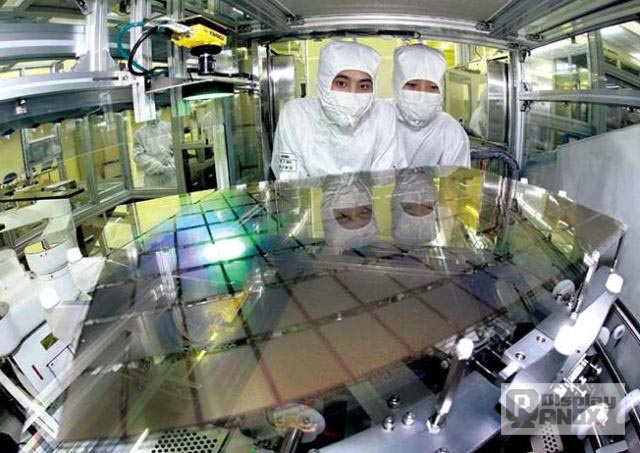

lcd panel photos factory

RM2CX8HJX–An employee of Samsung Electronics explains at the company"s showroom at its main factory in Asan, south of Seoul May 13, 2011. A fall in flat screen prices that has lasted more than a year has finally been arrested and demand growth is set to return as television makers prepare for new product launches ahead of a seasonal pick-up later this year, Samsung Electronics Co, the world"s No.1 LCD flat-screen maker, told Reuters. This in turn has lifted the profit outlook for the battered liquid crystal display (LCD) sector, Chang Wonkie, president of Samsung Electronics" LCD business, said at the R

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

If the issue persists on the external monitor, it may be an issue with the video card (GPU) or video settings and not the laptop LCD panel. Go to verify display or video issues in Windows Safe Mode. Otherwise, go to the next step.

Performance issues may occur if there is any damage to the LCD screen. The display may stop working, work intermittently, flicker, display horizontal or vertical lines, and so on, if there is damage to the display screen.

Dell laptops have integrated diagnostic tools that can determine if the screen abnormality is an inherent problem with the LCD screen of the Dell laptop or with the video card (GPU) and computer settings.

When you notice screen abnormalities like flickering, distortion, clarity issues, fuzzy or blurry images, horizontal or vertical lines, color fade, running a diagnostic test on the LCD helps identify if the issue is with the LCD panel.

Press and hold the D key and turn on the computer to enter the LCD built-in self-test (BIST) mode. Continue to hold the D key until you see the entire screen change colors.

If you do not detect any screen abnormalities in the integrated self-test mode, the LCD panel of the laptop is functioning properly. Go to the Update the video card (GPU) driver, monitor driver, and BIOS section.

If you notice any abnormalities in the LCD built-in self-test mode, contact Dell Technical Support to learn more about repair options that are available in your region.

Display settings like brightness, refresh rate, resolution, and power management may affect the performance of the LCD screen on your Dell laptop. Changing or adjusting the display settings can help resolve several types of video issues.

If the diagnostic tests on the LCD panel and the video card (GPU) passed, it is most definitely an issue that is related to software that is installed on the computer. If the above troubleshooting steps did not resolve the issue, you may try to restore the computer to factory default settings as a last resort.

Today’s vivid, immersive displays rely on layers of Corning glass to provide a stunning viewing experience. Wherever you look for news and entertainment, chances are Corning glass is there, too. We are the science and engineering powerhouse behind revolutionary display inventions, including glass cathode-ray bulbs for the first televisions and the LCD glass that made smartphones and laptop computers commonplace. We set the standard for the industry with Corning® EAGLE XG® Slim Glass substrates, manufacturing over 25 billion square feet — enough to pave the Great Wall of China 25 times, or cover nearly 390,000 football fields — while eliminating the equivalent of 6,000 truckloads of heavy metals from entering the environment. Today, we continue to enable the display industry and emerging technologies with our three-glass portfolio.

New design freedoms are taking shape with Corning LotusTMNXT Glass. Thanks to Corning Lotus NXT Glass, devices with OLED displays that curve, flex, or extend edge-to-edge across a device are all within reach. Flexible OLED devices use a plastic backplane substrate, which calls for Corning’s high-tech display glass to enable the manufacturing process —to date, it"s enabled more than 2 billion OLED devices. Corning Lotus NXT Glass continues to emerge as the leader most-advantaged glass for rigid and flexible OLED panels – outperforming competitors and enabling the designs and performance that consumers love.

Looking beyond incumbent LCD and OLED display technology, Corning"s display portfolio is finding new opportunities in emerging technology applications, including Quantum Dot, Micro LED and Mini LED. With our proven track record of successfully navigating the display technology roadmap, our proprietary fusion manufacturing platform and reliable supply network, our commitment to our customers and innovation, and our innovative portfolio, we are excited to support the next generation of displays.

Samsung Display will stop producing LCD panels by the end of the year. The display maker currently runs two LCD production lines in South Korea and two in China, according to Reuters. Samsung tells The Verge that the decision will accelerate the company’s move towards quantum dot displays, while ZDNetreports that its future quantum dot TVs will use OLED rather than LCD panels.

The decision comes as LCD panel prices are said to be falling worldwide. Last year, Nikkei reported that Chinese competitors are ramping up production of LCD screens, even as demand for TVs weakens globally. Samsung Display isn’t the only manufacturer to have closed down LCD production lines. LG Display announced it would be ending LCD production in South Korea by the end of the 2020 as well.

Last October Samsung Display announced a five-year 13.1 trillion won (around $10.7 billion) investment in quantum dot technology for its upcoming TVs, as it shifts production away from LCDs. However, Samsung’s existing quantum dot or QLED TVs still use LCD panels behind their quantum dot layer. Samsung is also working on developing self-emissive quantum-dot diodes, which would remove the need for a separate layer.

Samsung’s investment in OLED TVs has also been reported by The Elec. The company is no stranger to OLED technology for handhelds, but it exited the large OLED panel market half a decade ago, allowing rival LG Display to dominate ever since.

Although Samsung Display says that it will be able to continue supplying its existing LCD orders through the end of the year, there are questions about what Samsung Electronics, the largest TV manufacturer in the world, will use in its LCD TVs going forward. Samsung told The Vergethat it does not expect the shutdown to affect its LCD-based QLED TV lineup. So for the near-term, nothing changes.

One alternative is that Samsung buys its LCD panels from suppliers like TCL-owned CSOT and AUO, which already supply panels for Samsung TVs. Last year The Elec reported that Samsung could close all its South Korean LCD production lines, and make up the difference with panels bought from Chinese manufacturers like CSOT, which Samsung Display has invested in.

The 12.9-inch Liquid Retina XDR display has an IPS LCD panel supporting a resolution of 2732 by 2048 pixels for a total of 5.6 million pixels with 264 pixels per inch. To achieve Extreme Dynamic Range required an entirely new display architecture on iPad Pro. The all new 2D mini-LED backlighting system with individually controlled local dimming zones was the best choice for delivering the extremely high full-screen brightness and contrast ratio, and off-axis color accuracy, that creative professionals depend on for their workflows.

The Liquid Retina XDR display improves upon the trade-offs of typical local dimming systems, where the extreme brightness of LEDs might cause a slight blooming effect because the LED zones are larger than the LCD pixel size. This display is designed to deliver crisp front-of-screen performance with its incredibly small custom mini-LED design, industry leading mini-LED density, large number of individually controlled local dimming zones, and custom optical films that shape the light while maintaining image fidelity and extreme brightness and contrast.

Additionally, custom algorithms run on the advanced display engine of the M1 chip, working at the pixel level to control the mini-LED and LCD layers of the display separately, treating them as two distinct displays. These proprietary algorithms coordinate the mini-LED and LCD layers across transitions to deliver the optimal visual experience. Transitional characteristics of local dimming zones, such as a slight blur or color change while scrolling against black backgrounds, are normal behavior.

ProMotion technology automatically adjusts the display refresh rate up to 120 Hz (twice the rate of typical LCD displays) to the optimal rate for the content. The result is ultra-smooth scrolling and incredible responsiveness on the display, whether you’re using your finger or Apple Pencil. True Tone technology subtly adjusts the white balance onscreen to match the color temperature of the light around you, so images on the display look as natural as on a printed page. The cover glass on the Liquid Retina XDR display has an on-axis reflection of 1.8 percent due to a custom antireflective coating. As a result, iPad Pro delivers industry-leading reflectivity for a more comfortable viewing experience indoors and out.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey