possible to replace a broken lcd panel for an iphone made in china

Mandy, ETS is obviously a company that you are connected to and this could easily be taken for spam. I think we can make an exception at this time since you are asking a good market research question that may be useful to many.

Having checked out your video, I personally will not use the aftermarket screen as a replacement for my X. It just doesn"t have what I expect for a $1000 USD phone. I recognize that $300 USD for a replacement is hefty but the aftermarket screen does not appear to have the quality that I would expect for my phone.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

“Original” screens are those containing LCDs manufactured for Apple. “Copy” screens are compatible replacements entirely designed and manufactured by third-party companies not associated with Apple.

LCD display panel can have poorer resolution (i.e. looks “coarser”), worse brightness, contrast and vibrancy and reduced refresh rate amongst other problems.

Changes in specification from original can result in battery and performance issues. Certain badly-engineered screens could even damage the backlight circuitry.

Customers who bring their iPhones to us for a screen repair are offered two choices of replacement- an original or a “copy” screen. The most common response is “Is there a difference- and which one would you recommend?”

Originals are those screens containing LCDs that were manufactured for Apple. So-called “copy” screens are compatible replacements, but designed and manufactured entirely independently by third-party companies, typically in China.

Our answer is simple- the original screen is the one we’d go for ourselves, every time. Some people think we make more money on them, but this isn’t the case. We recommend originals because they’re far higher quality and the price difference is fairly small.

We’d rather only fit original screens. The only reason we don’t is that many people will shop around and choose purely on price. As such, we need to offer the cheaper copy screens to remain competitive and avoid losing these customers. In some cases, they didn’t even know there was a difference in the first place- especially since it’s not in some shops’ interest to draw people’s attention to the issue!

This may well be the worst copy screen we’ve ever come across. As a result, the unfortunate customer has ended up paying twice to have their screen replaced- we’re sure that had they been properly informed, they would have chosen an original in the first place.

While the difference in price between copies and originals can vary across devices, it’s generally around £10 – £14 extra to have an original screen fitted. This really isn’t a lot considering the improved quality and reliability.

We compare our prices to our competitors- and we know that we come out of it favourably. While we have to offer copy screens to remain competitive, we always advise customers to go for the original.

When you’ve spent- directly or indirectly- several hundred pounds for an iPhone with a Retina display, it doesn’t make sense to replace it with a lower-quality screen that can make a £400 phone look like a £40 one! Not only that, but you’re likely to have fewer issues, and a longer-lasting screen.

There’s nothing stopping any random person without training or experience opening up a smartphone repair shop. As a result, the industry is full of companies with little skill or experience who are only interested in getting hold of your money and installing the cheapest parts they can find.

Many- if not most- don’t even acknowledge the existence of copy screens, let alone explain the difference to the customer. Hardly in their interest to do so if they only fit cheap, low-quality copies. Some of them can hardly be blamed- they know so little, they’re not even clear on the differences between OEM, non-OEM and copy displays themselves! Others can be more deliberately misleading… and some outright lie.

Generally, these shops are looking for the cheapest price on replacement screens.. When offered a copy at a half or a third of a price of the original, they’re going to go for that. That might be fine if they offered the customer a cheaper price- what we disagree with is selling “supermarket beans” (i.e. the copy screens) at “Heinz beans” prices!

Heading towards the “blatantly fraudulent”, we’re aware of companies that shamelessly fit copy screens while claiming them to be original. Worse, they’ll take your broken original screen and sell that to a recycler for more than they paid for your copy!

Obtained or manufactured “off the clock” via the same production line that produced them for Apple- in some cases, from the stockpile of parts that didn’t meet Apple’s standards, or

Apple tightened up their supply chain around 2015, which reduced the number of screens available for repairs and increased their price dramatically. A lot of companies went bankrupt, and Chinese manufacturers responded by making their own “copy” screens from scratch. At first, these weren’t much cheaper than the Apple ones, but the price soon fell.

We should be clear that- despite the name- “copy” screens aren’t direct copies of the Apple originals. Rather, they’re compatible replacements that have been designed from scratch and- as a result- vary in some respects that have an effect on usability and quality.

One of the most important differences between an original and a “copy” screen is how the digitizer (touch sensor) is designed. Apple has it manufactured as part of the LCD itself, whereas the copies have it on the glass.

Although there are only a small number of manufacturers of the bare LCDs themselves, these are then bought by countless other companies who add the remaining components needed to turn these into a complete working screen. As a result, you could easily end up with an LCD from the best “copy” manufacturer, but the digitizer/touch (as part of the separately-manufactured glass) from the worst.

There are countless digitizers out there, and you can only take the supplier’s word that the quality is good. Many ship good ones at first, then switch to cheaper parts to make more profit. This is particularly bad with the iPhone 6S and 6S+, since Apple moved the chips responsible for touch processing onto the LCD itself. As a result, you’re not just getting a copy screen- you’re getting copy chips too.

The performance specification (power drain, etc.) of most copy screens isn’t identical to the originals. As a result, they can drain the battery more quickly and mislead the operating system which was optimised for the original screen design.

It’s even possible that this mismatch could damage your backlight. We do a lot of subcontracted repairs for less-experienced shops, and get backlight repairs in almost every day. We’ve had cases where we fixed the circuit, fitted the new copy screen to test it, and had it break the circuit again!

Copy screens can disrupt the touch ID fingerprint reader. With the 6S, 6S+, 7 and 7+, the home button- part of the 3D touch- is part of the screen assembly. Frequently the home button flexes on aftermarket designs don’t work properly and stop the touch ID working- annoying if you use it to unlock the phone or log in to your bank.

We’ve seen many lift away from the frame that holds them in place. This usually results in the flex cable getting torn, and the screen needing replacing. You don’t even need to have dropped the phone- this often happens through general everyday wear and tear.

That brings us to another major issue with the copies. When you drop an Apple original, the glass often breaks, but if the LCD itself is intact, you can continue to use it until it’s fixed. With the copies, the touch/digitizer is on the glass and stops working when that’s broken. Even worse, the LCD itself is more likely to break due to the thinner and more fragile glass.

We’re not convinced this will happen, since Apple recently changed their repair policy to accept iPhones with third-party screens. However, it is possible that copy screens could be stopped from working via an iOS update, since those make a number of security checks.

Use our “Get an Estimate” tool to review potential costs if you get service directly from Apple. The prices shown here are only for screen repair. If your iPhone needs other service, you’ll pay additional costs.

If you go to another service provider, they can set their own fees, so ask them for an estimate. For service covered by AppleCare+, your fee per incident will be the same regardless of which service provider you choose.

Your country or region offers AppleCare+ for this product. Screen repair (front) is eligible for coverage with a fee by using an incident of accidental damage from handling that comes with your AppleCare+ plan.

The Apple Limited Warranty covers your iPhone and the Apple-branded accessories that come in the box with your product against manufacturing issues for one year from the date you bought them. Apple-branded accessories purchased separately are covered by the Apple Limited Warranty for Accessories. This includes adapters, spare cables, wireless chargers, or cases.

Depending on the issue, you might also have coverage with AppleCare+. Terms and Conditions apply, including fees. Feature availability and options may vary by country or region.

We guarantee our service, including replacement parts, for 90 days or the remaining term of your Apple warranty or AppleCare plan, whichever is longer. This is in addition to your rights provided by consumer law.

Replacement equipment that Apple provides as part of the repair or replacement service may contain new or previously used genuine Apple parts that have been tested and pass Apple functional requirements.

Since the iPhone 7/7 Plus has been released for quite a long time, finally the China made iPhone 7/7 Plus screen replacementscame out in the market. we’ve got some iPhone 7 series LCD screen replacements samples and done some tests on them, now let’s take a closer look at these new iPhone 7 series LCD screen replacements!(TianmaandLGsources for testing)

After installing all the sample screens to the iPhone 7/7 Plus rear housing assembly, we found that all the China made iPhone 7 series screen replacements are fitting well just like the original ones - the home button fits well, the screen assembly and the rear housing also fits well.

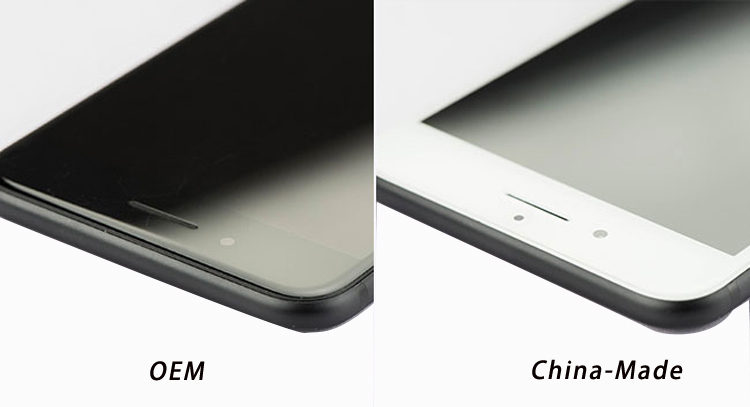

From the picture below, we can see that there is no difference between the China made iPhone 7 series display and the original ones, however, back to the rear side, we can easily figure out which one is which, cause the original one has Apple logo on it while the China made screen has none.

By comparing these two iPhone 7 screens, we can find that the screen flex cables are much different, there are extra IC on the China-Made iPhone 7 screen while the original one has none. And the original iPhone 7 series screen flex cable is integrated together while on the China-Made iPhone 7 series screen the touch function flex cable is soldered to the display and 3D touch flex cable.

Another difference between the original and China made iPhone 7 screen replacements is the exposed IC on the after-market iPhone screen, just like other China-Made iPhone 5 or 6 series screen replacement, which has more potential risk of electrostatic damage and more likely to get damaged and this problem needs to be improved.

During our test, we found that the display color between our after-market iPhone 7 screen and original screen seems a little different although they are not effecting the touch function. And to be honest, there may have some black dots on the screen because of impurities within the screen module when laminating the LCD and backlight together, without any doubt, this can be solved with technical improvement.

The screen touch sensitivity is another big concern for all of us, luckily, during our test, almost all home button and touch functionality on both iPhone 7 and 7 Plus works well, except one piece of iPhone 7, the 3D touch function is not acting so well on the central part of the screen.

The China-Made iPhone 7 series LCD screen assembly replacement still remains to be improved in quality and performance compared to the original ones, the exposed IC, heavier screen flex cable ribbon, and the screen color difference, the touch function stability, although the price is attractive. However, the China made iPhone 7 series screen replacement is under the improvement, and sooner or later their quality and performance can be quite close to original ones and acceptable, if you"re going to stock up some non-original iPhone 7 series LCD screen replacement, pay more attention and we’ll keep you updated with further information about after-market iPhone 7 series screen replacement!

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

With the lack stock of the original iPhone 5 & 6 series LCD screen, the China made LCD screens becomes more and more popular among the repair shops. As the originaliPhone 6 Plus LCD screenprices are still high and not likely to fall down, plus more and more repair shops are tending to accept the China made LCD screens replacement instead, therefore, China made iPhone 6 Plus LCD screen appeared on the market naturally.

Recently we have got some samples of the China Made 6 Plus LCD screen, which have been called ‘LG 1:1 version’ on the market. We did some tests with these samples and found some differences compared to other China made LCD screens.

After tests, we found some differences in LCD frame height, glass screen thickness and the home button location among these 5 samples. You may wonder why these differences exist while they are sourcing from the same manufacturer?

Thus we need to learn the production process of the China made LCD screens, which was assembled by the 3rd party manufacturers, who purchased the China made LCD,LCD frame,glass lens,metal shields, screen foam and digitizer from different manufacturers, which could be original or high copied ones. Since there are some differences among theseglass lenses, LCD frames and so on, even though they shared the same LCD, there will still be some difference.

There is no doubt that significant differences existed between these 2 kinds of LCDs whether in display effect or working stability. In pursuit of greater profits, there is no strict requirements and standards for China made LCDs production process as long as the LCDs can achieve the basic using requirements. Therefore there is quite a gap in color difference, viewing angle and working stability compared to original ones, as the LCDs which are designed for the other brand cellphones, after replacing the IC and flex cable, have been inspected strictly before flowing to the market. (Such as the Samsung GalaxyS3 LCD screen assemblywhich are transformed from the GiONEE phones. Due to the few original stock in availability, most of the S3 LCD screen assemblies are produced by Samsung through transforming GiONEE LCDs.

It is said that these China made iPhone 6 Plus LCD screens are transformed from the MeiZu Meilan Note LCDs (Also features 5.5 inches) which are produced by Sharp and AUO, the overall performances of these LCD screens are better than LT/TM/JDF’s. And what’s big different from the other LCD screens is that there is one more LCD drive IC on the screen flex cable.

Because of the big production MOQ and long R & D cycle, the customized China made LCD screens had some difficulties intechnologyimprovementwith the changes of the marketing demands, while the original LCD features higher quality and reliability.

For these China made iPhone 6 Plus LCD screens, theLCD frametending to pop off and LCD screens are thicker. But in display effects, China made iPhone 6 plus LCD screens are better than5 series. Those customers who cared more about the prices will have one more choice once the improvements of the China made iPhone 6 Plus have been implemented. And we also will continue to focus on the China made iPhone 6 Plus LCD screen assembly.

As part of its new $149 iPhone screen replacement service, Apple has installed advanced display calibration machines at its retail stores that help simplify the process for employees.

A picture of the new machine was published this week by 512pixels.net, offering a glimpse at how iPhone 5 screens are replaced behind the scenes at Apple retail stores. Employees conduct the repair, and the machine is used afterward to automatically calibrate the display"s functionality.

One Apple retail employee reportedly said the new machine is like "bringing China to the Genius Room," referencing the fact that Apple"s iPhones are currently built overseas by Foxconn.

iPhone repairs are said to have been made a priority for employees of Apple"s Genius Bars. With sales of 47.8 million iPhones last quarter alone, Apple"s smartphone sold more than every other product in the company"s portfolio combined.

Word first surfaced earlier this week that Apple began repairing iPhone 5 screens in its stores as part of the company"s overhaul of its AppleCare warranty program. Previously, broken units were swapped out for refurbished devices.

AppleInsider first reported in May that Apple would begin conducting advanced in-store repairs of iOS devices. Beyond iPhone displays, retail employees will be able to replace cameras, sleep/wake buttons, and logic-boards by July.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

After Samsung, iPhone screens tend to be the ones that require frequent repairs. This could be because iPhone screens are made of glass - they crack pretty easily if subjected to rough usage!

There is no dearth of iPhone replacement screens in the market. Such is the quality of the ‘high copies’, that it becomes extremely difficult to distinguish it from the original!

All original Apple screens are manufactured by LG or Sharp, whereas the high copies are manufactured by aftermarket companies such as Longteng (IVO), TianMa, ShenChao, KingWo (Teevo), JingDongFang (JDF/BOE) and AUO.

Let us take the example of an IVO screen. A company first contacts IVO and asks them if they can produce a kind of LCD for their phone. They cannot ask IVO to develop LCDs for an iPhone outright - this could lead to copyright and patent issues with the parent company, Apple!

IVO and the company will sign an agreement, post which the company asks IVO to study the LCD in question. Once IVO produces the LCD, the company will ask its own factory or a third party’s factory to assemble the screens and proceed to sell.

Once the demand for these screens builds up, the company looks for other factories to assemble the screens for them, and continues to sell them in the market.

Eventually, the company will not assemble the screens themselves, as more brands keep coming in. They will directly sell the IVO LCDs to certain factories. These factories purchase the spare parts like the glass, frame, backlight, OCA, etc. themselves, and assemble the LCD with these spare parts.

To create a more effective cost-benefit ratio, and to compete with other similar factories, they may use different grades of spare parts, resulting in the differing quality of LCDs. In fact, the quality of Aftermarket LCD depends not only on the LCD, but also the quality of the spare parts used.

While it is always ideal to advise customers to buy original screens, the price differences between the originals and the copies could lead them to look around, and choose the cheaper alternative anyway!

In order to ensure that the customer is not cheated, it is important to explain the differences between the originals, good-quality Aftermarket copies and poor-quality Aftermarket copies. Some of the glaring differences are given below:

It is clear that the copies aren’t direct ‘copies’ of the original iPhone LCDs. They are closely compatible replacements that have been manufactured from scratch and may have varying differences in quality. Here are some of the quality issues customers may have to face:

One feature that differentiates an original from the copy is how the digitizer (touch sensor) is designed. In the case of an original, it is manufactured as part of the LCD itself. In the case of a copy, the digitizer is placed on the glass.

As mentioned earlier, while the bare LCDs are manufactured by a few, several other companies purchase these and assemble them along with the other spare parts to make them functioning screens. The quality of the spare parts used determines the ultimate quality of the screen.

So, even if you could purchase an LCD from the best “copy” manufacturer, the digitizer/touch (as part of the separately-manufactured glass) might have been sourced from non-dependable sources!

Unfortunately, the quality of the digitizers used would only be as good as the supplier’s word for them. A lot of them might switch to cheaper ones to gain a better margin!

For instance, with the iPhone 6S and 6S+, Apple moved the chips responsible for touch processing onto the LCD itself. The ‘copy’ screen will end up having ‘copy’ chips too!

Additionally, if you drop an Apple original, the glass often breaks, but if the LCD itself is unharmed, you can continue to use it until the glass is fixed. This is usually how Mobile Repair Stores and Aftermarket Suppliers refurbish original parts with aftermarket glass. As for the copies, since the digitizer is on the glass, it stops working when it breaks. In fact, the LCD itself is more likely to break due to the thinner and more fragile glass.

The LCD panels may have poor image quality, as mentioned earlier. They could have issues in brightness and contrast, a more ‘coarse’ look as compared to the original, and a reduced refresh rate.

There will always be a telling difference between the performance specifications of an original and a copy. For instance, in the case of a copy, the battery can get drained more quickly and mess with the operating system which was meant for the original screen design. Your backlight could get damaged too!

With the 6S, 6S+, 7 and 7+, the home button- part of the 3D touch- is part of the screen assembly. A lot of times, the home button flexes on copies don’t work properly and stop the touch ID from working.

There are issues with the frame that holds the LCD in place - often, they just come off! This can cause damage to the flex cable, and the screen will need to be replaced.

Given the differences between the original and the Aftermarket copies, it might seem wrong to promote the sale of the latter. However, it is a fact that customers tend to choose the cheaper copies over the originals. Also, customers may have to wait longer to get original replacements as most Mobile Repair Stores don"t keep them in stock.

So, what is important is to get replacement screens that are as close as possible to the originals. As mentioned earlier in the article, some of the most popular brands available in the market are Tianma, IVO, BOE, etc.

KingWo claims to provide a close to perfect copy of the iPhone LCD, especially in terms of brightness and polarizer. Here are some of the features it offers:

The BOE screen is thicker than the original because of a plastic layer added to the phone glass lens. The assembly weight, the home button size, and the thickness of the whole screen and glass lens are higher than the original.

In terms of price, ShenChao and JDF are usually considered as the cheapest screens you can find on the market. For Middle of the pack in terms of quality with a competitive pricing TianMa and Longteng are good choices. For the highest quality on the market KingWo (Teevo) and AUO are your immediate go to choices.

At TechRepair, we provide iPhone LCD screens and digitizers that are individually tested and packed into premium boxes. These parts are tested when manufactured and certified by our team to ensure the highest quality standards.

Looking for someone to sell your broken or unwanted screens? Sell them to us for in-store credit or PayPal! All screens will be tested by our team to verify the working status, and offer you the best rates on the market!

We guarantee the function of our products, any product found with manufacturing error will be exchanged immediately with a new piece in your next order. If you break a part during installation, we can’t replace it. If you accidentally damage the part after installation, we cannot replace it. C.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

I built a like-new (but really refurbished) iPhone 6S 16GB entirely from parts I bought in the public cell phone parts markets of Huaqiangbei. And it works!I’ve been fascinated by the cell phone parts markets in Shenzhen, China for a while. I’d walked through them a bunch of times, but I still didn’t understand basic things, like how they were organized or who was buying all these parts and what they were doing with them.

So when someone mentioned they wondered if you could build a working smartphone from parts in the markets, I jumped at the chance to really dive in and understand how everything works. Well, I sat on it for nine months, and then I dove in.

You might wonder why I chose to make an iPhone 6s and not an iPhone 7. I had two reasons. The first was that I already own an iPhone 6s that I bought in an Apple store, and I thought I might end up needing to have an identical phone to the one I was trying to build that I knew was assembled by Apple to compare against. In the end, this was never really an issue, and I never ended up having to open it up. It is nice to be able to show people the phone I built side-by-side with a phone bought in an Apple store though.

However, the other reason, which turned out to be far more important, is that iPhone 7 parts are pretty hard to come by in the markets. It’s not totally clear why this is, but I have some ideas. A lot of the parts come from recycled/broken phones, and so it would make sense that there just isn’t that much supply yet. I also think there’s probably really high demand for iPhone 7 parts, so what parts are available may get traded before they make it out into display cases. In some cases, even iPhone 6s parts were a bit hard to come by (mostly the logic board). I keep asking people about this, and people keep saying things like “there should be more after Spring Festival” (which has come and gone) or “there should be more in a month or two – it’s just a temporary shortage right now”. I’ll keep my eyes out – it’ll be interesting to see how this evolves over time.

Logic board – This is like the motherboard in a computer. It’s the circuit board that has the processor, flash memory, wifi/cell chips, etc on it. Everything plugs into this. The one I bought is refurbished/repaired, almost undoubtedly from a real, legitimately purchased phone made by Apple that was recycled at some point.

It came with the touch id sensor, because the processor and touch id sensor are cryptographically paired. This means that touch id no longer works if you swap out the touch id sensor. This is for security reasons, to make it harder for someone to malicious bypass touch id to unlock your phone without your permission. But it’s a really crappy restriction when it comes to repairing/refurbishing phones.

Screen – I really wanted to assemble my own. But there were two issues – you need a bunch of bulky equipment and I had an incredibly hard time trying to buy a bare lcd/digitizer. You can get them apparently, but they don’t seem to be readily available over the counter in the markets. So instead, I bought a broken screen from a phone repair booth, and had them completely disassemble and then reassemble it with new parts, other than the lcd/digitizer.

Back/Shell – I originally wanted to make a gray phone with a black front, to match my everyday carry phone I bought in an Apple store. That way I would have something to compare against. But I ended up having a hard time finding a logic board with a black touch id button. However, there were lots of logic boards with white touch id buttons with rose colored rings, meant for a rose colored phone. So I ended up buying a second, rose colored back, hence the rose colored phone. The back I bought had an Apple logo, but zero laser markings inside or outside, so I’m pretty sure it’s not from a used phone.

Today marks a set back for the right to repair movement. Henrik Huseby, a Norwegian small business owner and repairer lost his legal battle against $1 trillion company Apple in Norway’s Supreme Court. With this decision, Apple continues to effectively shut off access to refurbished or after market spare parts for independent repairers.

Apple claimed that Huseby was allegedly importing “counterfeit” iPhone screens. Huseby denied this, saying that he simply used refurbished iPhone screens that he never advertised to the public as “genuine” parts from Apple.

While the Oslo District Court ruled in 2018 that Huseby did not violate Apple’s trademark, because Huseby never claimed to be using unused original spare parts, the Court of Appeal ruled in 2019 that the imported screens are illegal copies. The case was then brought to the Supreme Court.

“This is a big victory for companies like Apple who want to shut down small businesses like mine and control the prices of repair. They can claim that the cost of changing a screen will be the same as buying a new one, so there is no value in repairing. They are blocking their competition and creating a monopoly” says Huseby.

Huseby took a considerable risk taking this case all the way to his Supreme Court, when other businesses in the same situation have given in to Apple in order to avoid trial and considerable legal expenses.

He was supported by €10,000 in donations to his crowdfunders that arrived from hundreds of donors from Norway, Europe and the rest of the world. After having paid fees for his appeals, he now faces severe financial consequences, which include paying his own legal team and €23,000 to Apple.

The Norwegian judges made the final decision purely assessing trademark violations on these screens, based on obscure and technical details that are entirely invisible to consumers. They didn’t revisit the ruling of the Court of Appeal, while Huseby still maintains they were refurbished.

Refurbished screens made in China come from companies that remove smashed glass from the high-quality original Apple LCD and apply a new glass on it. Usually the rest of the assembly is an original, reused part, and the glass is made by a third party.

As Huseby puts it, Apple uses intellectual property law as a “weapon” by putting multiple logos and QR-codes on each component part of its screens, knowing that the Chinese grey market will not specifically cater to repairers in other countries that zealously enforce intellectual property. This creates a kind of “roulette” for repairers who want to import affordable, refurbished parts from China. Apple can then ask customs authorities in these countries to seize refurbished parts shipments.

Meanwhile, Apple refuses to sell genuine spare parts to independent repairers in Europe. So they have a choice: buy either inferior generic parts or refurbished or after-market parts, like the kind Huseby bought.

Apple’s aggressive use of intellectual property in order to shut down independent repairs will ultimately raise prices for consumers, if they are forced to choose Apple’s far more expensive authorised repairers who have access to new, genuine parts. For example, while Apple in Norway charges 1 959.75 NOK (185 EU) for mail-in service to replace the screen in an iPhone 6s, Apple’s authorised repair services in Norway charge 2699 NOK (255 EU), more than three times as much as Huseby charges, 800 NOK (75 EU).

A recent Eurobarometer survey by the European Commission shows that almost 8 in 10 Europeans think manufacturers should be required to make it easier to repair electronic devices or replace parts.

This costs the planet too, as high prices for repair push consumers to cycle through products faster and faster. A report by the EEB showed that extending the life of European smartphones by just one year would save the CO2 equivalent of taking one million cars off the road.

“This case was both about Apple using its power to pressure Norwegian authorities and control the process, and about the letter of the law being inappropriate to the moment we are living. Extending mobile lifecycles via repair is the best way to reduce their environmental impact, and refurbished parts are the greenest and cost-effective option.”

The Right to Repair European campaign has helped with his fundraising efforts and is now calling for measures to prevent other repairers like Huseby having to go through this again.

We are now holding the European Commission to its commitment to “a Right to Repair” in the Circular Economy Action Plan, to ensure universal access to affordable genuine spare parts for all electronics for both repair professionals and consumers.

To inform them of Apple’s environmentally damaging, anti-competitive win in Norway, we are sending a letter to EU Competition Commissioner Vestager and European MEPs from different political groups.

This very articulately and eloquently written article reports very bad news on all counts and a depressing legal and environmental precedent. The Norwegian Supreme Court needs its backside kicked hard for this disgracefully inequitable, illogical and perverse decision that is not remotely in the wider consumer, public or environmental interest. The Norwegian authorities have clearly been politically pressurised by Apple using its ill-gotten commercial power. Time for a serious boycott of capitalist Apple and its over-rated restricted products by all technology consumers – there are plenty of perfectly adequate and cheaper open-source alternatives on the market.

I do not understand how copyright laws can apply to physical objects. A copyright is used to protect visual and auditory information. I can see it may be a violation of trademark if someone advertises or claims to be using official manufacturer parts when it is not official parts. But if the claim is not official parts, then there should be no reason for a manufacturer to hinder a party from using them to refurbish or repair a product.

Once Apple has sold a phone, it should have no control of what the owner does to that phone, and no say if another company repairs that phone with whatever parts to bring it to functional condition. This is an abuse of copyright laws. The EU should pass right to repair laws that allows anyone to do as they please to products that they own, since the original manufacturer has already profited from the sale of the product.

We can see that original manufacturers want to block owners from being able to repair their products with parts not sanctioned by the original manufacturer to increase sales. This is bad for everyone, leads to greater waste, and hinders a thriving economy in repairs and manufacturing of parts.

Another way that Apple blocks the ability to repair of their products is by putting software locks (cryptographic keys) in their parts. This is supposedly for security purposes, but it’s clearly to make sure people can’t repair their products, so consumers have no option but to trash their old phones and computers and buy new ones. This is so completely hypocritical coming from Apple, a supposedly environmentally conscientious company.

I’ve been an apple user all my adult life, loved the quality of product. I’m now going to switch to other brands. This ‘beating the little guy’ will cost apple far more in the long run, it costs their integrity. Makes the 1984 advert seem like a big con.

I don’t think this is fair article. In Norwegian media this case is presented differently. It wasn’t “allegedly counterfeit”, it was entirely counterfeit. All the products had the same identical serial number and was made in a Chinese factory that had nothing to do with Apple.

The only reason Huseby won the case is because he never claimed that they were genuine parts, however the parts still had illegal Apple logos and the judge in the supreme court decided that logos on counterfeit parts are a breach of trademarks. Which they are. Apple has every right to fight people who try to sell counterfeit products that has a counterfeit Apple logo.

I’m not saying that Huseby imported counterfeit parts on purpose, but he did and that’s between him and the Chinese company. However he is, on purpose, not giving a fair representation of this case by pretending that he imported genuine parts while clearly they were not (experts confirmed this). A witness in this case, Louis Rossmann (“god” of right to repair), changed his opinion on this case because of the new information that Huseby hid: https://www.youtube.com/watch?v=xKEdi6vXMrU

The right to repair is not “lets slap any logo on counterfeit parts cause it’ll be cheaper.” I’m sorry that Huseby got scammed, but it’s not about deceit and scamming customers with fake parts. I wish an organisation that fights for something so close to my heart would have given a fair representation instead of trashing Apple at any cost, even the truth.

This is nothing new as Apple is a symbol of typical American hedgemony. They will use their power to monopoly the market and suppress competition. The existing law has to change and reflect the growing technology landscape. Failing that, the consumer should stop buying and using Apple products… That I am sure will send a message to Apple and get them to change the business practice very quickly.

The fact that you actually believe that silliness is the crime. This is an example of greedy douche bags Being greedy douche bags. That would be Apple and the Chinese factory. Huseby was just trying to provide a service. All countries need to pass the same laws That Car Companies were subjected to back in the 60s. They need to supply parts at a reasonable price for a specific period of time.

My mom had been using the same pan for 29 years, it is uneven, drooping and lost its handle. But she says that is the first thing she brought after she got married. She repairs her shoes at local repair shops and has made her marriage work for 29 years.

I was shocked after reading this post, iPhone is a very good company but it does some unexpected things https://www.ukassignmenthelp.uk/marketing-assignment/ I also used iPhone for a long time, Functionality was amazing, but battery time was not.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey