building display screens factory

Aqualite Outdoor TV supply IP66 and IK10 rated weatherproof, waterproof factory TV display systems for usein meat, dairy and fish factories, bakeries, chilled and frozed food production units,cold stores, warehousesand distribution centres.

The Aqualite Outdoor range of factory TV screen monitors anddigital displaysare suitable for use in the harshest indoor and outdoor climate conditions.

Big screen LED TV display screens are becoming the most effect way for companies to communicate their messages to their customers and also their employees on the factory floor. Aqualite Outdoor TV supply, design, install, maintain and service complete IP66 and IK10 rated weatherproof, waterproof, digital display systems, LED messaging displays, electronic display screens and monitors.

LED TV digital display screens have become a vital media for effective corporate communications in farms, large factories, offices, warehouses and commercial buildings. These anti glare LED billboards, video walls and display screens can be installed indoors and outdoors in the most strategic places where employees can see them frequently, such as at factory entrances, in front of office building lifts, in dining rooms, etc.

Please click on the links below for more information on Aqualite’s range of high brightness, waterproof, indoor and outdoor big screen LED digital display screens, signage panels, electronic noticeboards and LED or LCD TV display screens for smart farms, food factories, warehouses, distribution depots and offices.

Big LED TV display screens can be used to reinforce employees’ training and increase the effectiveness of training by repetitively displaying that information or message on screens around the office complex, factory site or warehouse distribution centre.

Digital TV display screens can monitor and display production, trading or sales figures or to recognize the outstanding performance of employees, such as displaying on screen factory production targets, top salesman of the month or best company employee of the month. Personal recognition can raise morale among employees.

With the aid of modern electronic notice board and messaging screen system, companies can regularly address factory and office employees and broadcast messages on all the company’s displays to reinforce the company’s corporate culture.

It is always a great challenge for a bigger company to develop effective internal communications across large or multi site offices and factories. Digital signage can constantly deliver dynamic, up-to-date information, Aqualite Outdoor’s high visability display screens will attract employees’ attention and can keep everyone updated on major policy changes or all the recent progress in each division and department.

Employees can book a meeting room on the system and change information immediately from their own computers. Screens can show the current meeting and agenda in each meeting room around the factory or office

How do you display your metrics? Paper printouts or white boards? LED Scoreboards at each production line? Or perhaps you’ve thought about deploying a manufacturing data display to show your production stats in different areas of your plant. Our Manufacturing Data Display supports your LEAN and paperless manufacturing initiatives with real-time production metrics, KPIs, and inventory figures right on your plant floor.

By communicating directly with your existing database (even data from multiple sources) and displaying it on strategically located screens, our manufacturing data display provides your employees and floor managers with consistent and accurate information when they need it.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

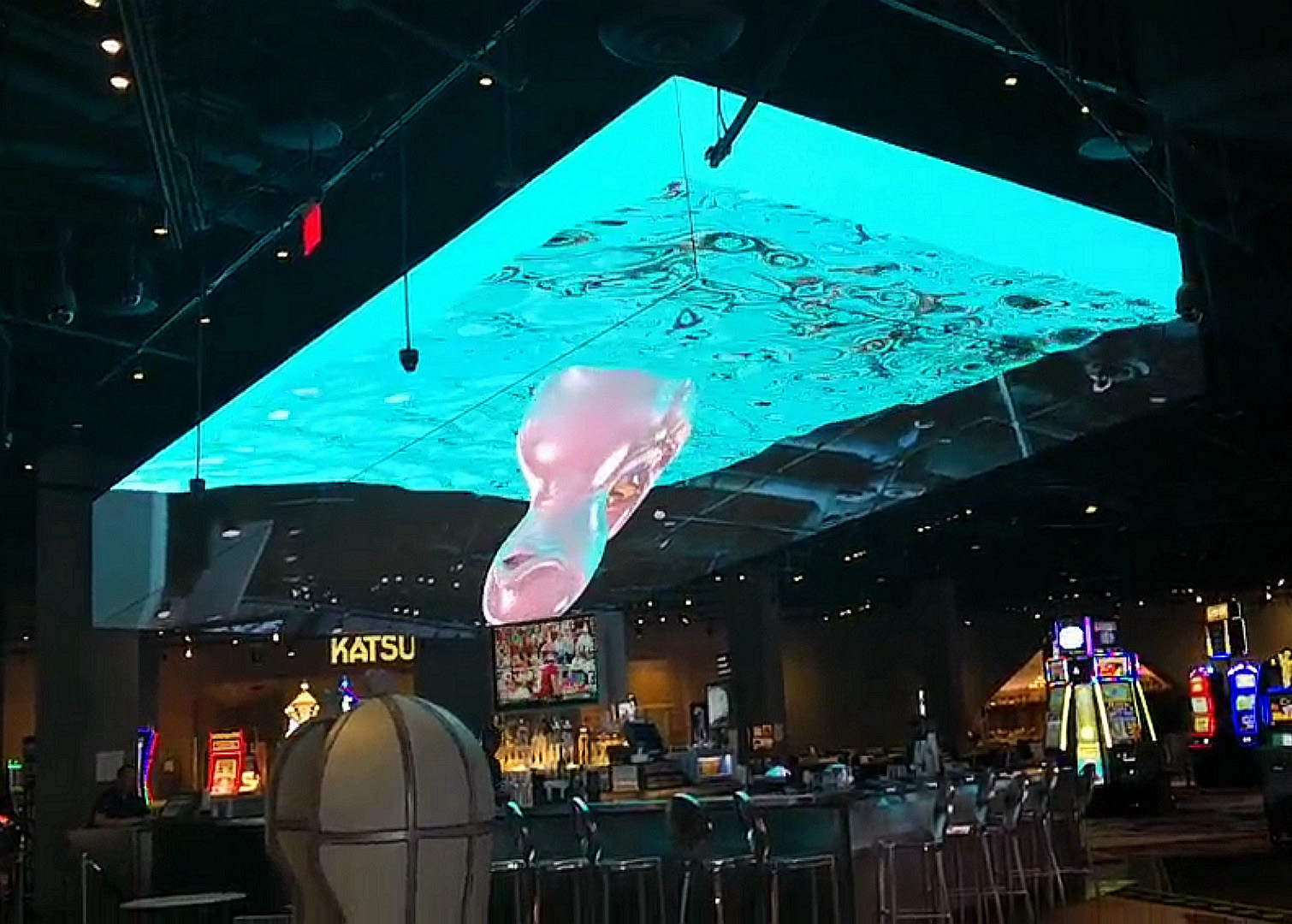

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

Foxconn, one of the electronics manufacturers that makes Apple"s iPhones, revealed plans today to build a factory in Wisconsin to produce flat-screen displays. Foxconn"s total investment in the Wisconsin factory amounts to $10 billion, more than the original $7 billion that Foxconn had been talking about investing in US manufacturing since Donald Trump took office as President. The factory will create at least 3,000 jobs and upwards of 13,000 jobs, as well as up to 22,000 induced jobs in other parts of Wisconsin. President Trump praised the deal at the press event, claiming it was a win for anyone who "believes in the label "Made in the USA.""

Foxconn will build flat-screen LCD display panels at the new factory under the Sharp brand, which the company bought in 2016 for $1.5 billion. At the press event, Gou and Governor Walker emphasized LCD display manufacturing for the automotive, healthcare, and other industries, rather than OLED display manufacturing.

Currently iPhones still use LCD displays, which means the Wisconsin factory could potentially provide LCD panels for those handsets. However, Sharp President Tai Jeng-wu has suggested in the past that Apple could use OLED displays in the future. There have also been rumors of OLED displays being used in forthcoming iPhone 8 models, but nothing has been confirmed. Currently there"s no official word that any panels made in the new Wisconsin factory will be used in Apple products going forward.

One of today’s modern technological wonders is the flat-panel liquid crystal display (LCD) screen, which is the key component we find inside televisions, computer monitors, smartphones, and an ever-proliferating range of gadgets that display information electronically.What most people don’t realize is how complex and sophisticated the manufacturing process is. The entire world’s supply is made within two time zones in East Asia. Unless, of course, the factory proposed by Foxconn for Wisconsin actually gets built.

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass.On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through.That’s how you can get electrical signals to the middle of a screen.Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts.This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen.Each step has to be precisely aligned to the previous one within a few microns.Remember, the average human hair is 40 microns in diameter.

The fab is enormous, 1.3 km from one end to the other, divided into three large buildings connected by bridges.LCD fabs are multi-story affairs.The main equipment floor is sandwiched between a ground floor that is filled with chemical pipelines, power distribution, and air handling equipment, and a third floor that also has a lot of air handling and other mechanical equipment.The main equipment floor has to provide a very stable environment with no vibrations, so an LCD fab typically uses far more structural steel in its construction than a typical skyscraper.I visited a Gen 5 fab in Taiwan in 2003, and the plant manager there told me they used three times as much structural steel as Taipei 101, which was the world’s tallest building from 2004- 2010.Since the equipment floor is usually one or two stories up, there are large loading docks on the outside of the building.When they bring the manufacturing equipment in, they load it onto a platform and hoist it with a crane on the outside of the building.That’s one way to recognize an LCD fab from the outside – loading docks on high floors that just open to the outdoors.

LCD fabs have to maintain strict standards of cleanliness inside.Any dust particles in the air could cause defects in the finished displays – tiny dark spots or uneven intensities on your screen.That means the air is passed through elaborate filtration systems and pushed downwards from the ceiling constantly.Workers have to wear special clean room protective clothing and scrub before entering to minimize dust particles or other contamination.People are the largest source of particles, from shedding dead skin cells, dust from cosmetic powders, or smoke particles exhaled from the lungs of workers who smoke.Clean rooms are rated by the number of particles per cubic meter of air.A class 100 cleanroom has less than 100 particles less than 0.3 microns in diameter per cubic meter of air, Class 10 has less than 10 particles, and so on. Fab 9 has hundeds of thousands of square meters of Class 100 cleanroom, and many critical areas like photolithography are Class 10.In comparison, the air in Harvard Square in Cambridge, MA is roughly Class 8,000,000, and probably gets substantially worse when an MBTA bus passes through.

Since most display manufacturing has to be done in a cleanroom and handling the glass requires such precision, the factory is heavily automated.As you watch the glass come in, it is placed into giant cassettes by robot handlers, and the cassettes are moved around throughout the factory.At each step, robots lift a piece of glass out of the cassette, and position it for the processing machines.Some of the machines, like the ones that deposit silicon or ITO, orient the glass vertically, and put them inside an enormous vacuum chamber where all the air is first pumped out before they can go to work.And then they somehow manage to deposit micrometer thin layers that are extremely uniform.It is a miracle that any of this stuff actually works.

It is undeniable that communication and interaction between organizations and the public have been transformed by technological advancements witnessed in the 21st century. Previously, organizations conveyed their messages, announcements, and other relevant information through traditional channels such as billboards, posters, and so on. These traditional channels have been replaced by digital signage, which utilizes screens to display the information popularly known as information screens.

The effectiveness of digital signage systems relies heavily on content presentation and content control method. Based on this holding, digital signage systems should utilize the most effective and interactive information screens since they influence content presentation and the method for controlling content. The content presentation can be enhanced by including software and hardware in information screens, which enable the user-friendly interface and enhance user-machine interaction. Other requirements such as internet connectivity, share and download applications, and so on should be taken into consideration when building information screens depending on the intended purpose of the screen.

Developers of information screens for office spaces and factories should emphasize on hardware and software which allow user-friendly content control. This is because a majority of people use or view information screens in search of answers to urgent questions. Therefore, user-friendly content control methods will enable quick and easy management of content displayed. An example of user-friendly content control is an auto-update software that replaces old data with the most recent data collected from organizations’ central systems. Additionally, automatic updating software can reduce organizations’ workload by updating the list of ‘frequently asked questions’ and providing appropriate answers on their systems, which can be easily accessed by office visitors by interacting with information screens installed in the waiting halls and lobbies. Providing answers to frequent questions via information screens also reduces the time wasted by visitors in queues, hallways, and lobbies. It is also important for information screens installed in offices and factories to include applications for upload, download, and sharing such as Bluetooth to allow for easy access and retrieval of the content, for example, employees can access their work schedules using touch technology on information screens and send, share, or download their schedules wirelessly to their phones.

Information screens used in factories have the potential to promote meaningful and high-level interaction among workers across and within factories’ public spaces such as cafés and recreation centers by linking employees through a web-based application. This requires the installation of large information screens in the café, which is connected to the internet to allow employees to edit their profiles and share content with fellow employees. The high level of interaction creates a sense of community and belonging, particularly to new employees.

PresentationPoint is among a few digital signage companies which have evolved along with technological advancements. The company offers DataPoint, iPoint and SignageTube products, which are among the leaders in the digital signage software industry. DataPoint allows for interactive and auto-updated information screens, PowerPoint decks, and notice boards. DataPoint software is used by over 10,000 customers and companies globally and enable automatic update of content presentation in real-time information screens. Users can also generate snapshot presentations for distribution using DataPoint. PresentationPoint also offers iPoint and SignageTube, which consists of a player to run playlist content on a remote computer and scheduler to plan, cue, and monitor content on digital signage systems. All PresentationPoint products allow information screens to attain a high level of interaction and user-friendliness required to convey organizations’ content to visitors and users effectively.

Every BoldVu® display is engineered to deliver the highest performance in the intended application and end-use environment. We’re so confident in our displays that we offer the industry’s only guarantee on performance for display brightness, contrast, and color saturation in the outdoor space – a guarantee that’s good for 10 years.

A key factor in our ability to guarantee optical performance is our SmartVu display optimization software which intelligently compiles and autonomously responds to 150+ environmental and operational parameters to optimize image quality and power consumption, thousands of times per second.

To round out the enterprise solution, we operate a global monitoring and support network to offer remote and on-site service for every display we deploy. Because of our proactive approach to display monitoring and our intelligent display software, we are able to resolve most incidents before the display owner is even aware that something went awry.

Moving between stereo-pairs (i.e. the images of the left and right eye get momentarily switched) a subtle “cross-eyed” effect may be noticeable. This is less apparent on displays that have more images in their quilt as there are more image pairs available with less horizontal distance between them.

Facial tracking displays like Sony’s SRD take advantage of the micro lenses mentioned above in addition to a facial tracking camera embedded within the display’s housing. This allows the display to track the position of the user in space and show a view of the 3D subject that would correspond to where they are with respect to the screen. This allows for both horizontal and vertical parallax, giving users more freedom to examine the subject from various angles.

The biggest limitation of this methodology is that it is truly a single user display. Any other viewers in the space aside from the primary, facially tracked user will see a warped perspective designed solely for the first user. A similar problem exists if there are no users present: the display doesn’t know what perspective to show. In this case, it is important to leverage the facial tracking data (or lack thereof) and have the screen fall back to a 2D image to attract users as opposed to a visually distorted image. Sony’s SRD SDK does this automatically.

Naturally, these types of displays will also suffer from the shortcomings of facial tracking technology in general. Masks and other types of facial coverings, whether pandemic or culturally related, will limit tracking ability. Darker skin tones are also a known failure point for many facial tracking toolkits so it is important to thoroughly test lighting conditions, device positions, and other factors to maximize accessibility for all users.

With any of the displays below, one thing is exceedingly clear: they are NOT regular screens. The content intended to be shown MUST be carefully curated and designed to maximize the 3D effect. Below are some principles and suggestions we noted to make 3D visuals more successful.

Solitary “hero” objects work best as they provide the largest contrast between the foreground object and the empty space they exist in. Seeing a scene that extends across the whole display and gets cut off at the boundary slightly ruins the illusion. Note the difference between the LGF 8K Squid video versus the LGF rabbit scene below.

A:The mesh screen is designed mostly for glass surface building, but it"s some difficult to find the support position for the frame. Sunrise can provide OEM size for the frame to hold the cabinet. You just need to send us the concerning building draw, and other jobs will be done for Sunrise!

advertising publish, retail store, shopping mall, display of dishes, welcome display, self-service business, exhibition hall, wayfinding, airport, subway, elevator, Restaurant & Hotel Supplies, education, medical treatment

Apple could underline its interest in MicroLED displays by investing close to $334 million in a dedicated MicroLED factory in Taiwan, a Tuesday report for the Economic Daily News claims.

MicroLED is another future display technology Apple has been actively investigating for some time. While it sounds similar to the MiniLED tech rumored to play a part in many future Apple devices, it is very different.

The main difference is that MicroLED does not use a backlight to light up the display. Like the OLED displays used in current iPhones, MicroLED controls its individual pixels for better contrast. However, it has significant advantages in terms of power consumption. It also offers high levels of brightness, ultra high definition, impressive color saturation, fast response rate, and more.

“MicroLED are much smaller than Mini-LED. The size of the diodes are in the order of microns, so they are a millionth of a meter in size. Each MicroLED is placed in a pixel, thus they illuminate at the pixel level. Since they are tinier, they are also harder and more costly to produce, but more demand will bring economies of scale. MicroLED provide better luminance and higher resolution than OLED, so they are ideal for premium displays.”

Provided this report is accurate, this is not the first time that Apple has invested in a factory. Apple paid a large piece of the $1.5 billion to build an LCD factory with display maker Japan Display in 2015. This doesn’t seem to have been such a success, however. After Japan Display took a turn for the worse, the company has been struggling to pay Apple back the money it owes as part of their agreement.

At present, OLED and MiniLED screens seem to be where Apple’s main focus is. This year’s iPhone 12 handsets are expected to feature OLED displays on every model. Meanwhile, Apple will reportedly ship its first MiniLED iPad sometime next year. Nonetheless, the company has shown significant interest in MicroLED before. Back in 2014, Apple acquired LuxVue Technology, a small California-based company that specializes in building these displays for consumer electronics applications.

Large signage equipment can also be used in factories for various purposes. A production line is often installed with a real-time progress display system that consists of large monitors and a production control system to show figures and charts to the shop floor staff. The shop floor may also have additional large monitors installed so that the department staff can share information on any problem detected in the manufacturing process and can discuss and consider corrective actions. Large monitors are often used for an in-house network through which the production line staff can exchange views with other related departments or can receive training materials from the Human Resources Training Department. Moreover, employee cafeterias are often installed with large monitors for meal-time narrowcasting to ensure that employee benefit information and other information from the General Affairs Department will be shared equally factory-wide.

NEC Display Solutions offers two types of visual display equipment, namely projectors and LCD monitors for use as large in-factory monitors. We select from our product range to custom-build digital signage systems to best suit customer needs including installation locations, intended purposes, and required performance. We cooperate with NEC and system vendors to custom-build digital signage systems from small to large.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey