prusa mk3 lcd displays f free sample

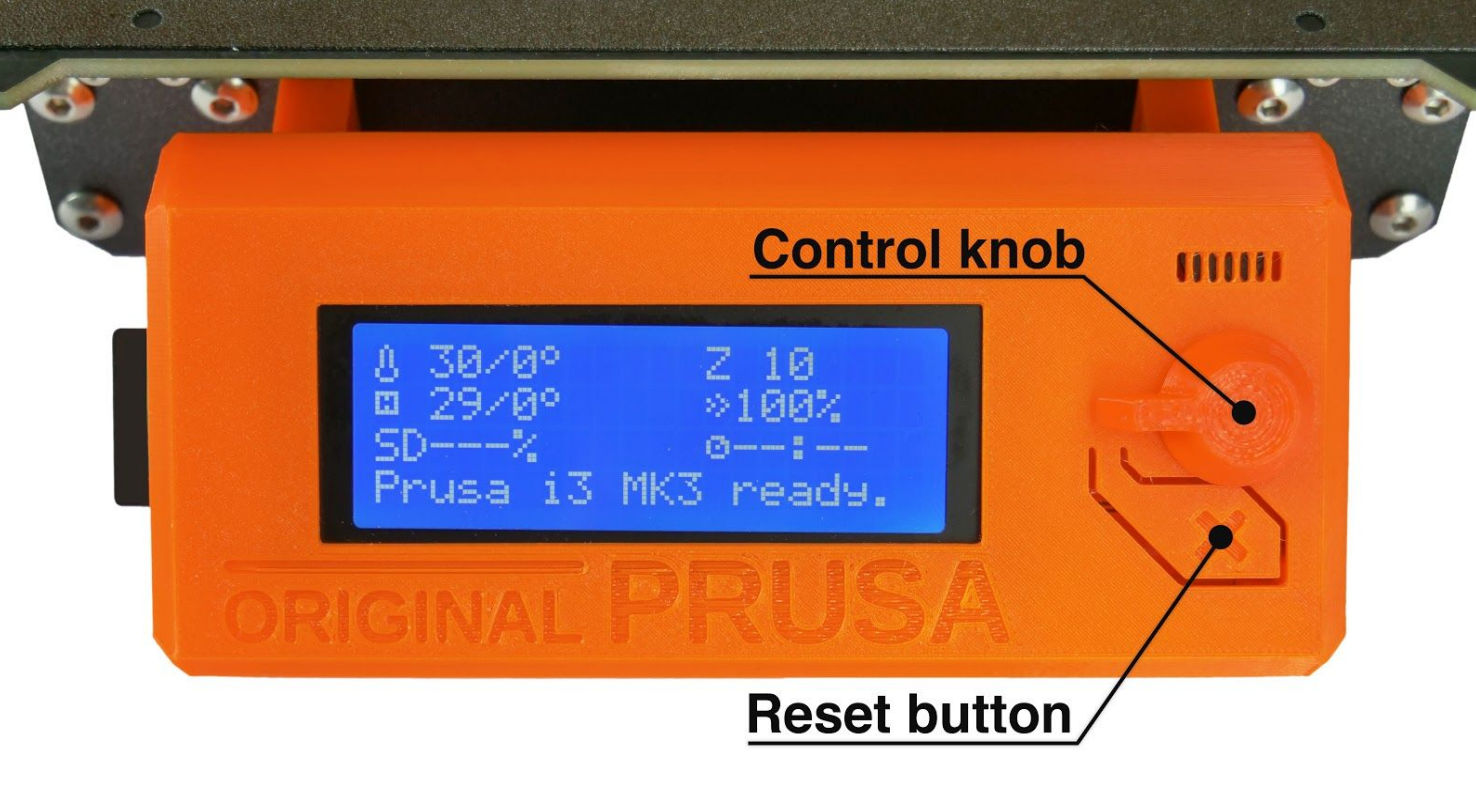

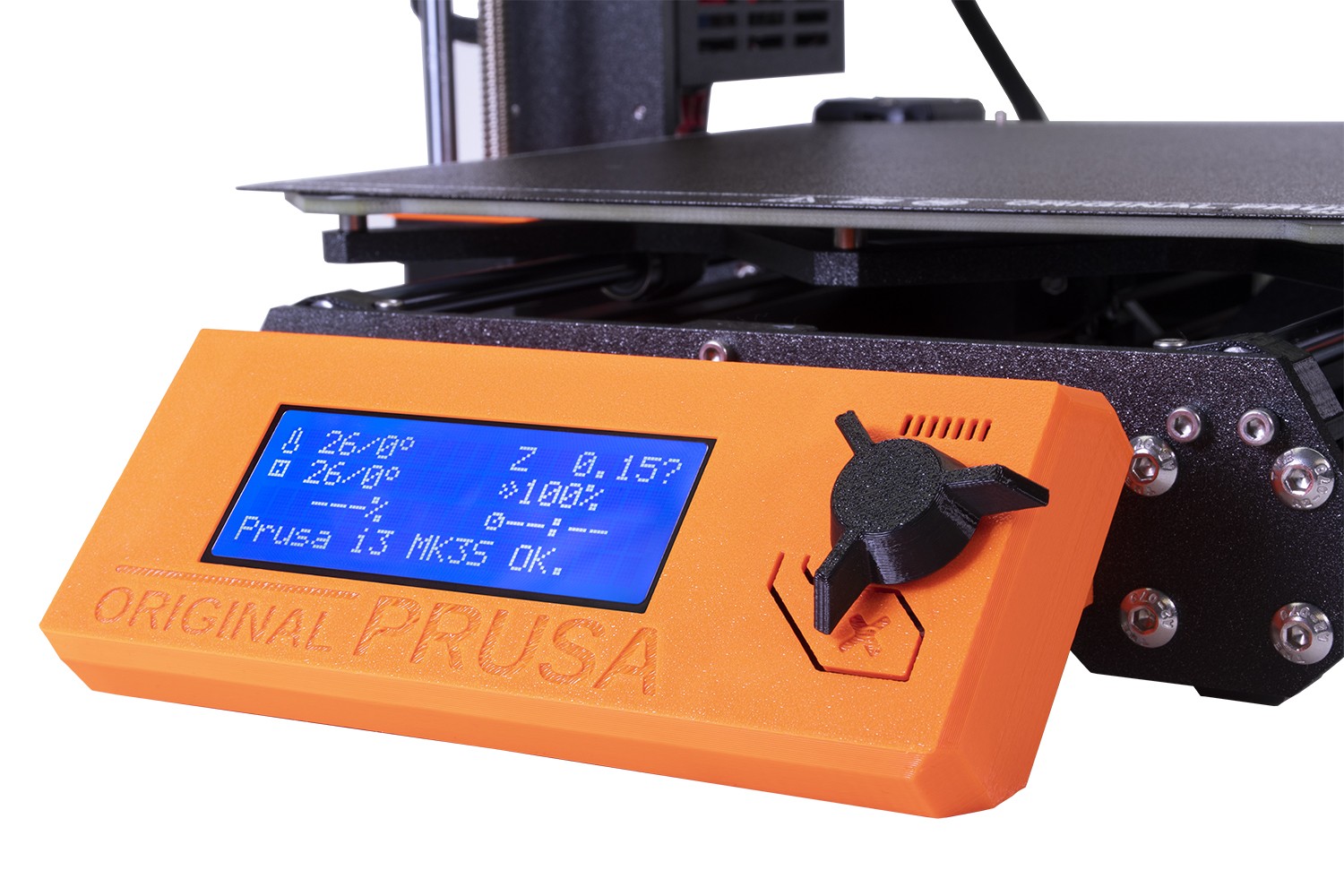

Controlling the LCD screen is done by a single control element: a rotational knob that you press to confirm the selection. By single pressing the control button on the information screen, you enter the main menu.

The reset button is placed directly under the control knob. Pressing the reset button equates to quickly toggling the power switch (hard reset). It is useful when the printer exhibits weird behavior or you see a failed print that requires immediate cancellation.

Shortcut: Quick access to change Printing speed - While on the Info-screen, spin the knob either direction, more than one rotation, and see the percentage change.

This is a list of currently implemented G Codes in Prusa firmware as of 7th of May 2021. The description is only for Prusa Research-specific G-codes. The rest can be found on RepRap Wiki. With exception of M117, they are all shown in order of appearance in the code. There are reasons why some G Codes aren"t in numerical order.

Full G-code documentation for Original Prusa MINI is yet to be published, but except for some differences, the best source of information is the official Marlin2 documentation.

These are used by internal functions to process certain actions in the right order. Some of these are also usable by the user. They are processed early as the commands are complex (strings). These are only available on the MK3(S) as these require TMC2130 drivers:

SuperPINDA sensor has internal temperature compensation and no thermistor output. There is no point of doing temperature calibration in such case. If PINDA_THERMISTOR and SUPERPINDA_SUPPORT is defined during compilation, calibration is skipped with serial message "No PINDA thermistor". This can be caused also if PINDA thermistor connection is broken or PINDA temperature is lower than PINDA_MINTEMP.

WARNING! USE WITH CAUTION! If you"ll try to probe where is no leveling pad, nasty things can happen! In Prusa Firmware this G-code is deactivated by default, must be turned on in the source code.

It is used for setting the current position of each axis. The parameters are always absolute to the origin. If a parameter is omitted, that axis will not be affected. IfX, Y, or Z axis are specified, the move afterwards might stutter because of Mesh Bed Leveling. E axis is not affected if the target position is 0 (G92 E0). A G92 without coordinates will reset all axes to zero on some firmware. This is not the case for Prusa-Firmware!

Set position in SD card file to index in bytes. This command is expected to be called after M23 and before M24. Otherwise effect of this command is undefined.

This function assumes the bed has been homed. Specifically, that a G28 command has been issued prior to invoking the M48 Z-Probe repeatability measurement function. Any information generated by a prior G29 Bed leveling command will be lost and needs to be regenerated.

The number of samples will default to 10 if not specified. You can use upper or lower case letters for any of the options EXCEPT n. n must be in lower case because Marlin uses a capital N for its communication protocol and will get horribly confused if you send it a capital N.

bit 0 = Auto-report temperatures bit 1 = Auto-report fans bit 2 = Auto-report position bit 3 = free bit 4 = free bit 5 = free bit 6 = free bit 7 = free

Parameters S and R are treated identically. Command always waits for both cool down and heat up. If no parameters are supplied waits for previously set extruder temperature.

Allows programming of steps per unit (usually mm) for motor drives. These values are reset to firmware defaults on power on, unless saved to EEPROM if available (M500 in Marlin)

During some lengthy processes, such as G29, Marlin may appear to the host to have “gone away.” The “host keepalive” feature will send messages to the host when Marlin is busy or waiting for user response so the host won’t try to reconnect (or disconnect).

Print the firmware info and capabilities Without any arguments, prints Prusa firmware version number, machine type, extruder count and UUID.M115 U Checks the firmware version provided. If the firmware version provided by the U code is higher than the currently running firmware, it will pause the print for 30s and ask the user to upgrade the firmware.

FIRMWARE_NAME:Prusa-Firmware3.8.1based on Marlin FIRMWARE_URL:https://github.com/prusa3d/Prusa-Firmware PROTOCOL_VERSION:1.0 MACHINE_TYPE:Prusa i3 MK3S EXTRUDER_COUNT:1 UUID:00000000-0000-0000-0000-000000000000

This causes the given message to be shown in the status line on an attached LCD. It is processed early as to allow printing messages that contain G, M, N, or T.

Returns the current state of the configured X, Y, Z endstops. Takes into account any "inverted endstop" settings, so one can confirm that the machine is interpreting the endstops correctly.

This boolean value S 1=true or 0=false enables automatic retract detect if the slicer did not support G10/G11: every normal extrude-only move will be classified as retract depending on the direction.

In Prusa Firmware this G-code is only active ifEXTRUDERS is higher then 1 in the source code. On Original i3 Prusa MK2/s MK2.5/s MK3/s it is not active.

This tells the printer to allow movement of the extruder motor above a certain temperature, or if disabled, to allow extruder movement when the hotend is below a safe printing temperature.

PID Tuning refers to a control algorithm used in some repraps to tune heating behavior for hot ends and heated beds. This command generates Proportional (Kp), Integral (Ki), and Derivative (Kd) values for the hotend or bed. Send the appropriate code and wait for the output to update the firmware values.

M403 - Set filament type (material) for particular extruder and notify the MMU M403 - Set filament type (material) for particular extruder and notify the MMU

This command resets all tunable parameters to their default values, as set in the firmware"s configuration files. This doesn"t reset any parameters stored in the EEPROM, so it must be followed by M500 to write the default settings.

This command asks the firmware to reply with the current print settings as set in memory. Settings will differ from EEPROM contents if changed since the last load / save. The reply output includes the G-Code commands to produce each setting. For example, Steps-Per-Unit values are displayed as an M92 command.

Sets the Z-probe Z offset. This offset is used to determine the actual Z position of the nozzle when using a probe to home Z with G28. This value may also be used by G81 (Prusa) / G29 (Marlin) to apply correction to the Z position. This value represents the distance from nozzle to the bed surface at the point where the probe is triggered. This value will be negative for typical switch probes, inductive probes, and setups where the nozzle makes a circuit with a raised metal contact. This setting will be greater than zero on machines where the nozzle itself is used as the probe, pressing down on the bed to press a switch. (This is a common setup on delta machines.)

Sets the printer IP address that is shown in the support menu. Designed to be used with the help of host software. If P is not specified nothing happens. If the structure of the IP address is invalid, 0.0.0.0 is assumed and nothing is shown on the screen in the Support menu.

Initiates Filament change, it is also used during Filament Runout Sensor process. If theM600 is triggered under 25mm it will do a Z-lift of 25mm to prevent a filament blob.

Sets the advance extrusion factors for Linear Advance. If any of the R, W, H, or D parameters are set to zero the ratio will be computed dynamically during printing.

Set digital trimpot motor current using axis codes (X, Y, Z, E, B, S). M907 has no effect when the experimental Extruder motor current scaling mode is active (that applies to farm printing as well)

Sliced with PrusaSlicer 2.0.0, Printing on MK3S with Firmware v3.7.1. This is only second print with this slicer/FW combination. I don"t think the F? was there before but not absolutely sure. It seems to be printing OK.

Check if the printer is thinking it has an MMU. The F? indenticates which filament is loaded. The question mark because it has no information about it.

I"ve the same isse from time to time, and another guy in the FB group too. My suggestion, it is caused from noise on the port where normally the MMU is connected, or an PWM, an fan. Maybe an bad powersupply or bad contact.

3D printing is quickly becoming a widely accessible and user-friendly technology. Despite this fact, some users (especially beginners) can sometimes run into various difficulties during the printing process. Such problems are usually caused by improper configuration or just by a random accident.

We have compiled a list of five more-or-less common issues you can theoretically encounter with your 3D printer. Plus, we’re offering useful tips how to solve these problems or prevent them from happening completely.

This is by far the most common 3D printing problem, and probably the first one you may encounter. The first layer is the essential one as it is the base of the printed object. Therefore, if it isn’t perfect, the chance of print failure increases.

What happens when the first layer isn’t perfect? Most of the time you will not be able to start the printing process, or the printed objects may continue to constantly detach from the print surface.

Proper calibration of the first layer – First, you must perform the First layer calibration. Once you are happy with the result, you can start printing. Later on, you may apply small adjustments to the nozzle height through the Live Adjust Z option when the printer is creating the initial three layers. Just press the Knob and go to the Live Adjust Z. If you are not sure how the proper first layer looks, check out the photo above.

Prepare the print surface – Keep the surface free of grease. Otherwise, your first layer will have a difficulty sticking to the print bed. Before starting any of your prints from ABS, PLA and many other materials, simply wipe the print surface clean with IPA 90%+. Also, you should use Acetonefrom time to time, when prints stop sticking – but do not use it on daily basis. PETG is an exception, so do not use IPA 90%+and Acetonewhen you are printing with this material. For PETG, we recommend using a separating agent (e.g. a glue stick). A complete guide how to prepare the print surface can be found atPEI print surface preparation

Use proper printing temperatures – Make sure to use the proper nozzle and especially the correct heatbed temperatures. If you are experimenting with new materials that don’t adhere well, you can try to bump up the heatbed temperature by 5-10°C. This way the plastic will stick a bit better.

Decrease the printing speed– If everything above failed, then try decreasing the printing speed. The easiest way how to do it is by rotating the knob during the printing process. Anti-clockwise = decrease speed, Clockwise = increase speed. We suggest decreasing the speed to about 75% for first three layers, then return it to normal.

Layer shifting is an error which causes some of the layers to shift from their designated positions. It is usually associated with improper movement of an axis, leading the extruder head to be misaligned mid-printing without any notice. In other words, there is at least one layer which is not properly aligned.

You may experience layer shifts in different axis movements. To troubleshoot the issue correctly, it is crucial to diagnose to which axis it is happening. To clarify, check out the photo below which demonstrates three different kinds of layer shifts. Troubleshooting itself is the same for both axes.

Check your printer’s power mode – For objects larger than 200–300g, or for objects with a complex geometry, run the printer in Normal mode. You can change Power mode in the LCD Menu – Settings – Mode.

Check your X/Y axis pulleys – Make sure that the pulley on the motor shaft is secured and theidler pulley can move freely on the opposite end. A loose pulley is usually the main cause of staircase layer shifts.

Make sure nothing is blocking the movement of your axis – Make sure there are no obstructions in the path of the bearings or any possible waste from previous printings stuck around the belt (usually around the Y-axis pulley). You can read more about general printer maintenance in this article.

Difficult geometry to print – Objects with larger overhangs are generally harder to print. These overhangs might warp mid-printing and hit the nozzle. To prevent this, you can cut the object (check out one of our previous articles Cutting STL models). You can also try to increase the print fan speed or increase the Z-hop distance in Slic3r PE. Both of these settings can be changed in our Slic3r PE. Print fan speed in Filament settings – Cooling and Z-hop distance inPrinter Settings – Extruder 1.

Stringing usually appears if your print settings are not accurate, while you are printing complex objects (such as Moon city) or multiple objects at once. This is recognizable as a marginal line of plastic left behind or between the object/s. In other words, it’s that hairy bit of plastic we don’t like to see.

Keep in mind that some filaments, such as PETG or flexible filaments, may be stringy even with perfect print settings. In the photo below, you can see an extreme case of stringing. Usually, the stringing is not so severe, but if you encounter something similar to the objects in the photo, follow the instructions below.

Check the tension bolts – Before you touch any of the settings, make sure that the Tension boltslocated on the extruder idler are properly tightened, although, this is not that common.

Use proper printing settings – We highly recommend using the preset settings in Slic3r PE or PrusaControl. However, if you are printing with your own settings, make sure that you have the retraction settings set correctly. Retraction settings can be found in Slic3r PE in Printer Settings – Extruder 1.

Don’t bother, just use a heat gun! – If you don’t feel like tweaking any of the settings, well, then there is an alternative. You can get rid of the strings with a heat gun (or possibly with a lighter). Just set it to around 200°C and aim at the strings for one or two seconds. This will melt the strings, and the printed object should remain undamaged.

Even though the name of this printing error sounds pretty cool, that’s about the only thing that’s good about it. It usually happens after most of the printing is complete.

As mentioned above, once the first layer isn’t perfect, the chance of any type of print failure increases. The so-called spaghetti monster is a perfect example of this. What usually happens is that the printed object detaches from the print bed mid-printing, and the remaining layers stop sticking to the object. The other common source of this problem may be an error within the STL object.

Check the first layer – Simply make sure that the first layer is sticking properly to the whole print surface. You can refer to “Thefirst layer does not stick”chapter mentioned above.

Check the object for errors – Always check the generated G-code in the Preview of our Slic3r PE. In case you find any gaps or broken geometry, you can either repair the STL object yourself or you can use one of our previous guides where we show How to repair corrupted 3D objects.

Try to increase the bed temperature – If you have already experienced this error, try to re-run the print and increase the bed temperature by 5°C. This should help with the first layer adhesion. You don’t have to re-slice the object and prepare a new G-code. Just start the print, go to the LCD Menu – Tune – Bed.

Extruder blob is one of the worst printing problems you might face with your 3D printer. Unlike the spaghetti monster, this issue occurs earlier in the process, usually during the initial 5 minutes of the print. The first layer becomes detached and covers the nozzle, while the extruder keeps extruding and the blob grows and grows, leaving you with a non-working printer.

Don’t worry, it is really easy to prevent this situation from happening. However, it is quite tricky to clear it after it happens. Just to make it a bit easier for you, we have prepared a short video where we show you how to remove it.

Check the first layer – Since an improper first layer is the source of extruder blob in most of the cases, make 100% sure that the first layer is sticking properly to the entire print surface. You can refer to the “First layer not sticking”above.

Monitor the print for 5–10 minutes – Let the printer run for 10 minutes and check the progress. We recommend doing this every time. If you observe any issues, restart the print. If everything seems running okay, then you can just let your printer finish the job. After the initial 10 minutes, it is unlikely your printer would create an extruder blob.

The Original Prusa i3 MK3S+ is the latest version of our award-winning 3D printers. We have upgraded the MK3S with a brand new SuperPINDA probe for improved first layer calibration, added high-quality bearings and various useful design tweaks to make the printer easier to assemble and maintain. The MK3S+ includes all the proven features of the previous models, including the heatbed with removable PEI spring steel print sheets, automatic Mesh Bed Leveling, filament sensor, power loss recovery (power panic) and safety features. And it is still as silent as ever!The functionality of the MK3S+ can be further enhanced by ourfor printing with up to 5 filaments simultaneously.

Winter holidays are just around the corner! If you decided to buy one of our 3D printers for someone else and you’re not sure if the package is going to make it in time,

SuperPINDA probe features a hiqh-quality sensor for a fully-automatic Mesh Bed Leveling process. Before every print, the printer probes the bed in several places and creates a virtual heightmap of the print area. This process ensures that the first layer will always be spot on!

The MK3S+ features a new set of metal clips for the high-quality bearings on the Y-axis. The belt tensioning mechanism on the X-axis was reworked and the X-end plastic parts reinforced. The filament path in the extruder was altered for better support of flexible filaments.

Spring steel sheets are easy to maintain and make removing the printed object from the print surface a breeze. We offer three types of print surface: smooth, textured and satin to cover all your needs when printing from a wide range of different materials - most of which do not require any special separation layers or surface preparation.

The MK3S+ features an aluminum extrusion Y-axis assembly. Thanks to the milled dural frame, the MK3S+ is stable, rigid, and easy to assemble. Combined with our internally developed extruder featuring Bondtech gears and the E3D V6 hotend, the MK3S+ can print high-quality objects up to 210 mm in height.

Are you afraid of a blackout ruining your 48-hour print? Worry no more - the MK3S+ can deal with that! The printer can fully recover from the loss of power and continue printing exactly where it left off. It detects power interruptions and shuts down the heatbed and extruder heating, and saves the last known location.

The MK3S+ further enhances the reworked extruder from the MK3S. The built-in filament sensor uses a reliable trigger system, which detects whether a strand of filament is inserted into the extruder. It can detect any type and color of filament and is not susceptible to mechanical wear.

Thanks to the SuperPINDA probe, the MK3S+ can use the Mesh Bed Leveling process to compensate for microscopic imperfections of the print sheet, and inconsistencies caused by the assembly and stacking of the manufacturing tolerances of various parts. Achieving a great-looking first layer is quick and easy.

Our internally developed multiplatform slicer comes with in-house made and fully tested profiles for all of our 3D printers and a wide range of filaments. With built-in tools, such as advanced support generation, cutting, automated object distribution, ironing and many others, you will turn your 3D models into print files in no time!

The MK3S+ is fully compatible with a wide range of various types of materials. No matter whether you want to print something for fun from PLA and flexible materials, or you need to produce durable prototypes from PETG, ASA, Polycarbonate and Polypropylene - the MK3S+ can handle them with ease.

We develop firmware for all of our 3D printers and test every new version thoroughly before release. Ongoing development and regular updates ensure that our machines are packed with useful features, such as print sheet profiles, automated calibration, Mesh bed leveling, advanced diagnostics, remaining print time estimation, Octoprint support and more!

Wide range of thermoplastics, including PLA, PETG, ASA, ABS, PC (Polycarbonate), CPE, PVA/BVOH, PVB, HIPS, PP (Polypropylene), Flex, nGen, Nylon, Carbon filled, Woodfill and other filled materials.

* Consumable parts, such as PEI sheets (smooth, textured, etc.) are not covered by warranty as the coatings are designed to diminish over time unless failure has occurred due to a defect in materials or workmanship. Cosmetic damage, including but not limited to scratches, dents, cracks, or other cosmetic damage is also not covered by the warranty. Only defective sheets on arrival are covered by warranty.

Controller: EINSY RAMBo 8-bit board with Trinamic 2130 drivers (256 microstepping), co-developed with Ultimachine, sensorless homing for X and Y axes

Print sheet profiles: Firmware supports print sheet profiles to store Live Z calibration data to enable quick switching between different print sheets.

Thanks to all of these (and many other) features,the MK3S became the “Best 3D Printer” according to ALL3DP. The MK3S is alsothe highest-rated3D printer, and the “Editor’s Choice”, in the prestigious MAKE:MAGAZINE’s Digital Fabrication Guide 2019. The MK3S is also featured in as The best all-around 3D printer.wrote that"...of the 11 printers we’ve tested over the past five years, the Prusa i3 MK3S printer has produced the largest and best-looking prints."According toZDNet,the MK3S is"The best pro-sumer 3D printer under 1000 USD."

We offer 24/7 tech support via live chat and email in seven languages. Our printers come with detailed instructions and guides for easy assembly and maintenance. You can also visit our knowledge base, community forum, Facebook groups and official Blog, where we publish useful 3D printing tips and tricks, contests and more!

The MK3S+ assembly kit is an excellent first step into the world of 3D printing. You will get to know your 3D printer inside out and find out how it works! The assembly is quite easy, requires no soldering, all cables are cut to length and ready to be plugged in. The assembly instructions are easy to follow and all texts are translated into 8 languages. All of this makes the kit very friendly to younger builders, too!

Original Prusa 3D printers are well-known for their reliability and safe operation. Every part of our printers is thoroughly tested in-house. The MK3S+ is equipped with three thermistors and comes with a custom-built high-quality Delta power supply. The printer can recognize issues with heating and stop operation to prevent damage.

All parts of our printer are open-source, which means we publish all source codes and blueprints online. The community around our products is huge and the feedback is overwhelmingly positive - don"t believe us? Check out Facebook groups and YouTube videos! There"s so much to do with your 3D printer - buying it is just the beginning!

Multi Material Upgrade 2S is our unique add-on option for printing with up to 5 different filaments simultaneously. Multi-material could be your next step in the 3D printing world and the MK3S and MK3S+ are completely ready for the upgrade! MMU2S also allows you to print a soluble support interface - check out the video!

One of the most popular features of the Original Prusa i3 concept is upgradability. When you buy our 3D printer, you can upgrade it later to a newer version, so you don"t need to buy a whole new model every two years like, for example, your phone or laptop. We also keep supporting our 3D printers with regular firmware updates that bring new features!

All fasteners and mechanical parts have 1:1 drawing so you can easily find them, and there is no chance of you picking a wrong one. You don"t have to be MIT graduate to assemble our kit ;-)

We provide high print settings with the printer, so you don"t have to dive into complex new programs the second you finish the build. You can start printing right away, and this gives you a great head start!

These settings are great for all kinds of objects, not just for a couple of prepared showpieces. After a while, when you"re familiar with the printer, you can, of course, dive into tinkering ;-)

We are developing our own slicing software. feature-rich, frequently updated tool that contains everything you need to export the perfect print filesfor your Original Prusa 3D printer.But of course, we also have the settings for the third party slicers like Simplify3D, Cura, etc.

Introduced in the firmware version 3.8.0 on the MK2.5, MK2.5S, MK3, MK3S, and MK3S+ there is a section in the Settings menu, called “HW setup”. It allows you to inform the printer/firmware of hardware changes and which actions to take in case of a conflict.

By default, all Original Prusa printers are shipped with the 0.4 mm nozzle. In case you change the nozzle, you can set the correct diameter. The printer will then compare the stored value of the nozzle diameter with parameters saved by our Prusa Slicer in the G-code. If there is a mismatch, the printer is able to inform you and thus prevent a print failure.

This setting does not affect extrusion rates (flow) during First Layer Calibration. The article Different nozzle types will tell you more about First layer calibration for different nozzles.

Besides checking the nozzle diameter, the printer is now able to check other parameters to warn you about incompatible settings. Before a print starts, the printer will compare parameters stored in the memory with the G-code.

The Original Prusa i3 MK3S+ is the latest version of our award-winning 3D printers. We have upgraded the MK3S with a brand new SuperPINDA probe for improved first layer calibration, added high-quality bearings and various useful design tweaks to make the printer easier to assemble and maintain. The MK3S+ includes all the proven features of the previous models, including the heatbed with removable PEI spring steel print sheets, automatic Mesh Bed Leveling, filament sensor, power loss recovery (power panic) and safety features. And it is still as silent as ever!The functionality of the MK3S+ can be further enhanced by ourfor printing with up to 5 filaments simultaneously.

Winter holidays are just around the corner! If you decided to buy one of our 3D printers for someone else and you’re not sure if the package is going to make it in time,

SuperPINDA probe features a hiqh-quality sensor for a fully-automatic Mesh Bed Leveling process. Before every print, the printer probes the bed in several places and creates a virtual heightmap of the print area. This process ensures that the first layer will always be spot on!

The MK3S+ features a new set of metal clips for the high-quality bearings on the Y-axis. The belt tensioning mechanism on the X-axis was reworked and the X-end plastic parts reinforced. The filament path in the extruder was altered for better support of flexible filaments.

Spring steel sheets are easy to maintain and make removing the printed object from the print surface a breeze. We offer three types of print surface: smooth, textured and satin to cover all your needs when printing from a wide range of different materials - most of which do not require any special separation layers or surface preparation.

The MK3S+ features an aluminum extrusion Y-axis assembly. Thanks to the milled dural frame, the MK3S+ is stable, rigid, and easy to assemble. Combined with our internally developed extruder featuring Bondtech gears and the E3D V6 hotend, the MK3S+ can print high-quality objects up to 210 mm in height.

Are you afraid of a blackout ruining your 48-hour print? Worry no more - the MK3S+ can deal with that! The printer can fully recover from the loss of power and continue printing exactly where it left off. It detects power interruptions and shuts down the heatbed and extruder heating, and saves the last known location.

The MK3S+ further enhances the reworked extruder from the MK3S. The built-in filament sensor uses a reliable trigger system, which detects whether a strand of filament is inserted into the extruder. It can detect any type and color of filament and is not susceptible to mechanical wear.

Thanks to the SuperPINDA probe, the MK3S+ can use the Mesh Bed Leveling process to compensate for microscopic imperfections of the print sheet, and inconsistencies caused by the assembly and stacking of the manufacturing tolerances of various parts. Achieving a great-looking first layer is quick and easy.

Our internally developed multiplatform slicer comes with in-house made and fully tested profiles for all of our 3D printers and a wide range of filaments. With built-in tools, such as advanced support generation, cutting, automated object distribution, ironing and many others, you will turn your 3D models into print files in no time!

The MK3S+ is fully compatible with a wide range of various types of materials. No matter whether you want to print something for fun from PLA and flexible materials, or you need to produce durable prototypes from PETG, ASA, Polycarbonate and Polypropylene - the MK3S+ can handle them with ease.

We develop firmware for all of our 3D printers and test every new version thoroughly before release. Ongoing development and regular updates ensure that our machines are packed with useful features, such as print sheet profiles, automated calibration, Mesh bed leveling, advanced diagnostics, remaining print time estimation, Octoprint support and more!

Wide range of thermoplastics, including PLA, PETG, ASA, ABS, PC (Polycarbonate), CPE, PVA/BVOH, PVB, HIPS, PP (Polypropylene), Flex, nGen, Nylon, Carbon filled, Woodfill and other filled materials.

* Consumable parts, such as PEI sheets (smooth, textured, etc.) are not covered by warranty as the coatings are designed to diminish over time unless failure has occurred due to a defect in materials or workmanship. Cosmetic damage, including but not limited to scratches, dents, cracks, or other cosmetic damage is also not covered by the warranty. Only defective sheets on arrival are covered by warranty.

Controller: EINSY RAMBo 8-bit board with Trinamic 2130 drivers (256 microstepping), co-developed with Ultimachine, sensorless homing for X and Y axes

Print sheet profiles: Firmware supports print sheet profiles to store Live Z calibration data to enable quick switching between different print sheets.

Thanks to all of these (and many other) features,the MK3S became the “Best 3D Printer” according to ALL3DP. The MK3S is alsothe highest-rated3D printer, and the “Editor’s Choice”, in the prestigious MAKE:MAGAZINE’s Digital Fabrication Guide 2019. The MK3S is also featured in as The best all-around 3D printer.wrote that"...of the 11 printers we’ve tested over the past five years, the Prusa i3 MK3S printer has produced the largest and best-looking prints."According toZDNet,the MK3S is"The best pro-sumer 3D printer under 1000 USD."

We offer 24/7 tech support via live chat and email in seven languages. Our printers come with detailed instructions and guides for easy assembly and maintenance. You can also visit our knowledge base, community forum, Facebook groups and official Blog, where we publish useful 3D printing tips and tricks, contests and more!

Compared to the assembly kit, the assembled printer differs only in the form in which you receive it. The printer comes pre-assembled and tested right out of the box. To start your first print, simply plug it in, run the initial calibration, and you are good to go. It is an ideal choice for businesses where there is a need to start printing as soon as possible.

Original Prusa 3D printers are well-known for their reliability and safe operation. Every part of our printers is thoroughly tested in-house. The MK3S+ is equipped with three thermistors and comes with a custom-built high-quality Delta power supply. The printer can recognize issues with heating and stop operation to prevent damage.

All parts of our printer are open-source, which means we publish all source codes and blueprints online. The community around our products is huge and the feedback is overwhelmingly positive - don"t believe us? Check out Facebook groups and YouTube videos! There"s so much to do with your 3D printer - buying it is just the beginning!

Multi Material Upgrade 2S is our unique add-on option for printing with up to 5 different filaments simultaneously. Multi-material could be your next step in the 3D printing world and the MK3S and MK3S+ are completely ready for the upgrade! MMU2S also allows you to print a soluble support interface - check out the video!

One of the most popular features of the Original Prusa i3 concept is upgradability. When you buy our 3D printer, you can upgrade it later to a newer version, so you don"t need to buy a whole new model every two years like, for example, your phone or laptop. We also keep supporting our 3D printers with regular firmware updates that bring new features!

We provide high print settings with the printer, so you don"t have to dive into complex new programs the second you finish the build. You can start printing right away, and this gives you a great head start!

These settings are great for all kinds of objects, not just for a couple of prepared showpieces. After a while, when you"re familiar with the printer, you can, of course, dive into tinkering ;-)

We are developing our own slicing software. feature-rich, frequently updated tool that contains everything you need to export the perfect print filesfor your Original Prusa 3D printer.But of course, we also have the settings for the third party slicers like Simplify3D, Cura, etc.

Our discount program for the Original Prusa i3 assembled printer owners gives you a 10% discount on subsequent orders of the Original Prusa i3 assembled printers and selected filaments.

To enter the discount program, you only need to purchase your first Original Prusa i3 assembled printer for the full price. After the assembled printer is delivered to you, your Prusa account automatically applies the 10% discount on the assembled i3 printers. So your next assembled i3 printer will be discounted by 10% :-). Make sure to be always logged into your Prusa account, to have the discount applied.

Along, with the discount on the assembled i3 printers, the discount does apply to selected filaments too. Most importantly including our high-precision filament, the Prusament!

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This page tries to describe the flavour of G-codes that the RepRap firmwares use and how they work. The main target is additive fabrication using FFF processes. Codes for print head movements follow the NIST RS274NGC G-code standard, so RepRap firmwares are quite usable for CNC milling and similar applications as well. See also on Wikipedia"s G-code article.

There are a few different ways to prepare G-code for a printer. One method would be to use a slicing program such as Slic3r, Skeinforge or Cura. These programs import a CAD model, slice it into layers, and output the G-code required to print each layer. Slicers are the easiest way to go from a 3D model to a printed part, however the user sacrifices some flexibility when using them. Another option for G-code generation is to use a lower level library like mecode. Libraries like mecode give you precise control over the tool path, and thus are useful if you have a complex print that is not suitable for naive slicing. The final option is to just write the G-code yourself. This may be the best choice if you just need to run a few test lines while calibrating your printer.

As many different firmwares exist and their developers tend to implement new features without discussing strategies or looking what others did before them, a lot of different sub-flavours for the 3D-Printer specific codes developed over the years. This particular page is the master page for RepRap. Nowhere in here should the same code be used for two different things; there are always more numbers to use... The rule is: add your new code here, then implement it.

Unfortunately human nature being what it is, the best procedures aren"t always followed, so some multiple uses of the same code exist. The rule which should be followed is that later appearances of a code on this page (later than the original use of a code), are deprecated and should be changed, unless there is a good technical reason (like the general G-Code standard) why a later instance should be preferred. Note that the key date is appearance here, not date of implementation.

Slicers will (optionally?) add G-code scripts to the beginning and end of their output file to perform specified actions before and/or after a print such as z-probing the build-area, heating/cooling the bed and hotend, performing ooze free "nozzle wipe" startup routine, switching system power on/off, and even "ejecting" parts. More info on the Start GCode routines and End GCode routines pages.

To find out which specific G-code(s) are implemented in any given firmware, there are little tables attached to the command descriptions, like this one:

There is some support for the G-code. Often it is required to check out the source code branch for the firmware (usually stored in a different branch) or to flip configuration switches on the mainboard.

The firmware handles this G-code automatically, so there"s no need to send the command. An example is power supply on/off G-code (M80/M81) in the Teacup firmware.

For the technically-minded, G-code line endings are Unix Line Endings (\n), but will accept Windows Line Endings (\r\n), so you should not need to worry about converting between the two, but it is best practice to use Unix Line Endings where possible.

A RepRap G-code is a list of fields that are separated by white spaces or line breaks. A field can be interpreted as a command, parameter, or for any other special purpose. It consists of one letter directly followed by a number, or can be only a stand-alone letter (Flag). The letter gives information about the meaning of the field (see the list below in this section). Numbers can be integers (128) or fractional numbers (12.42), depending on context. For example, an X coordinate can take integers (X175) or fractionals (X17.62), but selecting extruder number 2.76 would make no sense. In this description, the numbers in the fields are represented by nnn as a placeholder.

In RepRapFirmware, some parameters can be followed by more than one number, with colon used to separate them. Typically this is used to specify extruder parameters, with one value provided per extruder. If only one value is provided where a value is needed for each extruder, then that value is applied to all extruders.

The original NIST G-code standard requires gcode interpreters to be case-insensitive, except for characters in comments. However, not all 3D printer firmwares conform to this and some recognise uppercase command letters and parameters only.

In RepRapFirmware, some commands support quoted strings when providing file names and other string parameters. This allows file names, WiFi passwords etc. to contain spaces, semicolons and other characters that would otherwise not be permitted. Double-quote characters are used to delimit the string, and any double-quote character within the string must be repeated.

Unfortunately, some gcode sender programs convert all characters to uppercase and don"t provide any means to disable this feature. Therefore, within a quoted-string, the single-quote character is used as a flag to force the following character to lowercase. If you want to include a single quote character in the string, use two single quote characters to represent one single quote character.

RepRapFirmware 3.1 and later allow parameter values to be computed from an expression enclosed in { }. Such an expression may include constants, values from the machine object model, operators and functions. Example:

Some firmwares also obey the CNC G-code standard, which is to enclose comments in round brackets. Comments of this form must start and end on the same line:

Comments and white space will be ignored by your RepRap Printer. It"s better to strip these out on the host computer before sending the G-code to your printer, as this saves bandwidth.

If checking is supported, the RepRap firmware expects line numbers to increase by 1 each line, and if that doesn"t happen it is flagged as an error. But you can reset the count using M110 (see below).

If present, the checksum should be the last field in a line, but before a comment. For G-code stored in files on SD cards the checksum is usually omitted.

The 8-bit checksum provides insufficient protection against noise on the received data connection in some situations, for example where the cable from a display device runs close to an extruder cable. Therefore RepRapFirmware allows a CRC to be used in place of a checksum. If present, the CRC should be the last field in a line, but before a comment. RepRapFirmware assumes that * followed by 5 digits is a CRC, whereas * followed by 1, 2 or 3 digits is a checksum. The polynomial used is 0x1021 as for CCITT CRC16.

The checksum "cs" for a G-code string "cmd" (including its line number) is computed by exor-ing the bytes in the string up to and not including the * character as follows:

RepRapFirmware 3.01 and later supports conditions and loops in GCode. Properties from the firmware object model (e.g. current position, current tool) can be included in controlling expressions. See https://duet3d.dozuki.com/Wiki/GCode_Meta_Commands for details.

If buffering is supported, the RepRap firmware stores some commands in a ring buffer internally for execution. This means that there is no (appreciable) delay while a command is acknowledged and the next transmitted. In turn, this means that sequences of line segments can be plotted without a dwell between one and the next. As soon as one of these buffered commands is received it is acknowledged and stored locally. If the local buffer is full, then the acknowledgment is delayed until space for storage in the buffer is available. This is how flow control is achieved.

Typically, the following moving commands are buffered: G0-G3 and G28-G32. The Teacup Firmware buffers also some setting commands: G20, G21, G90 and G91. All other G, M or T commands are not buffered.

RepRapFirmware also implements an internal queue to ensure that certain codes (like M106) are executed in the right order and not when the last move has been added to the look-ahead queue.

When an unbuffered command is received it is stored, but it is not acknowledged to the host until the buffer is exhausted and then the command has been executed. Thus the host will pause at one of these commands until it has been done. Short pauses between these commands and any that might follow them do not affect the performance of the machine.

In the above example, we first set the feedrate to 1500mm/min, then move to 50mm on X and 25.3mm on Y while extruding 22.4mm of filament between the two points.

However, in the above example, we set a feedrate of 1500 mm/min, then do the same move, but accelerating to 3000 mm/min. Everything stays synchronized, so extrusion accelerates right along with X and Y movement.

The RepRap spec treats the feedrate as simply another variable (like X, Y, Z, and E) to be linearly interpolated. This gives complete control over the acceleration and deceleration of the printer head in a way that ensures everything moves smoothly together and the right volume of material is extruded at all points.3

To reverse the extruder by a given amount (for example to reduce its internal pressure while it does an in-air movement so that it doesn"t dribble) simply use G0 or G1 to send an E value that is less than the currently extruded length.

1Some firmwares allow for the RepRap to enable or disable the "sensing" of endstops during a move. Please check with whatever firmware you are using to see if they support the H parameter in this way, as damage may occur if you assume incorrectly. In RepRapFirmware, using the H1 or H2 parameter on a delta printer causes the XYZ parameters to refer to the individual tower motor positions instead of the head position, and to enable endstop detection as well if the parameter is H1. H3 may be used to measure axis lengths and H4 can be used to stop when an endstop is hit while updating the position only (H4 is supported in 3.2-b4 and later).

2In the RS274NGC Spec, G0 is Rapid Move, which was used to move between the current point in space and the new point as quickly and efficiently as possible, and G1 is Controlled Move, which was used to move between the current point in space and the new point as precise as possible. In RepRapFirmware, G1 is always a linear move but G0 may not be linear (e.g. on a SCARA machine); however a G0 move will never go below the lower of the initial and final Z height of the move.

4RepRapFirmware provides an additional "R" parameter to tell the machine to add the coordinates of the specified restore point to all axis coordinates mentioned in the G0 or G1 command. Axes that are not mentioned in the G0 or G1 command are not moved. When a print is paused, the coordinates are saved in restore point #1. When a tool change is commenced, the coordinates are saved in restore point #2. Coordinates can also be saved in restore points explicity using the G60 command.

Some older machines, CNC or otherwise, used to move faster if they did not move in a straight line. This is also true for some non-Cartesian printers, like delta or polar printers, which move easier and faster in a curve.

(Move in a Clockwise arc from the current point to point (X=90.6,Y=13.8), with a center point at (X=current_X+5, Y=current_Y+10), extruding 22.4mm of material between starting and stopping)

(Move in a Counter-Clockwise arc from the current point to point (X=90.6,Y=13.8), with a center point at (X=current_X+5, Y=current_Y+10), extruding 22.4mm of material between starting and stopping)

In this case sit still doing nothing for 200 milliseconds. During delays the state of the machine (for example the temperatures of its extruders) will still be preserved and controlled.

On Marlin, Smoothie and RepRapFirmware, the "S" parameter will wait for seconds, while the "P" parameter will wait for milliseconds. "G4 S2" and "G4 P2000" are equivalent.

Perform a direct, uninterpolated, and non-kinematic synchronized move of one or more steppers directly. Units may be linear (e.g., mm or inches on DELTA) or specified in degrees (SCARA). This command is useful for initialization, diagnostics, and calibration, and should be disabled on production equipment. This type of move can be potentially dangerous, especially for deltabots, so implementations should do their best to limit movement to prevent twerking and damaging the carriage assembly.

Remember that any parameter that you don"t specify will automatically be set to the last value for that parameter. That usually means that you want explicitly to set Z0.0. RepRapFirmware will report the tool parameters if only the tool number is specified.

The precise meaning of the X, Y (and other offset) values is: with no offset this tool is at this position relative to where a tool with offset (0, 0, 0) would be. So if the tool is 10mm to the left of a zero-offset tool the X value would be -10, and so on.

The R value is the standby temperature in oC that will be used for the tool, and the S value is its operating temperature. If you don"t want the tool to be at a different temperature when not in use, set both values the same. See the T code (select tool) below. In tools with multiple heaters the temperatures for them all are specified thus: R100.0:90.0:20.0 S185.0:200.0:150.0 .

1Marlin uses G10/G11 for executing a retraction/unretraction move. Smoothie uses G10 for retract and G10 Ln for setting workspace coordinates. RepRapFirmware interprets a G10 command with no P or L parameter as a retraction command.

2It"s usually a bad idea to put a non-zero Z value in as well unless the tools are loaded and unloaded by some sort of tool changer or are on indepedent carriages. When all the tools are in the machine at once they should all be set to the same Z height.

3If the absolute zero temperature (-273.15) is passed as active and standby temperatures, RepRapFirmware will only switch off the tool heater(s) without changing their preset active or standby temperatures. RepRapFirmware-dc42 does not support this setting.

4Tool offsets are applied after any X axis mapping has been performed. Therefore if for example you map X to U in your M563 command to create the tool, you should specify a U offset not an X offset. If you map X to both X and U, you can specify both offsets. (Not supported on all firmwares).

5L1 sets the offsets of the specified tool relative to the head reference point to the specified values. L2 sets the current workplace coordinate offsets to the specified values. L20 adjusts the current workplace coordinate offsets so that the current tool head position has the specified coordinates. NOTE on some firmwares L is required (and is required by NIST standard). P is also required to specify either the tool to update or the WCS to update.

RepRapFirmware recognizes G10 as a command to set tool offsets and/or temperatures if the P parameter is present, and as a retraction command if it is absent.

The use of G12 for tool cleaning clashes with the established use of G12 for circular pocket milling on CNC machines. For this reason, RepRapFirmware does not support G12.

This mode applies to G2/G3 arc moves. Normal arc moves are in the XY plane, and for most applications that"s all you need. For CNC routing it can be useful to do small "digging" moves while making cuts, so to keep the G-code compact it uses G2/G3 arcs involving the Z plane.

Units from now on are in inches. In RepRapFirmware, the inches/mm setting applies to regular printing and travel moves (G0, G1, G2 etc.) but not to configuration commands. Therefore configuration should be done in mm.

In RepRapFirmware, the inches/mm setting applies to regular printing and travel moves (G0, G1, G2 etc.) but not to configuration commands. Therefore configuration should be done in mm.

When executing a macro file, RepRapFirmware remembers the initial inches/mm setting and restores it after execution of the macro has completed. So a macro file such as pause.g (executed when a pause command is received) can safely use G21 at the start to switch the units to mm without affecting the job after the macro completes, regardless of whether the job was using inches or mm.

Use this command (along with G23) to have the firmware to do retraction moves (in contrast to generating an E axis G1 move). The retract length and speed are set in the firmware.

The G26 Mesh Validation Pattern is designed to be used in conjunction with various Mesh Bed Leveling systems – those that adjust for an uneven —rather than just tilted— bed. The G26 command prints a single layer pattern over the entire print bed, giving a clear indication of how accurately every mesh point is defined. G26 can be used to determine which areas of the mesh are less-than-perfect and how much to adjust each mesh point.

G26 has large feature list, including a built-in test that extrudes material onto the bed. By default this is configured for PLA temperatures and a nozzle size of 0.4mm. (This will be adjustable in an upcoming version of Marlin.)

Park the toolhead (i.e., nozzle) at a predefined XY position, with a Z raise value that applies over 0 or over the current position depending on the P parameter.

When the firmware receives this command, it quickly moves the specified axes (or all axes if none are given) to the endstops, backs away from each endstop by a short distance, and slowly bumps the endstop again to increase positional accuracy. This process, known as "Homing", is required to determine the position of the print carriage(s). Some firmware may even forbid movement away from endstops and other operations until the axes have been homed.

The X, Y, and Z parameters act only as flags. Any coordinates given are ignored. For example, G28 Z10 results in the same behavior as G28 Z. Delta printers cannot home individual axes, but must always home all three towers, so the X Y Z parameters are simply ignored on these machines.

Marlin firmware (version 1.1.0 and later) provides an option called Z_SAFE_HOMING for printers that use a Z probe to home Z instead of an endstop. With this option, the XY axes are homed first, then the carriage moves to a position –usually the middle of the bed– where it can safely probe downward to home Z.

RepRapFirmware uses macro files to home either all axes or individual axes. If all axes are homed, the file homeall.g is processed. For individual axes the homex.g, homey.g, or homez.g file will be used. On Delta printers, G28 command will always home all three towers by processing the homedelta.g file, regardless of any X Y Z parameters.

Because the behavior of G28 is unspecified, it is recommended not to automatically include G28 in your ending G-code. On a Cartesian this will result in damaging the printed object. If you need to move the carriage at the completion of a print, use G0 or G1.

2 Original Prusa i3 MK2/s, MK2.5/s, MK3/s supports a W parameter to suppress mesh bed leveling. If W is omitted, G28 will home only and NOT perform mesh bed leveling.

This command uses a probe to measure the bed height at 3 or more points to determine its tilt and overall flatness. It then enables compensation so that the nozzle will remain parallel to the bed. The printer must be homed with G28 before using this command.

Each firmware behaves differently and depends on the type of bed leveling that"s been configured. For example, Marlin 1.0.2 provides 3 different types of automatic bed leveling (probe required) and a manual bed leveling option. See your firmware"s documentation for the specific options available.

Marlin 1.1.0 and later allows the bilinear grid (i.e., "mesh") method to be used on all types of machines, not just deltas. This is the recommended leveling method going forward.

Also in Marlin 1.1.0 and later, the PROBE_MANUALLY option allows all forms of Auto Bed Leveling to be used without a probe. The procedure is similar to that of MESH_BED_LEVELING (see below). Begin the process with G29 to move the nozzle to the first point. Adjust the Z axis using G1 or your host software. Send G29 again to move to the next point and repeat until all points have been sampled.

T Generate a Bed Topology Report. Example: G29 P5 T for a detailed report. This is useful for manual bed leveling and finding flaws in the bed (to assist with part placement). Not supported by non-linear delta printer bed leveling.

E By default G29 will engage the Z probe, test the bed, then disengage. Include E or E1 to engage/disengage the Z probe for each sample. (This has no effect for fixed probes.)

Marlin firmware (version 1.1.0 and later) includes the AUTO_BED_LEVELING_UBL option for Unified Bed Leveling. UBL combines mesh leveling, tilted plane adjustment, 3-point leveling, and manual editing tools all together in a single package. To accomplish so much, UBL overloads `G29` with several new parameters and provides an additional G26 Mesh Tuning feature.

Marlin firmware (version 1.0.2 and later) also provides a MESH_BED_LEVELING feature that can be used to perform bed leveling on machines lacking a probe. This form of bed leveling compensates for uneven Z height across the surface of the bed using a mesh and bilinear interpolation.

Repetier firmware since v0.91 supports G29 with the optional Snnn parameter as described below. Useful to simply detect the Z bed angle so you can manually readjust your bed and get it as close to in plane as possible. If you wish to apply automatic software Z plane compensation on Repetier, use G32 instead with firmware 0.92.8 and above.

S1 Same as S0, except printer immediately moves to Z maximum position (Z max endstop required!), and calculates new Z maximum height. You must first issue G28 Z to home to Z maximum position before issuing G29 Snnn for this to work correctly, or the printer height will be invalid.

S0 (default if no S parameter) Probe the bed, save the height map in a file on the SD card, and activate the height map. The default folder for the height map file is /sys and the default file name is heightmap.csv.

In RepRapFirmware 3.2 and later, G29 runs macro file mesh.g if it exists, otherwise it behaves like G29 S0. The mesh.g file can perform other actions (e.g. homing or tool selection) and then use G29 S0 to do the probing.

Set the offset of the Z probe head. The offset will be subtracted from all probe moves. The calculated value is derived from the distance of the toolhead from the current axis zero point.

RepRapFirmware supports additional behaviour: if a Pn field is specified the probed X, Y, and Z values are saved as point n on the bed for calculating the offset plane or for performing delta printer calibration. If X, Y, or Z values are specified (e.g. G30 P1 X20 Y50 Z0.3) then those values are used instead of the machine"s current coordinates. A silly Z value (less than -9999.0) causes the machine to probe at the current point to get Z, rather than using the given value. If an S field is specified (e.g. G30 P1 Z0.3 S) the bed plane is computed for compensation and stored. The combination of these options allows for the machine to be moved to points using G1 commands, and then probe the bed, or for the user to position the nozzle interactively and use those coordinates. The user can also record those values and place them in a setup G-code file for automatic execution.

RepRapFirmware uses the value of the S parameter to specify what computation to perform. If the value is -1 then the Z offsets of all the points probed are printed, but no calibration is done. If the value is zero or not present, then this specifies that the number of factors to be calibrated is the same as the number of points probed. Otherwise, the value indicates the number of factors to be calibrated, which must be no greater than the number of points probed. In version 1.09, the number of factors may be 3, 4 or 5 when doing auto bed compensation on a Cartesian or CoreXY printer, and 3, 4, 6 or 7 when doing auto calibration of a Delta printer.

RepRapFirmware supports an optional H parameter, which is a height correction for that probe point. It allows for the Z probe having a trigger height that varies with XY position. The nominal trigger height of the Z probe (e.g. at bed centre) is declared in the Z parameter of the G31 command in the config.g file. When you probe using G30 and the probe triggers, the firmware will assume that the nozzle is at the nominal trigger height plus the value you have in the H parameter.

Tnnn (RepRapFirmware 1.17 and later) Z probe type to which these parameters apply, defaults to the current Z probe type as defined by M558 P parameter

When used on its own this reports whether the Z probe is triggered, or gives the Z probe value in some units if the probe generates height values. If combined with a Z and P field (example: G31 P312 Z0.7) this will set the Z height to 0.7mm when the Z-probe value reaches 312 when a G28 Z0 (zero Z axis) command is sent. The machine will then move a further -0.7mm in Z to place itself at Z = 0. This allows non-contact measuring probes to approach but not touch the bed, and for the gap left to be allowed for. If the probe is a touch probe and generates a simple 0/1 off/on signal, then G31 Z0.7 will tell the RepRap machine that it is at a height of 0.7mm when the probe is triggered.

In RepRapFirmware, separate G31 parameters may be defined for different probe types (i.e. 0+4 for switches, 1+2 for IR probes and 3 for alternative sensors). To specify which probe you are setting parameters for, send a M558 command to select the probe type before sending the G31 command, or use the T parameter.

1X and Y offsets of the Z probe relative to the print head (i.e. the position when the empty tool is selected) can be specified in RepRapFirmware. This allows you to calculate your probe coordinates based on the geometry of the bed, without having to correct them for Z probe X and Y offset.

2In RepRapFirmware, additional parameters "S" (bed temperature in oC at which the specified Z parameter is correct, default is current bed temperature) and "C" (temperature coefficient of Z parameter in mm/oC, default zero) can be set for the alternative (ultrasonic) sensor. This is useful for probes that are affected by temperature such as PINDA. RepRapFirmware 3.1 and later allow both first and second order temperature coefficients to be specified, e.g. C0.015:0.001.

This command is implemented as a more sophisticated form of bed leveling (which uses a transformation matrix or motorized correction. Smoothieware uses this code instead of `G29`.

Each firmware behaves differently. For example, Repetier firmware allows for motorized rotation of the bed whilst ReprapFirmware probes the bed with a transformation matrix.

RepRapFirmware executes macro file bed.g in response to the G31 command. The bed.g file is typically used to probe the bed and then perfor

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey