chinese people but also saves a lot of costs in the production of products. Therefore, made in China is so popular.

A guy on Quora mentions that”If you import a lot of raw Material from broad, it will cost a lot of money, but China has a very special weapon: infrastructure. Since the demand for products (mostly commodities) drives demand for raw material, that drives demand for infrastructure to route these raw materials effectively and cheaply. Unlike India, China has that infrastructure and system, and so raw material can flow in large batches and routed effectively to minimize cost.”

It is also true that in the eyes of foreign companies, Chinese products in almost any field can be produced. China’s development in the production field in recent years is very comprehensive, including raw materials, production, logistics, trade, and other supporting industrial chains, which can be said to be very complete. Therefore, foreign enterprises can find a complete industrial chain in a very short time when they come to China, so the reputation of Chinese manufacturing is also very good.

When it comes to cheap Labour, it is much cheaper in south-east Asia than in China. But why is China so popular? This involves the quality of the product. The reason why the labor force in many countries in southeast Asia is cheap is mainly that the economic level of these countries is not high, so no matter the production technology or technological level is inferior to China. To ensure the quality of their products, foreign companies naturally prefer to choose China.

In terms of product production efficiency, China is hard to compare with many other countries. According to relevant data, domestic product manufacturing efficiency is the highest in the world. On the one hand, this is because China’s factories have more comprehensive equipment and a high level of science and technology, which can shorten the production cycle of products. On the other hand, it is because of the high quality of Chinese workers, strong learning ability, and developed transportation, which also speeds up the operation of all aspects of product production.

In order to export more products to other parts of the world, the Chinese government has only a VAT system and only taxes value-added services. As a result, production costs are much cheaper than in other countries. On the other hand, the United States and some other developed countries do not impose low import tariffs on Chinese goods.

It is believed that with the continuous development of Chinese manufacturing and science and technology, made-in-china manufactures will become more popular in the future.

In this article, we are looking at the benefits of looking for Chinese TFT LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with STONE Tech.

There is no doubt that China has taken the mass manufacturing business by storm. There are few products that we can encounter in our lives that don’t have the words ‘Made in China’ scribbled underneath. There is a glut of products that are mass-manufactured by the Chinese and then shipped out internationally to be sold.

Handbags, wallets, phone cases, and other similar items have become the favorites of wholesalers and bulk buyers. These products are directly sold to end consumers. However, the fascinating thing about the Chinese production and manufacturing business is that it does not only cover the end-consumer products. Rather, you can also acquire raw and basic materials needed for the further manufacturing of goods and products. One such product is LCD displays.

LCD displays have become something of a necessity in today’s world of tech advancement. Many things in our daily life have been automated, and are operated using an interactive user interface. For these kinds of machines and gadgets, LCD displays are typically necessary.

In this article, we are looking at the benefits of looking for Chinese LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with Stoneitech.com.

STONE Tech is an LCD manufacturer located in Beijing, China. It was founded back in 2010, and it has been developing TFT LCD display modules ever since. These modules can be used for a variety of different machines including electric equipment, precision instruments, and civil electronics etcetera.

One of the main benefits that you get with Stoneitech.com is that there is a wide range of diverse products that you can purchase. For example, there are three different application types that you can choose from which include the Industrial Type, Advanced Type, and Civil Type. Similarly, there is a range of different sizes that you can choose from. There are 11 different sizes that you can buy, ranging from the smallest 3.5-inch display to the large 15.1-inch one. The same goes for the Android series which where you can choose between 4.5-inch and 31.5-inch displays.

This is probably the biggest advantage that you can get when working with manufacturers from China. It can even be assumed that this is probably the biggest reason why the Asian country is at the forefront of the mass manufacturing business.

When you are going to be ordering in bulk, you need to save up on costs as much as you can. The more you save up, the more profit you can make when reselling. Furthermore, lower costs can allow you to set lower prices when selling. This can attract more customers and your sales can increase.

In the initial period of your business, you want to build trust with your customers and give them more value than they expect. The best way you can achieve this is by making your products available for less than the average price. And this can only be done if you are saving up on costs yourself.

The same applies to LCD displays. When you save up on costs when buying LCD displays, you can set a lower price for the whole machine or gadget that you are producing.

This is a very useful benefit for small start-up companies. Generally, manufacturers in the USA are not going to be very willing to work with you unless you are a big company or unless you have a large recognition and following. Due to this, smaller companies can have trouble getting their demands heard. However, the refusal of suppliers to do so is not unjustified. Smaller companies are going to start off with smaller orders. Small orders are not very lucrative and beneficial for suppliers. The larger the order, the more convenient it will be for the manufacturer.

However, with Chinese manufacturers, this problem is minimized. The Chinese often don’t care how big a brand you are and what recognition your company has. As long as you meet the minimum order requirements, you can get your products easily. This is highly advantageous for smaller companies. Due to this, smaller firms can get started and kick off their business.

When it comes to LCD modules, the orders are not received by the hundreds or thousands as is the case with other smaller products such as handbags and wallets etcetera. One module can cost around $250, and it is for this reason that the dynamics are a little different with this business. That is why STONE offers single pieces for sale as well as multiple pieces. This encourages smaller businesses to make their purchases since they can easily purchase as many modules as they like. As long as you meet the limit stated by the supplier, you are good to go.

Typically, when you are paying less, you can have the expectation that the quality might not be good or the time taken may be too long. However, when you are buying from the Chinese, you don’t have to face any of these problems. While you are paying less, you can get satisfactory quality and even the production time is cut down.

The factories in China have more machines and workers working simultaneously. This means that you can get bigger orders more quickly. For example, if you are getting 10 units from a domestic supplier in 4 days, you will be able to get 12 units from a Chinese supplier in just 3 days. That means that the production rate is increased, and the time taken is also cut short. This is merely an example to show that both aspects of production are enhanced when you do business with the Chinese.

Another great benefit of getting production done in China is the option for expansion. What that means is that while you can transport your merchandise to your home country, you also have the option of making them available in China. Instead of only bringing the goods back home to resell, you can set up a business that makes your merchandise available for sale in China as well.

In the case of LCD modules, this benefit relates to a reselling business. For example, if you are planning on buying some modules to use in your machines etcetera, then there is not a very suitable opportunity for you to expand. If you want to start a business in another country, you will have to open a manufacturing unit there so that your products can be produced and then get sold. Or, you will have to transport your final products to the other country in order to run your business.

However, if you are buying the LCD modules to resale at a profit, you can use the Chinese markets to grow your business. You can buy the modules at a reduced price and then sell them at a profit in a different area or city where the people will be willing to pay more.

Now that we have seen the benefits of choosing Chinese manufacturers for LCD modules, let us narrow it down a bit and look at why you should choose STONE specifically.

With STONE, you get the option of buying a range of different-sized modules. If your business deals in making different electronics and machines that require panels of different sizes, you don’t have to look at multiple suppliers to fulfill your need. You could be making some products that require 3.5-inch panels, while some of your machines could be needing 15.1-inch modules. Instead of taking the trouble to go to different suppliers, you can enjoy an all-in-one experience from STONE.

STONE offers its customers ease when it comes to making a purchase. Generally, wholesalers and suppliers sell their merchandise in bundles of 10, 50, 100, etc. However, the STONE store gives you the option of buying single pieces so that you can buy as much as you presently need.

One of the main things that you have to look at in any supplier is the level of reliability and trust. This is usually determined by the level of experience and the time that the supplier has spent in the market. STONE was founded in 2010 and has been producing LCD modules for the past 10 years.

If you are looking to buy LCD modules in bulk, look no further than the Middle Kingdom. China has become the hub of mass manufacturing and is the favorite spot for wholesalers and business owners.

In case you need some convincing about buying from the Chinese, we have compiled a list of benefits that you can enjoy when looking for TFT LCD manufacturers in China.

The world’s top four LCD suppliers for TVs will be mostly from in 2020, while the total shipment from global LCD companies is likely to fall by 8.2% to 265 million units, according to market research firm IHS Markit on Dec. 18.

IHS Markit said this would mark the first time in 10 years to witness a decline in such panel shipments, as unlike Chinese companies that will continue to ship more, South Korean suppliers will be cutting their volume.

LG Display will take fifth place, falling from this year’s second, while Samsung Display will not be among the top five manufacturers. In 2016, LG Display and Samsung Display had been at No.1 and No.2 in the market.

In 2019, China’s BOE had climbed to No.1 for the first time, and market watchers expect the firm to remain at the top in 2020 with a 21% market share. China’s CSOT will be at second place with a 16% share, up from this year’s fourth place.

As with BOE, CSOT is mass producing Gen-10.5 and Gen-11 LCD panels. CSOT will also be ramping up production from its first Gen-11 LCD production line, the T6, by the end of this year. The T7, which is the firm’s second Gen-11 line, is to begin mass production by 2021.

Meanwhile, Taiwan’s Innolux is expected to maintain its No.3 status, while China’s HKC will rise to the fourth-largest supplier. HKC had earlier been cited as likely to acquire the Gen-8 LCD production lines at Samsung Display’s suspended panel plant, but Samsung has chosen a different Chinese manufacturer that had no display production lines.

In terms of country, China will ship 58% of the total amount of LCD panels for TVs to reflect a jump from this year’s 47%. South Korean firms, on the other hand, are to see their shipment fall to 17% from this year’s 27%. The 17% will be smaller than the share by Taiwanese firms, which are likely to ship around 22% of the total global volume.

You might be confused by different kinds of China made iPhone LCD brands. On the market, now for iPhone 6 China Made iPhone LCDs, there are around 11 brands. For iPhone 5 series, there are about 5-6 brands.

For those China made LCD screens, most of you may be familiar with Tianma, Longteng(IVO), Jingdongfang(BOE). For Longteng/LT, Its office name is IVO. For Jing Dongfang/JDF, its official name is BOE. The rest are Shenchao, innolux, AUO(Taiwan Brand), IVO, JDB etc.

Why do the China Made iPhone LCD screens come to the market? I believe all of you know that reason. iPhone 5 series OEM were very lack of stock and price rose. So there were people or companies that tried to look for substitute.

In the model, It is A that contacts Tianma company(A may be a company or some). They ask it to produce one kind of LCD for their mobile phone. Because they cannot ask Tianma company to produce iPhone LCD.

Besides, in case of getting trouble from Apple or government, they may made a fake phone as their own brand to match the LCD. Then both sides sign the agreement on it. A offers funds to Tianma company to study the LCD. What A to Tianma is like what Apple to Sharp/LG/Toshiba.

At the beginning, this China Made iPhone screen hasn"t had much market share. So after Tianma company produces the LCDs, A would ask factory B or its own factory to assemble the screens and sell to the markets.

After opening the market, the supply of these screens cannot meet the large demand of the market. A looks for more factories like C and D etc to assemble the screens for it and then A sells them to the market.

As more and more brands coming, A doesn’t want to assemble the screens itself any more but only sells the Tianma lcd to certain factories. Those factories buy the spare parts like glass, frame, backlight, OCA etc by themselves and assemble the LCD with these spare parts.

In order to lower the cost and benefit more or to compete with others or to survive, they would use different quality of spare parts, which leads to the different quality finally. Actually the quality of China Made iPhone LCD screen depends not only on LCD, the spare parts but also the technique each factory adopts. So even for Tianma screen, there is different price.

Tianma LCD Screen is not assembled by Tianma company. Actually it only produces display. So your "Tianma" LCD screen may not be the same like others". Don"t think that everyone"s Tianma screen is the same.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey