making lcd screen in stock

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

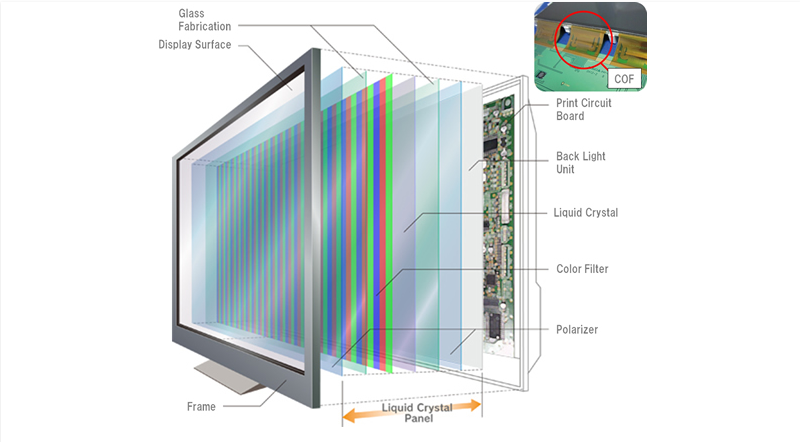

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

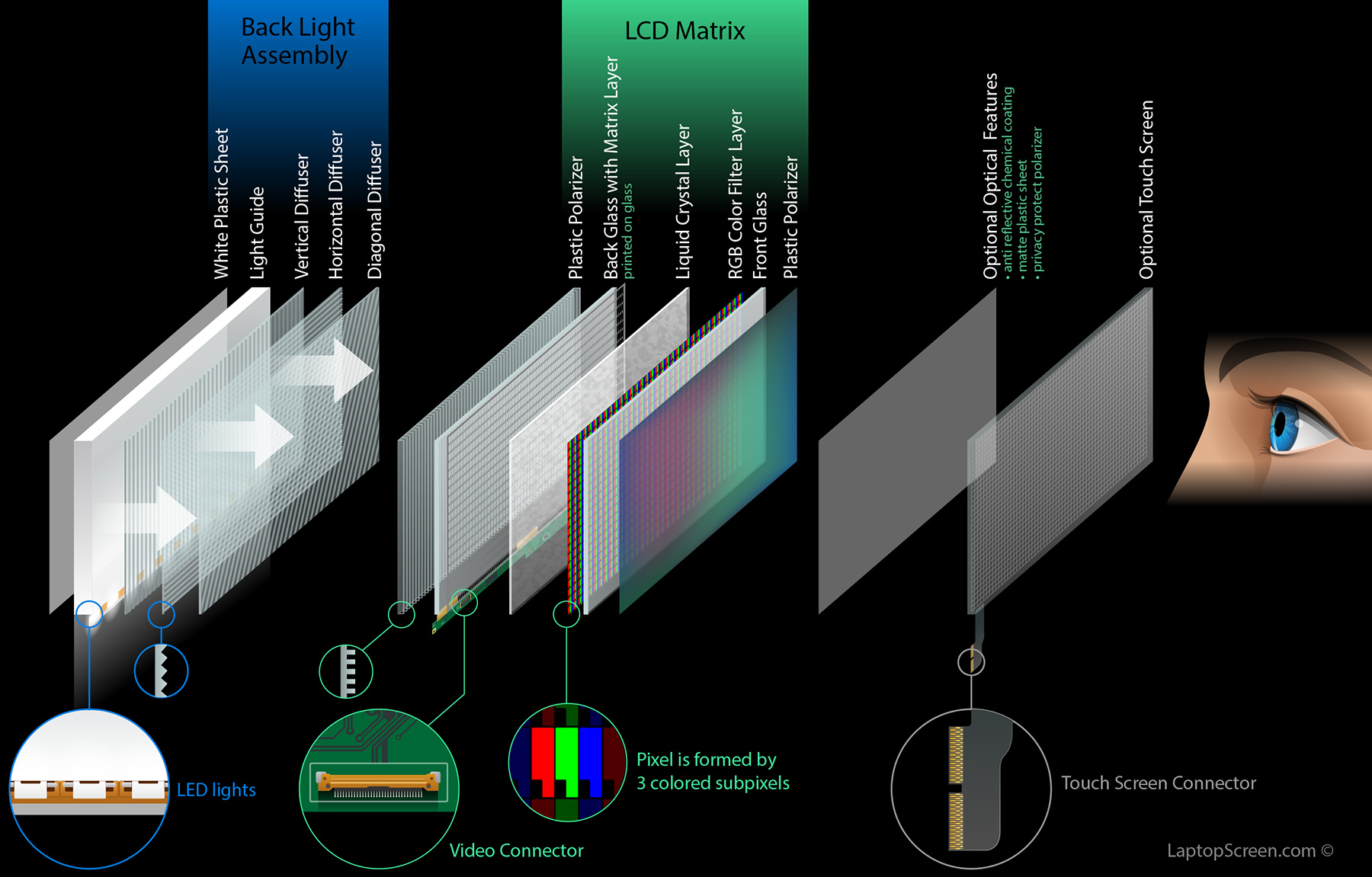

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

First of all, don’t be afraid of the word “custom” in front of LCD display. The idea of getting exactly what you need is very exciting, but your enthusiasm could be quickly deflated by all of the misconceptions of this process and not being able to meet your budget or schedule. At Phoenix Display International, we don’t want this to happen to you. In fact, our mission is to never let our customers go line-down. In other words, we want your display to be the one thing you don’t have to worry about.

Mass production manufacturing lead times are typically 8 weeks. The long lead-time component is typically the LCD glass at 6 weeks with 2 weeks available to manufacture the components into the complete LCD module. So, 8 weeks manufacturing with 4 weeks shipping, gives the standard and most economical 12-week lead time. With a simple expedited shipping this can easily be sped up to 8 weeks.

So with shipping accounted for, we’ll usually estimate eight to 12 weeks for your production LCD displays in total. An eight-week time frame if we’ll be shipping your display via air, and more of a 12-week time frame if it’ll be going by ocean.

So, there you have it. If you’re interested in a custom or standard LCD displays, we hope you’ll consider Phoenix Display International. We’ll turn around the highest quality product to you, and we’ll make sure we meet your timing and never leave you line down.

EarthLCD is a leading “Assembled In The U.S.A.” manufacturer of Industrial ezLCD “Smart” Touch Serial LCD’s for Embedded Systems, LCD Touch Monitors, Industrial Grade LCD Kits, LCD Touch Screen Kits, Industrial NTSC Monitors & Kits, Open Frame Monitors, Smart LCD Screens, Touch Screen Monitors, Industrial LCD Touch Screen Monitors, All in one Monitors, Custom OEM solutions, Integrated Solutions for OEM, LCD Touch Screen Modules, Custom LCD Display and LCD Controller Cards.

EarthLCD is a division of Earth Computer Technologies, Inc. originally founded in 1984. A full line of products plus custom engineered solutions are available. We source LCD displays direct from major manufacturers world wide allowing for a cost advantage over our competitors. EarthLCD offer’s the world’s widest variety of LCD’s in fully integrated solutions for OEM supply chain requirements.

EarthLCD targets industries such as Point Of Sale, Industrial Automation, Security, Hospitality, Kiosks, Home Automation, OEM, Gaming, Banking, Service, Test Equipment and Monitoring, Embedded Systems, Automotive, and many other applications.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

We at iFixit also use cookies with the aim of making your purchase of spare parts and tools as easy as possible. Please click on "I agree" to go directly to the shop or click on "Individual Settings" to receive a detailed description of the cookies and to make an individual selection. You can refuse the use of cookies here. We would like to point out that, in connection with cookies, personal data is transmitted to service providers in the USA. When data is transferred to the USA, there is a fundamental risk that this data will be accessed by US authorities without being notified and without the possibility of legal remedies. With your consent, you agree to the data being transferred to the USA. You can find more information in our privacy policy.

Use our “Get an Estimate” tool to review potential costs if you get service directly from Apple. The prices shown here are only for screen repair. If your iPhone needs other service, you’ll pay additional costs.

Your country or region offers AppleCare+ for this product. Screen repair (front) is eligible for coverage with a fee by using an incident of accidental damage from handling that comes with your AppleCare+ plan.

RF2G8A3MY–Printed circuit board connected by flexible flat cable to LCD panel. Closeup of electronic components - micro chip, inductor or capacitor on green PCB.

RF2D74NJ6–Vector realistic TV led screen isolated on transparent background. Modern stylish lcd panel. Computer monitor display mockup. Blank television graphic

RFK8P262–Realistic TV screen hanging on the wall. Modern stylish TV lcd panel isolated. Large led computer monitor display mockup. Vector illustration

RF2D74NFN–Vector realistic TV led screen isolated on dark transparent background. Modern stylish lcd panel. Computer monitor display mockup. Blank television gr

RF2BGEP3B–Empty tv frame with reflection and transparency screen isolated. Lcd monitor vector illustration. Lcd display screen, tv digital panel plasma

RMW6KMNM–Chinese workers labor at the Xianyang High-tech Industrial Development Zone for CEC¤Xianyang 8.6-generation LCD panel production line project in Xiany

RF2D74NFX–Vector realistic TV led screen isolated on dark transparent background. Modern stylish lcd panel. Computer monitor display mockup. Blank television gr

RMDHJ99T–Flat panel 40" (diagonal) LCD television in room setting with photographers own copyright image inserted onto TV (see Alamy additional info panel)

RF2F0T8JC–Orange flexible circuit board in human hand detail. Electrotechnic engineer with plastic flex PCB for data signal parallel transmission to LCD panel.

RMW6KPKF–Chinese workers labor at the Xianyang High-tech Industrial Development Zone for CEC¤Xianyang 8.6-generation LCD panel production line project in Xiany

RF2D74NP2–Vector realistic light TV led screen isolated on white background. Modern lcd panel. Computer monitor display mockup. Blank television graphic design

RF2F8F25R–The backlight inverter in the LCD TV. it is a device for starting and stable operation of fluorescent lamps of the LCD panel backlight. Isolated on a

RFHRCPND–Interior car lever - button, design, dashboard, cluster instruments, lcd panel, door handle, climatronic function, sport steering wheel, Honda Civic

RF2F7EWC6–Detail of a LED or LCD panel for screen on concerts or different displays. Focus on a centre row of LED lights, others in soft focus. Array of LED RGB

RMW6KMFW–Chinese workers labor at the Xianyang High-tech Industrial Development Zone for CEC¤Xianyang 8.6-generation LCD panel production line project in Xiany

RF2D74NJ3–Vector realistic white TV led screen isolated on transparent background. Modern lcd panel. Computer monitor display mockup. Blank television graphic d

RF2BJCHHG–Black pocket game console blank screen edge, corner, display closeup, handheld gaming abstract background, copy space. Portable gaming device

RFHRCPNC–Interior car lever - button, design, dashboard, cluster instruments, lcd panel, door handle, climatronic function, sport steering wheel, Honda Civic

RF2F7EWCF–Detail of a LED or LCD panel for screen on concerts or different displays. Focus on a centre row of LED lights, others in soft focus. Array of LED RGB

RF2E9B613–Tv Screen Display. Black Monitor Design. Digital Lcd Panel. Wall Led Equipment. Modern Plasma Vector Mockup. Flat Technology High Definition Device. E

RMW6KN9M–Chinese workers labor at the Xianyang High-tech Industrial Development Zone for CEC¤Xianyang 8.6-generation LCD panel production line project in Xiany

Replace a cracked or scratched front glass panel or malfunctioning LCD display on your phone. A new screen and digitizer assembly will renew the appearance of your front panel, restore touch function, and eliminate the dead pixels or flickering on an aging display.

Unused electronics are the bane of the modern life. Perfectly functional gadgets sit quietly in a corner of the store room, doing nothing. If you"re wondering what to do with old computer monitors, here are a few easy ideas to repurpose unused screens.

Perhaps the best thing to do with an old flat-screen monitor is a DIY DAKboard. The DAKboard is a LCD wall display that shows the current time, weather forecast, calendar events, stock quotes, fitness data, and news headlines. It"s all displayed on a soothing photo. You could buy an official DAKboard, but the makers themselves have shown how to build your own wall display with a Raspberry Pi. when you can build one for far less money and a little geeky fun, the choice is obvious.

Sometimes, you"re working on something private in an open office, or browsing certain *cough* sites *cough* at home. You can"t have your colleagues or kids see what"s on the screen. To keep snooping eyes at bay, make a "your-eyes-only" monitor from an old one.

Basically, you will be cutting out the polarizing film of the old LCD monitor. This film will then be put on a simple pair of glasses. Now your screen appears white, but the glasses can "see" the content. It"s one of the best ways to keep prying eyes out of your PC.

If you have a broken old LCD monitor, it can be re-purposed into a usable mirror; but if you have a working old LCD monitor, adding a Raspberry Pi can turn it into a smart magic mirror!

If you"re on a tight budget for a first-time DIY project, consider the $100 smart mirror. It"s not the best version of turning an LCD monitor into a smart mirror, but you"ll get the basic features and not spend a bomb.

If you have the space available, the best thing you can do with an extra monitor is to boost your productivity with a dual-monitor setup. A second monitor has many potential purposes, such as extended screen space, a dashboard for your social media or news updates, or a dedicated video conferencing screen.

Make it a dedicated screen for Nintendo Wii:The Nintendo Wii can connect to a VGA monitor, so if you don"t have a Wii, buy one. In fact, buy a used one, they"re pretty cheap on Craigslist.

Like any gadget, monitors have a limited shelf life. If you"re looking to upgrade, you now have a few ideas of what to do with your old monitor. And that age should influence which project you chose. For example, given the effort involved in building a smart mirror, don"t go with a screen that"s already shown signs of trouble. The Raspberry Pi-based projects are usually the easiest to keep changing.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey