oled vs lcd displays factory

OLED displays have higher contrast ratios (1 million : 1 static compared with 1,000 : 1 for LCD screens), deeper blacks and lower power consumption compared with LCD displays. They also have greater color accuracy. However, they are more expensive, and blue OLEDs have a shorter lifetime.

OLED displays offer a much better viewing angle. In contrast, viewing angle is limited with LCD displays. And even inside the supported viewing angle, the quality of the picture on an LCD screen is not consistent; it varies in brightness, contrast, saturation and hue by variations in posture of the viewer.

There are no geographical constraints with OLED screens. LCD screens, on the other hand, lose contrast in high temperature environments, and lose brightness and speed in low temperature environments.

Blue OLEDs degrade more rapidly than the materials that produce other colors. Because of this, the manufacturers of these displays often compensate by calibrating the colors in a way that oversaturates the them and adds a bluish tint to the screen.

With current technology, OLED displays use more energy than backlit LCDs when displaying light colors. While OLED displays have deeper blacks compared with backlit LCD displays, they have dimmer whites.

LCDs use liquid crystals that twist and untwist in response to an electric charge and are lit by a backlight. When a current runs through them, they untwist to let through a specific amount of light. They are then paired with color filters to create the display.

AMOLED (Active-Matrix Organic Light-Emitting Diode) is a different form of OLED used in some mobile phones, media players and digital cameras. It offers higher refresh rates with OLEDs and consume a lot less power, making them good for portable electronics. However, they are difficult to view in direct sunlight. Products with AMOLED screens include Galaxy Nexus, Galaxy S II, HTC Legend and PlayStation Vita.

Tech observers and investors revel in lively discussions about the latest, greatest gadget and whose bottom line will get the greatest bounce. They enjoy debating the intricacies and details of materials that contribute to these devices, and the related trends and developments. For us at Corning, materials innovators for 165 years, it’s been great to see a recent uptick in discussions about OLED versus LCD display panel technology - a genuine #GlassAge debate.

Corning.com staff sat down with Mike Kunigonis, business director for Corning’s High Performance Displays Group, to understand key differences between OLED and LCD display technology.

Corning.com: Thanks for your time today, Mike. Let’s start with a key question: In the context of display panels, how does OLED technology work and what are the main differences between it and LCD technology?

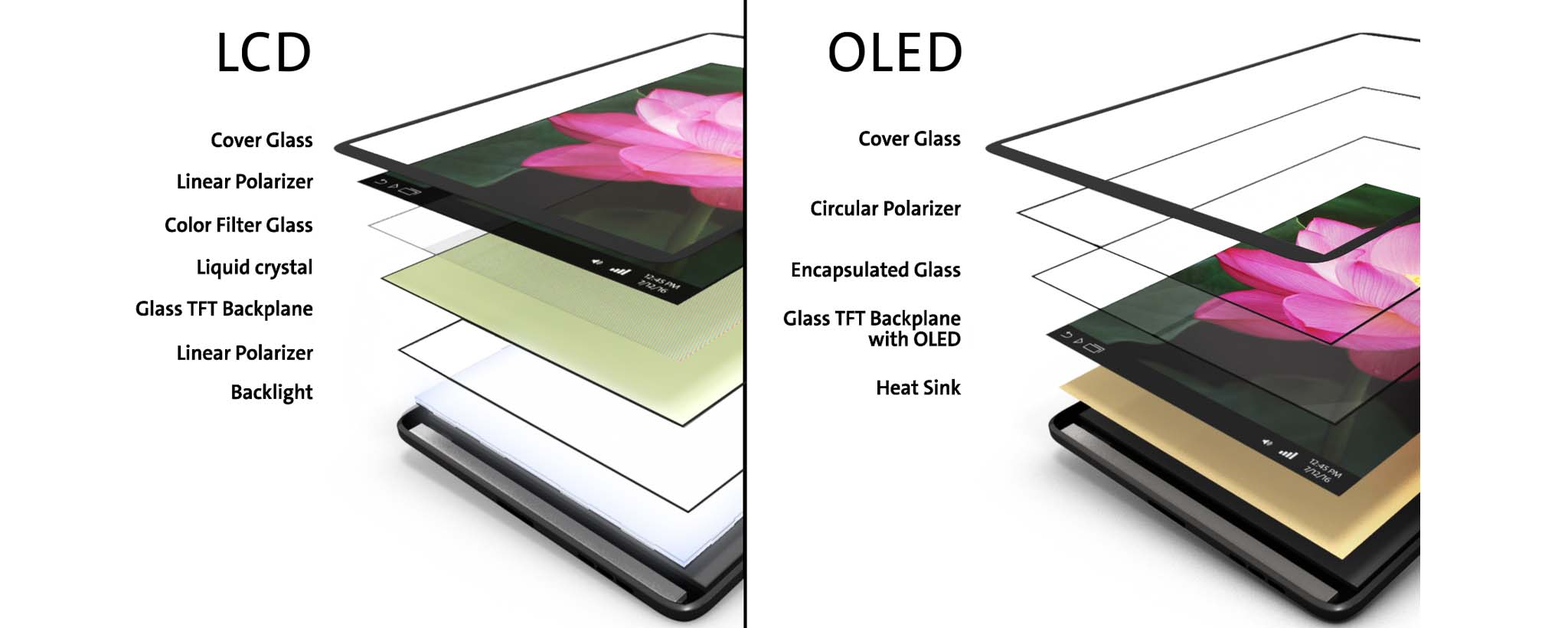

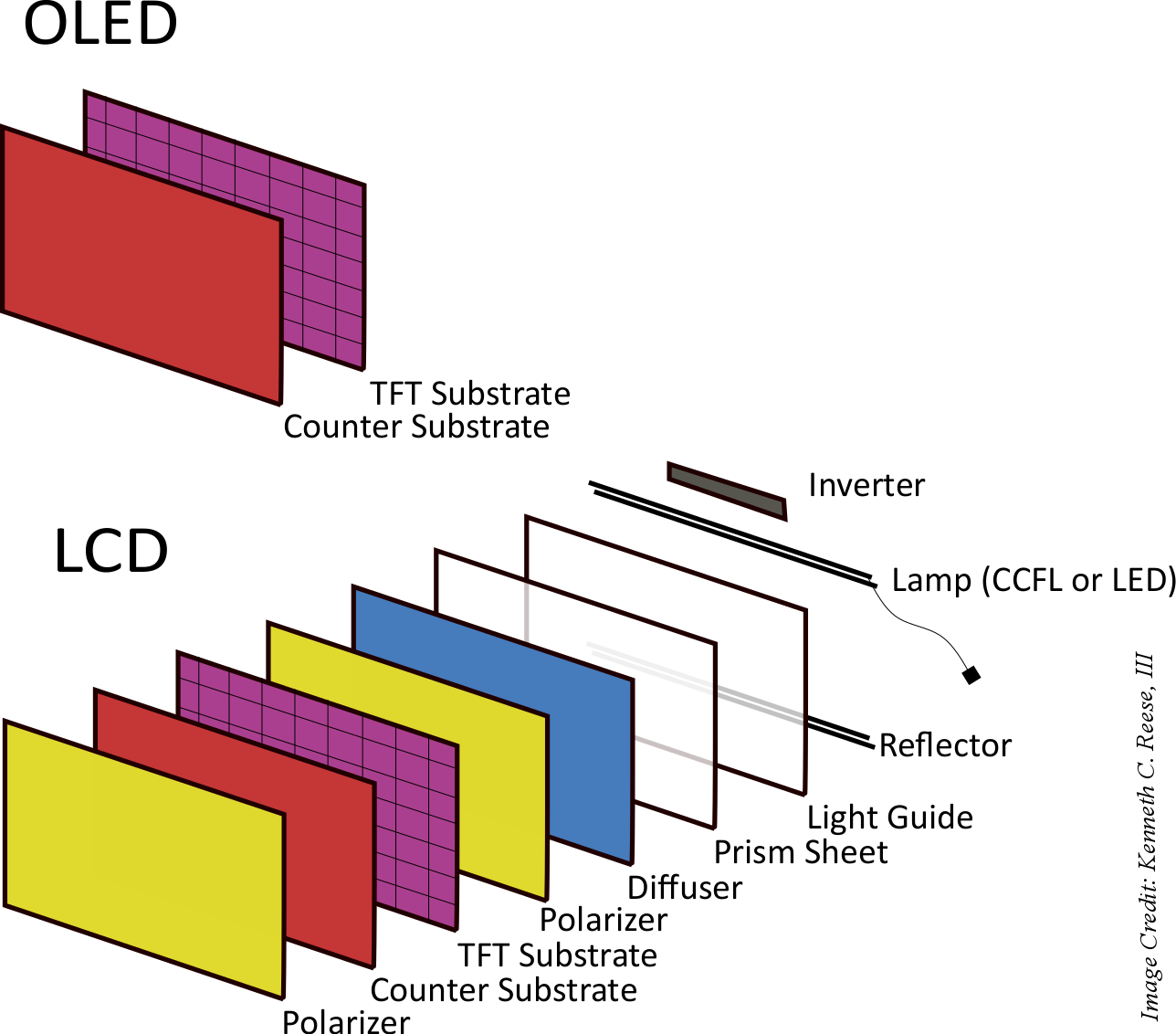

MK: OLED stands for Organic Light-Emitting Diode, or Organic LED. It’s an alternative to LCDs for consumer electronic devices that range in size from wearable to TVs. Like LCD, OLED is a type of panel that enables the displays on device screens. An OLED display picture is generated by turning on and off millions of tiny individual LEDs, each forming the individual pixels of a display. Compare this to LCD, where an always-on backlight projects light through a liquid crystal, sandwiched between two pieces of glass. When the liquid crystal is excited by an electrical current, it lets the light of an individual pixel pass through like a shutter. LCD and OLED display panels both excel at delivering vibrant consumer displays, each in its own unique way.

Corning.com: We’ve heard industry analysts with varying opinions on the benefits an OLED device offers. So why would a consumer prefer a device with an OLED display over an LCD display?

MK: Adoption of OLED displays on smaller, mobile devices is the driver behind most of today’s OLED industry growth, so let me focus on that. A handheld OLED display is attractive to consumers because of the industrial design and display attributes that this technology can support. For example, OLED displays can be curved, or be thinner, or have narrower bezels – or no bezels at all – or flex and bend. Plus, an OLED display will be a great solution for virtual reality applications because it can provide high resolution and superior response time and latency.

If you’re designing a display application or deciding what type of TV to get, you’ll probably have to choose between an OLED or LCD as your display type.

LCDs utilize liquid crystals that produce an image when light is passed through the display. OLED displays generate images by applying electricity to organic materials inside the display.OLED and LCD Main Difference:

graphics and images visible. This is the reason you’re still able to see light coming through on images that are meant to be dark on an LCD monitor, display, or television.

OLEDs by comparison, deliver a drastically higher contrast by dynamically managing their individual pixels. When an image on an OLED display uses the color black, the pixel shuts off completely and renders a much higher contrast than that of LCDs.OLED vs LCD - Who is better at contrast?

Having a high brightness level is important if your display is going to be used in direct sunlight or somewhere with high ambient brightness. The display"s brightness level isn"t as important if it’s going to be used indoors or in a low light setting.OLED vs LCD - Who is better at Brightness?

This means the display is much thinner than LCD displays and their pixels are much closer to the surface of the display, giving them an inherently wider viewing angle.

You’ll often notice images becoming distorted or losing their colors when tilting an LCD or when you view it from different angles. However, many LCDs now include technology to compensate for this – specifically In-Plane Switching (IPS).

LCDs with IPS are significantly brighter than standard LCDs and offer viewing angles that are on-par with OLEDs.OLED vs LCD - Who is better at Viewing Angles?

LCDs have been on the market much longer than OLEDs, so there is more data to support their longevity. On average LCDs have proven to perform for around 60,000 hours (2,500) days of operation.

With most LCDs you can expect about 7 years of consistent performance. Some dimming of the backlight has been observed but it is not significant to the quality of the display.

OLEDs are a newer technology in the display market, which makes them harder to fully review. Not only does OLED technology continue to improve at a rapid pace, but there also hasn’t been enough time to thoroughly observe their performance.

You must also consider OLED’s vulnerability to image burn-in. The organic material in these displays can leave a permanent afterimage on the display if a static image is displayed for too long.

So depending on how your OLED is used, this can greatly affect its lifespan. An OLED being used to show static images for long periods of time will not have the same longevity as one displaying dynamic, constantly moving images.OLED vs LCD - Which one last longer?

There is not yet a clear winner when it comes to lifespans between LCD and OLED displays. Each have their advantages depending on their use-cases. It’s a tie!

For a display application requiring the best colors, contrast, and viewing angles – especially for small and lightweight wearable devices – we would suggest an OLED display.

Liquid Crystal Displays or LCD is a fairly old technology that has seen a recent burst in advancement. From calculator screens, LCDs are now fairly common in mobile phones, PDAs, computers, and a lot more applications. OLEDs (Organic Light Emitting Diode) are an improved version of LEDs that utilizes organic compounds to produce light. OLEDs have been eyed by many manufacturers as a good replacement for LCDs in many applications due to multiple advantages.

From the phrase ‘light emitting’ we can deduce that OLEDs produce their own light unlike LCDs which require a backlight that means fewer parts. Another advantage that this presents is the lower power consumption; a great amount of the power consumed by LCDs goes to the backlight, thus the big power difference. The lack of a backlight also means that an OLED display can be significantly slimmer than an LCD display. OLEDs have also been observed to show warmer images with better contrast making their image quality far superior than what LCDs currently achieve.

Manufacturing OLEDs could also be a lot cheaper than manufacturing LCDs. LCD screens are made out of transistors that are expensive to manufacture. OLEDs on the other hand can be applied to a substrate that has been treated to accept organic compounds via printing methods just like ink. Any inkjet printer can do this, making it easier and more economical to mass produce OLED displays. The printing method of production could also make it viable to have OLED displays on different mediums like cloth and paper which are unthinkable places for LCD displays.

The current problem that most OLED displays face nowadays is the very short lifetime. OLEDs are currently rated to last for up to 14,000 hours of operation before elements in the display begin to fail. This means that it won’t last four years if used for 10 hours every day. LCDs are known to last for over 4 times longer at 60,000 hours. This limitation is currently being looked into to make OLED displays more viable and a good candidate as an LCD replacement.

Competition and innovation are hallmarks of the consumer electronics market which has experienced practically uninterrupted growth for decades. Many consumers own a range of electronic devices (laptop, smartphone, tablet, TV, etc.), each of which is available in a plethora of options: brands; grades, formats; technologies. This technological array is further complicated by marketing terms that try to differentiate between competing products. Acronyms like OLED and LCD are rife in the electronics sector, but what is the actual difference between the two?

The inordinate popularity of smart consumer devices continues to drive growth in the global display market, currently valued in the region of $135 billion. Screens based on LEDs (light-emitting diodes) used to be the industry-standard, but trends towards device miniaturization, portability, improved efficiency, and greater picture quality gradually fuelled OLED (organic light-emitting diode) panels. Over the next few years, the OLED market is expected to expand by a CAGR (compound annual growth rate) of 14.27%.

Currently, OLED televisions outperform traditional LED products on several fronts. They come in a versatile range of formats: panels as large as 88-inches satisfy the demands of premium TV displays; while smaller AMOLED (active-matrix OLED) screens set the benchmark of picture quality in the smartphone industry. Foldable OLED devices have finally begun to enter the consumer electronics market too, fulfilling a long-standing promise from proponents of the technology.

Traditional LED TVs are based on liquid crystal display (LCD) screen technology; a tried-and-tested panel structure. On an LCD screen, images are produced by a thin layer of liquid crystal solution overlaid on a transistor grid which uses small electrical charges to set the individual crystals to an open/closed state. This produces a pattern of light and dark pixels, but the light itself is produced by a bank of LEDs arranged at the edges of the screen or in a backlit array.

The best possible picture on LCD screens is produced using a full-array LED backlight with local-dimming which yields the widest possible contrast. However, LCDs comprise multiple sequential layers within the panel (color filters, polarizers, etc.) which are necessary for producing fully-saturated images but may inhibit picture uniformity and viewing angles. This also makes LED TVs thicker and heavier, rendering them undesirable for applications where reduction of thickness or weight is important.

OLEDs circumvent each of these issues by eschewing a backlight in favor of a self-emissive panel of organic carbon-based material. This allows each subpixel onscreen to be controlled independently. Alongside greater dynamic ranges and energy efficiency, the unique characteristics of OLED panels allow for significantly fewer layers in the screen matrix. Consequently, OLED TVs are typically thinner and lighter in weight than conventional LCDs, but cost significantly more to produce than LCD displays.

Avantama is one of the industry-leading formulators for consumer electronics applications, generating solutions for today’s cutting-edge displays and devices. If you would like more information about our full portfolio of nanoparticle inks and dispersions for OLED manufacturing, simply contact a member of the Avantama team today.

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Low power consumption and flexible: OLED doesn"t rely on backlight and consumes less power. OLED is essentially created on plastic film. It is bendable and easy to process.

High contrast and vivid color: OLED emits light itself, can produce very bright image with beautiful color. And because OLED can be turned off, it can produce true black.

Stroboscopic effect: most OLED screen uses PWM dimming technology. Some people who are easy perceive stroboscopic frequency may have sore eyes and tears.

Micro LED, sometimes called μLED is made up of tiny LED, measure less than 100μm. Another way of looking at this is that MicroLEDs are simply traditional LEDs shrunk down and placed into an array.

Replacing organic material with inorganic GaN material eliminates the need of polarizing and encapsulation layer, found in OLED. Micro LED is smaller and thinner, consumes less power.

In market, LCD means passive matrix LCDs which increase TN (Twisted Nematic), STN (Super Twisted Nematic), or FSTN (Film Compensated STN) LCD Displays. It is a kind of earliest and lowest cost display technology.

LCD screens are still found in the market of low cost watches, calculators, clocks, utility meters etc. because of its advantages of low cost, fast response time (speed), wide temperature range, low power consumption, sunlight readable with transflective or reflective polarizers etc. Most of them are monochrome LCD display and belong to passive-matrix LCDs.

TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy without running out of operation.

Normally, we say TFT LCD panels or TFT screens, we mean they are TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology. TFT is active-matrix LCDs, it is a kind of LCD technologies.

TFT has wider viewing angles, better contrast ratio than TN displays. TFT display technologies have been widely used for computer monitors, laptops, medical monitors, industrial monitors, ATM, point of sales etc.

Actually, IPS technology is a kind of TFT display with thin film transistors for individual pixels. But IPS displays have superior high contrast, wide viewing angle, color reproduction, image quality etc. IPS screens have been found in high-end applications, like Apple iPhones, iPads, Samsung mobile phones, more expensive LCD monitors etc.

Both TFT LCD displays and IPS LCD displays are active matrix displays, neither of them can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to make LCD showing colors. If you use a magnifier to see your monitor, you will see RGB color. With switch on/off and different level of brightness RGB, we can get many colors.

Neither of them can’t release color themselves, they have relied on extra light source in order to display. LED backlights are usually be together with them in the display modules as the light sources. Besides, both TFT screens and IPS screens are transmissive, it will need more power or more expensive than passive matrix LCD screens to be seen under sunlight. IPS screens transmittance is lower than TFT screens, more power is needed for IPS LCD display.

The LCD is currently the display of choice in small devices and is also popular in large-screen TVs. Regular LEDs often form the digits on digital clocks and other electronic devices. OLEDs offer many advantages over both LCDs and LEDs:

Because the light-emitting layers of an OLED are lighter, the substrate of an OLED can be flexible instead of rigid. OLED substrates can be plastic rather than the glass used for LEDs and LCDs.

OLEDs are brighter than LEDs. Because the organic layers of an OLED are much thinner than the corresponding inorganic crystal layers of an LED, the conductive and emissive layers of an OLED can be multi-layered. Also, LEDs and LCDs require glass for support, and glass absorbs some light. OLEDs do not require glass.

OLEDs do not require backlighting like LCDs (see How LCDs Work). LCDs work by selectively blocking areas of the backlight to make the images that you see, while OLEDs generate light themselves. Because OLEDs do not require backlighting, they consume much less power than LCDs (most of the LCD power goes to the backlighting). This is especially important for battery-operated devices such as cell phones.

OLEDs are easier to produce and can be made to larger sizes. Because OLEDs are essentially plastics, they can be made into large, thin sheets. It is much more difficult to grow and lay down so many liquid crystals.

OLEDs have large fields of view, about 170 degrees. Because LCDs work by blocking light, they have an inherent viewing obstacle from certain angles. OLEDs produce their own light, so they have a much wider viewing range.

Lifetime - While red and green OLED films have longer lifetimes (46,000 to 230,000 hours), blue organics currently have much shorter lifetimes (up to around 14,000 hours[source: OLED-Info.com]).

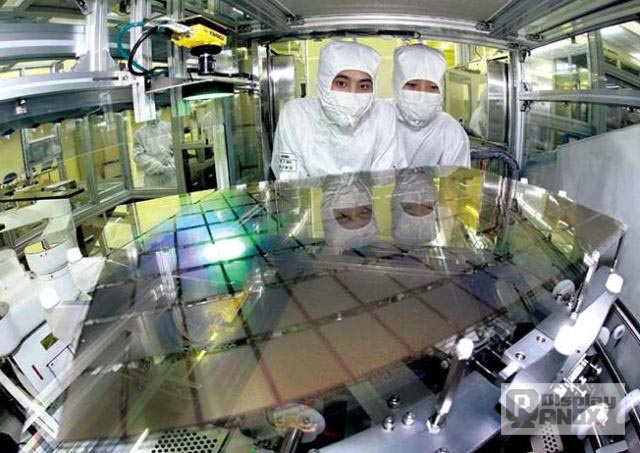

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Since its establishment, Truly Semiconductors has focused on researching, developing, and manufacturing liquid crystal flat panel displays. Now, after twenty years of development, it is the biggest small- and medium-sized flat panel display manufacturer in China.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

Founded in June 1998, Hannstar specializes in producing thin-film transistor liquid crystal display panels, mainly for use in monitors, notebook displays and televisions. It was the first company in Taiwan to adopt the world’s top ultra-wide perspective technology (AS-IPS).

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

TCL CSOT – short for TCL China Star Optoelectronics Technology (TCL CSOT) – was founded in 2009 and is an innovative technology enterprise that focuses on the production of semiconductor displays. As one of the global leaders in semiconductor display market, it has bases in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou, and India, with nine panel production lines and five large modules bases.

TCL CSOT actively produces Mini LED, Micro LED, flexible OLED, printing OLED, and other new display technologies. Its product range is vast – including large, medium, and small panels and touch modules, electronic whiteboards, splicing walls, automotive displays, gaming monitors, and other high-end display application fields – which has enabled it to become a leading player in the global panel industry.

In the first quarter of 2022, TCL CSOT’s TV panels ranked second in the market, 55 inches, 65 " and 75 inches second, 8K, 120Hz first, the first, interactive whiteboard and digital sign plate; LTPS flat panel, the second, LTPS and flexible OLED fourth.

EDO (also known as EverDisplay Optonics) was founded in October 2012 and focuses on the production of small- and medium-sized high-resolution AMOLED semiconductor display panels.

The company opened its first production line – a 4.5-generation low-temperature polysilicon (LTPS) AMOLED mass production line – in 2014, which started mass producing AMOLED displays in November 2014.

In order to ramp up production output, the company began construction of a 6th-generation AMOLED production line in December 2016, with a total investment of 27.3 billion yuan (almost $4 billion USD). The line, which has a production capacity of 30,000 glass substrates per month, produces flexible and rigid high-end AMOLED displays for use in smartphones, tablet pens, vehicle displays, and wearable devices.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

The company"s marketing network is all over the world, and its products are widely used in mobile phones, MP3/MP4 players, vehicle displays, instrumentation, household appliances, and other fields. In terms of technical level, product quality, product grade, and market share, it ranks at the forefront of the domestic industry and has become a leading enterprise in the field of small- and medium-sized displays.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Although Sony’s TVs use display panels from TCL CSOT (VA panel), Samsung. Sony still produces the world’s best micro-OLED display panels. Sony has many micro OLED model such as 0.23 inch, 0.39 inch, 0.5 inch, 0.64 inch, 0.68 inch, 0.71 inch. Panox Display used to test and sell many of them, compare to other micro OLED manufacuturers, Sony`s micro OLEDs are with the best image quality and highest brightness (3000 nits max).

TFT displays are also known as an “Active Matrix TFT LCD module” and have an array of thin film transistors fabricated on the glass that makes the LCD. There is one of these transistors for each pixel on the LCD.

LCDs use voltage applied to a field of microscopic liquid crystals to change the crystal’s orientation, which in turn changes the polarization of the liquid crystal which creates light or dark pixels on the display.

Beautiful, complex images: All of our TFT modules are full-color graphic displays. Unlike standard monochrome character displays, you can create complex images for an imaginative user experience.

Thin and light: These are ideal display modules for handheld devices, communications equipment, information displays, and test and measurement equipment.

Many of our character LCD modules use a standard HD44780 controller, so they can be quickly integrated into a new product or used as a replacement in your existing products.

Many of the LCD controllers on board our graphic LCD display modules also include a CGROM (character generator ROM) which allows for easy character information as well as full bit-mapped graphic information to be shown.

Some of the graphic LCD displays have the ability to render graphics in grayscale, enabling you to show images and elements of your UI (user interface) with more depth and definition.

Because OLEDs are emissive, these displays can always be used in dark environments. There is usually a software command or hardware setting that will allow OLEDs to be dimmed.

Some OLED displays are bright enough to be sunlight readable–these models will typically take more current and may have a shorter rated lifetime. Additionally, OLEDs have extremely wide viewing angles.

What makes OLEDs useful for display construction is that they can be fabricated in bulk. Using OLED fabrication techniques, all the diodes can be made at the same time, at a much lower cost. OLEDs also come in a wide variety of colors.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

limited at first. Will be benefits of the new screen make it worth the wait? Here’s a quick rundown on OLED (organic light emitting diode) technology and how it differs from today’s LCD (liquid crystal display) screens.

iPhone 8 and 8 Plus are built on a backlight—a panel as large as the screen itself that produces a constant white light anytime the screen is on. A series of polarizers and filters are layered in front of the backlight to control the light and produce the image you see on screen. It’s been the dominant technology used in flat-panel displays for almost two decades, but keeping that backlight on draws a lot of power—and that’s a big disadvantage in a portable device.

An OLED does away with the backlight completely. Each individual pixel has a tiny amount of organic material that fluoresces when current flows, so the pixels produce light directly. It’s also possible to control brightness at a per-pixel level.

It’s not the only reason to applaud OLED. Getting rid of the backlight allows for the entire display module to be thinner, which is an important consideration in a smartphone. Apple could use the extra space to make the phone thinner or add a little more battery capacity.

Just as important is the image. OLEDs display more vibrant colors, have deeper blacks and brighter whites and a greater contrast ratio so most people find them superior to LCD.

No. OLED screens began appearing in smartphones several years ago and are used today in phones from Samsung, LG, and other competitors. Several companies also offer OLED monitors and TV screens and flexible OLEDs are increasingly used in smartwatches, fitness bands, and automobile dashboards. Apple is already using an OLED in the Apple Watch.

In part it’s a problem of production. As the iPhone is the world’s best-selling smartphone, Apple needs to be able to ensure a reliable stream of OLED panels from its display partners, but OLED has proved a difficult technology to master.

To date, most of the world’s smartphone OLEDs are produced by Samsung Display, which leaves Apple at the mercy of a single supplier for a key component—typically a position the company has tried to avoid.

While Apple doesn’t comment on its supply chain, the availability of OLED panels is already expected to impact availability of the high-end iPhone with limited supplies being available at launch and back orders being the norm. It will also contribute to the expected record-setting price of the new handset.

![]()

Note: this is an excerpt from a six-part series from Focus Display Solutions of Chandler, Ariz. The series will provide non-technical insights into why products such as cell phones use a color display, and other instruments, such as a blood pressure monitor, use 20-year-old non-color monochrome technology. This series will cover terms such as half-life, power budget, NRE, transflective, and others, and address the different LCD module options available when selecting a display for your product by being broken down into the following parts:Which color LCD technology is best for your application?

When choosing between a color LCD display and a monochrome display, there are several variables to consider. These include cost, EOL (end-of-life), power consumption, ability to customize, and appearance or perception of your product.

End of life is when the product is no longer manufactured. Once a product is discontinued it then becomes Legacy. The world is in color so why don"t all new products use color displays? After all, nobody watches black and white TV anymore. Users have come to expect color displays in all of the products they purchase because the appearance of a color display sets certain products apart from those which use the old monochrome technology.

Three of the mainstream color LCD technologies currently in use are TFT, OLED and FSC. My goal is to help the OEMs understand and decide which display is best for their product and will appeal the most to their end customer.

The best way to introduce these two types of displays is to compare them side-by-side and discuss their advantages and disadvantages. Please keep in mind that what is cutting edge today may be obsolete tomorrow, some of the comparisons below are guaranteed to change in the next few years.

TFTs (thin-film transistor) have been around for several years and control a large percentage of the color LCD market. Although this is the most popular color technology in use today, OLEDs (organic light-emitting diodes) looks like they will surpass TFT technology in the next few years.

TFTs and OLEDs can be seen in applications such as cell phones, laptop computers, and digital cameras. Video and high-resolution photos are also possible on both types.

Winner: OLEDs. OLEDs operate at temperatures as low as -40ºC (-40ºF) and as high as 85ºC (185ºF). TFTs perform poorly below -20ºC (-4ºF) and above +70ºC (158ºF).

Winner: TFT. The current size of TFTs range from 0.9 inches up to, and exceeding 19.2 inches, whereas OLEDs range from 0.5 inches to 7.7 inches (Samsung Galaxy Tab 7.7). It is important to note that these sizes are not absolute. There are TFT and OLED displays that are larger than the sizes listed above, but they are not in mass production at this time.

When choosing the size of your display, keep in mind two major factors: the popularity of the size and the number of suppliers that manufacture that size. Popular displays are LCDs that are manufactured in large quantities. The greater the popularity of the display, the less likely it will be discontinued in the near future, thus the lower the cost. The greater the number of manufactures for a particular size, the lower the cost, an the easier to second source.

Winner: TFTs. Half-life is a measurement of how many hours of use before a display becomes half-as-bright as when it was first turned on. The blue in the OLED has a half-life of 14,000 hours. This does not mean the display will burn out at that point, but will only be half-as-bright as when it was first turned on. There is much research in progress to increase the number of hours.

Keep in mind that not all products require the display to be on 24/7. Many products that require batteries, such as cell phones and digital cameras, only make use of the LCD for one to two hours a day. Many of these devices will be obsolete before the display reaches 14,000 hours.

Winner: OLEDs. OLEDs are estimated to be less than 0.01 mS (milliseconds). TFT is in the neighborhood of 15 mS. That"s milliseconds. The human eye blinks every 300 to 400 milliseconds. There are 86,400,000 milliseconds in one day. The eye can barely consciously detect a difference of 15 mS but the brain can tell there"s something up.

TFTs have been around longer then OLEDs. This head start has allowed TFT manufacturers more time to dominate the market, offer more sizes and lower the cost. The OLED has a few technical set backs at this time, but as technology improves, many or all of these issues may go away.

Long researched in labs worldwide, OLED displays are becoming a market reality, especially in mobile phones. OLEDs offer the potential for vast improvements in image quality and also open up new possibilities for device design—such as TVs that can be rolled up. But for the time being, several challenges must be overcome for OLEDs to become mainstream in TVs. In particular, manufacturing costs need to come down and durability has to improve. As the following pages show, chemistry will play a key role in enabling the growth of the OLED display market.

Visitors to a store today will see that more than two-thirds of TV screens on the market are now larger than 40 inches. They’ll notice that Samsung and a few other firms are pushing a technology called quantum dots that seems to enhance colors and brightness. At some point, a TV model promoted by LG might attract attention, but perhaps more for its higher price than the performance improvement it offers. Alone among its competitors, LG manufactures a line of TVs making use of organic light-emitting diode technology.

Long the focus of research at academic and corporate labs worldwide, OLED displays are starting to trickle into the market. Although they currently represent only a small slice of the total pie and are so far mostly used in mobile phones, OLEDs are poised to rapidly gain market share in the coming years.

This growth will open up billions of dollars of market opportunity for chemical companies that supply materials to the electronics industry. But at the same time, such firms are keen to hold on to the business they have with makers of displays based on incumbent liquid-crystal display, or LCD, technology.

“The OLED display industry is at tipping point,” says David K. Flattery, business development manager for OLEDs at DuPont. “LG is the only producer of OLED TVs currently, but several others are building pilot plants, and we expect a few to proceed with commercialization.”

Like DuPont, market research firms expect the market for OLED displays—in both TVs and smaller devices such as smartphones—to grow significantly. IDTechEx, for example, forecasts that global sales of OLED displays will increase from $16 billion this year to $42 billion in 2020. Samsung, which uses OLEDs in its Galaxy smartphones, is currently the top manufacturer of OLED displays. But others, such as LG, are entering the market, lured by what OLED technology makes possible.

“OLED displays can be lighter, they can be flexible, and they allow designers more leeway with the shape of their devices,” says Guillaume Chansin, senior technology analyst at IDTechEx. Theoretically, he adds, OLEDs can be far more energy-efficient than the LCDs found in most TVs today. And because they are now manufactured on a plastic substrate instead of a glass one, “OLED displays can make phone screens shatterproof, or even foldable.”

The promise of OLEDs has generated much interest among researchers for decades. In an LCD, images are generated by a backlight—a light-emitting diode nowadays—that sends light through liquid crystals, polarizers, color filters, and several image-enhancing filters. The color black in an LCD is created not by turning off the backlight but by electro-orienting the liquid crystals to affect the angle at which the passing light hits the polarizers.

OLED displays are much simpler and thus can be far thinner than LCDs. Instead of a backlight, OLEDs feature pixels that individually emit the red, green, and blue lights required to form an image. OLEDs consist of organic molecules positioned between two electrodes. As current flows from the cathode to the anode, electrons and electron holes in the molecules combine, emitting flashes of light.

An OLED can be manufactured using a variety of substrates, including glass, plastic, and metal. It consists of several layers of organic materials sandwiched between two electrodes. When a voltage is applied across the OLED, a current of electrons flows from the cathode to the anode, adding electrons to the emissive layer and taking them away—or creating electron holes—at the anode. At the boundary between these layers, electrons find holes, fall in, and give up a photon of light. The color of the light depends on the type of organic molecule in the emissive layer. The most advanced OLEDs use electron and hole injection and transport layers to modulate electron movement.

An OLED can be manufactured using a variety of substrates, including glass, plastic, and metal. It consists of several layers of organic materials sandwiched between two electrodes. When a voltage is applied across the OLED, a current of electrons flows from the cathode to the anode, adding electrons to the emissive layer and taking them away—or creating electron holes—at the anode. At the boundary between these layers, electrons find holes, fall in, and give up a photon of light. The color of the light depends on the type of organic molecule in the emissive layer. The most advanced OLEDs use electron and hole injection and transport layers to modulate electron movement.

In an OLED display, black is created by leaving the corresponding pixels off rather than by blocking a backlight. OLED advocates claim that the resulting “true black” is one reason OLEDs can display sharper images. And energy is saved, because the parts of an OLED display that are dark don’t consume electricity.

Although the basic concept behind OLEDs is elegant and simple, turning it into practice has been another matter entirely. The color blue is a perennial headache because the molecules that create it don’t last as long as their red and green counterparts. The bonds in the blue molecules tend to break down, partly because they are fluorescent rather than phosphorescent and require more electricity to operate. In addition, the charge carriers in blue OLEDs recombine through the absorption of ultraviolet light. Moreover, from a performance point of view, the energy efficiency of blue OLEDs is also lower than for other colors.

When it comes to blue, says a spokesperson for the Japanese OLED materials supplier Idemitsu, display manufacturers can only convert about 40% of the electricity used into visible color. For red and green, the efficiency is already at 100%, she adds.

And OLED displays are prone to image retention, says Tadashi Uno, a senior analyst at the market research firm IHS Technology. This occurs when a display keeps showing the ghost of a previous image. Unless that problem is completely resolved, OLED will not gain widespread adoption among manufacturers of TVs and laptop computers. Currently, a temporary solution for owners of mobile phones with OLED displays is to download an app that reduces image retention.

The cost of making OLED displays is another issue. The core compounds at the heart of OLED displays are often made with expensive substances such as iridium, a rare metal that sells for nearly $19 per gram.

What’s more, the standard technique for depositing organic materials on an OLED substrate is a vacuum evaporation process in which a mask is laid over a substrate, molecules are deposited, the mask is taken off, and the mask is cleaned in a vacuum chamber. Industry insiders estimate that the process “wastes” between 70 and 90% of the expensive materials coated on the mask.

Despite these challenges, the number of OLED displays hitting the market is steadily rising, with some occasional setbacks. In 2013, both Samsung and LG launched OLED TVs, but Samsung quickly withdrew from the market because of prohibitive production costs.

However, with its launch of the Galaxy S4 smartphone that same year, Samsung put OLEDs in the hands of millions of customers worldwide. Last year, LG launched a new series of TVs with a higher resolution than its 2013 model. So far, LG’s TVs do not implement a full OLED design but rather use OLED technology as a sophisticated white backlight while colors are generated by color filters. Because each pixel can be individually turned off, the LG TVs can generate true black.

In recent months, commitments to OLED production have multiplied. In November, LG Display announced a massive $9 billion investment in an OLED TV plant scheduled to open in 2018. Numerous reports say Apple is going to source billions of dollars’ worth of OLED displays from Samsung for use in future iPhone models. Meanwhile, Applied Materials, a supplier of precision manufacturing equipment, disclosed last month that demand for tools to make OLEDs is sharply strengthening in 2016.

The drumbeat of announcements about expansion of OLED display production is a boon for Universal Display, a New Jersey-based developer and producer of OLED materials. It was founded in 1994 to be a technology licensor and materials supplier. Rather than operate its own production facilities, Universal Display uses PPG Industries as a contract manufacturer of the materials it sells.

With OLEDs constantly in the news, Universal Display’s stock has gained 25% in the past two months, a turbulent period for financial markets during which the S&P 500 stock index ended up flat. In late June, Universal Display announced the acquisition of Adesis, a contract research firm that was one of its partners. It also announced the acquisition of BASF’s OLED materials patent portfolio.

The growth of the OLED display market will likely accelerate once device designers start to fully take advantage of the technology’s potential, says Janice DuFour, vice president of technology commercialization at Universal Display. Given that OLEDs can operate even if the substrate is a thin sheet of plastic instead of glass, “the fixed shape of a device is not a given,” she says. “Imagine a display you can carry by rolling it up.”

Universal Display expects to be a major player as demand for OLED displays expands. “We made major discoveries on phosphorescent illumination back in the 1990s,” DuFour notes. “Today, we practically own specific colors that OLED displays can emit.”

Red and green light are now created with phosphorescent organic compounds that have greater quantum efficiency than the fluorescent compounds traditionally used in OLEDs. More research still has to be done on phosphorescent blue, DuFour says, but “we are hoping for a breakthrough soon.”

The high cost of display materials and the waste that occurs during mask cleaning will not hamper the growth of the OLED display market, DuFour adds. “One gram of our emitters may be used to make 3,000 phone displays.” she says. Meanwhile, PPG, Universal Display’s manufacturing partner, is developing techniques to reduce the materials loss, she says.

DuPont is betting that reducing the cost of OLED displays and improving their performance will require ink-jet printing processes and suitable inks. Whereas OLED displays are typically created with mask-based deposition of organic materials, DuPont has been conducting research for about 15 years on printing the materials. Last September, it opened a prototyping plant in Newark, Del., that allows its customers to test the viability of printing processes.

The manufacturing requirements for key OLED display materials are as exacting as they are for drug ingredients, Flattery notes, and it makes sense not to waste these materials. So far, DuPont’s proprietary ink-jet inks are producing good results, especially with the color blue. “We worked for years on blue materials,” Flattery says. “Currently, our blues perform at 95% after 2,000 hours of continuous use.”

To speed development of printed OLED technology, DuPont last year teamed up with the ink-jet equipment manufacturer Kateeva. But Flattery notes that DuPont has other undisclosed partnerships and that it won’t be long before a display manufacturer announces the construction of a plant that prints OLED displays. So far, he knows of as many as eight TV manufacturers that are testing the ink-jet process. “Several, if not all, will proceed with commercialization,” he claims.

Ink-jet printing for OLED displays is steadily advancing, confirms Christopher Savoie, chief executive officer of Kyulux, a developer of OLED display materials based in Fukuoka, Japan. The question, he says, is whether materials developers will succeed in designing inks that can last long enough for use in a television.

Significantly, Savoie explains, the materials that Kyulux offers don’t contain expensive metals such as iridium. Using materials that do not contain rare metals reduces the cost of making displays, even with the deposition process, Savoie says.

As OLED displays mature, progress also continues for mainstream LCD technology. Led by Samsung, more and more TV manufacturers are incorporating quantum dots in their models to boost color performance and image quality without having to switch to a completely new technology and manufacturing process.

Quantum dots are semiconducting nanocrystals that increase the range of colors an LCD can emit. They can be fitted into an LCD TV with only a minor modification to manufacturing processes, according to Jason Hartlove, CEO of Nanosys, which calls itself the leading manufacturer of quantum dots. Currently, Nanosys supplies 95% of the quantum dots used in displays, he claims.

In the TV market, quantum dots are far more popular than OLEDs, Hartlove says, appearing in about 40 models to date. He expects that, within five years, as much as 30% of the TV market, measured by total display area, will implement quantum dots.

“OLEDs should theoretically offer a better performance, but we’re very cost-effective,” Hartlove says. OLEDs are uniquely capable of displaying true black, he concedes. But the human eye can only detect true black in a completely darkened room, blurring the performance differences between OLED displays and LCDs with quantum dots. “It’s quite rare to watch TV in a pitch-black room,” he notes.

With OLED technology rapidly emerging but LCDs remaining competitive, established suppliers of display materials must allocate their R&D resources to best take advantage of the emerging market while still supporting the LCD business. JSR, a major Japanese supplier of LCD materials, is hedging its bets by developing OLED materials while continuing to vigorously support LCDs, according to Hiroaki Nemoto, general manager of JSR’s display solution division.

“At JSR, we think that the OLED market will be a good opportunity for us to expand our portfolio,” Nemoto says. At the same time, “LCD technology can be further improved in terms of thinness, robustness, and power efficiency.”

OLED displays will not be a major business for some time because their high growth rate is from a small base, Nemoto believes. So far, JSR has focused on modifying some of its LCD materials, such as color resists and color films, so that they can be used in OLEDs. The company has also developed a new desiccant to protect water-averse OLED materials.

With OLED technology becoming standard in mobile phones but making only hesitant progress in TVs, the display industry is currently at a crossroads, says Uno, the IHS analyst. “It all really depends on the adoption rate by companies like Apple,” he says.

But OLED displays provide such significant advantages over LCDs in terms of weight, thinness, robustness, and flexibility that change will happen fast once key hurdles are overcome, Uno adds. “If manufacturers can develop a process that achieves high yields,” he says, “I am certain the whole display industry will shift to OLEDs.”

LG Display has started mass-production at its second OLED panel production plant, the company announced Thursday. The new plant, located in Guangzhou, China, has the capacity to initially produce 60,000 OLED sheets a month, which combined with LG’s existing plant in Paju, South Korea means that LG Display’s total OLED production capacity has almost doubled to 130,000 sheets monthly.

According to LG, the panels produced at its new plant will be used to create displays ranging in size from 48 to 77-inches. They’re for TVs, in other words. LG Display is a major supplier of OLED panels for TVs across the industry. 19 brands, including LG, Vizio, Sony, Panasonic, Hisense, Bang & Olufsen, and Toshiba, use LG Display OLED panels in their TVs according to FlatPanelsHD.

The opening of LG Display’s new plant comes as it and competitor Samsung Display are shifting their attention away from LCD panels, which the majority of TVs currently use. LG Display announced earlier this year that it is ending production of LCD TV panels in South Korea, Reutersreports, while Samsung Display said it was ending LCD display production in South Korea and China.

LG Display’s CEO, James Hoyoung Jeong, said he hoped the new plant will “enable more rapid adoption of OLED displays in the market.” He called large OLED displays an “essential growth engine” for LG Display. LG Display says that production capacity could increased to 90,000 sheets a month in the future at the new factory.

By 2021, LG Display has said it wants OLED panels to make up 50 percent of its revenue, up from around 30 percent in 2018, according to Reuters. Samsung Display, meanwhile, is pinning its hopes on quantum dot, with ZDNet reporting that its future QD displays will incorporate an OLED panel rather than the LCD layer used by its existing displays.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey