twisted nematic tn lcd panel made in china

![]()

TN stands for twisted nematic. This is a type of LED (a form of LCD) panel display technology. TN panels are characterized as being the fastest and cheapest among the other main types of display panels, VA (vertical alignment)and IPS (in-plane switching). As such, they work great for gaming monitors and gaming laptops. However, TN panels also offer the worst viewing angles and color when compared to VA and IPS panels.

PerformanceFastest: low response times, highest refresh rates, minimal motion blur; Low input lagLongest response times typically; Higher refresh rates possibleSlower response times than TN, faster response times than VA; Gaming-quality refresh rates are rare

DisplayWorst viewing angles;Worst colorViewing angles typically better than TN, worse than IPS; Good color; Best contrast;Best image depthBest viewing angles; Best color

This article is introduce what is TN lcd and STN display, what is difference for FSTN and FFstn lcd? what types of lcd panel available for lcd technology? how the lcd panel display working. what is difference between FSTN and FFSTN lcd display definition? what does STN stand for? let"s see the introduction as following:

LCD is including monochrome lcd and color lcd types,monochrome lcd have TN LCD, STN LCD (yellow-green mode, blue mode, gray mode, black-white mode/FSTN,FFSTN), monochrome tft lcd. color lcd including color STN LCD and color TFT lcd types, color STN LCD (CSTN lcd) is almost phase out because it is no better than TFT in contrast, Now all CSTN LCDs were replaced by tft lcd dsiplay.

TN lcd means (twisted nematic) LCD, the namatic liquid crystal elements inside the lcd glass cell,its twisted angle is 90 degree, integrated the front and rear polarizes on the lcd, the polarized angle is also in 90 degree in cross, it control the light transmission and make the tn lcd display on and off.

STN lcd is super-twisted nematic lcd display, it is a type ofmonochrome lcd display,it is also passiveliquid crystal display(LCD). compare to TN lcd, STN LCD twist angle is 240 degree, instead of 90 degree of TN LCD, so we call it STN LCD. STN lcd have yellow-green display mode, gray,black-white mode,blue display mode,available.

The STN LCD is not only difference on twist angle in 240°, in the same time, because the liquid crystal has the double-reflective characteristic, the ambient light through the polarizer, it would change to linear polarized light, the linear polarized light go through the STN LCD cell with 240° twist angle, it would turn to oval polarized light because of the double-reflective of liquid crystal characteristic (the linear polarized light turn to two group lights via240° twist angle liquid crystal, and the two group light intervened to oval polarized light). the oval polarized lights are always with colors, that that is the reason ofyellow-green or blue color come from for the STN LCD.

With the twist angle in 240°, it bring higherdisplay contrast as the twist angle from TN 90° to STN 240°, as see the graph as below, as the increasing about the lcd contrast in twist angle, when TN lcd can support 8 commons driver (1/8 duty), such as segment lcd, because the TN liquid crystal sharpness is less than STN LCD, if the commons higher than 8, the TN lcd contrast would be decreased dramatically. while STN lcd could support 240 commons (1/240 duty) in maximum. STN not only support 16x2, 20x4 characters lcd, and could support 128x64, 320x240 graphic lcd as well, it is all because the contrast increased due to liquid crystal"s twist angle for STN lcd.

Meanwhile, as the display contrast increased for the STN LCD, it bring wider viewing angle for STN lcd than TN lcd display. STN lcd viewing angle could be reach 120 degree, while TN lcd viewing angle around 90 degree.

FSTN lcd display mode is the profession name for black-white STN mode, it is white background and black display characters. it is the nearest color to paper in monochrome lcd, even its real background is a little near to gray. FSTN LCD mode is one of STN mode, it is mean film STN, instead of the background color to yellow-green color or blue color, FSTN LCD add a optics compensating film on the front of FSTN LCD, the optics compensating film compensate the linear polarize light and color from STN LCD, the STN LCD color turn to white background after light through the optics compensator film. that is the compensating film turn the oval polarized light to the linear polarized light again,then we could get thewhite and black lcd display. it is the display mode that near to paper.FSTN lcd is widely used in many display application because of its background.

FFSTN is FSTN LCD in negative display mode, it is also a kind of white-black stn lcd mode, FFSTN lcd is negative background with white display characters, while FSTN lcd is white background with black characters, its background would be in black, and display white characters. FSTN lcd would need one layer polarized light compensation, FFSTN would need two layers polarized light compensation on the front and rear polarizers, it would need higher cost than other STN LCD, but FFSTN LCD is best lcd soluton in STN LCD. it is higher contrast than other types of lcd.

CSTN lcd means color STN LCD, its display technology is based on FFSTN mode, but it have a RGB color filter in side the lcd glass, so it can realize to color display, and because FFSTN have high contrast, so instead lcd font display to other STN LCD, CSTN LCD is better in image display than other monochrome lcd. but CSTN lcd is still type of stn lcd, it have cross-talk effect, which decreased the contrast than TFT LCD which is active display mode without cross-talk.

Because STN lcd display is 240 degree twist angle, it have better display contrast than TN display in 90 degree twist angle. the STN display could support the 1/240 duty lcd, that with 480 segment x240 common graphic lcd. and the TN lcd only support 1/8 duty with 8 commons maximum. so TN lcd is mainly used in segment lcd display or icon lcd display. STN display is mainly used in graphic lcd display. of course, if STN lcd is also can be used segment lcd display or icon lcd display, but its cost would be around double than TN lcd display.

STN LCD display require less power and are less expensive to manufacture than,STN displays typically has lower image quality and slowerresponse timecompare than TFT displays. and tft lcd display is mainly in color display, but STN LCDs have the advantage that it can be made purely reflective for viewing under direct sunlight. STN LCD is a good choice for sunlight readable display in outdoor, for it has a display effect in outdoor and less power consumption. such as transflective STN lcd or reflective STN LCD, it can be display good without backlight light on.

TFT (thin film transistor)is still one kinds of lcd, but it active matrix lcd which without cross-talk with higher contrast than STN LCD or monochrome TN LCD. because of the thin film transistor inside, it is without cross-talk problem, and easily to get the high contrast. besides IPS tft, most of tft lcd is still TN LCD display mode, that is 90 degree twist angle to the liquid crystal.

TN displays have a 90° or less twist (the rotation of the molecules from one plane of the display to the other). All passive direct drive, active matrix, and most passive low level (x2 to x32) multiplexed LCDs have a 90° twist.

The basic Twisted Nematic (TN) LCD consists of a layer of liquid crystal material supported by two glass plates. The liquid crystal material is a mixture of long, cylindrically shaped molecules with different electrical and optical properties, depending on direction.

The TN technology comes in a single coloration; it is Black characters on a gray background. It is the least expensive, but has the lowest visual quality, primarily in viewing angle.

![]()

TN (TN English Twisted Nematic acronym) is a liquid crystal 90 degrees twisted nematic liquid crystal. Twisted nematic liquid crystal display (LCD) appeared in the 70s of last century. Besides the basic characteristics of LCD, it has the characteristics of high contrast, simple manufacturing technology, low cost and so on. At present, a large number of portable calculators, clocks and instruments are used in this type of liquid crystal display. At present, the domestic LCD manufacturers are also the production of such products.

Twisted nematic (TN) liquid crystal display is made between two pieces of ITO glass plate with twisted nematic (TN) liquid crystal material is formed, the thickness of the liquid crystal is generally 5 m, the thickness and birefringence of liquid crystal material rate, on the ITO glass substrate coated layer orientation, Li with the interaction of liquid crystal molecules and the alignment layer surface, the friction and surface orientation of liquid crystal molecules arranged parallel to the direction with 2 - 3 degrees tilt angle as shown in figure 1-2. On the substrate of directional friction into 90 degrees, so that the liquid crystal molecules twisted into 90 degrees, and mixed with a small amount of chiral liquid crystal materials to the agent, the liquid crystal molecules distortion in the direction of the effect. A polarizing plate is attached on the outer part of the upper and lower glass substrates, and the optical axis of the polarizer is consistent with the friction direction of the glass substrate, so that the display of the white light is displayed on the LCD screen. When the polarization of the incident light surface with the liquid crystal molecules rotate 90 degrees, the polarized light through a polarizer, the bright state. When a voltage is applied is liquid crystal molecules with the electric field direction of linearly polarized light polarization invariant, polarized light can not pass out of Polaroid light side of the dark state, so the liquid crystal display is a light electric control valve. But because of the twisted nematic liquid crystal display (TN) is currently in the optimal conditions, it is actually the biggest number of scanning lines can reach 32, the information capacity is very small, and because it can only be made of black and white, color, low contrast (20:1) liquid crystal display, from the perspective of only 30 degrees, relatively narrow, panel size a maximum of only three inches, so greatly limits the application scope of his. It can only be used on spreadsheets, calculators, and simple handheld games.

A type of LCD panel technology. In this type of panel, when no electric current is running through the liquid crystal cells, the cells naturally align in a twisted form between two substrate panes of glass which blocks the transmission of light from the backlight. This renders the crystals opaque and results in a black display screen. When an electric current is applied, the liquid crystal cells untwist allowing light to pass through resulting in a white display screen. TN panels have relatively narrow viewing angles especially in the vertical direction and color reproduction is poor; however, they are economical and suitable for a wide-range of general uses, particularly with office tasks (e.g. word processing).

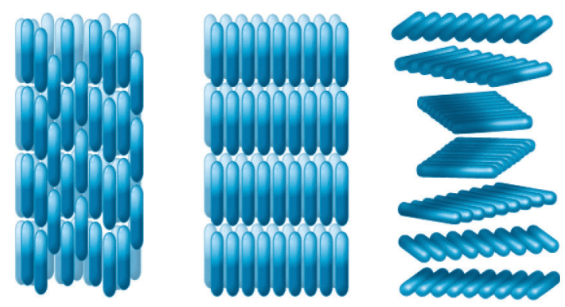

The Nematic liquid crystal state is a unique state not included in the above 3 states. It is a state between the crystalline (solid) and isotropic (liquid) states. Even in the state of liquid crystals, there are several types of liquid crystal states, as below.

The nematic liquid crystal phase is characterized by molecules maintain the general order of tending to point in the same direction. It has one dimensional order. See Fig.1

In smectic phase, molecules show two-dimensional order not present in the nematic. The molecules maintain the general orientationally of nematic, but also tend to align themselves in layers or planes. It is the state between nematic (one-dimensional order) and solid state (three-dimensional order). See Fig.1.

The cholesteric (or chiral nematic) liquid crystal phase is typically the molecules are directionally oriented and stacked in a helical pattern, with each layer rotated at a slight angle to the ones above and below it. See Fig.1.

The field of the invention is that of cockpit displays in which the display devices comprise a liquid crystal matrix, also called “LCD”, standing for “Liquid Crystal Display”. These display screens are nowadays tilted in all types of fixed or revolving wing aircraft in both civilian and military domains.

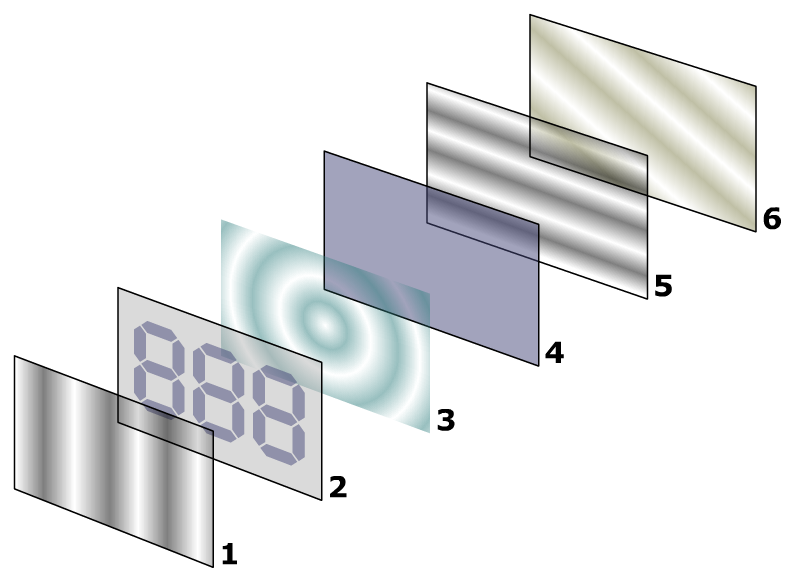

An LCD screen operates on the principle of matrix addressing. As can be seen in FIG. 1, the LCD screen is made up of coloured individual pixels organized in a matrix. Six pixels P are represented in FIG. 1 with different shades of grey representing the colours of the pixels. Each pixel P is made up of a thin thickness of liquid crystal contained between two electrodes, a first so-called control electrode and a second, back electrode B, called “backplane”, common to all the matrix and symbolized by ellipses in FIG. 1. The potential difference or ddp between the electrodes is controlled by a so-called “TFT” (thin film transistor) transistor. This potential difference acts on the orientation of the liquid crystal molecules and therefore on their light transmission. Each transistor TFT is located at the intersection of a row L and of a control column C. The gate G of each transistor TFT is linked to a particular row and the drain D to a particular column.

The LCD screens used are generally based on the so-called “twist nematic” (TN) technology because it offers the advantage of offering more optical transmission than the other technologies.

FIGS. 2aand 2brepresent, as a function of the time t, the voltages applied in volts in two configurations of use. In the first, so-called “BLACK LCD”, configuration, the liquid crystal is opaque; in the second, so-called “WHITE LCD”, it is transparent. The “backplane” voltage represented by a dotted line in FIGS. 2aand 2bis continuous and set at around 6 volts. In both cases, in order not to create a marking, the liquid crystal receives an alternately positive then negative DDP corresponding to the “positive phases” and “negative phases” of FIGS. 2aand 2b.

The drawback of this technology is that it naturally presents a white screen that is said to be “normally white” when the latter is defective or uncontrolled. This white screen with strong brightness compared to a traditional display with dark background of the “PFD” (primary flight display) can be a nuisance to the pilot.

FIG. 3 represents a set of two dual displays denoted LCD1 and LCD2. The expression “dual display” should be understood to mean a display comprising a single LCD matrix arranged in such a way as to display two totally independent or segregated images. More specifically, a dual display comprises two independent power supplies, two independent light boxes, two independent graphic generations and two independent sets of row and column drivers. Thus, a first failure of any kind does not result in the total loss of the display device. In FIG. 3, the left hand display LCD1 is perfectly functional and presents two displays denoted D1Gand D1D. The left hand part D2Gof the right hand display LCD2 has failed and displays a white screen. Only the right hand part D2Dis operational.

The device according to the invention does not present these drawbacks. It makes it possible to force a black display on an LCD screen of twisted nematic type even if the latter is no longer controlled after, for example, a failure of the row drivers or of the column drivers. In the case of use of a dual screen, the device according to the invention also makes it possible to keep the second display operational without the pilot being hampered by the failed display that has become white. Thus, neither the system nor the pilot has to be concerned with the failure of the LCD. The device according to the invention therefore has a dual action: to not present an erroneous image and to avoid hampering the pilot.

More specifically, the subject of the invention is a display device (e.g., as shown in FIG. 7) comprising an active liquid crystal matrix of twisted nematic type,

The display device according to the invention conventionally comprises an active liquid crystal matrix of twisted nematic type comprising:a first set of pixels, a first set of rows and of columns, a first electronic control device and first means for monitoring or detecting the correct operation of the first electronic control device;

These simple arrangements make it possible, by slightly modifying the basic electronics of an LCD screen, to be able to force a “normally white” TN LCD to display black and to do so regardless of the operational state of said screen.

In the case of a dual display, the preceding cut-off means are duplicated for each display area. The system is no longer required to cut off all the equipment when just one of the displays is effected, as can be seen in FIG. 5 which uses the same notations as FIG. 3. The still-functional half-screen D2Dof the display LCD2 is maintained, thus making it possible to retain the reconfiguration capabilities as demanded by the aeronautical safety requirements.

Thus, in the display system of FIG. 3, the failure of the display of the half-screen D2Gresulted both in the appearance of the white screen and the loss of the so-called “PFD” information display, information that is essential for piloting. In the case of the display system of FIG. 6, the failure of the display of the half-screen D2Gresults in both the appearance of the much more ergonomic black screen and the reconfiguration of the so-called “PFD” information display on the still-functional part D2Gof the display LCD2.

Everyday, we look at LCD display, TV, cell phone, monitor. It becomes a necessity in modern society. LCD panel is the most important part of an LCD display. It determines LCD screen"s performance, e.g. brightness, contrast, color and viewing angle. Therefore, picking the right type of LCD panel is critical to your application.

These names reflect the alignment of crystal molecules inside the LCD, and how they change when they are charged electrically. All liquid crystal displays change the alignment of liquid crystal molecules to work, but the manner in which they do so can drastically affect the image quality and response time. Each panel type has its advantages and disadvantages. The easiest way to choose between them is to decide which attributes are most important to your project. It mainly depends on what you use your LCD display for, and your budget.

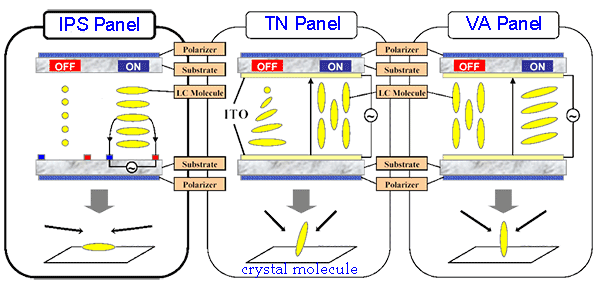

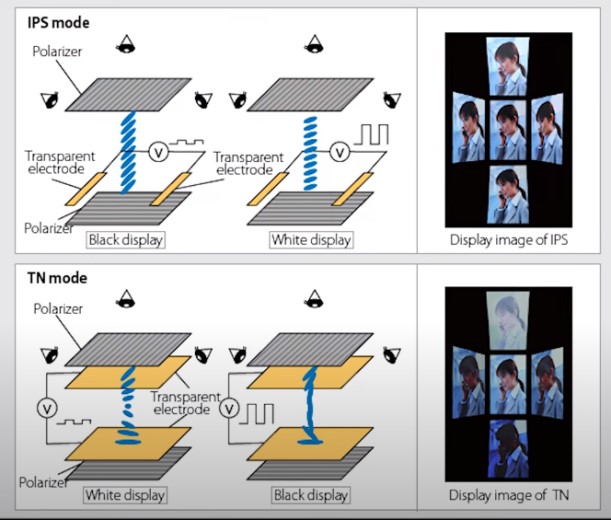

TN is the most mature technology in LCD panel manufacturing. When there is no voltage difference between the two transparent electrodes, liquid crystal molecules are twisted 90 degrees, in combination of upper and bottom polarizers, allows light to pass through LCD. As voltage applied, crystal molecules are untwisted and aligned to the same direction, blocking light.

In IPS panel, crystal molecules are parallel to the glass substrates at initial stage, LCD is off. When the in-plane electrodes is charged, crystal molecules are rotated, modifying light"s direction. Which lights up the LCD display.

As its name suggests, VA panel"s liquid crystals are aligned vertically without charged. When a voltage is applied, the molecules tilt and modifying light direction.

So in summary, TN panels twist, IPS panels use a parallel alignment and rotate, while VA panels use a perpendicular alignment and tilt. These difference create LCD display with distinctive performance.

IPS LCD is the clear winner in this aspect. It has 178/178 viewing angle ratings. Which means you can look at IPS LCD display from any angle without the image shifting in color and contrast. VA LCD has pretty wide viewing angle, too. But it has contrast shifts at off-center angles. As for TN LCD, viewing angle is its weakest point.

Most TN LCDs have 6-bits colors. Manufacturers use frame rate control (FRC) to enhance its color performance. For IPS and VA panels, you can still find 6-bits entry level LCD. But most of them are 8-bits. And IPS technology can provide natively 10-bits colors.

Color gamut is another part that VA and IPS panels shine at. The best TN LCD can reach sRGB gamut. VA panels typically start with full sRGB coverage, and get to around 90% DCI-P3 coverage. With IPS LCD panel, you could find the best ones full DCI-P3 and Adobe RGB coverage. That is why you see most professional grade LCD displays use IPS panel.

There is no inherent differences among the three panel technologies, because LCD backlight is the main factor here. However, there is a big gap in terms of contrast ratio. TN LCD panel tends to have the lowest value among the three. IPS LCD screen sits in the middle can reach 1500:1. For VA panel, the best one can exceed 4500:1 easily. VA LCD display provides far darker screen than TN & IPS. That is why they are used in vehicle dashboard.

TN panel does have an advantage when it comes to refresh rate. The panel offers the best refresh rate and response time. This is the reason why most gaming LCD monitors are made of TN panel.

TN LCD provides the best refresh rate and economic solution. If your application requires wide viewing angles and good color presentation, VA panel is probably the choice. While IPS has the best overall visual performance, in general it is more expensive than the other two.

Liquid crystal displays mainly use electro-optic effects, including dynamic scattering, distortion effects, phase change effects, guest-host effects, and electrically controlled birefringence effects. From the perspective of technological development, the liquid crystal display device (Liquid Crystal Display device, LCD) has mainly experienced four development stages.

In 1968, G.H. Heilmeier of the Princeton Institute of Radio Corporation of America (RCA) discovered the dynamic scattering phenomenon of liquid crystals. In the same year, the company successfully developed the world"s first dynamic scattering liquid crystal display (Dynamic Scattering LCD, DS-LCD). From 1971 to 1972, the first watch using DS-LCD was developed, marking the practical stage of LCD technology. Since the movement of ions in dynamic scattering easily destroys liquid crystal molecules, this display mode is quickly eliminated.

In 1971, Swiss M. Schadt et al. disclosed the twisting effect of nematic liquid crystals for the first time. In 1973, Japan"s Shengbao Company developed the Twisted Nematic-Liquid Crystal Display (TN-LCD), which was used to make digital displays for electronic calculators. Due to the low manufacturing cost and low price, TN-LCD was mass-produced in the 1970s and 1980s, mainly used for pen-segment digital display and simple character display.

In 1984, T. Scheffer discovered the super twisted birefringence effect and invented the super twisted nematic liquid crystal display (Su per Twisted Nematic-LCD, STN-LCD) technology. Compared with TN-LCD, STN-LCD has greatly improved display capacity and viewing angle. Because STN-LCD has the characteristics of high resolution, wide viewing angle and good contrast, it will soon be widely used in notebook computers, graphics processors and other office and communication equipment with large information capacity display, and become the mainstream product of this era.

In the late 1980s, Japanese manufacturers mastered the production technology of Thin Film Transistor LCD (TFT-LCD) and began mass production. In 1988, 10.4in TFT-LCD was born; in 1990, notebook computers using TFT-LCD were mass-produced; in 1998, liquid crystal display technology entered the application field of desktop displays, and reflective TFT-LCD began production. Based on the rapid development of active-matrix liquid crystal displays, LCD technology has begun to enter the stage of high-quality liquid crystal displays. With the further development of technology, the production cost of TFT-LCD has dropped significantly, eventually surpassing the market share of CRT. After entering the 21st century, with the development of TFT-LCD production lines from the 8.5th generation line to the 10th generation line, the increasing popularity of large-screen LCD TVs has fundamentally changed the face of the display industry. The liquid crystal display industry has developed into a new industry with an annual output value of hundreds of billions of dollars, occupying a leading position in the field of information display.

As the key component behind liquid crystal displays (LCD), these materials change light polarization to create vibrant, high-resolution images on digital screens. The growth of LCD technology has helped propel the larger display panel market enormously, with industry valuation projected to reach $178.20 billion by 2026.

A prolific variety of LCD types has been developed to best meet their exact use-cases and end-environments. Displays may be optimized for power consumption, contrast ratio, color reproduction, optimal viewing angle, temperature range, cost, and more.

Passive Matrix LCDs are addressed with common and segment electrodes. A pixel or an icon is formed at the intersection where a common and a segment electrode overlap. Common electrodes are addressed one-at-a-time in a sequence. Segment electrodes are addressed simultaneously with the information corresponding to all pixels or icons connected to the current common electrode. This method is referred to as multiplexing.

Passive Matrix LCDs offer a cost advantage (both parts and tooling) and are highly customizable. The counterpart to Passive Matrix displays are Active Matrix displays.

Active-Matrix LCDs were developed to overcome some of the limitations of Passive Matrix LCDs – namely resolution, color, and size. Within an Active-Matrix LCD, an “active element” is added to each pixel location (the intersection between a horizontal row and vertical column electrode). These active elements, which can be diodes or transistors, create a threshold and allow control of the optical response of the liquid crystal structure to the applied voltage. Transistors are used as switches to charge a capacitor, which then provides the voltage to the pixel. Whenever a row is turned on, one at a time, all transistor switches in that row are closed and all pixel capacitors are charged with the appropriate voltage. The capacitor then keeps the voltage applied to the pixel after the row is switched off until the next refresh cycle.

Furthermore, the processes used for manufacturing Active-Matrix LCDs can create much finer details on the electrode structure. This allows splitting each pixel in three sub-pixels with different color. This together with the better voltage control allows full color displays.

Currently the most common Electronics Display Technology on the market is LCD technology and among LCD technologies, TFT display technology is the most widely used across consumer applications (laptops, tablets, TVs, Mobile phones, etc.) as well as many industrial, automotive, and medical applications.

Nematic refers to one of the common phases of liquid crystals (LC). In this phase, rod-like molecules tend to self-align more or less parallel to each other.

As the first commercially successful LCD technology, Passive Matrix Twisted Nematic (TN) LCDs use a 90° twist of the nematic LC fluid between two polarizers to display information. The twist of the LC fluid either blocks light from passing through the LCD cell or allows light to pass, depending on the applied voltage. The applied voltage changes the twisted nematic orientation into an orientation that does not change the polarization of tight. This is called the TN effect.

TN displays can be normally white (NW) when they use two orthogonal liner polarizers or normally black (NB) when parallel linear polarizers are used. ‘Normally’ refers to what happens when no voltage is applied.

Initially, Passive TN LCDs were used in segmented, icon, or character displays where an image element was turned “on” and “off” depending on how the fluid was driven. Improvements were made along the way to address the limited viewing angle of TN technology, which can suffer from contrast loss or even inversion at shallow angles.

It can be advantageous to twist the director of the nematic phase a bit more than 90 degrees, but less than 180 degrees. Displays like this are a subset of TN displays and are sometimes caller Hyper Twisted Nematic Displays.

The numbers of rows or icons that can be addressed in a TN display without Active Matrix addressing is very limited. This is related to how strongly the liquid crystal responds to the applied voltage. Twisting the LC nematic fluid more than 180 degrees (typically between 210 and 270 degrees) causes the display to require a much smaller voltage difference between on and off pixels. This in turn allows addressing of many more rows without an active matrix. Displays with a twist between 210 and 270 degrees are called Super Twisted Nematic displays.

The higher display resolution of STN displays comes at a price. The optical effect is no longer neutrally black and white as in a TN display. Rather these displays are naturally yellow and black or blue and white. The color can be somewhat compensated with colored polarizers, but that comes at the expense of brightness and contrast.

The color in STN displays is caused by birefringence. Adding the same birefringence in the opposite direction can compensate for the effect. Initially this was done by stacking two STN displays on top of each other. This is referred to as Double STN or DSTN, but this is of course thicker and more expensive.

The birefringence of an STN display can be approximated with a stretched transparent plastic film. Adding such a film to an STN display instead of the 2nd STN display is a lot more attractive and has almost the same performance. This is referred to as a Film Compensated STN display (FSTN, or sometimes if two films are used as FFSTN).

FSTN displays are used commonly in consumer, medical and industrial display applications that require low cost and do not need high resolution images or full color.

Another development to the TN display was to use the same concept as in FSTN displays on TN displays. However, the film cannot just be a stretched polymer. Instead, a twisted liquid crystal structure is made and polymerized into a film that is used as a compensation film for TN displays. As this method mostly improves the display characteristics at shallow viewing angles while preserving the excellent performance in straight on viewing, this technology is called Wide View Twisted Nematic (WVTN).

Due to the ability in AM displays to address one row while the other rows are isolated, the demands on the electro-optical performance of the Liquid Crystal Configuration are less stringent. In principle, all the above mentioned configurations can be used in AM displays. In practice, TN, and WVTN are frequently used as well as some versions of VA technology described below. (MVA, AIFF-MVA, PVA, ASV).

The advantage of these technologies is a much wider and more symmetrical viewing angle along with the elimination of the contrast inversion (or color shift) seen in TN TFT LCDs when viewed from various angles. IPS and FFS displays also are less sensitive to pressure, which is a big advantage in touchscreen displays.

Legacy LCDs normally have the driver ICs (integrated circuit) mounted on a printed circuit board (PCBA) which consists of a flat sheet of insulating material used to mount and connect the driver IC and electronic periphery to the LCD. PCBs can be a single-sided, double-sided or multi-layer.

New Vision Display (NVD) has decades of experience designing and manufacturing custom display and touch panel assemblies for some of the world’s largest original equipment manufacturers (OEMs) in the automotive, medical, industrial, and consumer markets.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey