cracked lcd screen iphone made in china

Having checked out your video, I personally will not use the aftermarket screen as a replacement for my X. It just doesn"t have what I expect for a $1000 USD phone. I recognize that $300 USD for a replacement is hefty but the aftermarket screen does not appear to have the quality that I would expect for my phone.

Since the iPhone 7/7 Plus has been released for quite a long time, finally the China made iPhone 7/7 Plus screen replacementscame out in the market. we’ve got some iPhone 7 series LCD screen replacements samples and done some tests on them, now let’s take a closer look at these new iPhone 7 series LCD screen replacements!(TianmaandLGsources for testing)

After installing all the sample screens to the iPhone 7/7 Plus rear housing assembly, we found that all the China made iPhone 7 series screen replacements are fitting well just like the original ones - the home button fits well, the screen assembly and the rear housing also fits well.

From the picture below, we can see that there is no difference between the China made iPhone 7 series display and the original ones, however, back to the rear side, we can easily figure out which one is which, cause the original one has Apple logo on it while the China made screen has none.

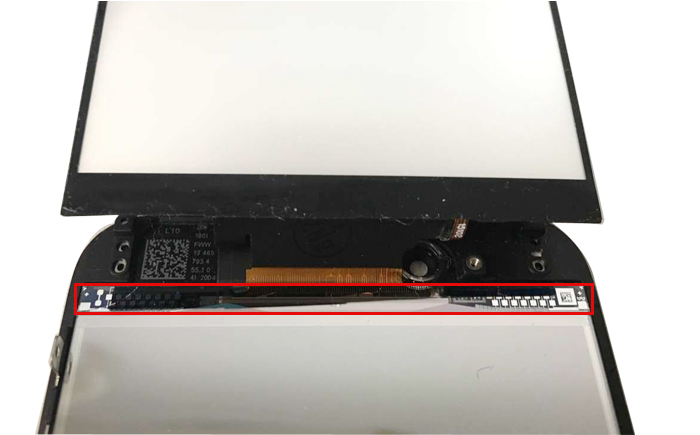

By comparing these two iPhone 7 screens, we can find that the screen flex cables are much different, there are extra IC on the China-Made iPhone 7 screen while the original one has none. And the original iPhone 7 series screen flex cable is integrated together while on the China-Made iPhone 7 series screen the touch function flex cable is soldered to the display and 3D touch flex cable.

Another difference between the original and China made iPhone 7 screen replacements is the exposed IC on the after-market iPhone screen, just like other China-Made iPhone 5 or 6 series screen replacement, which has more potential risk of electrostatic damage and more likely to get damaged and this problem needs to be improved.

During our test, we found that the display color between our after-market iPhone 7 screen and original screen seems a little different although they are not effecting the touch function. And to be honest, there may have some black dots on the screen because of impurities within the screen module when laminating the LCD and backlight together, without any doubt, this can be solved with technical improvement.

The screen touch sensitivity is another big concern for all of us, luckily, during our test, almost all home button and touch functionality on both iPhone 7 and 7 Plus works well, except one piece of iPhone 7, the 3D touch function is not acting so well on the central part of the screen.

The China-Made iPhone 7 series LCD screen assembly replacement still remains to be improved in quality and performance compared to the original ones, the exposed IC, heavier screen flex cable ribbon, and the screen color difference, the touch function stability, although the price is attractive. However, the China made iPhone 7 series screen replacement is under the improvement, and sooner or later their quality and performance can be quite close to original ones and acceptable, if you"re going to stock up some non-original iPhone 7 series LCD screen replacement, pay more attention and we’ll keep you updated with further information about after-market iPhone 7 series screen replacement!

Recently we have got some samples of China Made 6 Plus LCD screen. We did some tests with these samples and found some differences compared to other screens.

“Original” screens are those containing LCDs manufactured for Apple. “Copy” screens are compatible replacements entirely designed and manufactured by third-party companies not associated with Apple.

LCD display panel can have poorer resolution (i.e. looks “coarser”), worse brightness, contrast and vibrancy and reduced refresh rate amongst other problems.

Changes in specification from original can result in battery and performance issues. Certain badly-engineered screens could even damage the backlight circuitry.

Customers who bring their iPhones to us for a screen repair are offered two choices of replacement- an original or a “copy” screen. The most common response is “Is there a difference- and which one would you recommend?”

Originals are those screens containing LCDs that were manufactured for Apple. So-called “copy” screens are compatible replacements, but designed and manufactured entirely independently by third-party companies, typically in China.

Our answer is simple- the original screen is the one we’d go for ourselves, every time. Some people think we make more money on them, but this isn’t the case. We recommend originals because they’re far higher quality and the price difference is fairly small.

We’d rather only fit original screens. The only reason we don’t is that many people will shop around and choose purely on price. As such, we need to offer the cheaper copy screens to remain competitive and avoid losing these customers. In some cases, they didn’t even know there was a difference in the first place- especially since it’s not in some shops’ interest to draw people’s attention to the issue!

This may well be the worst copy screen we’ve ever come across. As a result, the unfortunate customer has ended up paying twice to have their screen replaced- we’re sure that had they been properly informed, they would have chosen an original in the first place.

While the difference in price between copies and originals can vary across devices, it’s generally around £10 – £14 extra to have an original screen fitted. This really isn’t a lot considering the improved quality and reliability.

We compare our prices to our competitors- and we know that we come out of it favourably. While we have to offer copy screens to remain competitive, we always advise customers to go for the original.

When you’ve spent- directly or indirectly- several hundred pounds for an iPhone with a Retina display, it doesn’t make sense to replace it with a lower-quality screen that can make a £400 phone look like a £40 one! Not only that, but you’re likely to have fewer issues, and a longer-lasting screen.

Many- if not most- don’t even acknowledge the existence of copy screens, let alone explain the difference to the customer. Hardly in their interest to do so if they only fit cheap, low-quality copies. Some of them can hardly be blamed- they know so little, they’re not even clear on the differences between OEM, non-OEM and copy displays themselves! Others can be more deliberately misleading… and some outright lie.

Generally, these shops are looking for the cheapest price on replacement screens.. When offered a copy at a half or a third of a price of the original, they’re going to go for that. That might be fine if they offered the customer a cheaper price- what we disagree with is selling “supermarket beans” (i.e. the copy screens) at “Heinz beans” prices!

Heading towards the “blatantly fraudulent”, we’re aware of companies that shamelessly fit copy screens while claiming them to be original. Worse, they’ll take your broken original screen and sell that to a recycler for more than they paid for your copy!

Apple tightened up their supply chain around 2015, which reduced the number of screens available for repairs and increased their price dramatically. A lot of companies went bankrupt, and Chinese manufacturers responded by making their own “copy” screens from scratch. At first, these weren’t much cheaper than the Apple ones, but the price soon fell.

We should be clear that- despite the name- “copy” screens aren’t direct copies of the Apple originals. Rather, they’re compatible replacements that have been designed from scratch and- as a result- vary in some respects that have an effect on usability and quality.

One of the most important differences between an original and a “copy” screen is how the digitizer (touch sensor) is designed. Apple has it manufactured as part of the LCD itself, whereas the copies have it on the glass.

Although there are only a small number of manufacturers of the bare LCDs themselves, these are then bought by countless other companies who add the remaining components needed to turn these into a complete working screen. As a result, you could easily end up with an LCD from the best “copy” manufacturer, but the digitizer/touch (as part of the separately-manufactured glass) from the worst.

There are countless digitizers out there, and you can only take the supplier’s word that the quality is good. Many ship good ones at first, then switch to cheaper parts to make more profit. This is particularly bad with the iPhone 6S and 6S+, since Apple moved the chips responsible for touch processing onto the LCD itself. As a result, you’re not just getting a copy screen- you’re getting copy chips too.

The performance specification (power drain, etc.) of most copy screens isn’t identical to the originals. As a result, they can drain the battery more quickly and mislead the operating system which was optimised for the original screen design.

It’s even possible that this mismatch could damage your backlight. We do a lot of subcontracted repairs for less-experienced shops, and get backlight repairs in almost every day. We’ve had cases where we fixed the circuit, fitted the new copy screen to test it, and had it break the circuit again!

Copy screens can disrupt the touch ID fingerprint reader. With the 6S, 6S+, 7 and 7+, the home button- part of the 3D touch- is part of the screen assembly. Frequently the home button flexes on aftermarket designs don’t work properly and stop the touch ID working- annoying if you use it to unlock the phone or log in to your bank.

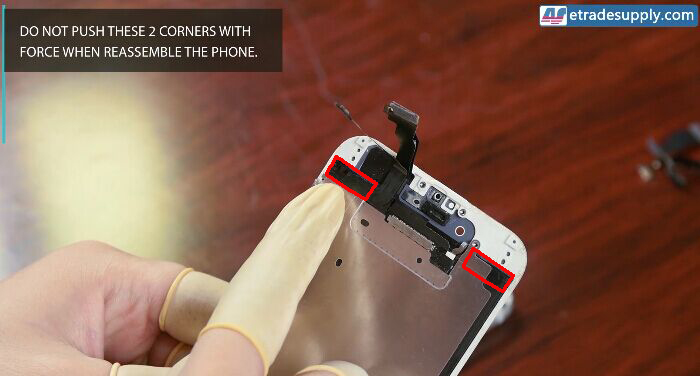

We’ve seen many lift away from the frame that holds them in place. This usually results in the flex cable getting torn, and the screen needing replacing. You don’t even need to have dropped the phone- this often happens through general everyday wear and tear.

That brings us to another major issue with the copies. When you drop an Apple original, the glass often breaks, but if the LCD itself is intact, you can continue to use it until it’s fixed. With the copies, the touch/digitizer is on the glass and stops working when that’s broken. Even worse, the LCD itself is more likely to break due to the thinner and more fragile glass.

We’re not convinced this will happen, since Apple recently changed their repair policy to accept iPhones with third-party screens. However, it is possible that copy screens could be stopped from working via an iOS update, since those make a number of security checks.

All the test procedures were analyzed in detail with opinions proposed. Now, let’s take a close look to the first China madeiPhone 7 Plus LCD Screen sample with professional testing report below.

To analyze inside layers of the iPhone screen, we tear it down layer by layer .The sample China made screen applies G + G layer structure, there is a glass base touch layer,

The quality and performance is quite close to OEM and acceptable, and sure it will come with impressive lower price offer. The display panel is China made with G + G layer structure, and the screen is assembled with a third-party driver IC solution.

With the lack stock of the original iPhone 5 & 6 series LCD screen, the China made LCD screens becomes more and more popular among the repair shops. As the originaliPhone 6 Plus LCD screenprices are still high and not likely to fall down, plus more and more repair shops are tending to accept the China made LCD screens replacement instead, therefore, China made iPhone 6 Plus LCD screen appeared on the market naturally.

Recently we have got some samples of the China Made 6 Plus LCD screen, which have been called ‘LG 1:1 version’ on the market. We did some tests with these samples and found some differences compared to other China made LCD screens.

After tests, we found some differences in LCD frame height, glass screen thickness and the home button location among these 5 samples. You may wonder why these differences exist while they are sourcing from the same manufacturer?

Thus we need to learn the production process of the China made LCD screens, which was assembled by the 3rd party manufacturers, who purchased the China made LCD,LCD frame,glass lens,metal shields, screen foam and digitizer from different manufacturers, which could be original or high copied ones. Since there are some differences among theseglass lenses, LCD frames and so on, even though they shared the same LCD, there will still be some difference.

There is no doubt that significant differences existed between these 2 kinds of LCDs whether in display effect or working stability. In pursuit of greater profits, there is no strict requirements and standards for China made LCDs production process as long as the LCDs can achieve the basic using requirements. Therefore there is quite a gap in color difference, viewing angle and working stability compared to original ones, as the LCDs which are designed for the other brand cellphones, after replacing the IC and flex cable, have been inspected strictly before flowing to the market. (Such as the Samsung GalaxyS3 LCD screen assemblywhich are transformed from the GiONEE phones. Due to the few original stock in availability, most of the S3 LCD screen assemblies are produced by Samsung through transforming GiONEE LCDs.

It is said that these China made iPhone 6 Plus LCD screens are transformed from the MeiZu Meilan Note LCDs (Also features 5.5 inches) which are produced by Sharp and AUO, the overall performances of these LCD screens are better than LT/TM/JDF’s. And what’s big different from the other LCD screens is that there is one more LCD drive IC on the screen flex cable.

Because of the big production MOQ and long R & D cycle, the customized China made LCD screens had some difficulties intechnologyimprovementwith the changes of the marketing demands, while the original LCD features higher quality and reliability.

For these China made iPhone 6 Plus LCD screens, theLCD frametending to pop off and LCD screens are thicker. But in display effects, China made iPhone 6 plus LCD screens are better than5 series. Those customers who cared more about the prices will have one more choice once the improvements of the China made iPhone 6 Plus have been implemented. And we also will continue to focus on the China made iPhone 6 Plus LCD screen assembly.

Not too long ago, we’ve just got some samples of the new China Made iPhone 6 LCD Display. No doubt that this will be another option for all who are suffering from the high price of the iPhone screens. Let’s take a deep look of these screens.

At the moment, there are two companies producing the iPhone 6 LCD screens, one is LT, the other one is JDF (no iPhone 6 screens made by TM are available now). Below are some detailed comparisons after our tests.

When taking a closer look at both of the LT and JDF iPhone 6 screens under direct light, you’ll see the digitizer textures. While for the original screen, the textures had been hidden by a special painted layer.

The glass lens of LT made iPhone 6 screen is far too thin compared with the original one, which can’t secure the display well. At the same time, thinner glass lens will make the home button stick up above the screen. While for the JDF made the screen, a plastic layer has been added to make it thicker.

It’s hard to be realized through eyes, but it’s easily to be touched. When you grab the iPhone 6 with LT made screen, it’s hard to ignore that annoying uncomfortable feeling. At this point, the JDF made screen is much better.

High and low temperature tests have been applied to both the LT and JDF iPhone 6 screens. Both of them have survived and worked well after been putted in a 55 centi degrees room for 2 hours and -5 centi degrees room for 2 hours.

Through our tests, the first version of both the LT and JDF displays are not good choices for the repair industry. The obvious color differences, thickness differences still need to be improved. If you have any questions regarding the LT/JDF iPhone 6 screens, please leave your comment below, we’ll try our best to answer it.

Use our “Get an Estimate” tool to review potential costs if you get service directly from Apple. The prices shown here are only for screen repair. If your iPhone needs other service, you’ll pay additional costs.

Your country or region offers AppleCare+ for this product. Screen repair (front) is eligible for coverage with a fee by using an incident of accidental damage from handling that comes with your AppleCare+ plan.

The Apple Limited Warranty covers your iPhone and the Apple-branded accessories that come in the box with your product against manufacturing issues for one year from the date you bought them. Apple-branded accessories purchased separately are covered by the Apple Limited Warranty for Accessories. This includes adapters, spare cables, wireless chargers, or cases.

LCD Screen and Digitizer Assembly Replacement (Made by China Manufacturer, Brighter/Lumen) + Disassemble Repair Opening Tool Set for iPhone 6s 4.7 inch - White

Alibaba.com offers 91,054 lcd screen repair products. such as machinery repair shops, manufacturing plant, and retail. You can also choose from 1 year, 6 months, and 2 years. As well as from provided. And whether lcd screen repair is white, gray, or black.

Yes, we recycling broken, cracked and damaged LCD/ OLED cell phone screens, and cell phone screens with backlights, dead spots, liquid damage, shadows or pink glow. Our LCD/ OLED buyback program include two brands Apple and Samsung. We encourage to send ALL LCD screens that fit our recycling conditions.

1. Make sure the screens are filled with anti-vibration material which allows for no sway in the carton. Use a bubble wrap for every LCD / OLED screen if possible.

5. You are responsible for the safety of the LCD/ OLED screens during the transportation, PLEASE MIND we won’t be liable for any damage during shipping.

In most cases, our clients receive their full balance within 2 business days after confirmed our test report about the screens, resulting in an optimal cash-flow experience for our clients.

Although we believe that most people are good, scammers do exist and have hit many online LCD/ OLED cell phone screen buyback program companies hard. We’re able to keep our prices competitive by not having to factor in such expected losses that undoubtedly result when offering a prepayment option.

Usually, we will need 1-2 working days to complete the testing upon receiving of the LCD/ OLED cell phone screens, then send you the test report, after you confirmed our test reports about the screens we will settle the payment within 2 business days.

For these reason, it’s important to ensure you ship often to ensure the best price, typically no longer than every two weeks, depending on the total volume LCD/ OLED cell phone screens you have.

Normally, if we receive your screens over 7 days from the time you submit the order details, we will settle the payment with you according to the latest price of HuaQiangBei, the largest LCD screens trading market in China.

Yes, we’d like to send back the screens that filed in testing, but it will need you to bear the shipping cost. We usually finish tested and send it back from Hong Kong.

Our company was located in HuaQiangBei, Shenzhen, China, we had big advantage in sell LCD/ OLED phone screens that made in China. In this regard, we have natural geographical and market advantages. We can provide you with the most comprehensive selection of screens and the most competitive quotation. More details please to visit at our “HOME” page.

Our test is conducted with specialized testing boxes for iPhone and our internally developed (publicly available) LCD Screen Tester app for Android. We test the following defects:

In most all cases, any of these failure reasons results in a failed LCD assembly. The test runs through a range of color pallets, which increased the chances a trained eye can see the above defects.

If you don’t agree with the test report of your screens, we can provide you relevant record for your reference, or we can return those screens to you if necessary.

Yes, except screens recycling and refurbish, our business also include wholesale sell iPhone LCD screens by factory direct price, we have 8+ years of manufacturer experience in iPhone LCD screen industry. More details please to check page “LCD Screen Wholesale”.

What exactly is short in the market? Your iPhone’s screen is one solid unit made up of several elements that are fused together with OCA (optically clear adhesive). The exterior glass, the digitizer panel (touch sensor), the polarizer and LCD panel. The LCD panel is the key component that is in short supply. Originally Apple had 3 manufacturers to produce LCD panels (LG, Sharp and Toshiba). Apple’s authorized manufacturers have the exclusive technology to produce LCD panels. Other Chinese manufacturers can copy the glass, digitizer, polarizers, OCA, flex cables, backlights, frames and everything except for the main component of the LCD assembly.

How were we getting these parts before? A big leak in Apple’s supply chain. The iPhone 5, 5S and 5C all share most of the same raw components including the LCD panel, the only difference is the flex cable and plastic frame. Independent factories in China can produce these components and can manufacture any 5 series assembly from an LCD panel. Shown on the left is a pulse pressing machine, used to connect the flex cable to the LCD. We use one of these to repair LCDs with damaged flex cables.

So what’s happening?A few things, first Apple has cut off LG and Toshiba, making Sharp their exclusive supplier for iPhone LCD panels and implemented very tight security. Secondly, they have had Foxconn destroy stockpiles of series 5 LCD panels to reduce the parts and material leakage to factories that re-engineer them for the independent repair industry. Along with this strategy, Apple has instructed Foxconn to reduce series 6 materials leakage from their manufacturing centers. Lastly, Apple is working aggressively with US Customs to seize inbound parts.

How long is this shortage going to last? In short,we have no idea. At the time of this writing, LCD prices have been steadily rising for 6 months and replacement iPhone 6S LCDs cost twice what Apple charges for their repair service. Apple does not intend to compete with independent repair shops, instead they are squeezing the profit out of the industry. LCD refurbishing may help shops cut cost but without new LCD panels entering the system it won’t last long.

What does this mean for the independent repair community?Apple is the only repair operation that is immune. Even the Chinese LCD refurbishing plants used by the large chain repair companies are running out of LCDs. Continually rising costs may push out the big chains but with lower overhead and clever problem-solving, the owner-operated shops stand a fighting chance.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey