diy alternatives to lcd displays manufacturer

Looking to take your project to the next level in terms of functionality and appearance? A custom LCD display might be the thing that gets you there, at least compared to the dot-matrix or seven-segment displays that anyone and their uncle can buy from the usual sources for pennies. But how does one create such a thing, and what are the costs involved? As is so often the case these days, it’s simpler and cheaper than you think, and [Dave Jones] has a great primer on designing and specifying custom LCDs.

The video below is part of an ongoing series; a previous video covered the design process, turning the design into a spec, and choosing a manufacturer; another discussed the manufacturer’s design document approval and developing a test plan for the module. This one shows the testing plan in action on the insanely cheap modules – [Dave] was able to have a small run of five modules made up for only $138, which included $33 shipping. The display is for a custom power supply and has over 200 segments, including four numeric sections, a clock display, a bar graph, and custom icons for volts, amps, millijoules, and watt-hours. It’s a big piece of glass and the quality is remarkable for the price. It’s not perfect – [Dave] noted a group of segments on the same common lines that were a bit dimmer than the rest, but was able to work around it by tweaking the supply voltage a bit.

We’re amazed at how low the barrier to entry into custom electronics has become, and even if you don’t need a custom LCD, at these prices it’s tempting to order one just because you can. Of course, you can also build your own LCD display completely from scratch too.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

Icons: A silhouette of any shape can be placed on the glass which enhances the ability to display data. For example, a symbol of a heart can be made to denote heart rate or an icon for a low battery to show that the battery needs to be charged. Icons are counted as a single pixel or segment and can give a lot more details than similar-sized text.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

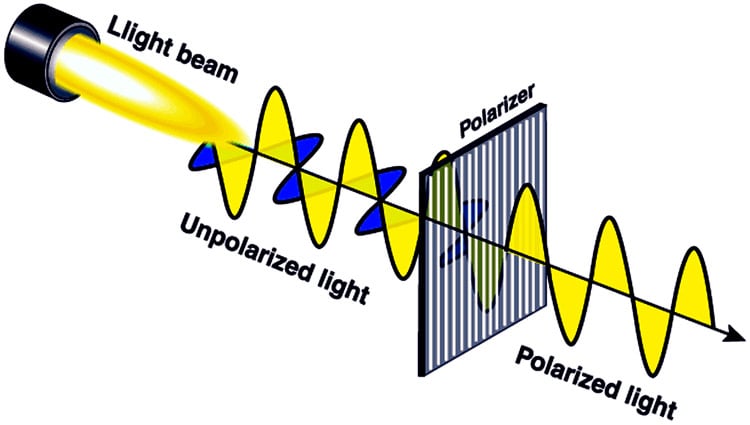

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

In Layman’s language, when an electric current is applied to the electrodes, i.e. to the segment line and common line, it twists the Liquid Crystals w.r.t to the polarizing filter, obstructing the light in that particular area as shown in the figure below. Hence, that area becomes darker and prominent.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

If your products need to be used with a switchable backlight, then trans-reflective reflectors are best to be used for front reflectors. If the device has to be used without backlight, then we can select a reflective polarizer for the back-panel as it gives the best contrast ratio.

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

Anti-glare filters are bonded with the top polarising filters using adhesive. It improves the viewability by re-directing light waves so they don’t reflect back towards the viewer thus reducing glare. Newer materials are capable of reducing the front glare by up to less than 0.3%.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

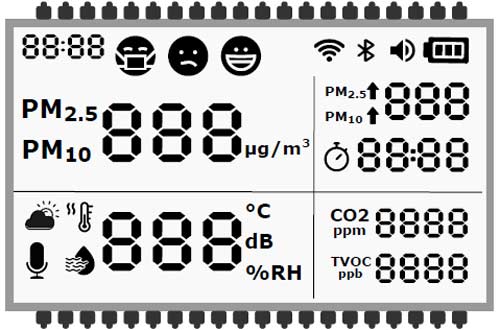

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

We started by listing down our requirements and drew a mock-up of the display on paper. After finalizing the placement of all the segments and icons on the prototype sketch of the display, we then decided which all icons and segments have to be kept on for the whole time and which needs to be driven. Realizing that there are too many segments, characters and icons, hence we selected a multiplex drive with 8 common pins which helped us bring down the total pins from an estimated 180 pins to less than 40 pins.

Since the device was meant to be used inside houses and offices, which are more often than not well lit and protected from environmental conditions, we opted for a positive mode display. For superior contrast ratio and better viewing angle, we chose a Film Super Twisted Nematic Display (FSTN) with a drive condition of 1/8 Duty and bias of 1/4.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

In the above image of a custom display design, we sent to the manufacturer, the red lines over multiple characters indicate that all these are considered as a single segment. For the sake of simplicity, we added test like T, S, U, B to denote Text, Symbols, Units, and Battery respectively. These characters were followed by numbers to simplify communication between us and the manufacturer. For example, if we needed any particular text or symbol to remain on, we can easily specify that to the manufacturer by using the corresponding text for that segment.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

The tooling time and cost depend on how detailed and accurate designs you sent to the manufacturer. They then send the exact dimensions and technical details of the product they will be manufacturing. Once you confirm the design, they manufacture and ship the product which might take 4-8 weeks to arrive depending on the size of the order and mode of transportation selected.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

Adding a display to your Arduino can serve many purposes. Since a common use for microcontrollers is reading data from sensors, a display allows you to see this data in real-time without needing to use the serial monitor within the Arduino IDE. It also allows you to give your projects a personal touch with text, images, or even interactivity through a touch screen.

Transparent Organic Light Emitting Diode (TOLED) is a type of LED that, as you can guess, has a transparent screen. It builds on the now common OLED screens found in smartphones and TVs, but with a transparent display, offers up some new possibilities for Arduino screens.

Take for example this brilliant project that makes use of TOLED displays. By stacking 10 transparent OLED screens in parallel, creator Sean Hodgins has converted a handful of 2D screens into a solid-state volumetric display. This kind of display creates an image that has 3-dimensional depth, taking us one step closer to the neon, holographic screens we imagine in the future.

Crystalfontz has a tiny monochrome (light blue) 1.51" TOLED that has 128x56 pixels. As the technology is more recent than the following displays in this list, the cost is higher too. One of these screens can be purchased for around $26, but for certain applications, it might just be worth it.

The liquid crystal display (LCD) is the most common display to find in DIY projects and home appliances alike. This is no surprise as they are simple to operate, low-powered, and incredibly cheap.

This type of display can vary in design. Some are larger, with more character spaces and rows; some come with a backlight. Most attach directly to the board through 8 or 12 connections to the Arduino pins, making them incompatible with boards with fewer pins available. In this instance, buy a screen with an I2C adapter, allowing control using only four pins.

Available for only a few dollars (or as little as a couple of dollars on AliExpress with included I2C adapter), these simple displays can be used to give real-time feedback to any project.

The screens are capable of a large variety of preset characters which cover most use cases in a variety of languages. You can control your LCD using the Liquid Crystal Library provided by Arduino. The display() and noDisplay() methods write to the LCD, as shown in the official tutorial on the Arduino website.

Are you looking for something simple to display numbers and a few basic characters? Maybe you are looking for something with that old-school arcade feel? A seven-segment display might suit your needs.

These simple boards are made up of 7 LEDs (8 if you include the dot), and work much like normal LEDs with a common Anode or Cathode connection. This allows them to take one connection to V+ (or GND for common cathode) and be controlled from the pins of your Arduino. By combining these pins in code, you can create numbers and several letters, along with more abstract designs—anything you can dream up using the segments available!

Next on our list is the 5110 display, also affectionately known as the Nokia display due to its wide use in the beloved and nigh indestructible Nokia 3310.

These tiny LCD screens are monochrome and have a screen size of 84 x 48 pixels, but don"t let that fool you. Coming in at around $2 on AliExpress, these displays are incredibly cheap and usually come with a backlight as standard.

Depending on which library you use, the screen can display multiple lines of text in various fonts. It"s also capable of displaying images, and there is free software designed to help get your creations on screen. While the refresh rate is too slow for detailed animations, these screens are hardy enough to be included in long-term, always-on projects.

For a step up in resolution and functionality, an OLED display might be what you are looking for. At first glance, these screens look similar to the 5110 screens, but they are a significant upgrade. The standard 0.96" screens are 128 x 64 monochrome, and come with a backlight as standard.

They connect to your Arduino using I2C, meaning that alongside the V+ and GND pins, only two further pins are required to communicate with the screen. With various sizes and full color options available, these displays are incredibly versatile.

For a project to get you started with OLED displays, our Electronic D20 build will teach you everything you need to know -- and you"ll end up with the ultimate geeky digital dice for your gaming sessions!

These displays can be used in the same way as the others we have mentioned so far, but their refresh rate allows for much more ambitious projects. The basic monochrome screen is available on Amazon.

Thin-film-transistor liquid-crystal displays (TFT LCDs) are in many ways another step up in quality when it comes to options for adding a screen to your Arduino. Available with or without touchscreen functionality, they also add the ability to load bitmap files from an on-board microSD card slot.

Arduino have an official guide for setting up their non-touchscreen TFT LCD screen. For a video tutorial teaching you the basics of setting up the touchscreen version, YouTuber educ8s.tv has you covered:

With the touchscreen editions of these screens costing less than $10 on AliExpress, these displays are another great choice for when you need a nice-looking display for your project.

Looking for something a little different? An E-paper (or E-ink depending on who you ask) display might be right for you. These screens differ from the others giving a much more natural reading experience, it is no surprise that this technology is the cornerstone of almost every e-reader available.

The reason these displays look so good is down to the way they function. Each "pixel" contains charged particles between two electrodes. By switching the charge of each electrode, you can influence the negatively charged black particles to swap places with the positively charged white particles.

This is what gives e-paper such a natural feel. As a bonus, once the ink is moved to its location, it uses no power to keep it there. This makes these displays naturally low-power to operate.

This article has covered most options available for Arduino displays, though there are definitely more weird and wonderful ways to add feedback to your DIY devices.

Now that you have an idea of what is out there, why not incorporate a screen into your DIY smart home setup? If retro gaming is more your thing, why not create some retro games on Arduino?

Since its initial communalization in the 1990s, active matrix thin-film-transistor (TFT) displays have become an essential and indispensable part of modern living. They are much more than just televisions and smartphones; they are the primary communication and information portals for our day-to- day life: watches (wearables), appliances, advertising, signage, automobiles and more.

There are many similarities in the display TFT manufacturing and semiconductor device manufacturing such as the process steps (deposition, etch, cleaning, and doping), the type of gases used in these steps, and the fact that both display and semiconductor manufacturing both heavily use gases.

However, there are technology drivers and manufacturing challenges that differentiate the two. For semiconductor device manufacturing, there are technology limitations in making the device increasingly smaller. For display manufacturing, the challenge is primarily maintaining the uniformity of glass as consumers drive the demand for larger and thinner displays.

While semiconductor wafer size has maxed because of the challenges of making smaller features uniformly across the surface of the wafer, the size of the display mother glass has grown from 0.1m x 0.1m with 1.1mm thickness to 3m x 3m with 0.5mm thickness over the past 20 years due to consumer demands for larger, lighter, and more cost-effective devices.

As the display mother glass area gets bigger and bigger,so does the equipment used in the display manufacturing process and the volume of gases required. In addition, the consumer’s desire for a better viewing experience such as more vivid color, higher resolution, and lower power consumption has also driven display manufacturers to develop and commercialize active matrix organic light emitting displays (AMOLED).

In general, there are two types of displays in the market today: active matrix liquid crystal display (AMLCD) and AMOLED. In its simplicity, the fundamental components required to make up the display are the same for AMLCD and AMOLED. There are four layers of a display device (FIGURE 1): a light source, switches that are the thin-film-transistor and where the gases are mainly used, a shutter to control the color selection, and the RGB (red, green, blue) color filter.

The thin-film-transistors used for display are 2D transitional transistors, which are similar to bulk CMOS before FinFET. For the active matrix display, there is one transistor for each pixel to drive the individual RGB within the pixel. As the resolution of the display grows, the transistor size also reduces, but not to the sub-micron scale of semiconductor devices. For the 325 PPI density, the transistor size is approximately 0.0001 mm2 and for the 4K TV with 80 PPI density, the transistor size is approximately 0.001 mm2.

Technology trends TFT-LCD (thin-film-transistor liquid-crystal display) is the baseline technology. MO / White OLED (organic light emitting diode) is used for larger screens. LTPS / AMOLED is used for small / medium screens. The challenges for OLED are the effect of < 1 micron particles on yield, much higher cost compared to a-Si due to increased mask steps, and moisture impact to yield for the OLED step.

Mobility limitation (FIGURE 2) is one of the key reasons for the shift to MO and LTPS to enable better viewing experience from higher resolution, etc.

The challenge to MO is the oxidation after IGZO metalization / moisture prevention after OLED step, which decreases yield. A large volume of N2O (nitrous oxide) is required for manufacturing, which means a shift in the traditional supply mode might need to be considered.

Although AMLCD displays are still dominant in the market today, AMOLED displays are growing quickly. Currently about 25% of smartphones are made with AMOLED displays and this is expected to grow to ~40% by 2021. OLED televisions are also growing rapidly, enjoying double digit growth rate year over year. Based on IHS data, the revenue for display panels with AMOLED technol- ogies is expected to have a CAGR of 18.9% in the next five years while the AMLCD display revenue will have a -2.8% CAGR for the same period with the total display panel revenue CAGR of 2.5%. With the rapid growth of AMOLED display panels, the panel makers have accel- erated their investment in the equipment to produce AMOLED panels.

There are three types of thin-film-transistor devices for display: amorphous silicon (a-Si), low temperature polysilicon (LTPS), and metal oxide (MO), also known as transparent amorphous oxide semiconductor (TAOS). AMLCD panels typically use a-Si for lower-resolution displays and TVs while high-resolution displays use LTPS transistors, but this use is mainly limited to small and medium displays due to its higher costs and scalability limitations. AMOLED panels use LTPS and MO transistors where MO devices are typically used for TV and large displays (FIGURE 3).

This shift in technology also requires a change in the gases used in production of AMOLED panels as compared with the AMLCD panels. As shown in FIGURE 4, display manufacturing today uses a wide variety of gases.

These gases can be categorized into two types: Electronic Specialty gases (ESGs) and Electronic Bulk gases (EBGs) (FIGURE 5). Electronic Specialty gases such as silane, nitrogen trifluoride, fluorine (on-site generation), sulfur hexafluoride, ammonia, and phosphine mixtures make up 52% of the gases used in the manufacture of the displays while the Electronic Bulk gases–nitrogen, hydrogen, helium, oxygen, carbon dioxide, and argon – make up the remaining 48% of the gases used in the display manufacturing.

The key ga susage driver in the manufacturing of displays is PECVD (plasma-enhanced chemical vapor deposition), which accounts for 75% of the ESG spending, while dry etch is driving helium usage. LTPS and MO transistor production is driving nitrous oxide usage. The ESG usage for MO transistor production differs from what is shown in FIGURE 4: nitrous oxide makes up 63% of gas spend, nitrogen trifluoride 26%, silane 7%, and sulfur hexafluoride and ammonia together around 4%. Laser gases are used not only for lithography, but also for excimer laser annealing application in LTPS.

Silane: SiH4 is one of the most critical molecules in display manufacturing. It is used in conjunction with ammonia (NH3) to create the silicon nitride layer for a-Si transistor, with nitrogen (N2) to form the pre excimer laser anneal a-Si for the LTPS transistor, or with nitrous oxide (N2O) to form the silicon oxide layer of MO transistor.

Nitrogen trifluoride: NF3 is the single largest electronic material from spend and volume standpoint for a-Si and LTPS display production while being surpassed by N2O for MO production. NF3 is used for cleaning the PECVD chambers. This gas requires scalability to get the cost advantage necessary for the highly competitive market.

Nitrous oxide: Used in both LTPS and MO display production, N2O has surpassed NF3 to become the largest electronic material from spend and volume standpoint for MO production. N2O is a regional and localized product due to its low cost, making long supply chains with high logistic costs unfeasible. Averaging approximately 2 kg per 5.5 m2 of mother glass area, it requires around 240 tons per month for a typical 120K per month capacity generation 8.5 MO display production. The largest N2O compressed gas trailer can only deliver six tons of N2O each time and thus it becomes both costly and risky

Nitrogen: For a typical large display fab, N2 demand can be as high as 50,000 Nm3/hour, so an on-site generator, such as the Linde SPECTRA-N® 50,000, is a cost-effective solution that has the added benefit of an 8% reduction in CO2 (carbon dioxide) footprint over conventional nitrogen plants.

Helium: H2 is used for cooling the glass during and after processing. Manufacturers are looking at ways to decrease the usage of helium because of cost and availability issues due it being a non-renewable gas.

N2 On-site generators: Nitrogen is the largest consumed gas at the fab, and is required to be available before the first tools are brought to the fab. Like major semiconductor fabs, large display fabs require very large amounts of nitrogen, which can only be economically supplied by on-site plants.

Individual packages: Specialty gases are supplied in individual packages. For higher volume materials like silane and nitrogen trifluoride, these can be supplied in large ISO packages holding up to 10 tons. Materials with smaller requirements are packaged in standard gas cylinders.

Blended gases: Laser gases and dopants are supplied as blends of several different gases. Both the accuracy and precision of the blended products are important to maintain the display device fabrication operating within acceptable parameters.

In-fab distribution: Gas supply does not end with the delivery or production of the material of the fab. Rather, the materials are further regulated with additional filtration, purification, and on-line analysis before delivery to individual production tools.

The consumer demand for displays that offer increas- ingly vivid color, higher resolution, and lower power consumption will challenge display makers to step up the technologies they employ and to develop newer displays such as flexible and transparent displays. The transistors to support these new displays will either be LTPS and / or MO, which means the gases currently being used in these processes will continue to grow. Considering the current a-Si display production, the gas consumption per area of the glass will increase by 25% for LTPS and ~ 50% for MO productions.

To facilitate these increasing demands, display manufacturers must partner with gas suppliers to identify which can meet their technology needs, globally source electronic materials to provide customers with stable and cost- effective gas solutions, develop local sources of electronic materials, improve productivity, reduce carbon footprint, and increase energy efficiency through on-site gas plants. This is particularly true for the burgeoning China display manufacturing market, which will benefit from investing in on-site bulk gas plants and collaboration with global materials suppliers with local production facilities for high-purity gas and chemical manufacturing.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Energy efficiency is crucial for future technologies. We need to make our products more power efficient to reduce the stress we put on the environment. Consumers demanding wireless products without bulky cables is another reason to reduce power. Hardware engineers developing IoT projects are struggling to stay within the power budget where the display often is the main problem. To meet these challenges there is a huge demand for ultra-low power IoT displays. In this article, we summarize the three most common low energy displays from a power perspective.

Reflective LCD displays, such as 7 segment displays, have been around for a long time. We recognize them from all kinds of household appliances including thermometers, ovens, watches, toys and medical devices. Until recently, LCD has been the only option for low power but now two alternative technologies exist on the market; the E Ink display based on electrophoresis and the Rdot display based on electrochromism, both offering features that LCD is lacking.

In this article, we investigate E Ink, Reflective LCD and the Rdot Display from a power perspective. All these technologies are categorized as reflective displays. Reflective displays are essentially required for ultra low power applications since emitting light is very power consuming (read more about reflective, transflective, and transmissive displays here). We want to clarify that displays from different manufacturers have slightly different energy consumption, and the data presented here is an average from the suppliers with the most energy efficient displays.

Before we go too deep it is important to understand the driving requirements of each display technology. Reflective LCD displays need an active driver that varies the polarity of the voltage across the pixel in a frequency of about 60Hz. E Ink, on the other hand, doesn"t need any active control once the display has been updated, this feature is often referred to as bistability. Rdot Displays is somewhere in between LCD and E Ink; once the display has been switched the controller can go idle for about 15 minutes (there exist versions that can be idle for up to 24 hours as well). We usually call this phenomenon "semi-bistability". After this time a small refresh pulse is required to maintain the state. For E Ink and Rdot, energy is only required during switching and updating while no energy is consumed during idle state. Typically, the energy required for a full switch on an E Ink display is about 7 to 8mJ/cm2. The corresponding number for the Rdot display is about 1mJ/cm2 with the addition of 0,25mJ/cm2 every 15-60 minutes. LCD continuously consumes about 6µW/cm2.

Followed by the different driving characteristics of the displays, we need to look into how often the display is updated to truly understand which display is the most energy efficient for your specific application. This is done by calculating the average power as a function of the number of switches per day. As seen in the diagram the E Ink display is the most power effective choice if the application is switching less than seven times a day. Between 4 and 600 switches, the Rdot display is the most energy efficient choice. If the display switches more than 600 times a day reflective LCD would be the best option from a power perspective.

To summarize the findings we can conclude that the Rdot display is the most power efficient choice if you need a display that is supposed to switch 4-600 times a day. However, we need to remember that there might be other features to take into consideration as well. For example, the Rdot display is flexible in its standard appearance and can be offered in multiple different colors without additional cost.

Since 2001 we’ve provided product development, engineering design services, and turn-key solutions for all industries. Work with our engineers to develop the ideal display for your unique application.

For more than 20 years, Newhaven Display International has provided custom display solutions worldwide across various industries including medical, agriculture, industrial, handheld, audio/video, automotive, consumer, appliance, security, casino, military, energy, POS, test & measurement, and telecom.

Our US-based engineering staff works together to help you prototype, design, test, build, and manufacture your custom display solution to perfectly fit your application and make your product a success. Keep in mind that minimum order quantities (MOQ) and NRE may apply depending on your custom solution request.

Adjust length, position, and pinout of your cables or add additional connectors. Get a cable solution designed to make your connections streamlined and secure.

Enhance your user experience with capacitive or resistive touchscreen technology. We’ll adjust the glass thickness or shape of the touch panel so it’s a perfect fit for your design.

Easily modify any connectors on your display to meet your application’s requirements. Soldering for pin headers, boxed headers, right angles headers, and any other connectors which your display may require.

Choose from a wide selection of changes including shape, size, pinout, and component layout of your PCB to make it a perfect fit for your application.

Equip your display with a custom cut cover glass to improve durability. Choose from a variety of cover glass thicknesses and get optical bonding to protect against moisture and debris.

Custom backlight configurations can be made with voltage/input current, brightness or colors/NVIS. Perhaps it is just changing the assembly type from array to side LEDs.

We have complete control over our display products" design, manufacturing, and quality control processes. Our USA based Engineers will work with you on a prototype to validate and test your design.

Cable Customization Touchscreen Add-Ons Interface Customization Connector Customization PCB Modifications Cover Glass Additions Mounting Add-Ons Custom Backlight Keypads

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

We are a US based display manufacturer and specialist with a global presence. Our team of engineering experts works hard to deliver efficient and reliable results with friendly, personalized service. Our goal is to be the most trusted supplier in the display industry by providing top-quality display products, services, and custom design solutions to customers worldwide.

For over 20 years Newhaven Display has been one of the most trusted suppliers in the digital display industry. We’ve earned this reputation by providing top quality products, services, and custom design solutions to customers worldwide. With numerous expansions in both our workplace and capabilities over the years, we’ve managed to grow our business and our expertise while maintaining a personal touch. When you work with Newhaven Display you can count on efficient, professional, and reliable service every time.

They’re always working with customers to identify opportunities and solutions while studying the display technology landscape to stay ahead of the curve with new designs.

We are a US-based manufacturer of world-class display solutions with a global presence. Our sales team work closely with all of our customers to understand their ultimate goals.

Our employees are equipped with the best experience and technology to deliver effective solutions that meet customer’s needs and achieve their design goals. Every day we come to work with the goal of delivering exceptional results with friendly, personalized service.

How do we do it? Our agile workforce – from engineers and developers to supply chain experts – work together to respond quickly to a dynamically changing market, customizing solutions to fit each customer’s unique requirements.

We’re dedicated to working with our customers and collaborating internally to develop the ideal solution for every project. These unique qualities make Newhaven Display more than just another manufacturer or distributor. We’re your all-inclusive display solution provider.

Long-time display manufacturer Samsung Display will likely stop the production of LCD displays this year. A recent report says several factors have influenced the South Korean firm’s decision.

Samsung has been a reputed LCD display manufacturer since 1991. It manufactures panels for its own devices and also works as a supplier for several other Big Tech firms, such as Apple. Its displays are used in virtually all products, ranging from foldable smartphones to televisions and tablets.

Despite the company’s successful business, a recent report from The Korea Times suggests Apple is exiting the LCD production business for good. One of the biggest reasons cited for the decision is the increased competition from Chinese and Taiwanese display manufacturers in the recent past.

Samsung wanted to shut its LCD production late in 2020 and its move was on the cards for a while now. Samsung probably kept its LCD manufacturing facilities operational during the pandemic due to the sudden and unprecedented spike in demand. However, LCD technology has been eclipsed by OLED and QD-OLED technologies on most mainstream devices in the last few years. This is another reason why Samsung will probably shutter the business later this year.

Moreover, research firm Display Supply Chain Consultants (DSCC) believes the average price index of LCD panels measured as 100 in January 2014 will drop down to just 36.6 in September 2022. The figure is indicative of the demand for LCD panels and it plummeted to a record low of 41.5 in April this year. The April figure is a whopping 58 percent lower than the record-high index value of 87 in June 2021 when the pandemic was raging. This reduction in demand and price could also be detrimental to the company’s plans to soldier on producing LCDs.

The report says that in the future, Samsung will remain focused on manufacturing OLED panels and more advanced quantum dot OLED displays. LCD division staffers will likely be transferred to the QD-OLED division. Meanwhile, Samsung Display did not respond to the Korea Times’ request for comment.

One of the most common questions we’re asked when assisting businesses establish their digital signage systems is whether an LED or an LCD display is best for their business. The answer is always contextual to the clients’ needs. It starts by clarifying what the difference between the two actually is.

When we’re talking aboutconsumer products such as computer monitors and televisions the first thing to know is that an LED screenis an LCD screen, but an LCD screen is not always an LED screen. An LED monitor or television is just a specific type of LCD screen, which uses a liquid crystal display (LCD) panel to control where light is displayed on your screen.

For the display to be considered an LED screen, it means it is utilising ‘Light Emitting Diodes’ to generate the light behind the liquid crystals to form an image. A non-LED LCD screen has backlights (called fluorescent lamps) behind the screen that emit white light which cannot pass through the liquid crystals until an electric current is applied to the liquid crystals which then straighten out and allow light to pass through.

This is where it can get easy to divert away from giving clear advice on whether as LED or LCD display is best for your business, because consumer displays differ from commercial displays. We are not trying to give the reader direction on which monitor is best for their gaming set-up, but which screen type is ideal for communicating your business’ messages.

Commercial LED displays are typically referred to as Direct View LED. This is because they use LEDs as the individual pixels that make up the image itself. Using a surface array of LEDs removes any need for a liquid crystal display panel, which carries noticeable benefits for particular uses.

While LCD flat panels are available in resolutions of 1080P and 4K UHD, Direct View LED displays are measured by pixel pitch. Pixel pitch is the distance from the centre of one pixel cluster to the centre of the next pixel cluster in an LED screen. The smaller the pitch, the closer viewers can get to the display before they see the pixels themselves. Outdoor configurations may have a pitch of 10mm to 40mm, as they are viewed at longer distances.

For use indoors, where viewers would be closer to the display, a pitch of 10mm or less would be required, some have even sub-1mm pixel pitch. When considering Direct View LED displays, it is important to know the minimum viewing distance required. Multiplying the pixel pitch by 1,000 gives you a good rule of thumb for the minimum viewing distance.

Direct view LED displays can either use discrete oval LEDs which are basically one single self-contained diode, or Surface Mounted Device (SMD) LEDs. SMD LEDs contain 3 individual light-emitting diodes bunched together. Either way, it’s the light-emitting diodes that create the images you see on screen. This is explained in the image below, courtesy of LG Electronics

Commercial LCD screens are more closely related to their consumer counterparts like TVs but there are still differences to be aware of. It is not advised to simply purchase an LCD TV from your local electronics retailer and install it in a public setting and expect it to function as desired.

Both have been designed to be used differently. Commercial display manufacturers understand that their displays are going to be exposed to far different conditions than a living room television will be. The componentry in a commercial display is optimised to allow for the display to be on 24 hours a day, all year around. They take into account diverse environments such as hot kitchens, high foot traffic, and bad weather,ensuring the product won’t fail in such exposures. The addition of more durable and resistant technology means commercial LCD displays will typically be priced higher than their consumer cousins.

Brightness: When deployed in areas with strong ambient lighting, even the best LCDs can appear washed out and difficult to view, especially when from an angle. Direct view LEDs for outdoor applications can reach 9,000 nits, making them a brighter and better choice for most outdoor applications.

Size and shape: Direct view LED-based walls can be flat, curved, wrapped around pillars and more. With no size limit or set aspect ratio they can be used more flexibly than LCDs. Plus, panels have no bezels which means you can piece together Direct view LEDs to create large and uniquely shaped displays with no visible interruptions between units.

Lifespan and servicing: Most direct view LEDs are rated to last 10 years, compared to a typical 5 years for LCDs. Further, they can be easily replaced on-site, reducing maintenance costs.

Tougher: If you’re using an LCD for any outdoor application or one where the unit has to be protected from extreme temperatures or humidity, you’re going to need to include an enclosure and have an understanding of how to properly seal and vent the unit. Outdoor Direct view LEDs, on the other hand, are purpose-built to withstand harsh environments.

Price: The higher upfront cost of Direct LEDs could be the biggest sticking point when it comes to pitching a video wall. While prices have been steadily dropping, Direct view LEDs are still more expensive than LCD alternatives. However, make sure you consider the lifetime cost of the solution and other benefits mentioned above before you discount direct view LEDs.

Functionality: LCD screens can offer a wider range of functionality when it comes to set-up, display settings, and day-to-day control. There is also the addition of touch screen options for LCD displays which are a fairly sought-after feature these days.

Resolution: Whilst the fine pixel pitches available in direct view LEDs today make for impressively resolute images, LCD screens still boast are more uninterrupted image when viewed up close, particularly with the modern 4k displays. This makes them a better option for smaller retail stores, quick service restaurants or office meeting rooms.

As earlier stated, intended use for the display will determine which format you invest in. In outdoor environments or areas with high ambient lighting, brightness is the key concern. For indoor environments, the key concern is image quality and contrast. It’s also imperative to consider the usage environment and what the screen may be exposed to with regards to weather, temperature, humidity, direct contact and other factors. If you have a good understanding of your requirements for content, application, perception and budget then your first move should be to contact a supplier, like Black Lab Design, and we will be able to assist you with designing, building and installing the perfect digital display solution for your business.

LCD displays. Of course, there is only one color for the backlight and one color for the characters, but as you can see here on the picture above, there could be many colors of backlights. We can have a white backlight, orange, green, blue or any backlight color.

It does not fit every display technology, positive and negative, but as you can see on the picture above, there is a vast number of combinations of different technologies, positive, negative, STN, FSTN or VA technology (Vertical Alignment), a little bit different technology, allowing us to have wide viewing angles, and different backlight colors. So, we can have a lot of different variations that can be used to build every application.

The last part of this article covers graphic displays and character displays, the difference between them and how it influences the cost of an LCD display. The most basic LCD displays are the segmented monochrome LCD displays or icon displays. In this kind of LCD displays we have only some icons and characters, but they are defined when the display is being produced. What we see on the display is defined and we cannot have anything else, the other area is completely off. You can only switch on and off the display segments. This is the cheapest technology to produce, and it is made by mask during the production, so it is usually reserved for high volume applications, that are very well defined during the production phase. For example, this can a be kind of watch, or calculator, or temperature controller. The advantage is the cost, but the disadvantage is that later we cannot change anything, we cannot change the software and add another icon.

Another type of a display is a graphic display. So, we have character displays and a fully graphic display. The character display is also a very popular technology, and it is a combination between a segment display and the graphic display because we have the fields, that are defined, and they can show only the characters, letters, numbers, symbols and some added characters defined by the controller of a display. On this kind of screen, we cannot put the full graphic, because every character is physically separated from the other.

Next, we have the fully graphic display. In this kind of LCD display we have a matrix of pixels. It could be 64 by 256, or 64 by 128 pixels, so on this kind of screen we can show almost every image, because we can switch every pixel on and off. We can show letters, characters, images, small, big, anything we want. The disadvantage is the vast number of pixels that we need to connect. The controller and the glass are complicated, because we need to route the wires from every pixel out from the glass and connect it to the controller. So, in the monochrome LCD display family, this kind of display is the most expensive. Other kinds of displays are cheaper, not only because the glass is simple, but because the controllers are simple too.

Please remember to SUBSCRIBE our YouTube channeland fill out the MEMBERSHIP FORM, to be informed about our Riverdi University materials and live events!

– Arduino is an open-source platform used for building electronics projects. Arduino consists of both a physical programmable microcontroller and a piece of software, or IDE (Integrated Development Environment) that runs on your computer, used to write and upload computer code to the physical board.

– The Arduino platform unlike most previous programmable circuit boards, the Arduino does not need a separate programmer to load new code onto the board — you can simply use a USB cable. Additionally, the Arduino IDE uses a simplified version of C++, making it easier to learn to program.

– The open sources and extensible language: Arduino IDE is based on open source tool. The programming language used can be extended through the C++ library.

– The open source and expandable hardware: Arduino is based on Atmel’s ATMEGA 8-bit microcontrollers and its SAM3X8E and SAMD21 32-bit microcontrollers. Development boards and modules are planned to be released under the premise of following the “Creative Commons License Agreement”, so experienced circuit designers can make their own modules and carry out corresponding expansions and improvements. Even users who are relatively inexperienced can make a trial version of the basic Uno development board, which is easy to understand the principle of its operation and save costs.

– The Arduino hardware and software were designed for artists, designers, hobbyists, hackers, newbies, and anyone interested in creating interactive objects or environments. Arduino can interact with buttons, LEDs, motors, speakers, GPS units, cameras, the internet, and even your smart-phone or your TV.

Arduino Leonardo: Arduino’s first development board to use one microcontroller with built-in USB. It is cheaper and simpler. The code libraries allow the board to emulate a computer keyboard, mouse, and more.

LCD means liquid crystal display. Basically, any displays can be used with Arduino, including alphanumeric character LCD display, monochrome graphic LCD display, color TFT LCD display, IPS LCD display. It can also be used for non LCD displays like: PMOLED display, AMOLED display, E-ink (E-paper) displays. Orient Display developed easy interface (SPI, I2C) displays which can be easily used with Arduino.

LCD displays were first used for watches and calculators. Now, LCD display technology dominants the display world, it can be found in wearables, smart homes, mobile phones, TVs, laptops, monitors, kiosks, aircraft cockpit, digital cameras, lab instrument, power grid etc.

LCD itself can emit light itself. It has to utilize outside light sources. LCD display module normally includes LCD glass (or LCD panel), LCD driving circuitry ( can be COG, COB or TAB) and a backlight.

A LCD display 16*2 is actually a basic and simple to use LCD module. It includes LCD glass, COB (Chip on PCB Board) LCD control board, backlight, zebra to connect LCD glass and control board and a bezel to hold everything together. 16×2 LCD display can display 16 characters per line and there are two lines. Each character has 5×7 dot matrix pixels and the cursor underneath. All 16×2 LCD display originally used standard Hitachi HD44780 driver. Of course the legendary HD44780 controller had EOL long time ago. All the 16×2 LCD displays use HD44780 compatible LCD controllers. Some of them are drop replacement, some of them need to modify the initialization code a little.

Pin4 (RS pin or Register Select/Control Pin): This pin toggles among command or data register, used to connect a microcontroller unit pin and obtains either 0 or 1(0 = data mode, and 1 = command mode).

Pin5 (Read/Write/Control Pin): This pin toggles the display among the read or writes operation, and it is connected to a microcontroller unit pin to get either 0 or 1 (0 = Write Operation, and 1 = Read Operation).

Pin 6 (Enable pin/Control Pin): This pin should be held high to execute Read/Write process, and it is connected to the microcontroller unit & constantly held high.

Pins 7-14 (Data Pins): These pins are used to send data to the display. These pins are connected in two-wire modes like 4-bit mode and 8-bit mode. In 4-wire mode, only four pins are connected to the microcontroller unit like 0 to 3, whereas in 8-wire mode, 8-pins are connected to microcontroller unit like 0 to 7.

A 16×2 LCD has two registers like data register and command register. The RS (register select) is mainly used to change from one register to another. When the register set is ‘0’, then it is known as command register. Similarly, when the register set is ‘1’, then it is known as data register.

Command Register: The main function of the command register is to store the instructions of command which are given to the display. So that predefined tasks can be performed such as clearing the display, initializing, set the cursor place, and display control. Here commands processing can occur within the register.

Data Register: The main function of the data register is to store the information which is to be exhibited on the LCD screen. Here, the ASCII value of the character is the information which is to be exhibited on the screen of LCD. Whenever we send the information to LCD, it transmits to the data register, and then the process will be starting there. When register set =1, then the data register will be selected.

The resistor in the diagram above sets the LED backlight brightness. A typical value is 220 Ohms resistor, but other values will work too. Smaller resistors will make the backlight brighter. The potentiometer is used to adjust the screen contrast. I typically use a 10K Ohm potentiometer, but other values will also work.

All of the code below uses the LiquidCrystal library that comes pre-installed with the Arduino IDE. A library is a set of functions that can be easily added to a program in an abbreviated format. In order to use a library, it needs be included in the program. Line 1 in the code below does this with the command #include

Now we’re ready to get into the programming! I’ll go over more interesting things you can do in a moment, but for now let’s just run a simple test program. This program will print “hello, world!” to the screen. Enter this code into the Arduino IDE and upload it to the board:

There are 19 different functions in the LiquidCrystal library available for us to use. These functions do things like change the position of the text, move text across the screen, or make the display turn on or off. What follows is a short description of each function, and how to use it in a program.

The LiquidCrystal() function sets the pins the Arduino uses to connect to the LCD. You can use any of the Arduino’s digital pins to control the LCD. Just put the Arduino pin numbers inside the parentheses in this order:

This function sets the dimensions of the LCD. It needs to be placed before any other LiquidCrystal function in the void setup() section of the program. The number of rows and number of columns are specified as lcd.begin(columns, rows). For a 16×2 LCD, you would use lcd.begin(16, 2), and for a 20×4 LCD you would use lcd.begin(20, 4).

This function clears any text or data already displayed on the LCD. If you use lcd.clear() with lcd.print() and the delay() function in the void loop() section, you can make a simple blinking text program.

Similar, but more useful than lcd.home() is lcd.setCursor(). This function places the cursor (and any printed text) at any position on the screen. It can be used in the void setup() or void loop() section of your program.

The cursor position is defined with lcd.setCursor(column, row). The column and row coordinates start from zero (0-15 and 0-1 respectively). For example, using lcd.setCursor(2, 1) in the void setup() section of the “hello, world!” program above prints “hello, world!” to the lower line and shifts it to the right two spaces:

This function creates a block style cursor that blinks on and off at approximately 500 milliseconds per cycle. Use it in the void loop() section. The function lcd.noBlink() disables the blinking block cursor.

This function turns on any text or cursors that have been printed to the LCD screen. The function lcd.noDisplay() turns off any text or cursors printed to the LCD, without clearing it from the LCD’s memory.

These two functions can be used together in the void loop() section to create a blinking text effect. This code will make the “hello, world!” text blink on and off.

This function takes anything printed to the LCD and moves it to the left. It should be used in the void loop() section with a delay command following it. The function will move the text 40 spaces to the left before it loops back to the first character. This code moves the “hello, world!” text to the left, at a rate of one second per character.

This function takes a string of text and scrolls it from right to left in increments of the character count of the string. For example, if you have a string of text that is 3 characters long, it will shift the text 3 spaces to the left with each step.

lcd.noAutoscroll() turns the lcd.autoscroll() function off. Use this function before or after lcd.autoscroll() in the void loop() section to create sequences of scrolling text or animations.

This function sets the direction that text is printed to the screen. The default mode is from left to right using the command lcd.leftToRight(), but you may find some cases where it’s useful to output text in the reverse direction.

This command allows you to create your own custom characters. Each character of a 16×2 LCD has a 5 pixel width and an 8 pixel height. Up to 8 different custom characters can be defined in a single program. To design your own characters, you’ll need to make a binary matrix of your custom chara

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey