skr 1.3 lcd displays factory

I have an Ender 3 Pro with an Skr1.3 and TMC2209s fitted, which is almost silent, so I decided to go this route on the E5+. I did not, however, want to replace the stock screen. I only really need the screen for being able to stop a print, or to move the axis – I print from Octoprint so have no need of a BTT TFT3.5 V3 screen etc (although I DO have one on the Ender 3)

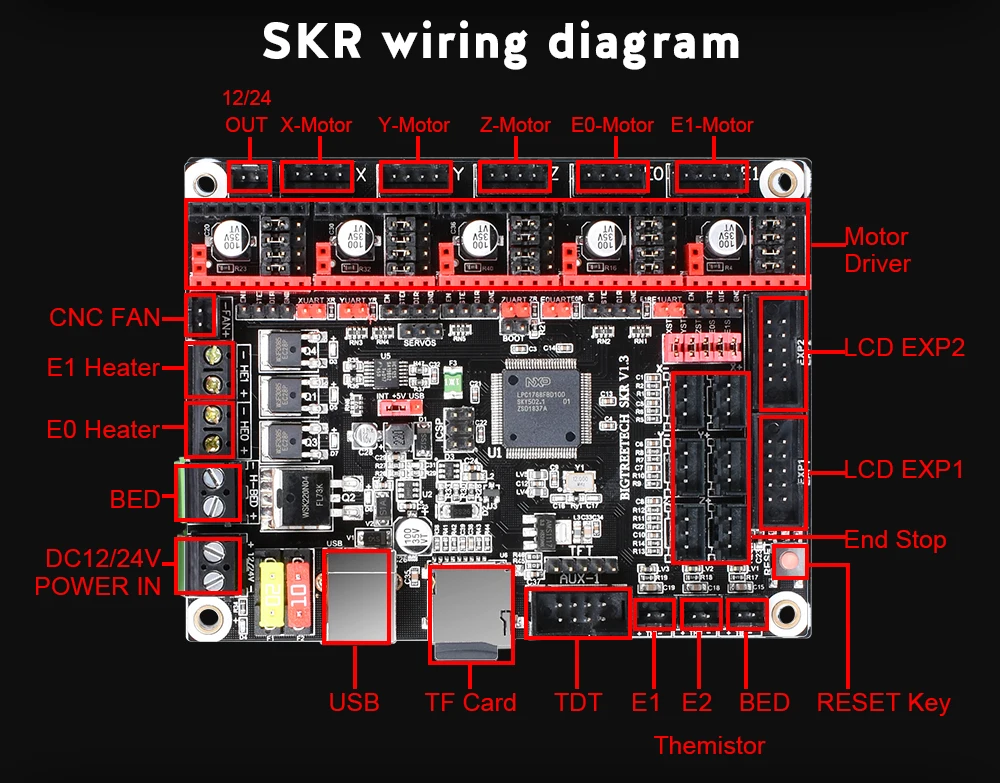

Remove the board, and mount the adapter plate you printed earlier, then attach the SKR1.3 to the mounting plate. (You may at this point find it easier to connect the blue USB cable and sdcard extender before mounting as space is tight!) Note, when mounting the end-stop plugs in the SKR you will need to carefully cut off one of the lugs so it can fit. Looking at the diagram above, they connect to the two rightmost pins in the relevant sockets.

#define MachineEnder5Plus#define BedDC#define ABL_BLTOUCH#define ABL_BI#define MelziHostOnly // Enable this to turn off local SD support and instead prioritize options for Octoprint or USB#define SKR13 // 32 bit board - assumes 2208 drivers#define SKR_2209

#define DualZ // Uses 5th driver on CRX or SKR boards as Z2#define MeshStd#elif ANY(MachineCR10Orig, SKR13, SKR14, SKR14Turbo) && DISABLED(SKR13_ReverseSteppers)

Cycle the power, and you should now have a working screen, with Marlin 2.0 on your SKR, running 2209s in UART mode (No need to set VREFS) and enjoy the silence!

In this video, I am showing you how to connect Bigtreetech TFT35 touch displays to your SKR 1.3 or 1.4 mainboard, why it has two different modes to use it and what to configure in Marlin 2.0 for it.

The second mode is the "Marlin" or 12864 simulation mode, which will show the original printer menu from the Marlin firmware running on the SKR mainboard.

So from the mainboard documentation, I know that the reset pin for the SKR 1.3 is the most right pin, so I will orient my cable connectors accordingly and plug them in with the reset pin on the most right pin and the other four go left to it.

Now, I am building and uploading this new firmware for the SKR mainboard with Auto Build Marlin and if you"ve missed my full guide how to do this, I"ve linked that particular video up here for you.

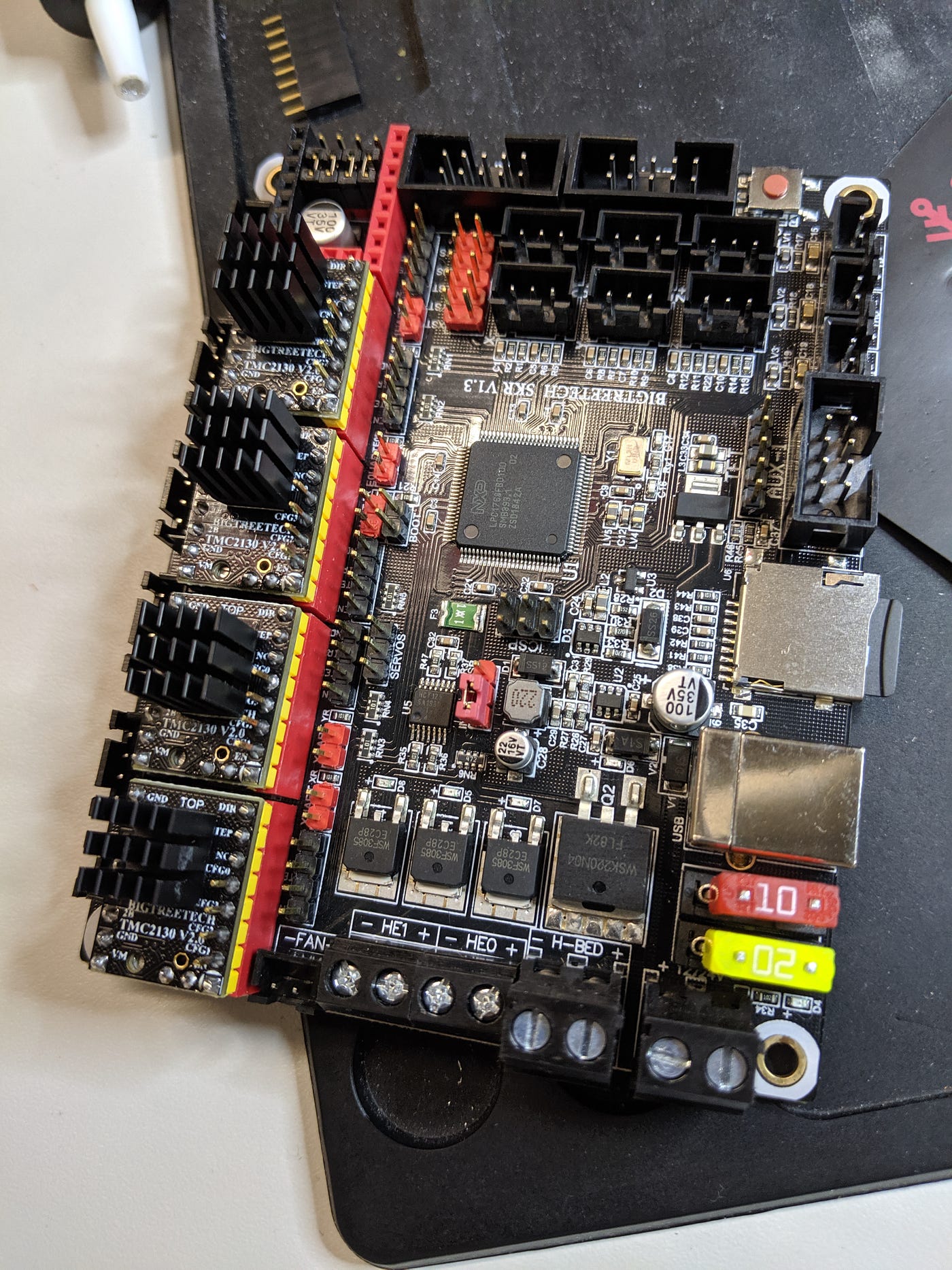

without white cover and extra fan being off, the TMC5160 drivers easily reached 60°C @ 28°C ambient temperature, causing a hard reset of the SKR approx. 90 min into the prints on three different occasions.

hence, i opted for forced cooling of the SKR, using a 12 VDC fan (60x60x10), connected to the 5VDC output of the DCDC module. also tried a 12VDC impeller from a radeon graphics card, connected to 5VDC. air flow was massive, but torque noise was way too loud.

BIGTREE-TECH’s SKR V1.3 offers a great amount for its money. Including 32-bit processing, built-in UART channels and Smoothieware and Marlin compatibility. Is this too good to be true? Let’s find out.

BIGTREE-TECH was kind enough to supply the SKR V1.3 along with some TMC2208’s V1.2. Furthermore they also supplied a TFT35 V1.2 Touch Screenfor the purpose of this review. However the set up guides for the firmware configuration and the BIQU TFT35 will be covered in a further post.

Firstly SKR V1.3 from BIGTREE-TECH, comes packaged in a black box with a RED logo on the front. On one side there is the companies official website address, and the other a link to their Facebook group.

Inside the box and the SKR V1.3 is sealed in an anti-static bag. While alongside is the supplied micro SD memory card and a USB cable. On the memory card you will find firmware for both Marlin 2 and Smoothieware. However it is likely out of date. But keep a hold of it for reference and start with the latest version of either Marlin V2 or Smoothieware. Also included is some spare jumper bridges and a business card with the company details.

One thing that is particularly nice on the SKR V1.3 is how cleanly soldered the board is. It makes a nice change to look at a PCB and get excited about how good it looks. Perhaps its a bit geeky to get excited over this. Nonetheless it makes a nice change not to wash flux off or re-solder any points.

The stepper drivers themselves are extremely clean. Only one TMC2208 had solder from the chip seeping through. This can be a normal occurrence and doesn’t effect the stepper drivers performance or its cooling. If you are wishing to setup the SKR V1.3 with TMC2208’s in UART mode chances are you are going to need to solder J2 on the back of the stepper driver to the adjoining pad.

Supplied in just an anti-static bag the BIQU TFT35 V1.2 Touchscreen isn’t quite as finely finished as the SKR V1.3 or the TMC2208’s V2.1. Whilst that’s not critical the functionality of the touch screen is important. The screen itself doesn’t seem very well handled during the manufacturing process. It is not particularly firmly attached and the rear of the screen is peeling away, with the amount of light from it I can only presume it is the TFT35’s backlight, and is not adhering well. However time will tell if this will affect performance. As long as it functions and behaves responsively, then it should not overly matter.

BIGTREE-TECH’s SKR V1.3 features the 100 MHz LPC1768 ARM cortex-M3 CPU for the SKR’s 32-bit processing. Supporting the following stepper drivers TMC2130, TMC2208, TMC2100, ST820, DRV8825, and A4988 stepper drivers.

Depending upon your particular printer setup, the SKR V1.3 can either be powered with a 12 V or 24 V and is protected with removable 10 Amp and 20 Amp blade fuses. The 20 Amp fuses is for the heating systems such as heat bed and extruder. Whilst the 10 Amp fuse is taking care of the stepper drivers and elements on the board itself.

The SKR V1.3 natively supports dual extruder setup with a single Z-axis, dedicated pins for TFT touch screen, and dedicated pins for a BLTouch automatic bed levelling probe.

BIGTREE-TECH’s SKR V1.3 is a remarkably capable 32-bit board, which punches way above its price tag. Ridiculously so! Currently for sale at around $19 USD with free delivery, that’s £15 delivered to us in the United Kingdom for the board.

Taking full advantage of what Marlin firmware V2 has to offer, the SKR V1.3 teamed with their faultless TMC2208’s offers faster and finer finished prints than an 8-bit setup. Whilst this is to be expected, I still was not expecting as good a performance for a board costing as low as the SKR V1.3.

If your thinking of moving from an 8-bit to a 32-bit board you cant go wrong with the SKR V1.3 from BIGTREE-TECH. If I was to say one thing it would be, Just order it! Ordinarily I would mumble to the screen if someone wrote that, but for a board with the capability of the SKR V1.3 and price. It would be simply mad not too!

It would have been an extra touch to have had supplied spare blade fuses, but not a deal breaker. The only complaint that I have with the SKR V1.3 is lack of dedicated servo pins. Despite there being workarounds in my opinion there should be more connectivity not less.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey